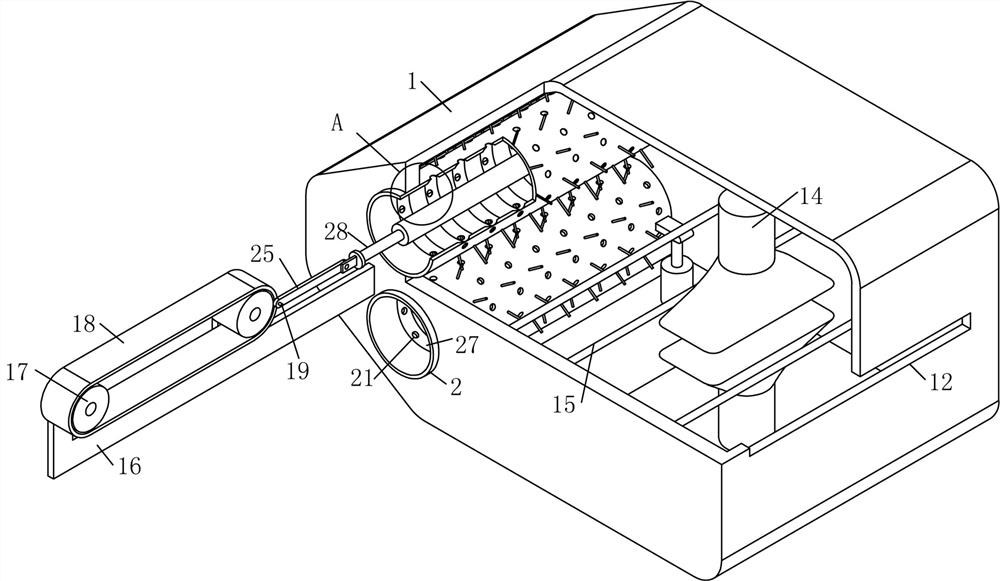

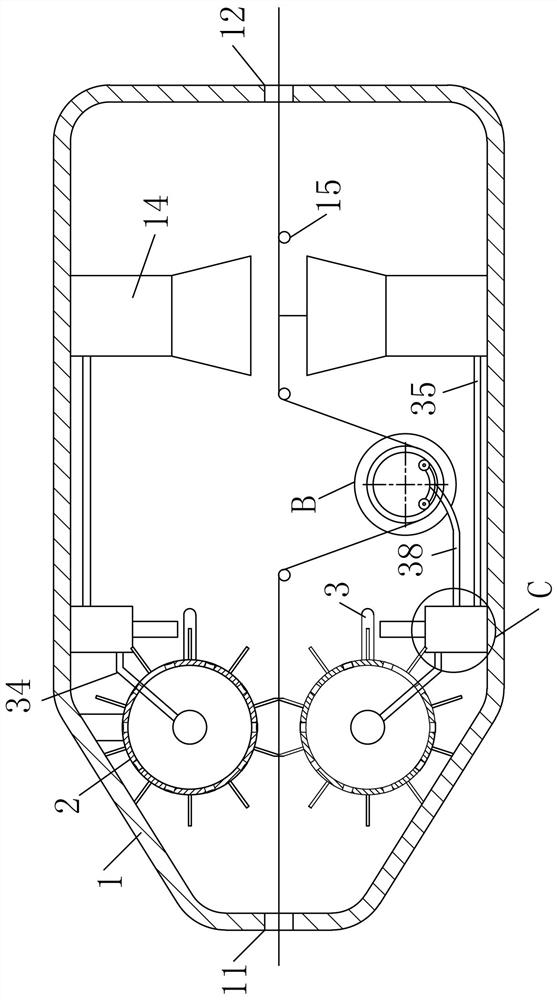

Textile fabric rapid carding equipment and working method thereof

A technology for textile fabrics and working methods, applied in spray/jet textile material processing, textile and papermaking, fabric surface trimming, etc. Increase efficiency, increase the effect of adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

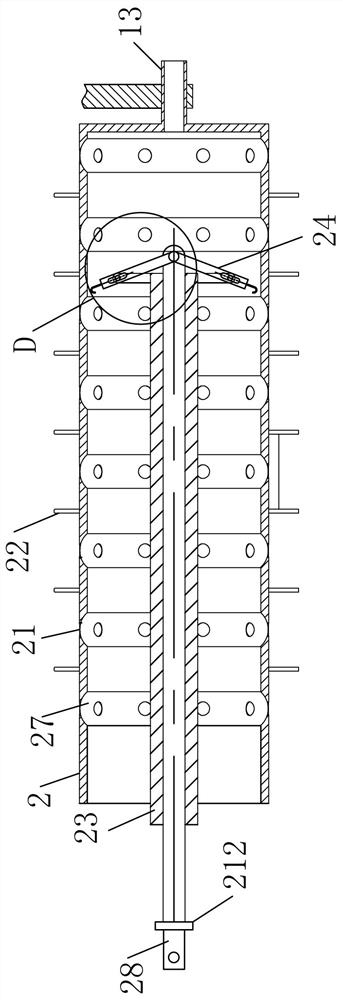

[0030] As an embodiment of the present invention, the negative pressure device includes a pressure rod 3, which is fixedly connected to the outer periphery of the cleaning roller 2; a cylinder 31 is fixedly connected to the position corresponding to the pressure rod 3 in the body 1, and the inside of the cylinder 31 A piston rod 32 and a piston rod 33 are slidably connected; a spring is arranged between the piston rod 32 and the bottom of the cylinder 31; A one-way valve is provided; the rodless cavity of the cylinder 31 communicates with the ironing unit 14 through the No. 2 pipe 35, and a heating ring 36 is arranged on the outer periphery of the rodless cavity of the cylinder 31, and the heating ring 36 is connected to a power supply through a controller; The pressure rod 3 squeezes the piston rod 33 when it rotates with the cleaning roller 2; the pressure rod 3 is driven by the cleaning roller 2 to rotate continuously, so that the pressure plate moves to the corresponding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com