Rabbit fur carding machine

A carding machine, rabbit hair technology, applied in the direction of deburring device, textile and papermaking, fiber processing, etc., can solve the problems of high production cost, foreign matter interference, large space occupation, etc., to improve carding efficiency, reduce The effect of fiber damage and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

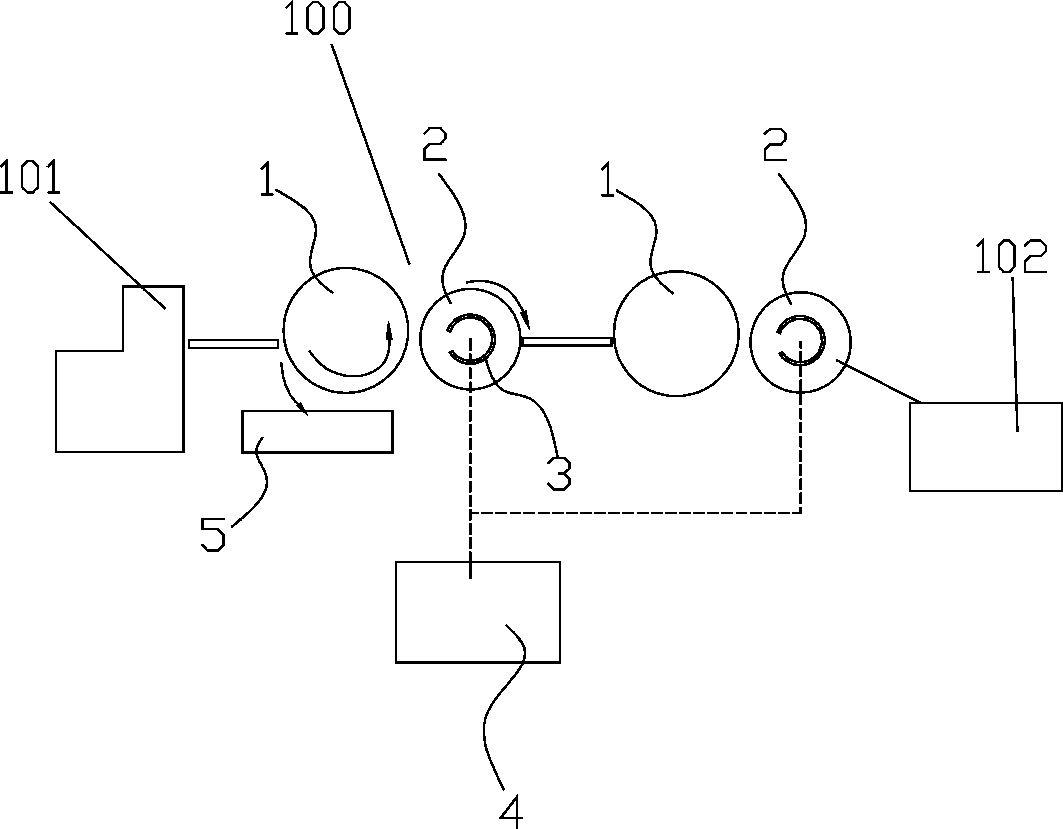

[0010] Below the present invention is described in further detail, see Figure 1 to Figure 3 , a rabbit hair carding machine, comprising a hair feeding mechanism 101, a plurality of carding devices 100 arranged in sequence, and a cashmere storage box 102 arranged on one side of the carding device 100, preferably the carding device 100 is provided with 10 paths to ensure that the final product can be obtained Fine enough rabbit fur. Of course, the number of carding devices can also be adjusted accordingly according to actual needs, which is not limited in the embodiment.

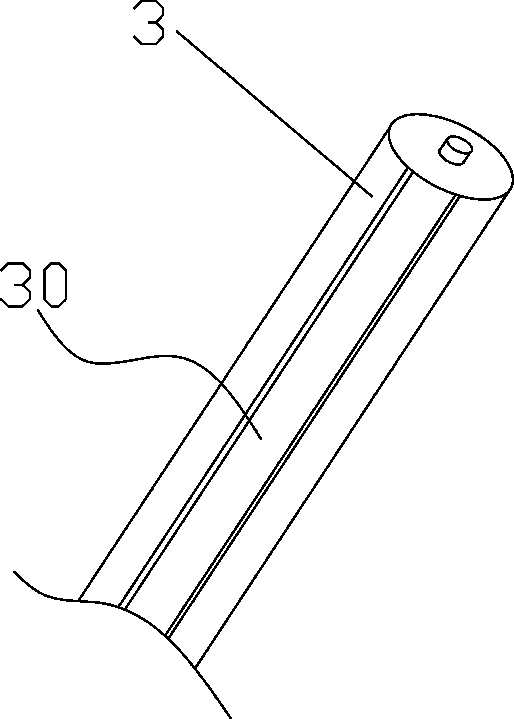

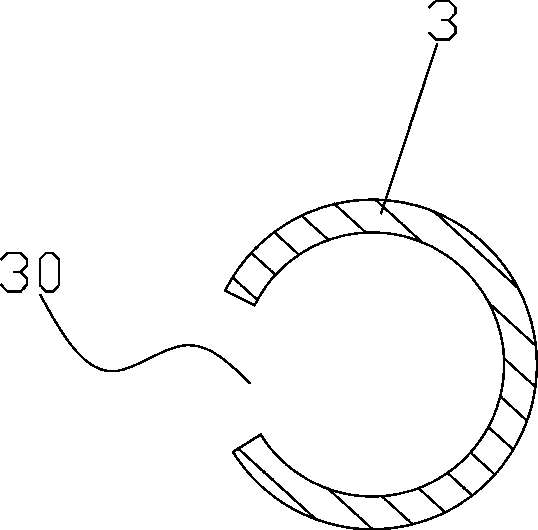

[0011] The carding device 100 includes a licker-in roller 1 and a mesh roller 2 arranged on one side of the licker-in roller 1, the mesh roller 2 is hollow, and has tiny mesh holes on the sidewall of the mesh roller 2, and the mesh roller 2 is hollow. A negative pressure roller 3 with a hollow inner cavity is provided inside, and the negative pressure roller 3 is provided with an elongated through hole 30 fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com