Carding machine with cotton yarn not likely to adhere for cotton yarn processing

A carding machine and cotton yarn technology, which is applied in the field of carding machines, can solve the problems of insufficient carding of cotton materials, inability to blow materials, and low control precision, so as to improve the efficiency of carding processing, improve the smoothness of operation, and improve the smoothness of operation Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

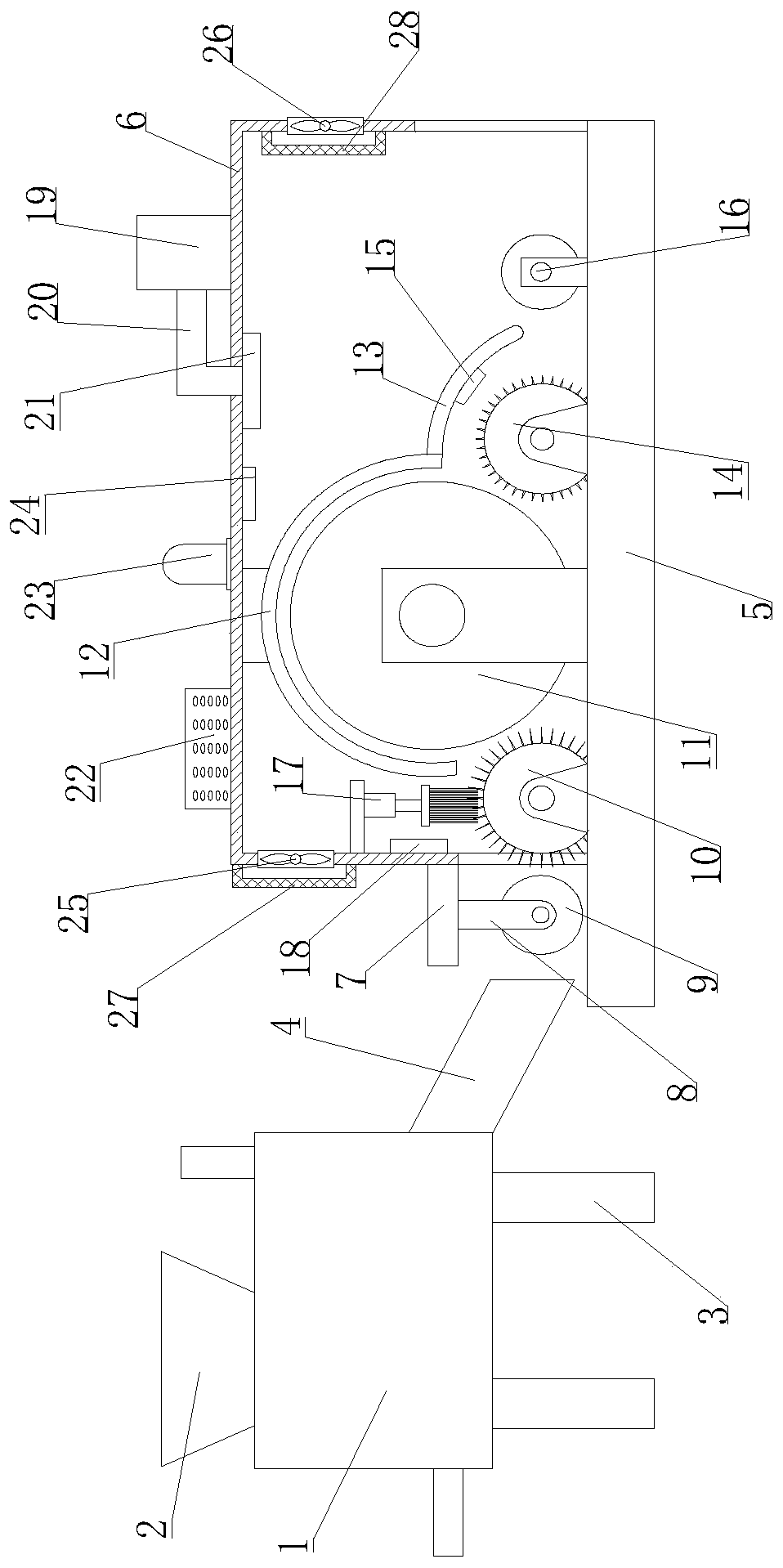

[0026] Reference Figure 1-4 , A carding machine for cotton yarn processing that is not easy to adhere to cotton yarn, including a feeding box 1, a carding frame body 5, a connecting plate 7, a licker roller 10, a cylinder 11, a doffer 14, a sliver roller 16, a Cotton device 17, first electrostatic plate 18, vacuum cleaner 19 and controller 22;

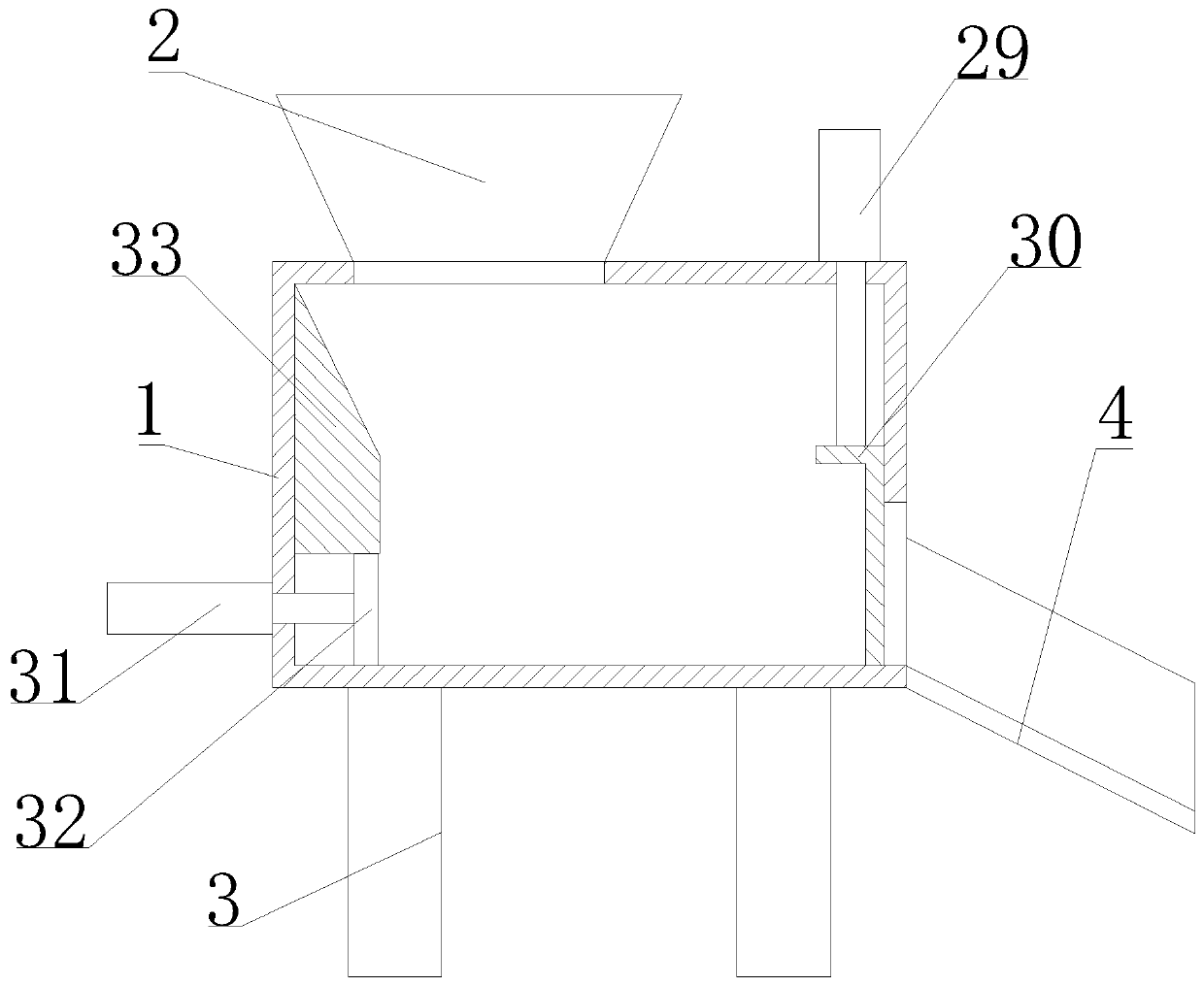

[0027] The lower end of the feeding box 1 is provided with a supporting leg 3, and the feeding box 1 is provided with a feeding hopper 2 and a feeding plate 4; the carding frame body 5 is arranged under the feeding plate 4, and the carding frame body 5 is arranged There is a carding machine cover 6;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com