Three-dimensional multi-point coarse wool and impurity removing and carding method and device

A carding and roughing technology, used in deburring devices, textiles and papermaking, fiber processing, etc., can solve the problems of long horizontal footprint, fluff detachment from card clothing, long footprint, etc., and achieves a small footprint. , The effect of high carding efficiency and small fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

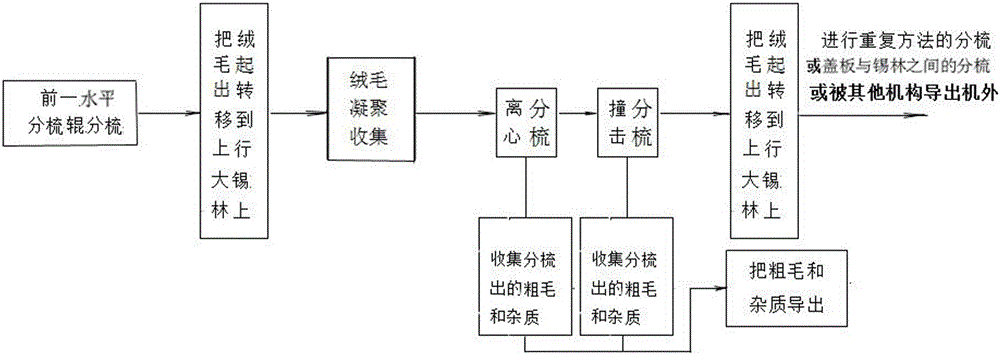

[0033] Such as figure 1 Shown, a kind of three-dimensional multi-point decoy combing method, described method comprises the following steps:

[0034] a. The clockwise rotating licker-in roller 2 installed in the horizontal direction of the carding machine first combs the fed hair bundle to remove coarse hairs and impurities, and the licker-in roller 2 that is hung on the licker-in roller 2 goes through carding. The mixed fluff cluster goes up with the licker-in roller;

[0035] b. The fluff clumps on the licker-in roller 2 are transferred to the big cylinder 3 by the up-moving big cylinder 3 installed behind the licker-in roller 2, and the fluff clumps move up with the big cylinder 3 ;

[0036] c. The fluff clusters are combed by 1-4 sets of carding mechanisms 1 installed on the upper half of the circular surface of the large cylinder 3 running upwards, and the coarse hairs and impurities are removed step by step;

[0037] d. fluff tuft is exported outside the machine by e...

Embodiment 2

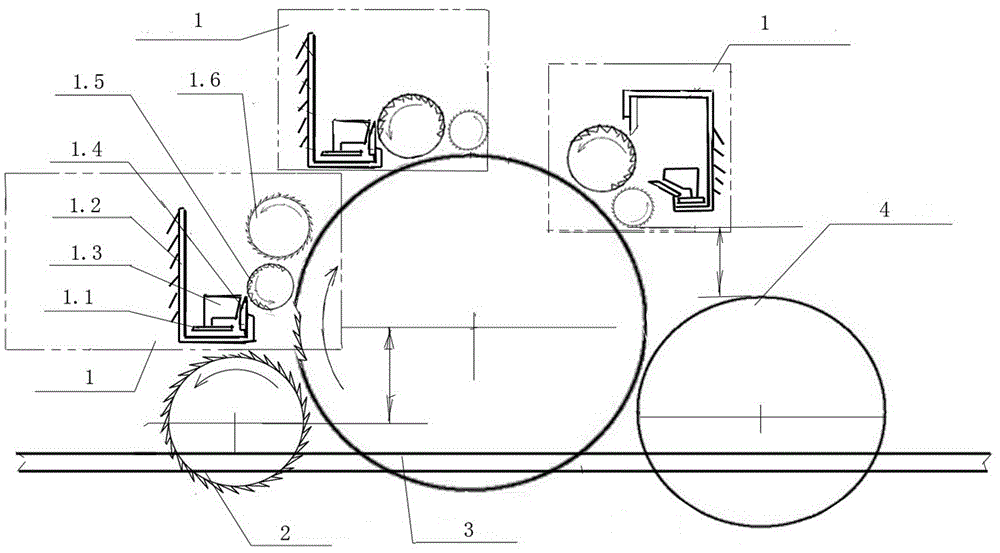

[0044] Such as figure 2 , 3 Shown, a kind of three-dimensional multi-point coarse impurity carding equipment, described carding equipment comprises licker-in roller 2, the big cylinder 3 that is arranged on the licker-in roller rear, the 1-4 sets that are installed on the circumference surface of the upper half of big cylinder The carding mechanism 1 and the fluff cluster transfer and export mechanism 4 arranged at the rear of the large cylinder; the licker-in roller 2 is a carding licker-in roller or a rough carding licker-in roller.

[0045] The carding mechanism 1 is composed of a conveyor belt 1.1, a collection tank 1.2, a scraper 1.3, a shearing knife 1.4, a stripping and carding roller 1.5, and a carding and condensing roller 1.6. The vertical tangent angle of the outer surface of the comb roller is installed on the collection tank. The conveyor belt is placed on the bottom of the collection tank and is parallel to the bottom of the collection tank. On the upper surfa...

Embodiment 3

[0057] Specific application examples for further improvement on the basis of Embodiment 1 and Embodiment 2.

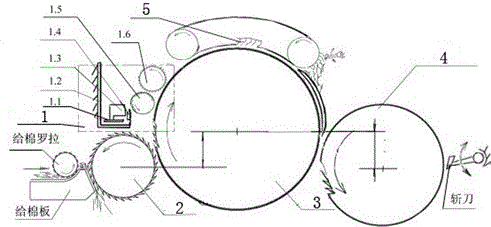

[0058] Such as Figure 7 As shown, the equipment consists of a feeding curtain; a cotton feeding board; a cotton feeding roller; a carding licker-in roller; an upward large cylinder; A new carding mechanism consisting of stripping and carding rollers wrapped with the same type of card clothing, carding and condensing rollers wrapped with the same type of card clothing; a doffer; a set of cutting knife mechanism.

[0059] The equipment installed in the horizontal direction of the carding machine has a carding licker-in roller with a diameter of 250 mm and a speed of 450 rpm, that is, 353.25 m / min (1 / 2.35 times the speed of the large cylinder line), and the needle direction is counterclockwise. , the carding roller is wrapped with 5613X56109 (AT5613x05611) metal sawtooth (rack) card clothing for cotton spinning (produced by Henan Guangshan Card Clothing Factory). The v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com