Yarn-combing tensioning frame

A technology of tension frame and thread combing, which is applied in the field of thread tension frame, which can solve the problems of low carding efficiency, heavy workload, inconvenient carding operation, etc., so as to improve carding efficiency, reduce workload, and facilitate The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

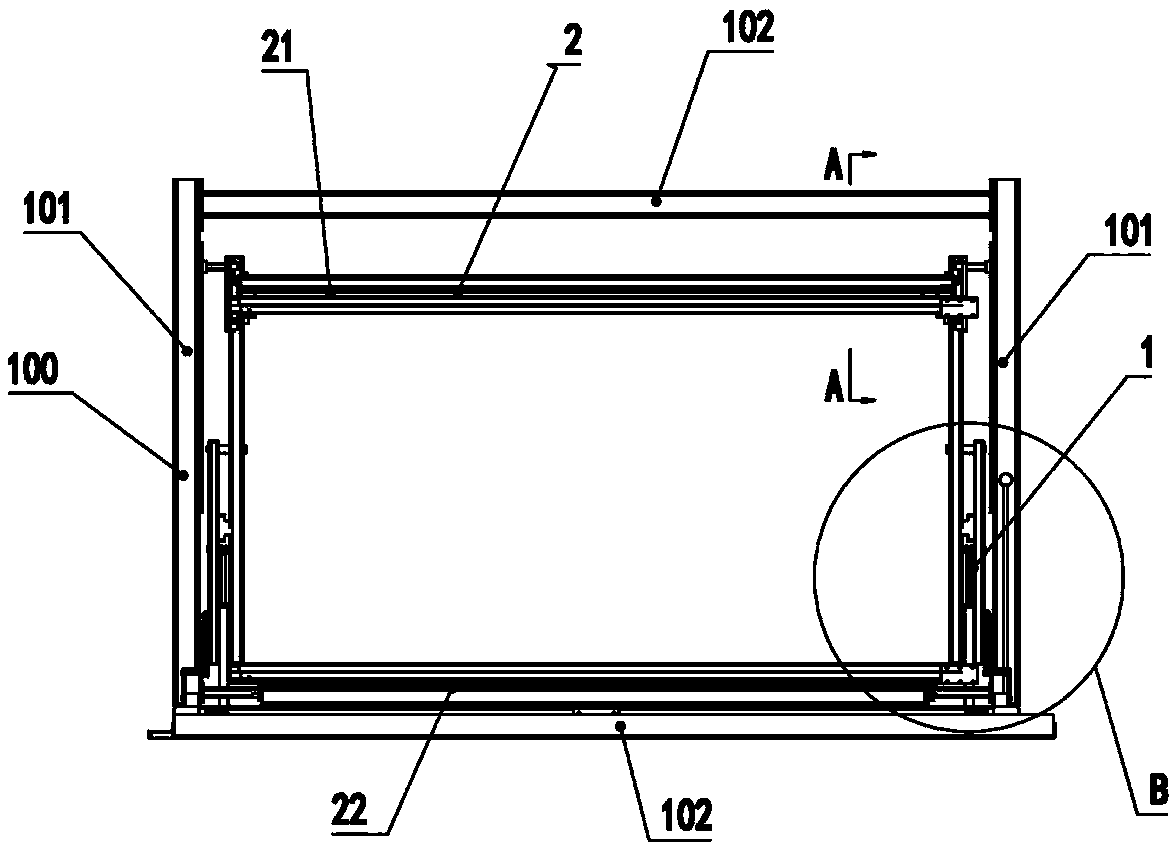

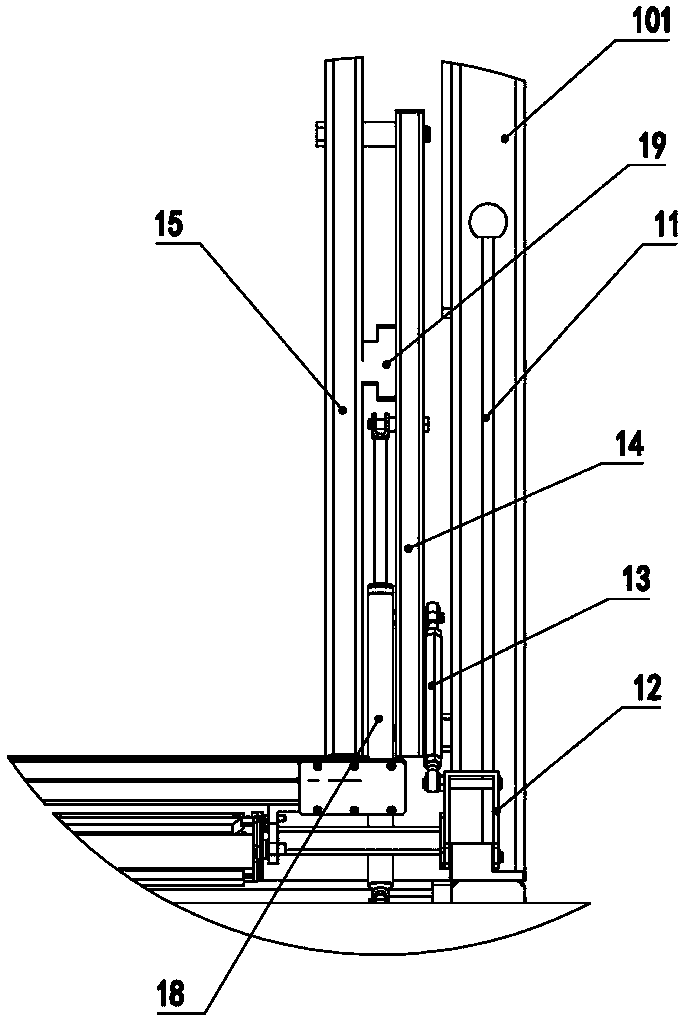

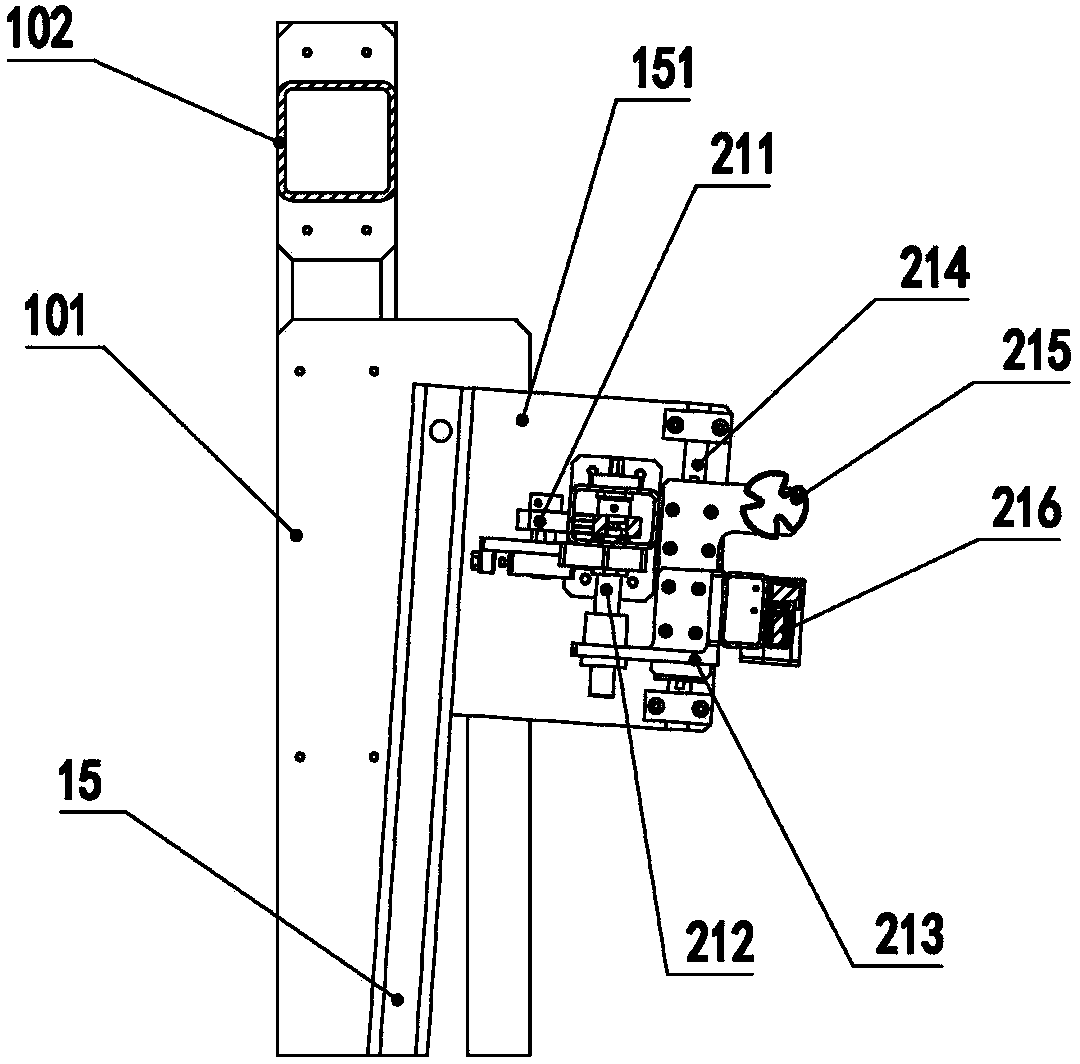

[0024] Figure 1 to Figure 8 The reference numerals in are: bracket 100; strong beam 101; beam 102; turning mechanism 1; control handle 11; adjusting seat 12; first hinge point 121; second hinge point 122; Rod 15; upper support plate 151; sliding member 16; guide plate 17; guide groove 171; buffer 18; limit block 19; tensioning mechanism 2; first tensioning mechanism 21; chain transmission mechanism 211; 212 ; transition plate 213 ; guide post 214 ; first tension roller 215 ; crimping device 216 ; second tension mechanism 22 ; second tension roller 221 .

[0025] Such as Figure 1 to Figure 8 As shown, a comb thread tensioning frame includes a support 100, a tensioning mechanism 2 for tensioning warp threads, and an overturning mechanism 1 that turns over the tensioning mechanism 2, and the overturning mechanism 1 is arranged on the support 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com