Patents

Literature

62results about How to "Improve ironing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

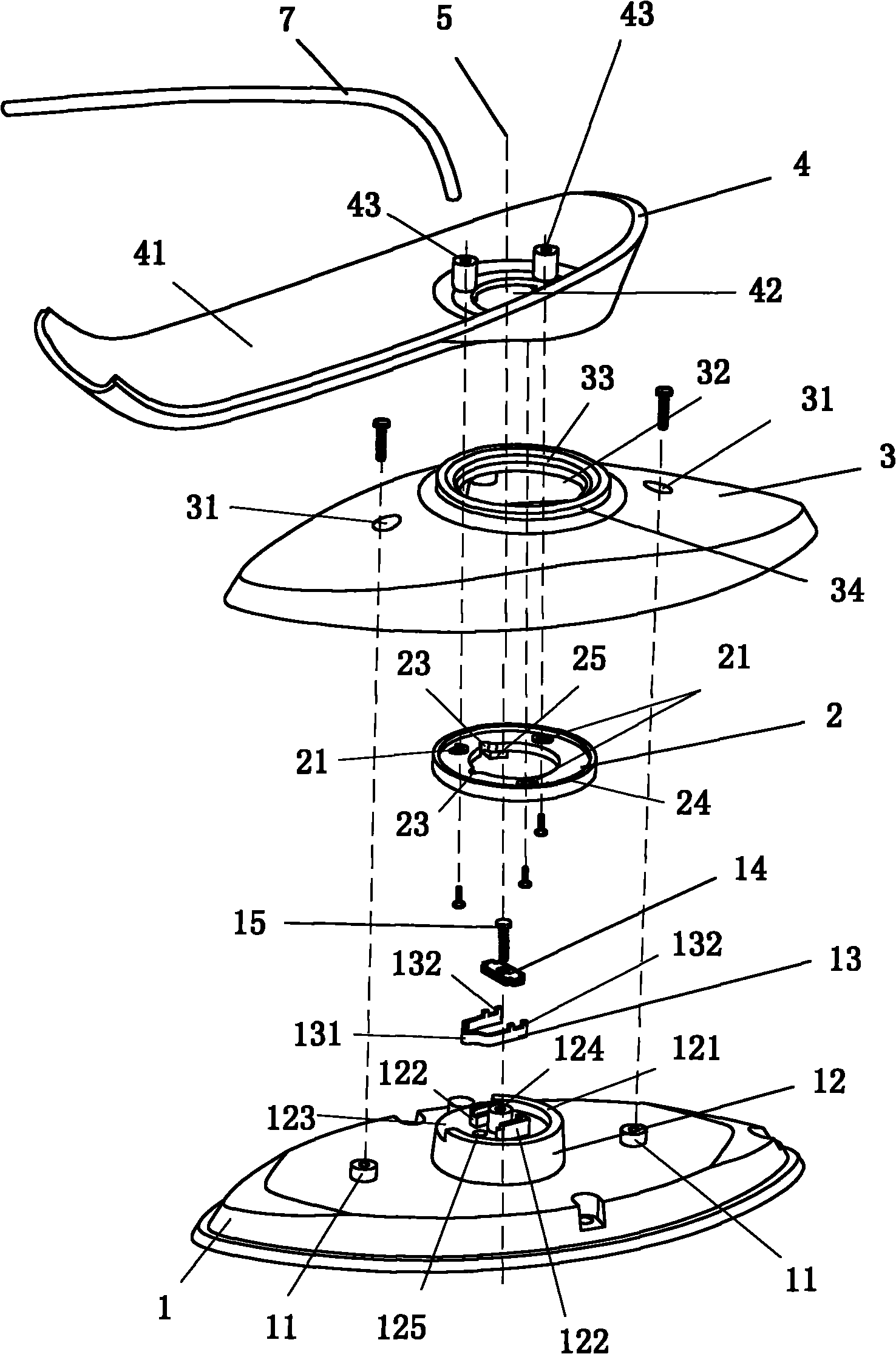

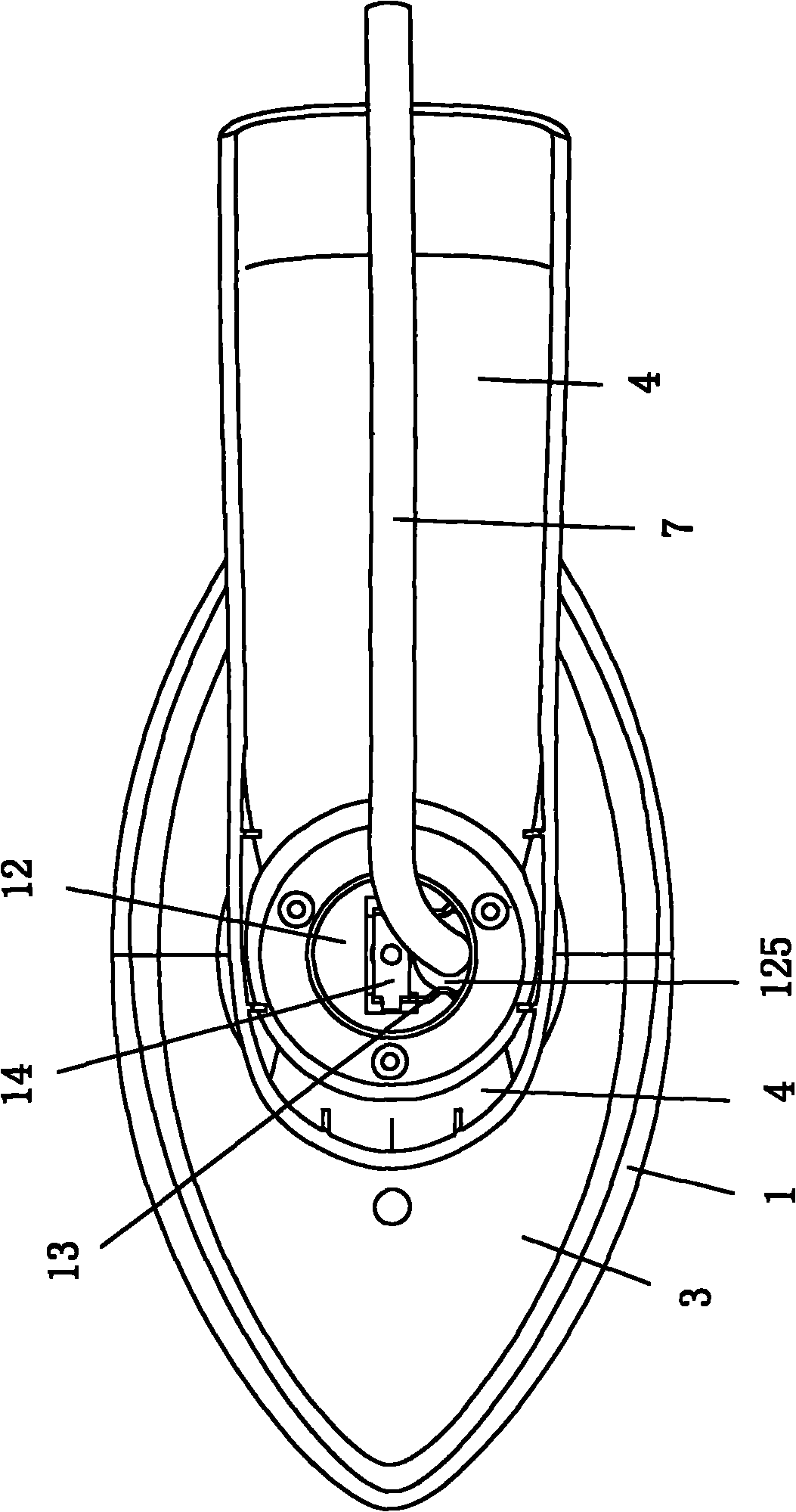

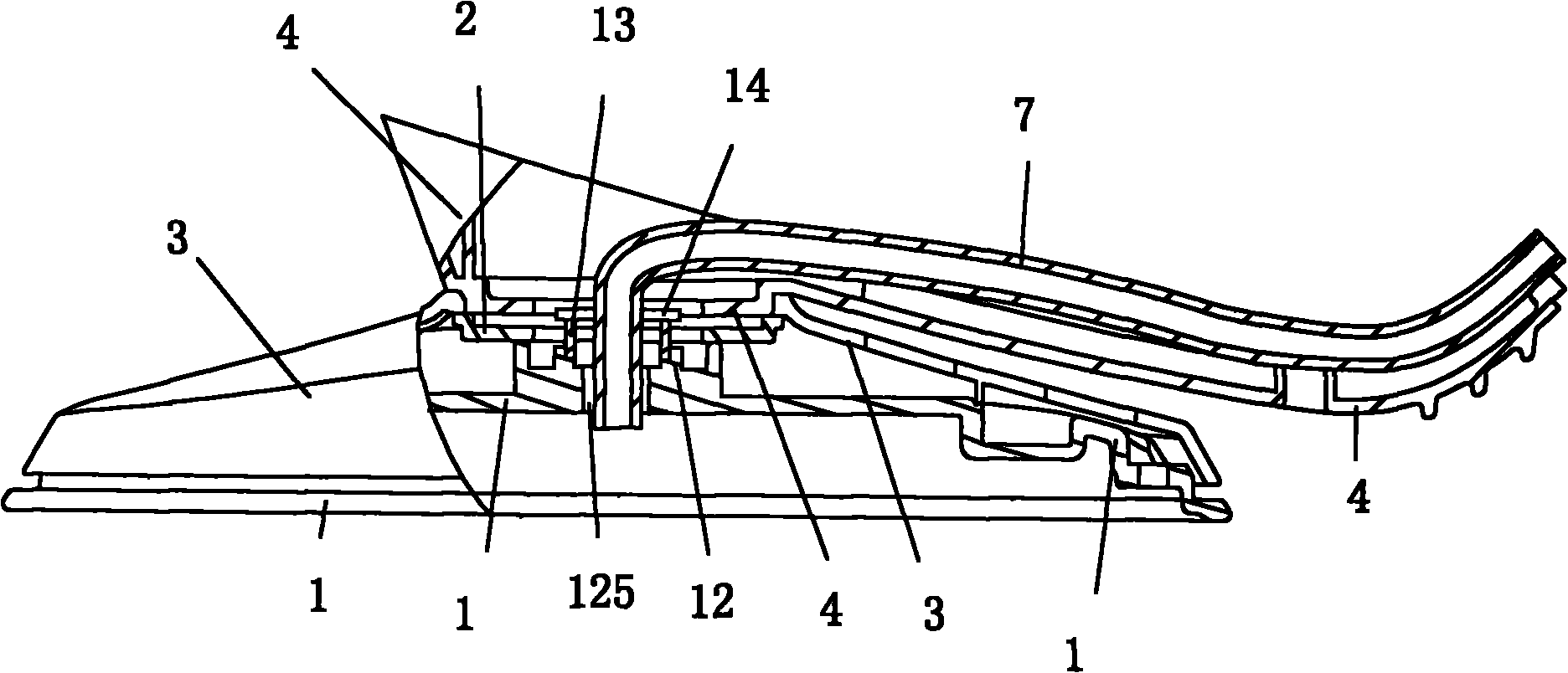

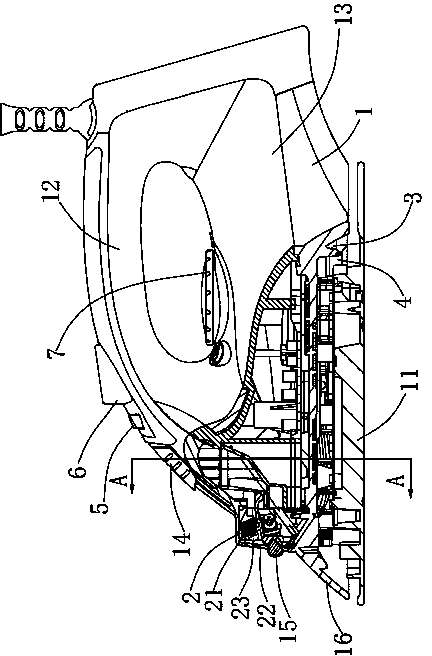

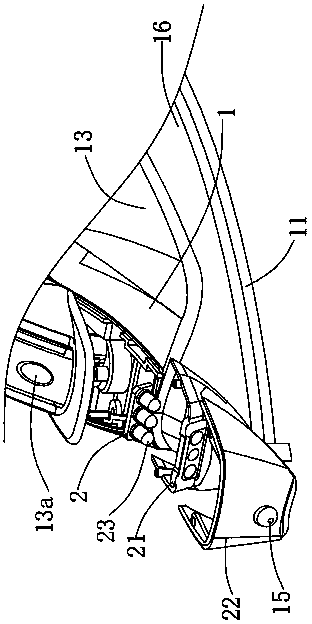

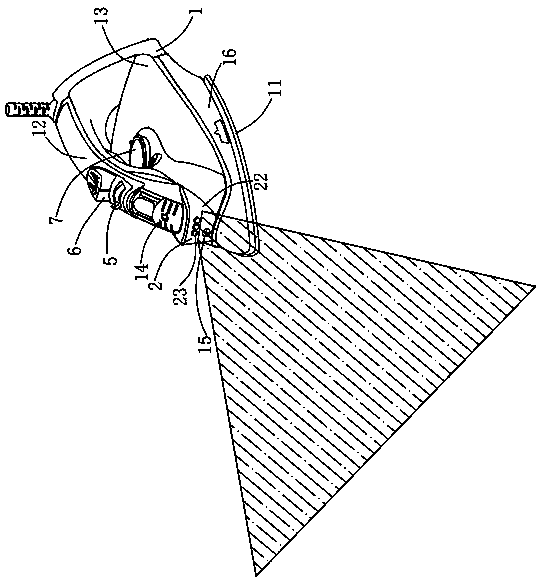

Rotatable electric iron and garment steamer with same

ActiveCN101922106AEasy to controlConvenience and safety in switching modes of useHand ironTextiles and paperEngineeringMechanical engineering

The invention relates to a rotatable electric iron and a garment steamer with the same. A body with an electric heater is provided with a shell. The rotatable electric iron is characterized in that a rotating body connects the body with a grip in a rotatable manner; a limiting mechanism limiting the rotating amplitude and an elastic locating mechanism locking the rotation angle position are arranged between the body and the grip. When the relative position of the grip and the body is locked, the electric iron is used as a steam iron. After a hairbrush cover is sleeved on the body, the grip rotates relative to the body and the electric iron is used as a steam brush. The invention solves the problem that the position of the grip relative to the body is fixed, thus the use mode is single and the flexible ironing requirement is hard to satisfy.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

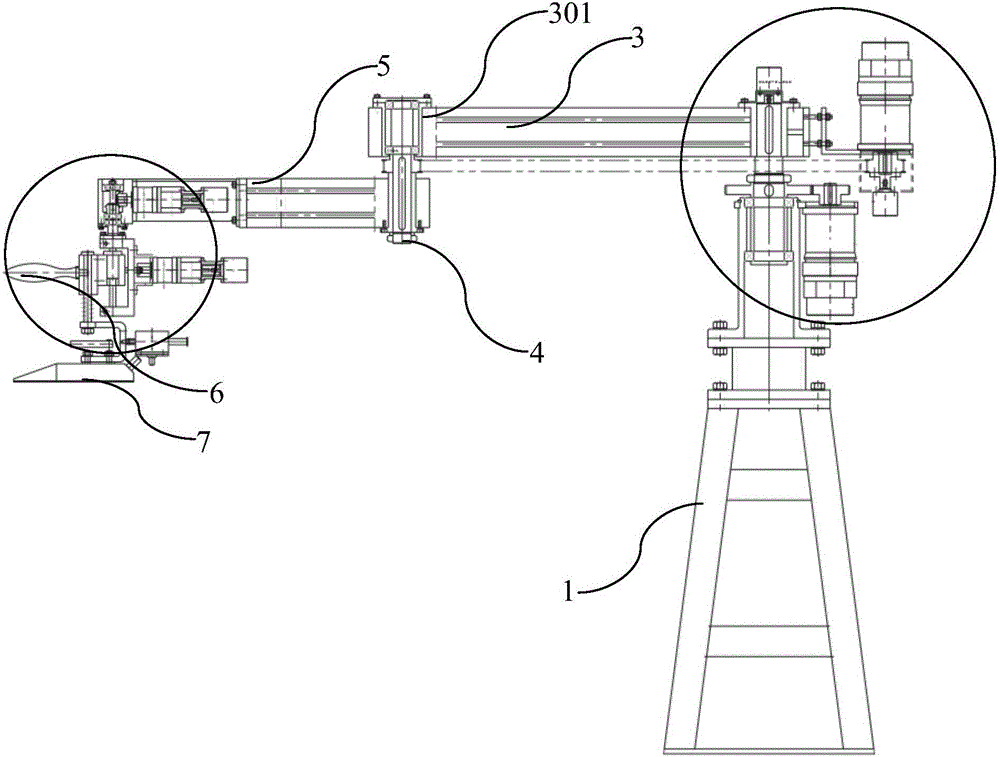

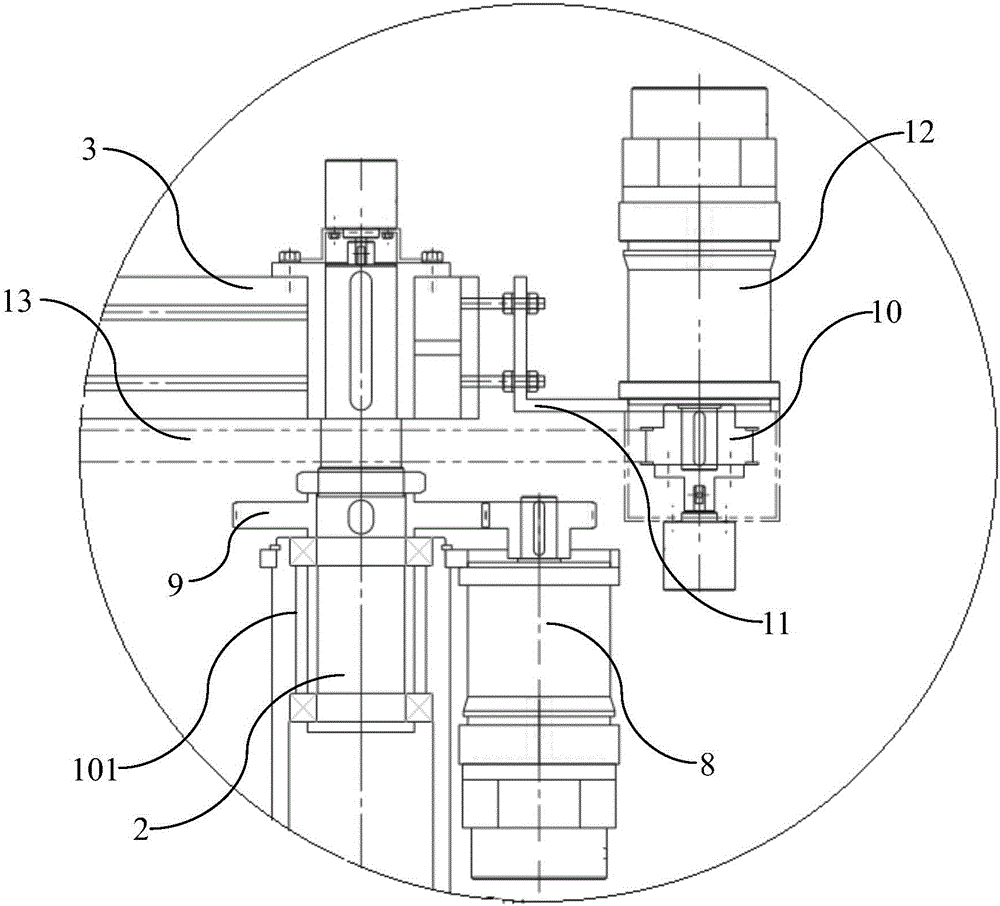

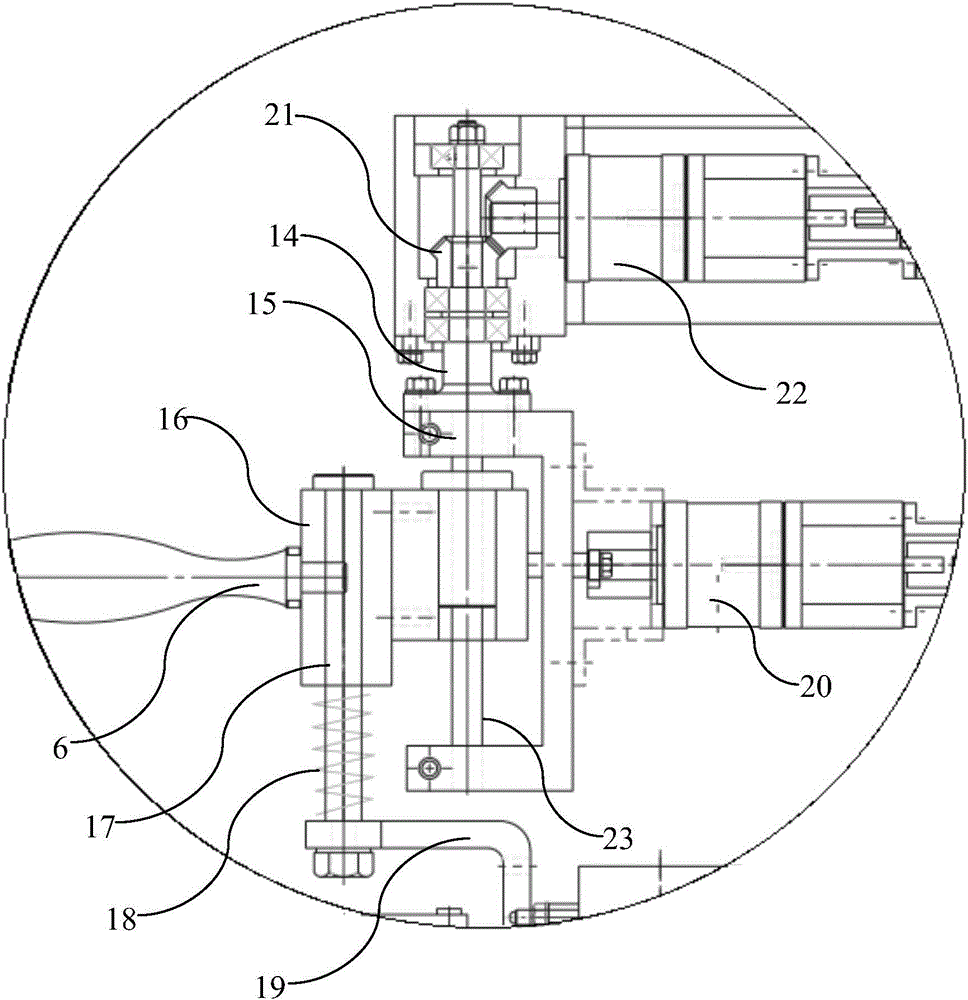

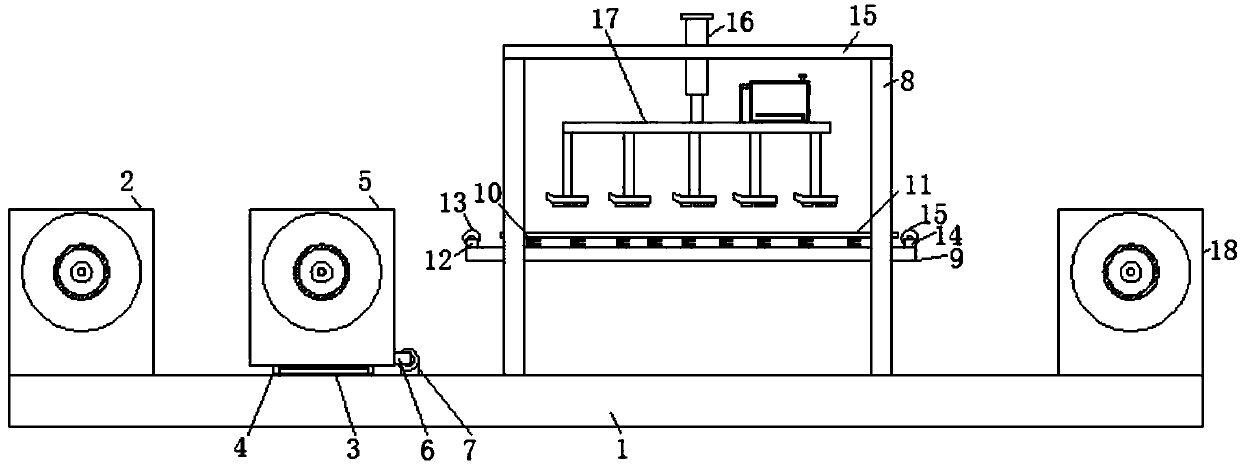

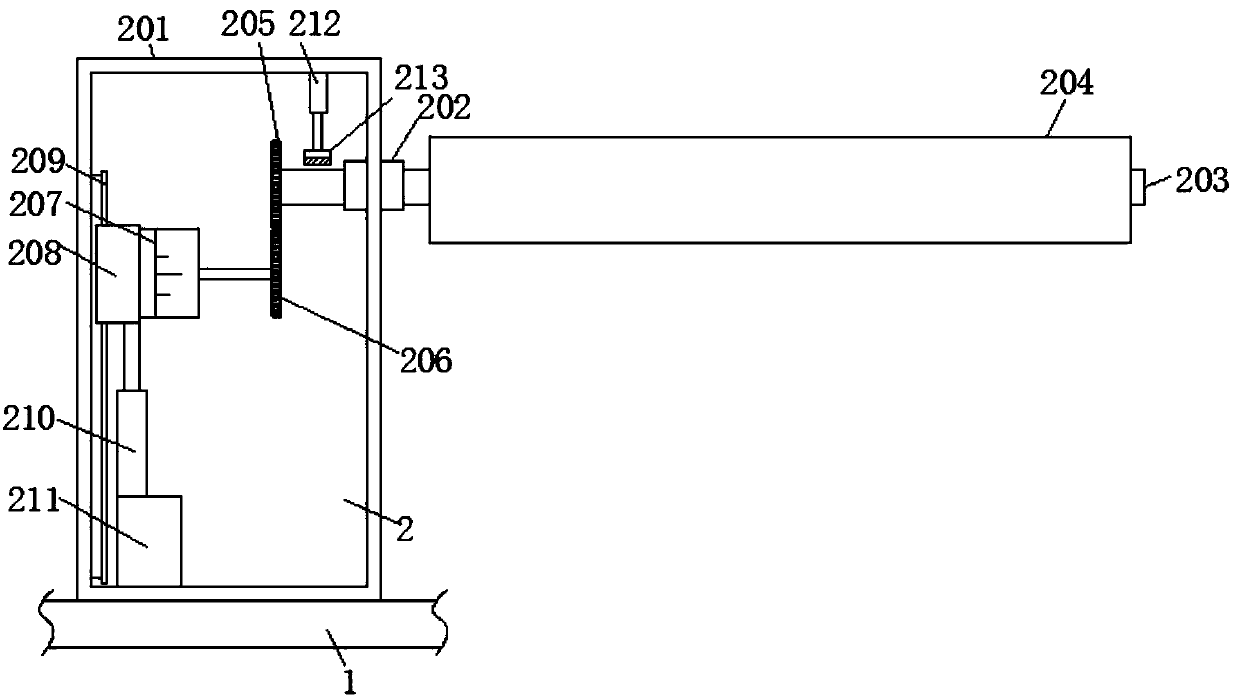

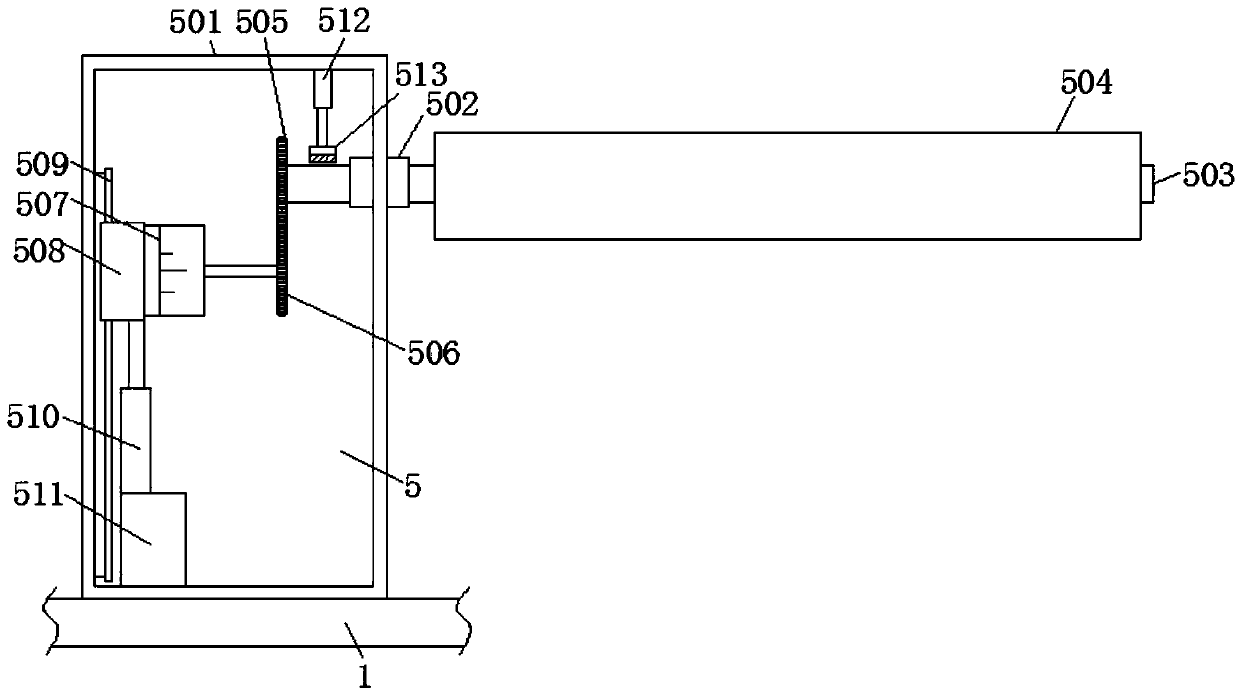

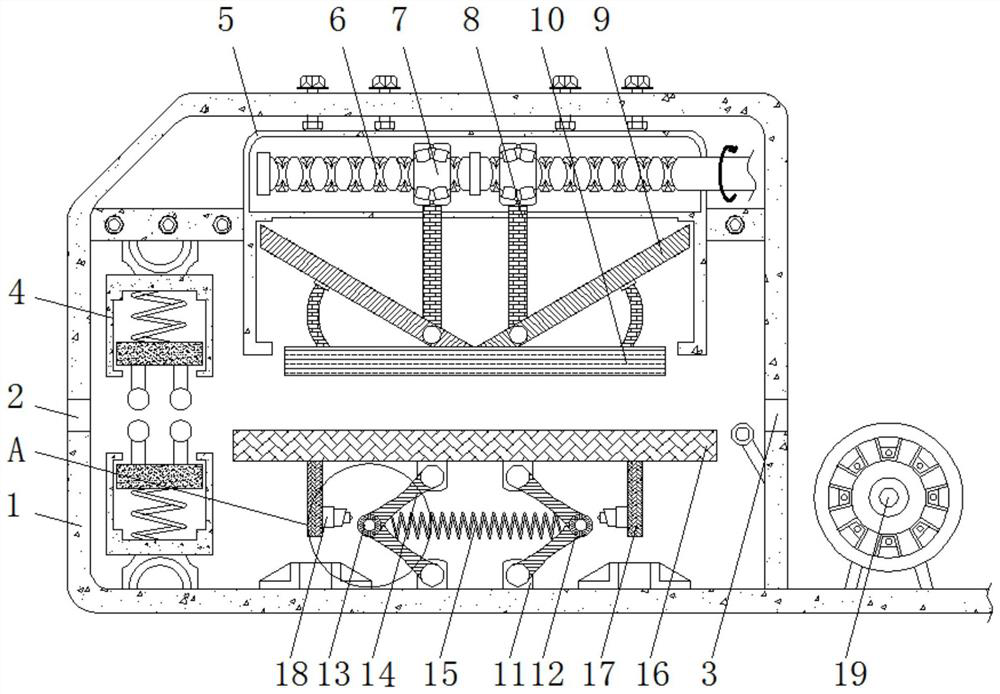

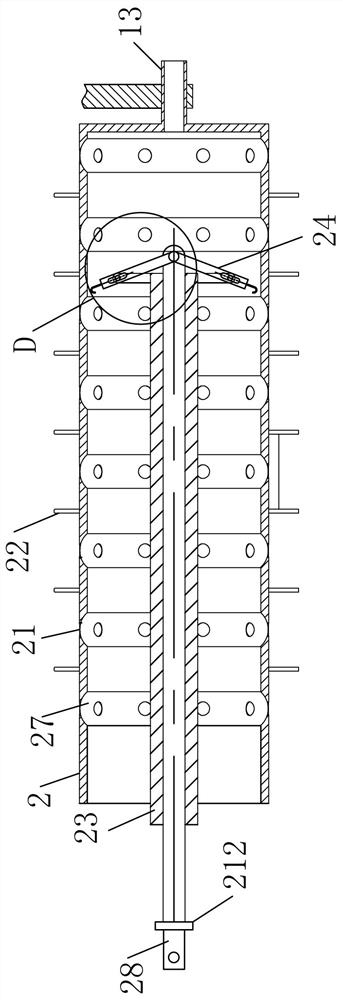

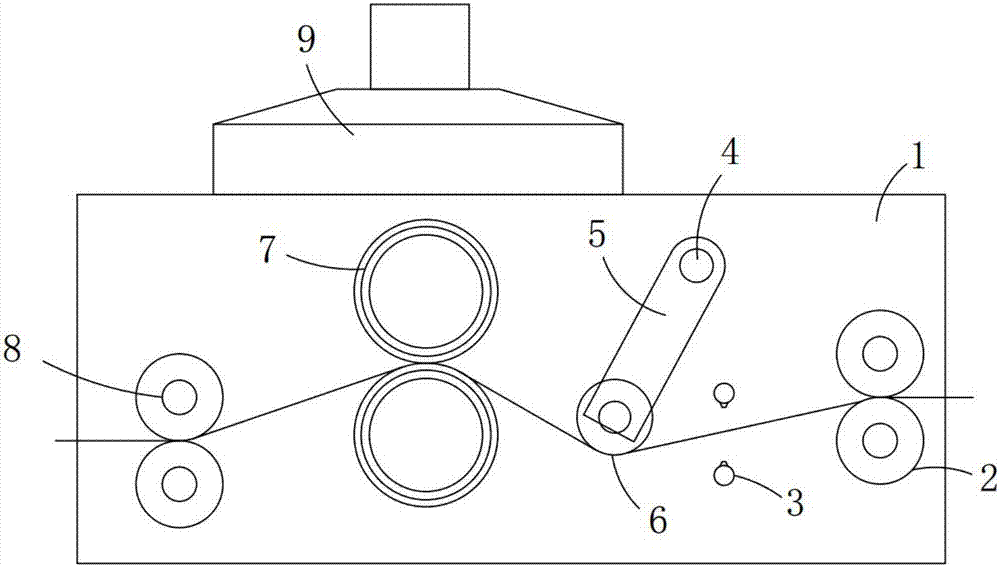

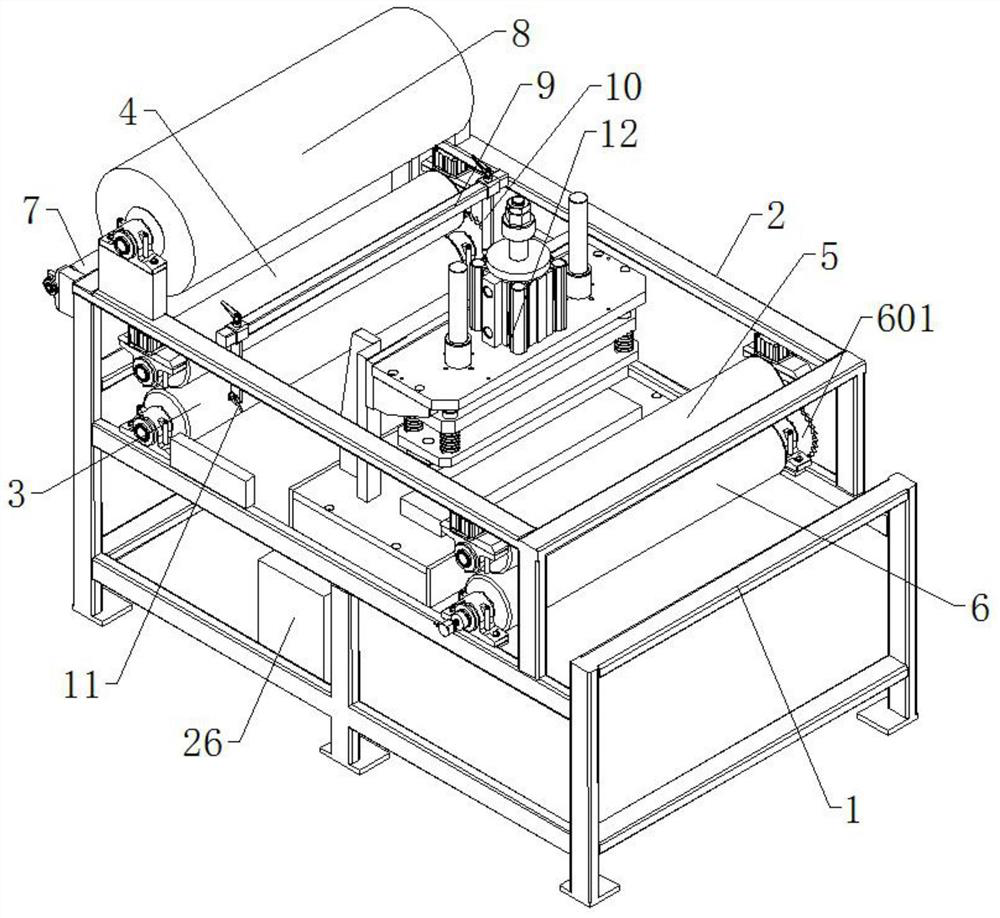

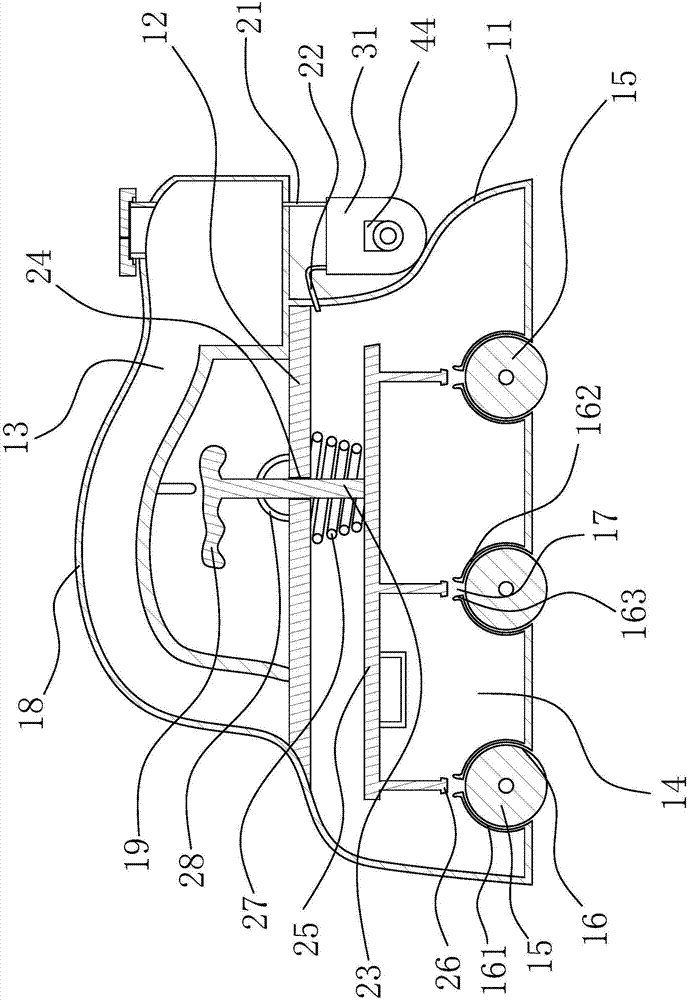

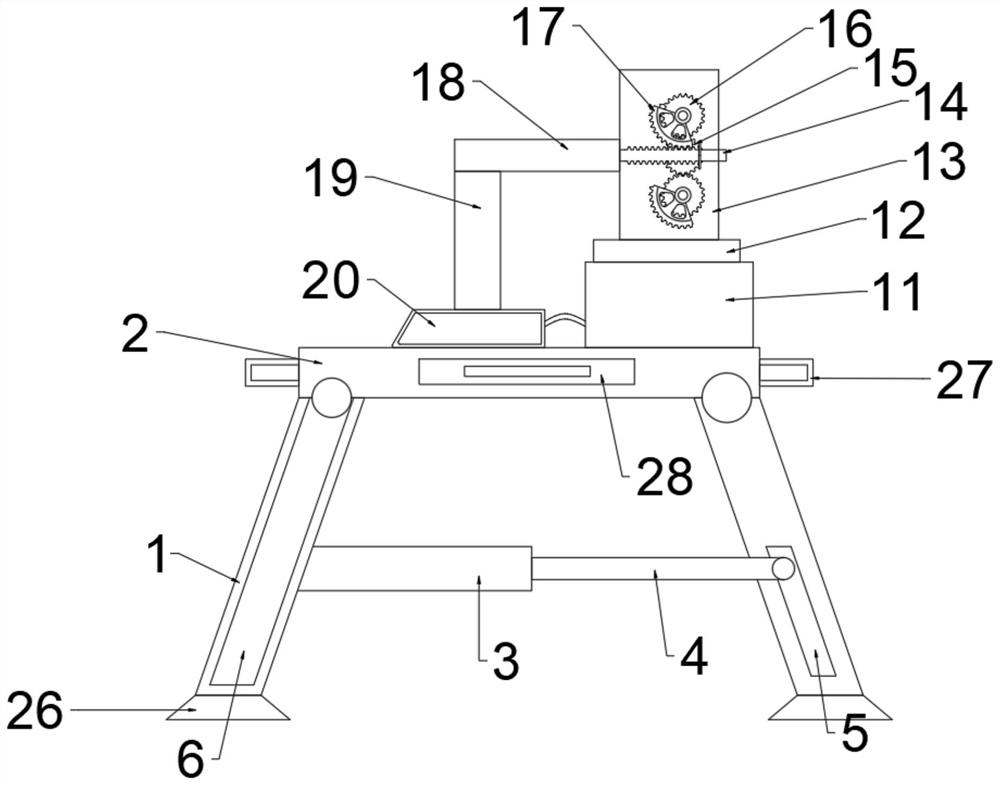

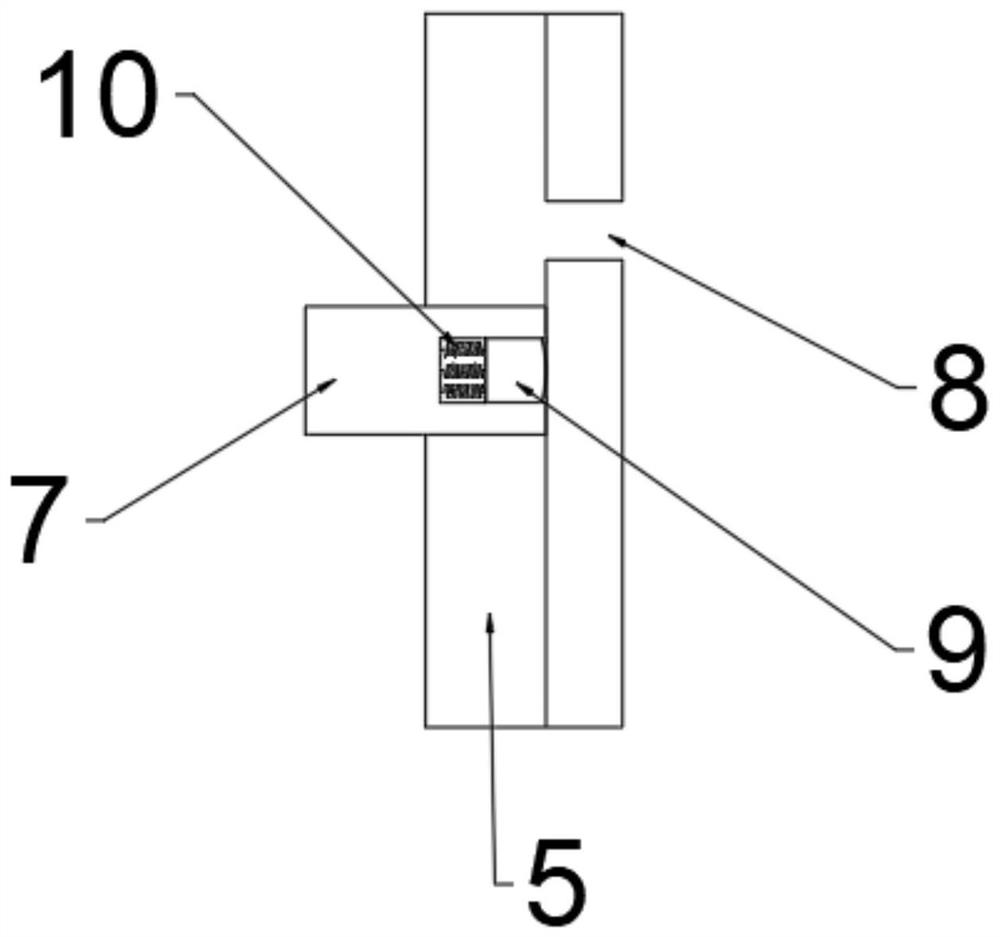

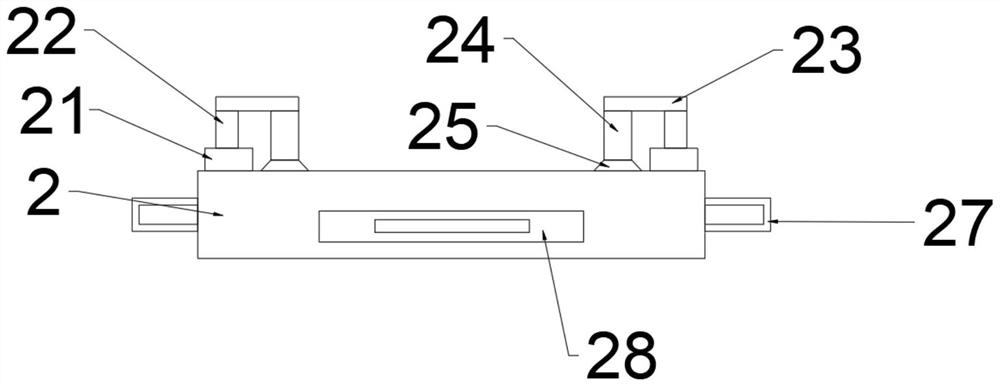

Industrial ironing machine

ActiveCN106811947AImprove ironing qualityImprove ironing efficiencyProgramme-controlled manipulatorIroning machinesRobot handMachine

The invention discloses an industrial ironing machine. The industrial ironing machine comprises an ironing machine body and a mechanical arm, and the ironing machine body and the mechanical arm are connected so that the mechanical arm can be utilized to control the ironing machine body to work. According to the industrial ironing machine, the ironing machine mechanical arm capable of recording a movement locus of manually ironing clothes and the ironing machine body matched with the mechanical arm are designed, the ironing machine mechanical arm can control the movement of the ironing machine body through the movement locus, and an ironing movement which is the same as a manual ironing movement is automatically conducted; meanwhile, through automatic ironing of the mechanical arm, the ironing efficiency is sharply improved, the labor workload is reduced, and ironing quality of the clothes is improved at the same time.

Owner:福州肆菱智能科技有限公司

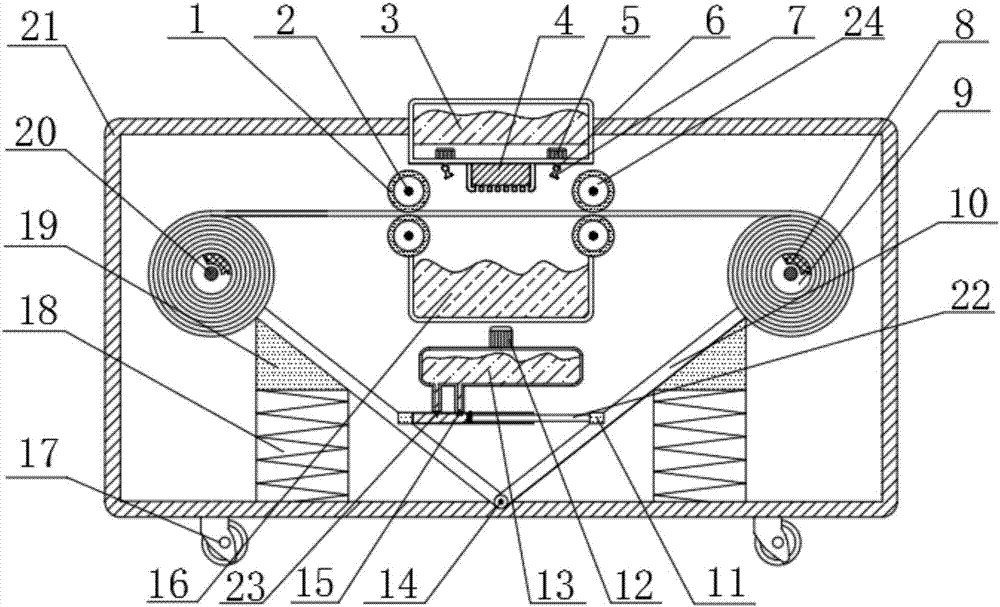

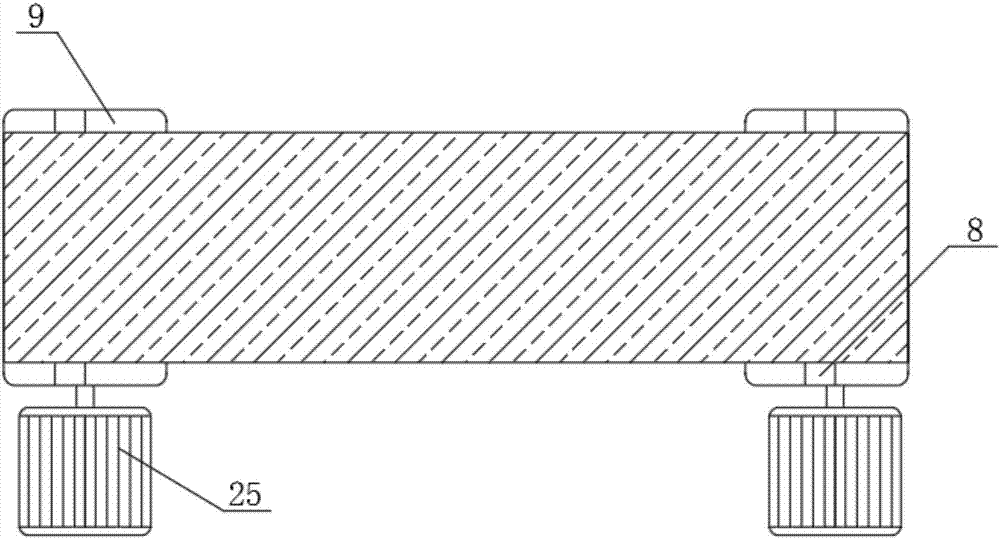

Novel textile fabric ironing device

InactiveCN106894189AIncrease the effect of straightening clothAvoid damageTextile shapingRotational axisWater storage tank

The invention discloses a novel textile fabric ironing device which comprises an electric heating wire, a first rotating shaft, a water storage tank, a steam spray nozzle, a water spray machine, a universal hinge, a water spray nozzle, a clamping block, a roller, a connecting rod, a rubber support rib, a hydraulic pump, a hydraulic box, a hinge, a hydraulic cylinder, a waste water tank, a roller wheel, a spring, a cushion rubber, a second rotating shaft, a housing, a piston rod, a check valve, a pressing wheel and a motor. The novel textile fabric ironing device provided by the invention is simple in structure, novel in design, easy to be realized, and the hydraulic device is added to play a role of straightening fabric during ironing, so as to improve the ironing quality; the water storage tank and water spray devices are also added to avoid damaging the fabric due to excessive temperature during ironing; the motor is added to solve a problem of low efficiency of manual ironing and improve the operating efficiency; the roller wheel are added to facilitate movement and transportation; the novel textile fabric ironing device has great economic benefits and wide market prospect, and is worth to be popularized and applied.

Owner:扬州市嘉鑫织造实业有限公司

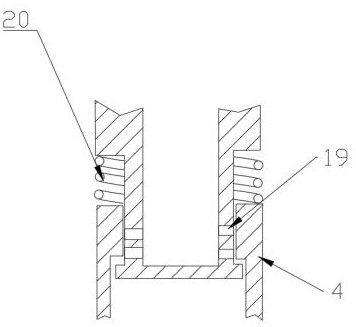

Electric steam iron

InactiveCN103397505AReduce power consumptionImprove ironing qualityHand ironTextiles and paperSpray nozzleElectric heating

The invention relates to clothing ironing devices in the field of articles for daily use, in particular to an electric steam iron. The electric steam iron is provided with an illuminating mechanism, a filler cap of the electric steam iron is good in performance, and the electric steam iron is durable and comprises a shell, a grip, a water tank, a spray nozzle, a bottom plate and an electric heating pipe. The grip is arranged on the shell, the water tank is arranged in the shell, the spray nozzle is arranged at the front end of the shell and can spray steam in the water tank, the bottom plate is arranged on the lower side of the shell, and the bottom plate can be heated by the electric heating pipe. The electric steam iron is characterized in that the filler cap in the front of the grip is arc-shaped, the radian of the arc-shaped filler cap is matched with that of the front of the grip, and the filler cap is closely connected with a filler when upwardly moving to the rear end, and moves smoothly and opens the filler when pushed downwardly; the illuminating mechanism is arranged at the front of the shell and is positioned on the rear upper side of the spray nozzle. The electric steam iron has the advantages that owing to the illuminating mechanism, the illuminance is improved when the electric steam iron is used, and the ironing quality is guaranteed; the filler cap can slide smoothly and is durable owing to improvement on the shape and the structure of the filler cap.

Owner:HUAYU ELECTRICAL APPLIANCE GROUP

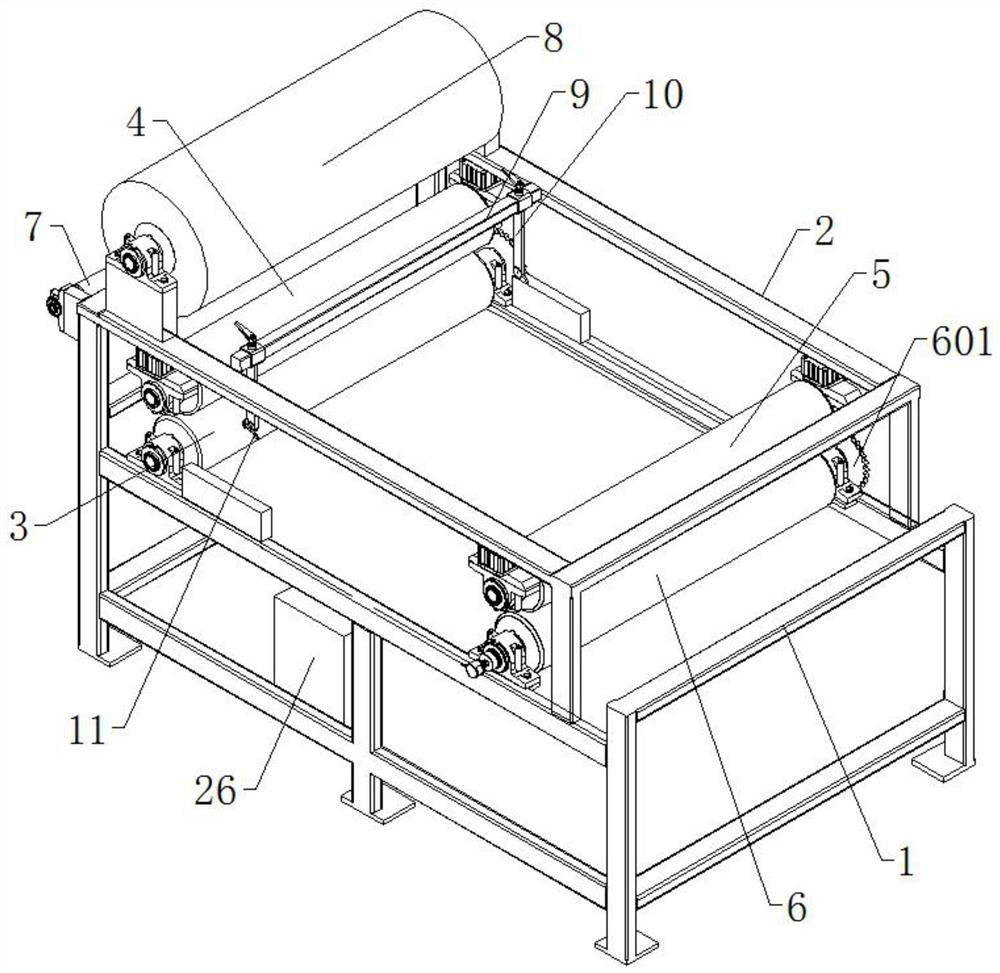

Continuous printing and dyeing ironing machine

PendingCN107938240APlay the effect of ironing fabricIncrease pulling forceTextile shapingWebs handlingWinding machineElectric machine

The invention relates to the technical field of printing and dyeing equipment and discloses a continuous printing and dyeing ironing machine. The continuous printing and dyeing ironing machine comprises a base plate, wherein the top of the base plate is fixedly connected with the bottom of a first unreeling machine and the bottoms of first sliding rails; in addition, the first sliding rails are positioned right above the first unreeling machine and are in sliding connection with a first sliding block; the tops of the first sliding rails are fixedly connected with the bottom of a second unreeling machine; one side, away from the first unreeling machine, of the second unreeling machine, is fixedly connected with one side of a baffle; the back side of the baffle is fixedly connected with thefront side of a first electric push rod. According to the continuous printing and dyeing ironing machine, the first unreeling machine which is fixedly connected with the top of the base plate and a reeling which is fixedly connected with the top of the base plate are matched with the first sliding rails, the first sliding block, the second unreeling machine and the first electric push rod; when cloth on the second unreeling machine is unreeled, cloth on the first unreeling machine is connected with the cloth on the second unreeling machine, so that an effect of continuously ironing the cloth is realized.

Owner:绍兴尹创机械科技有限公司

Cloth ironing device

PendingCN108950966AAvoid scaldingPrevent affecting ironing effectMechanical cleaningPressure cleaningEngineeringPre treatment

Owner:HAIYAN OULI CLOTHING

Ironing device for processing novel textile fabric

InactiveCN108660666AScientific and reasonable structureEasy to useTextile shapingMotor driveEngineering

The invention discloses an ironing device for processing a novel textile fabric. The device comprises a frame, the front side of the bottom end of the frame is fixedly connected with a dehumidifier, motors is arranged at the inner bottom end of the dehumidifier, the top end of every motor is rotatably connected with fan blades, a second carding roller is arranged at a position, close to the dehumidifier, in the frame, a first carding roller is arranged above the second carding roller, and a carding driven gear is mounted at one end of the second carding roller. The ironing device has a scientific and reasonable structure, and high-temperature steam is generated by a steam generated and is conveyed into an ironing plate in order to comprehensively iron the fabric, so the artificial labor intensity is reduced, and the production efficiency is improved; and the motors drive the fan blades to rotate in order to dry the textile fabric, so the processing cost is reduced, the ironing efficiency is improved, the ironing quality is improved, and the ironing device is suitable for being comprehensively promoted and used.

Owner:XIANGSHUI YONGTAI TEXTILE GARMENT CO LTD

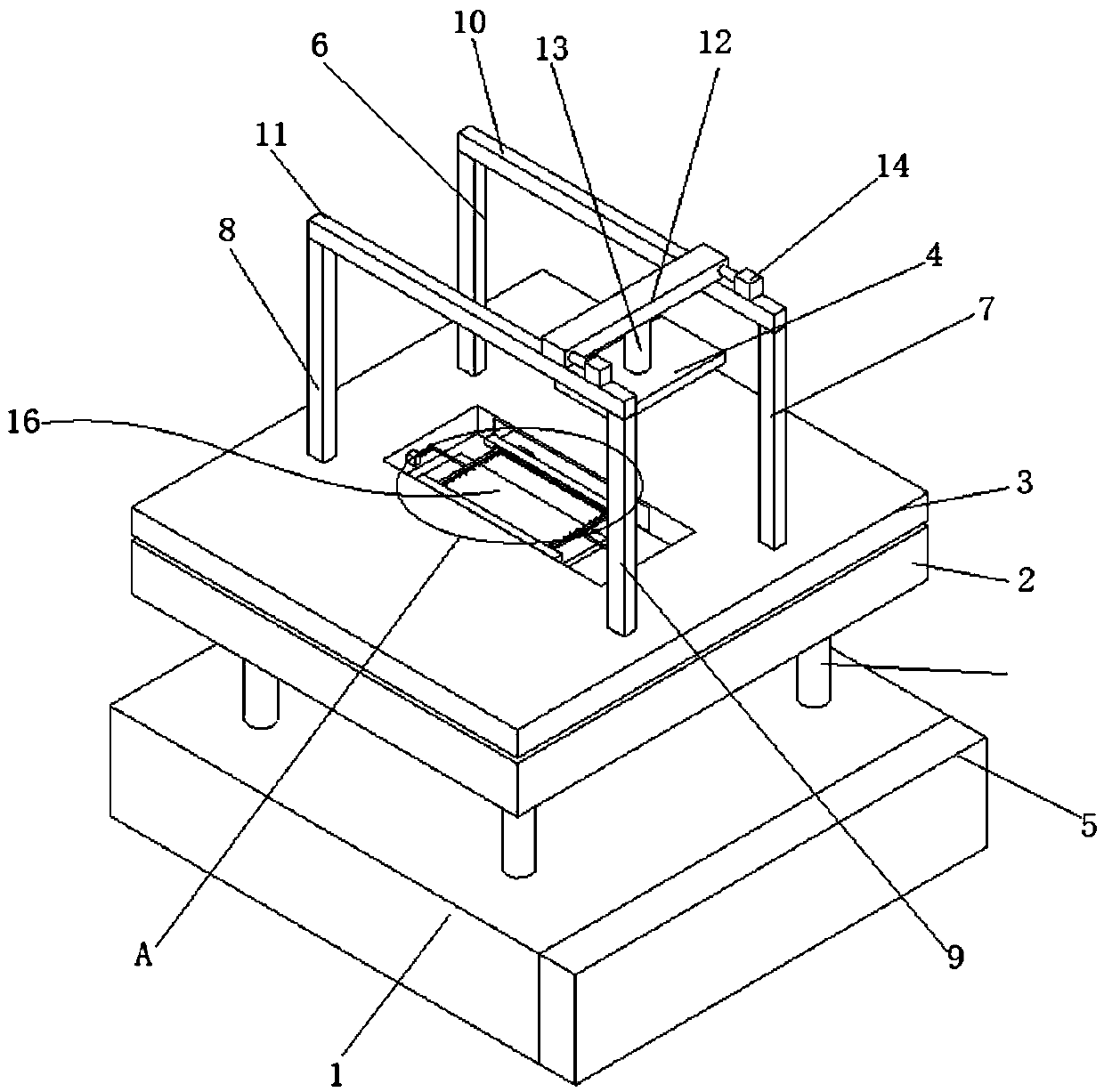

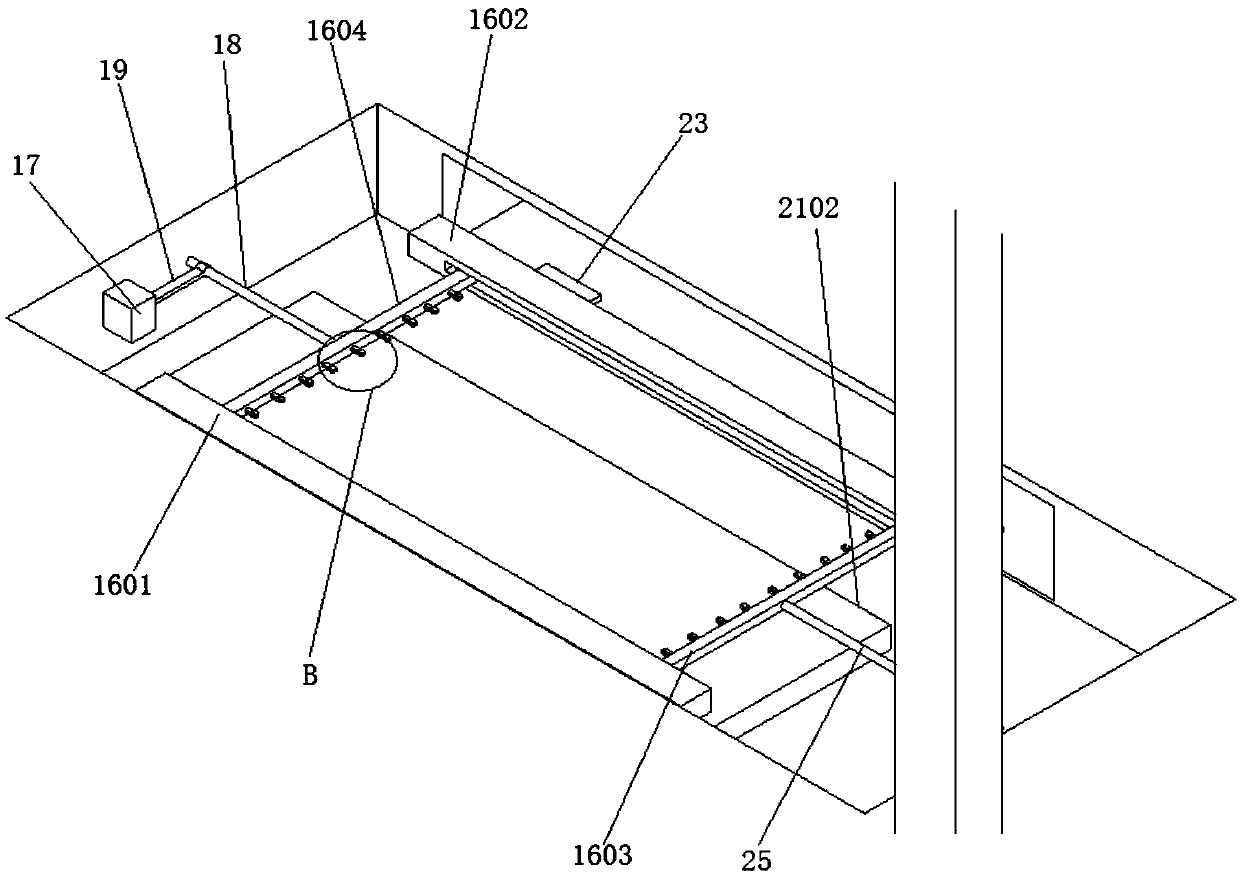

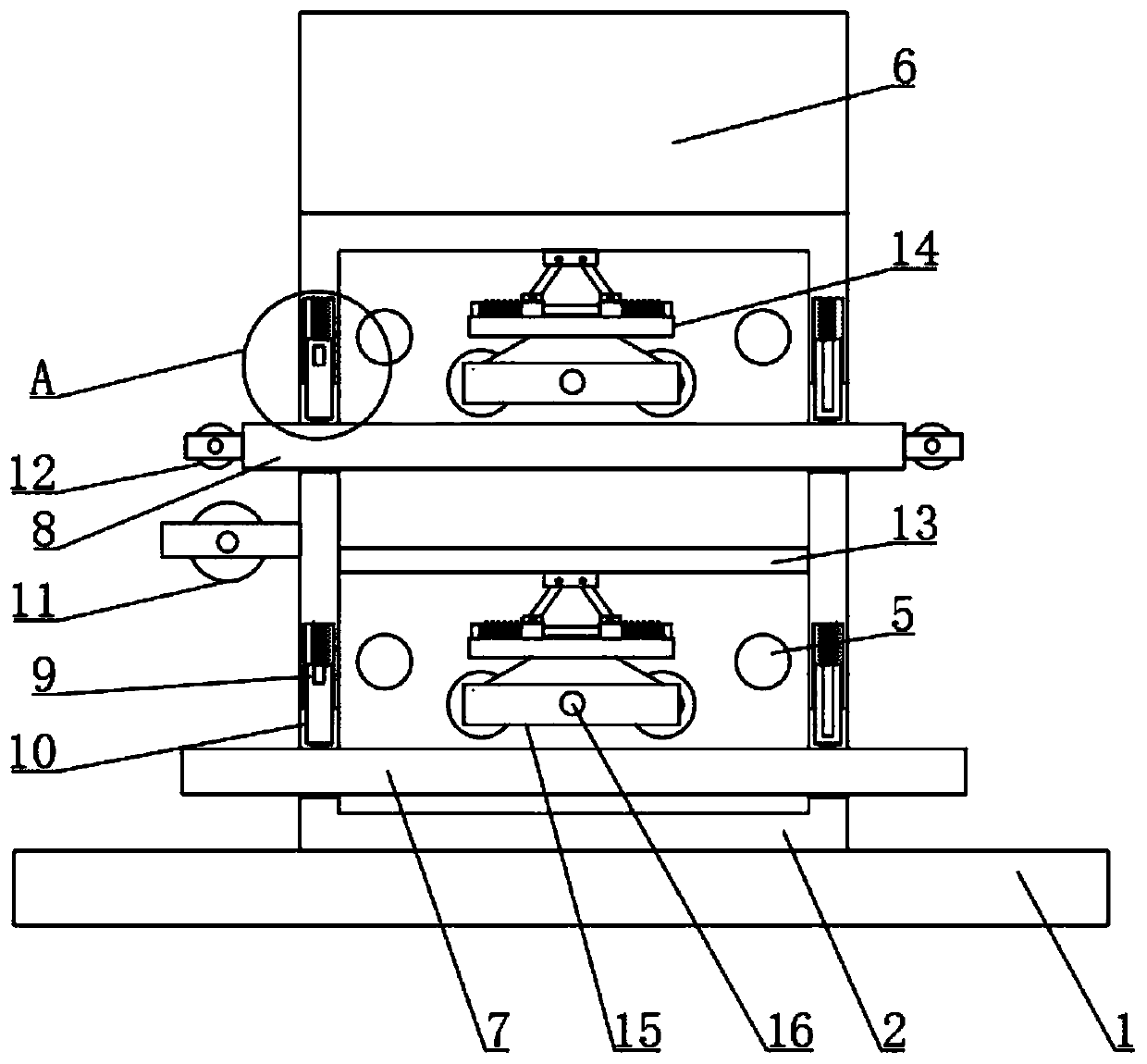

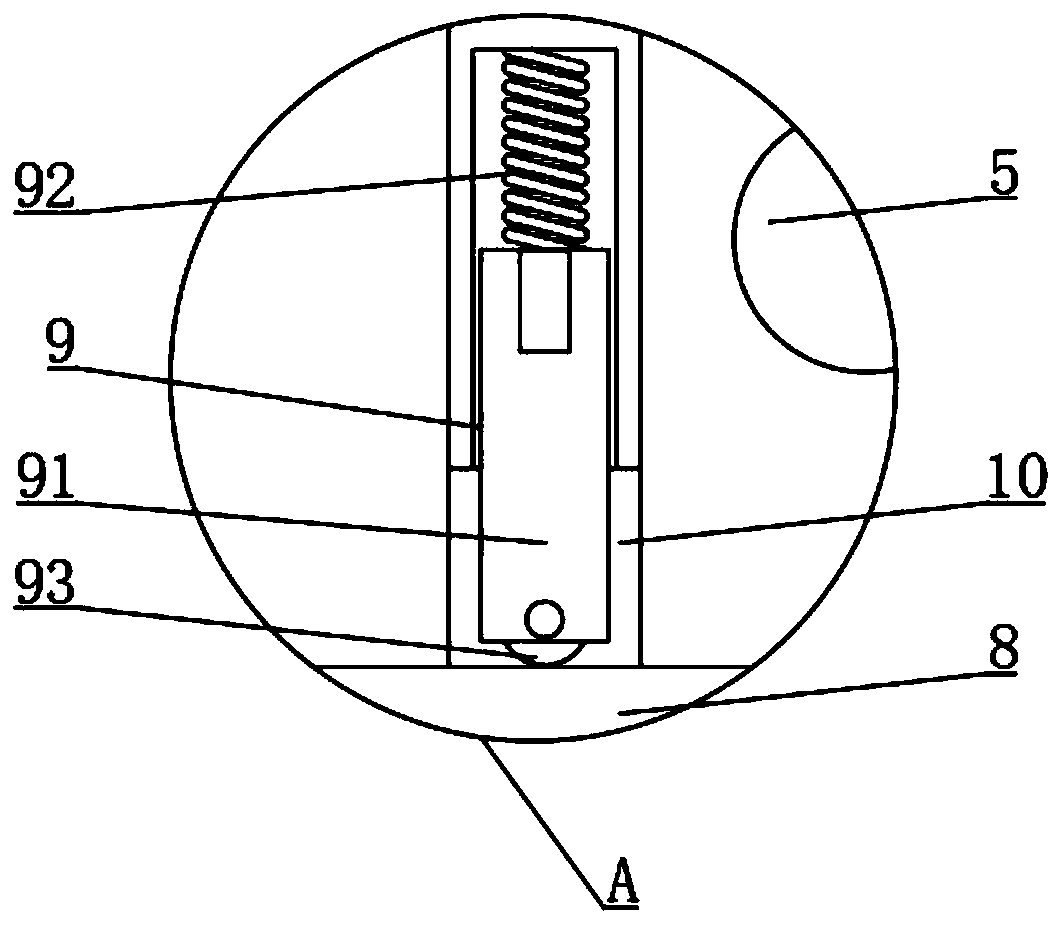

Ironing table for garment processing

InactiveCN111394972ARealize automatic ironingSimple structureIroning machinesTextiles and paperEngineeringMechanical engineering

The invention discloses an ironing table for garment processing. The ironing table comprises a base, a first lifting mechanism, a fixing plate, an ironing plate, an ironing device and a controller, wherein the fixing plate is fixedly connected with the base through the first lifting mechanism, the ironing plate is detachably arranged on the fixing plate, a support is arranged on the ironing plate,the ironing device is arranged below the support, the support is further provided with a vertical driver and a horizontal driver which drive the ironing device to move, a rectangular hollowed-out area located below the support is arranged in the ironing plate, a clothes fixing mechanism is placed in the rectangular hollowed-out area, one end of the clothes fixing mechanism is rotationally connected with the inner wall, opposite to the clothes fixing mechanism, of the rectangular hollowed-out area through a rotating shaft, the other end of the clothes fixing mechanism is rotationally connectedwith the inner wall, opposite to the clothes fixing mechanism, of the rectangular hollowed-out area through a telescopic rotating mechanism, the ironing plate is provided with a hollow cavity, and aclothes pressing mechanism is arranged in the hollow cavity. According to the ironing table, automatic ironing of garment cloth is achieved, automatic turnover can be achieved in the ironing process,manual ironing is avoided, time and labor are saved, the working efficiency is improved, and the ironing quality is high.

Owner:上海飘林服饰有限公司

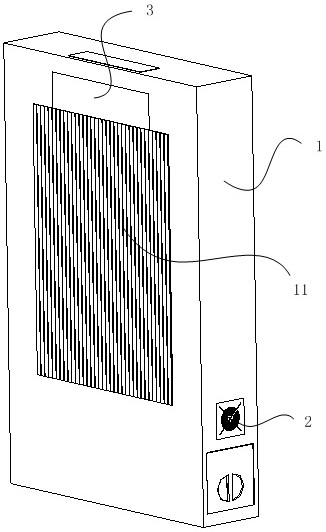

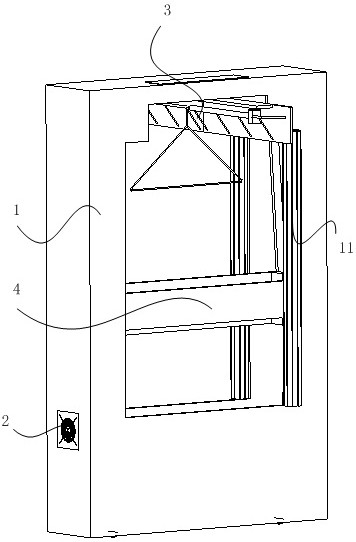

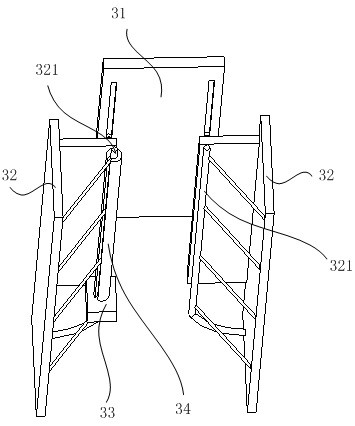

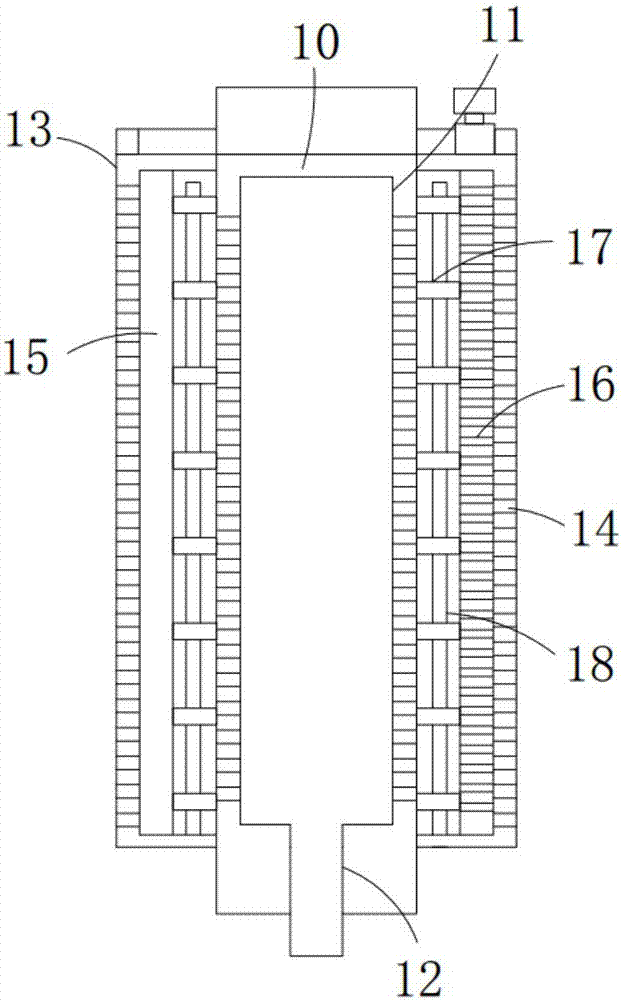

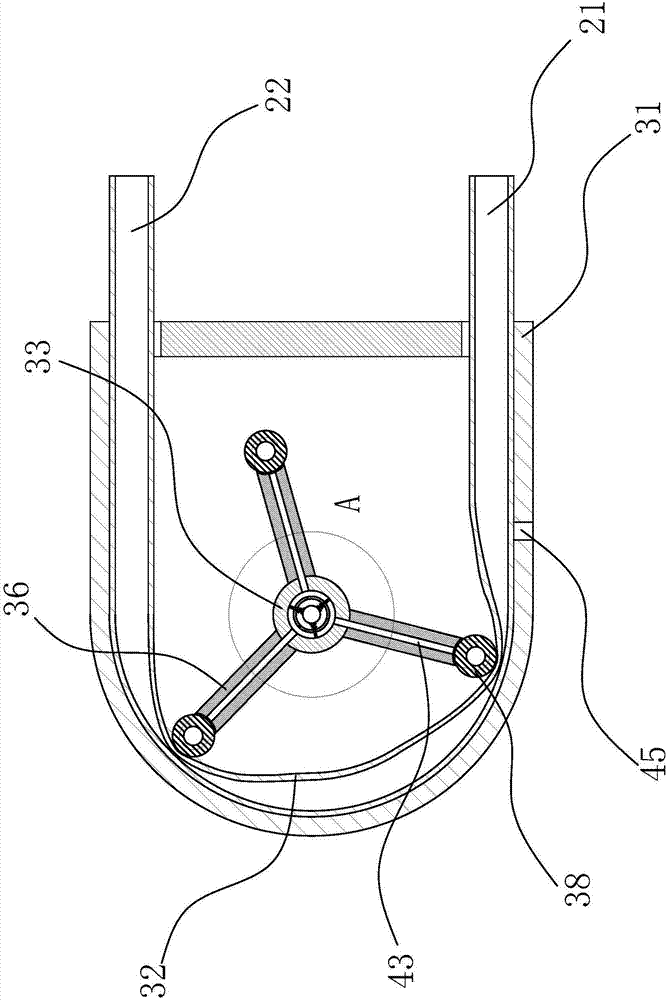

Steam ironer

InactiveCN103276575AGuaranteed stabilityImprove ironing qualityHand ironTextiles and paperEngineering

The invention relates to a steam ironer which comprises an ironer body, a steam guide pipe, a sprayer and a supporting frame arranged on the ironer body, wherein a steam generator is arranged inside the ironer body, and the sprayer is communicated with the steam generator through the steam guide pipe. The supporting frame comprises an upper supporting part and a lower supporting part, the upper supporting part and the lower supporting part are connected with each other through a rotary shaft and are located in an ironing state through a locating device, one side, facing the lower supporting part, of the upper supporting part is bent to form an ironing part in the ironing state, an ironing plate is arranged on the ironing part in a detachable mode, and at least a part of the ironing plate stretches out of the other side of the lower supporting part. As the ironing plate stretches out of the other side of the lower supporting part, the stretched length of the ironing plate is regulated to enable the center of gravity of the supporting frame to be located at the center of the steam ironer, the steam ironer will not fall down when clothes are place on the ironing plate to be ironed, and stability of the center of gravity of the steam ironer is guaranteed.

Owner:FOSHAN SHUNDE SINCERE HOME HOME APPLIANCE MFG CO LTD

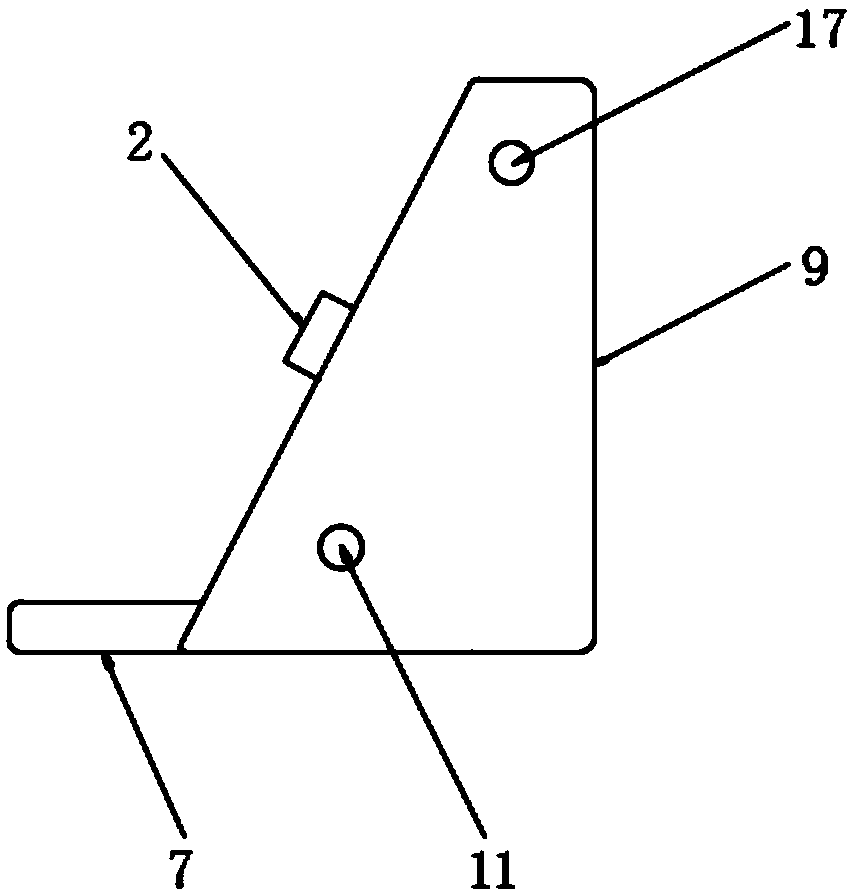

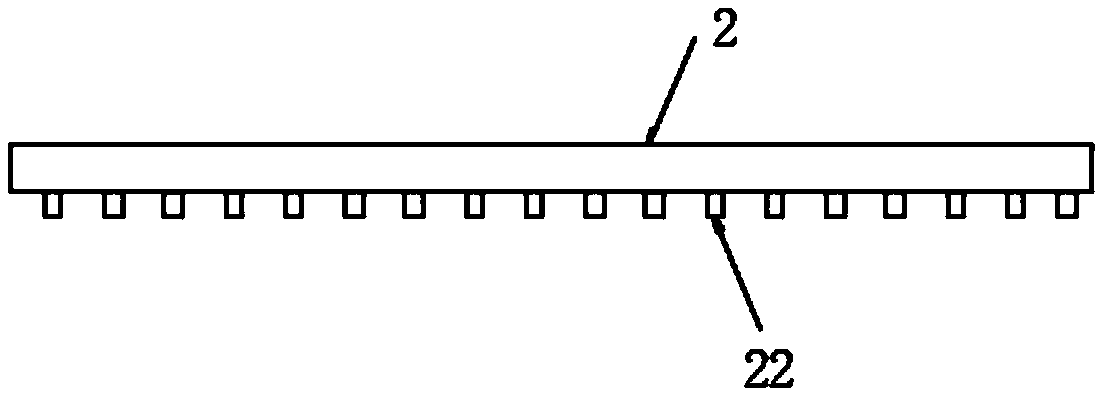

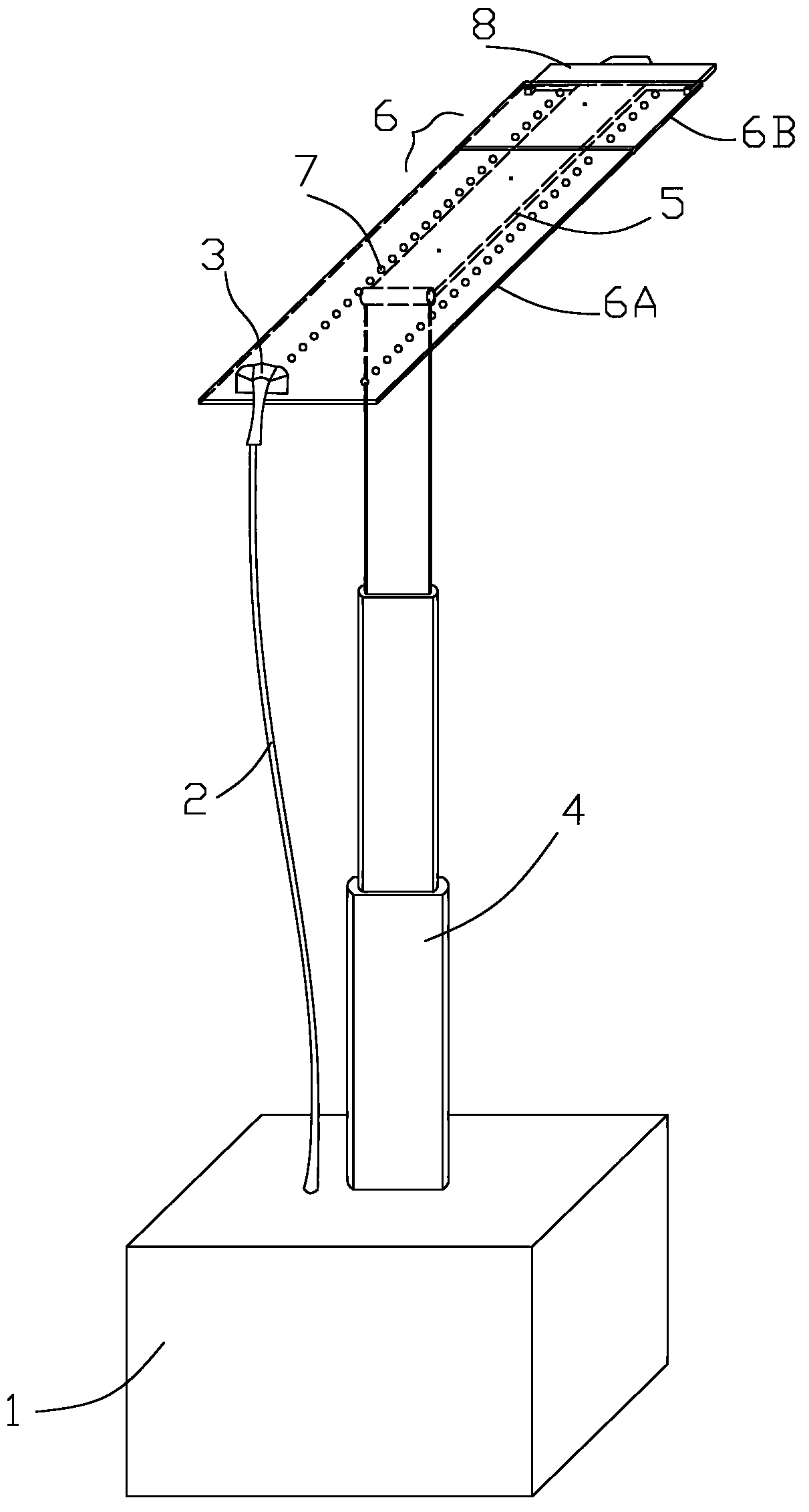

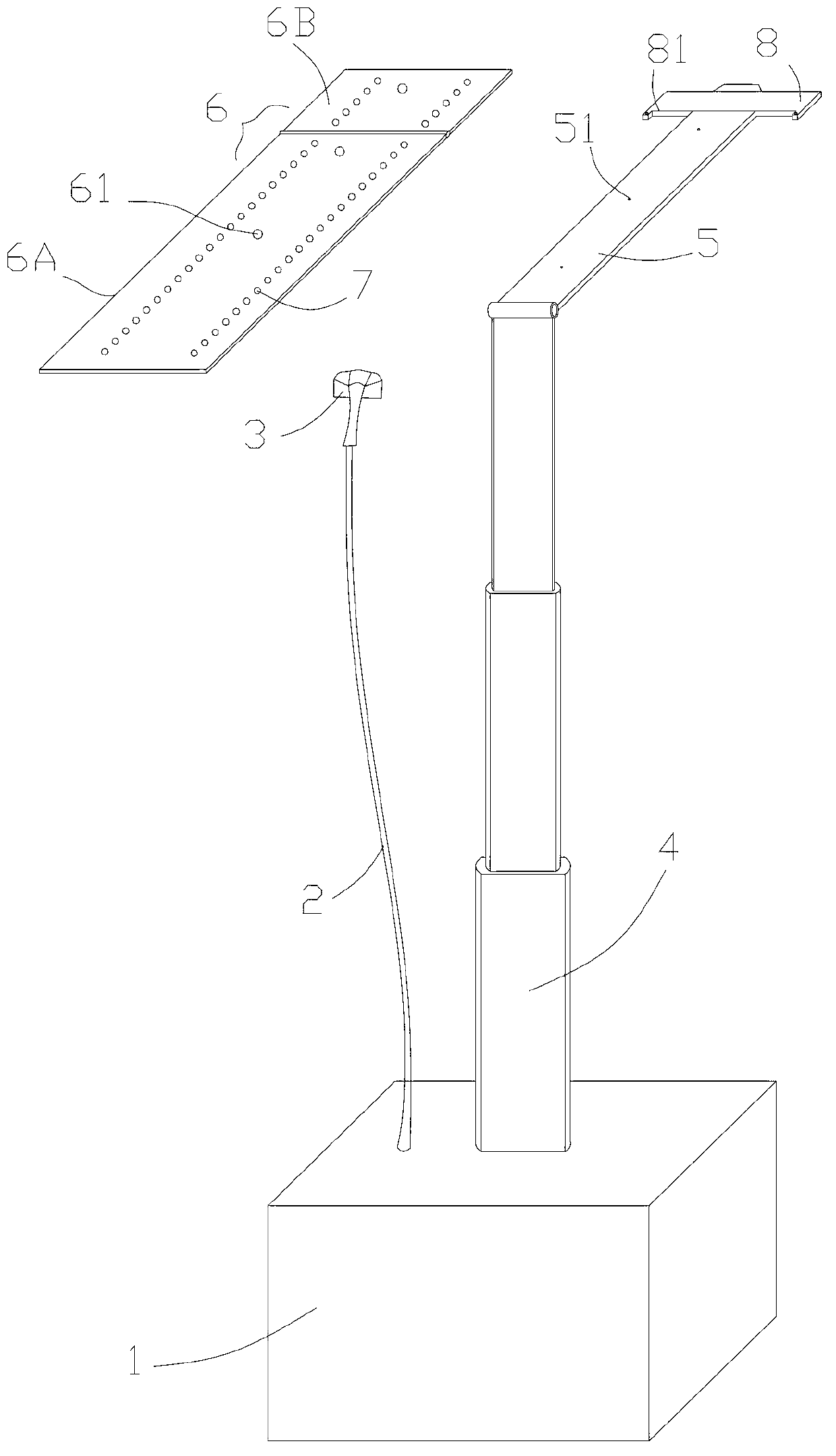

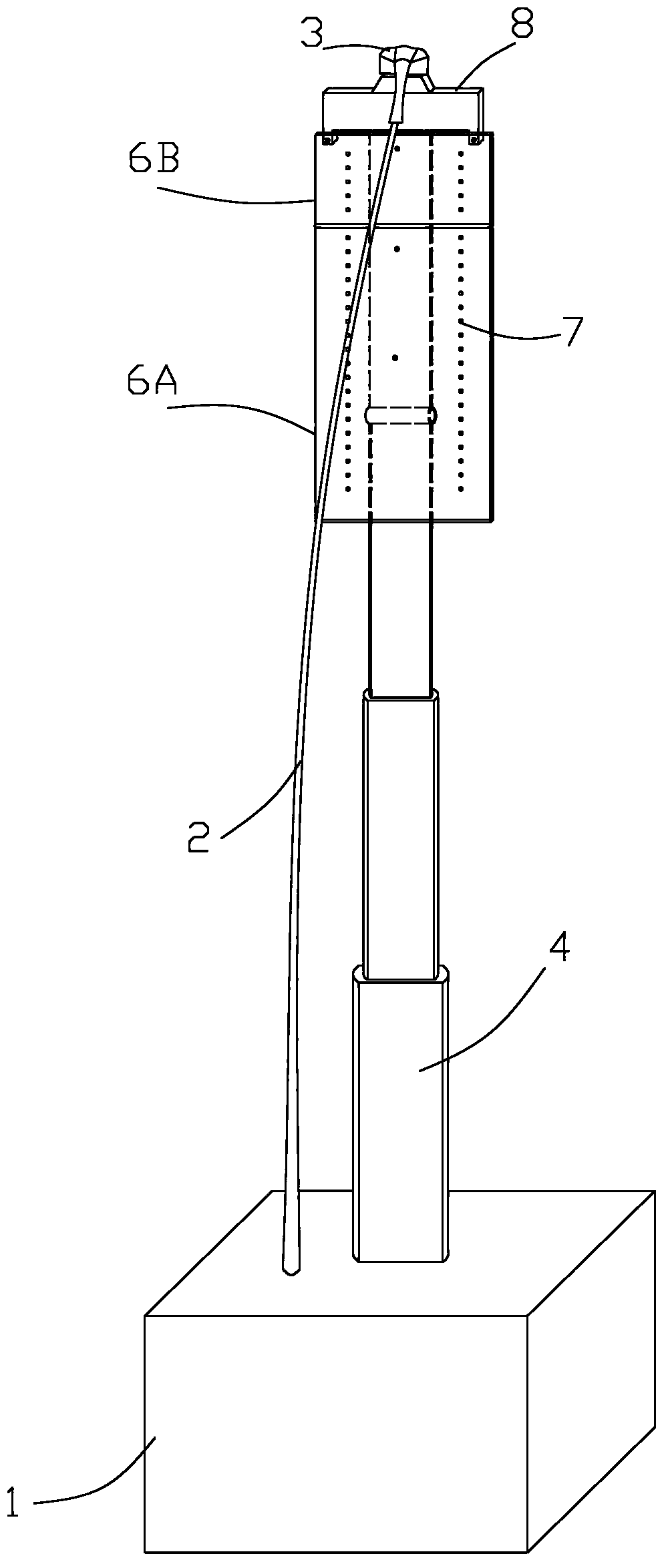

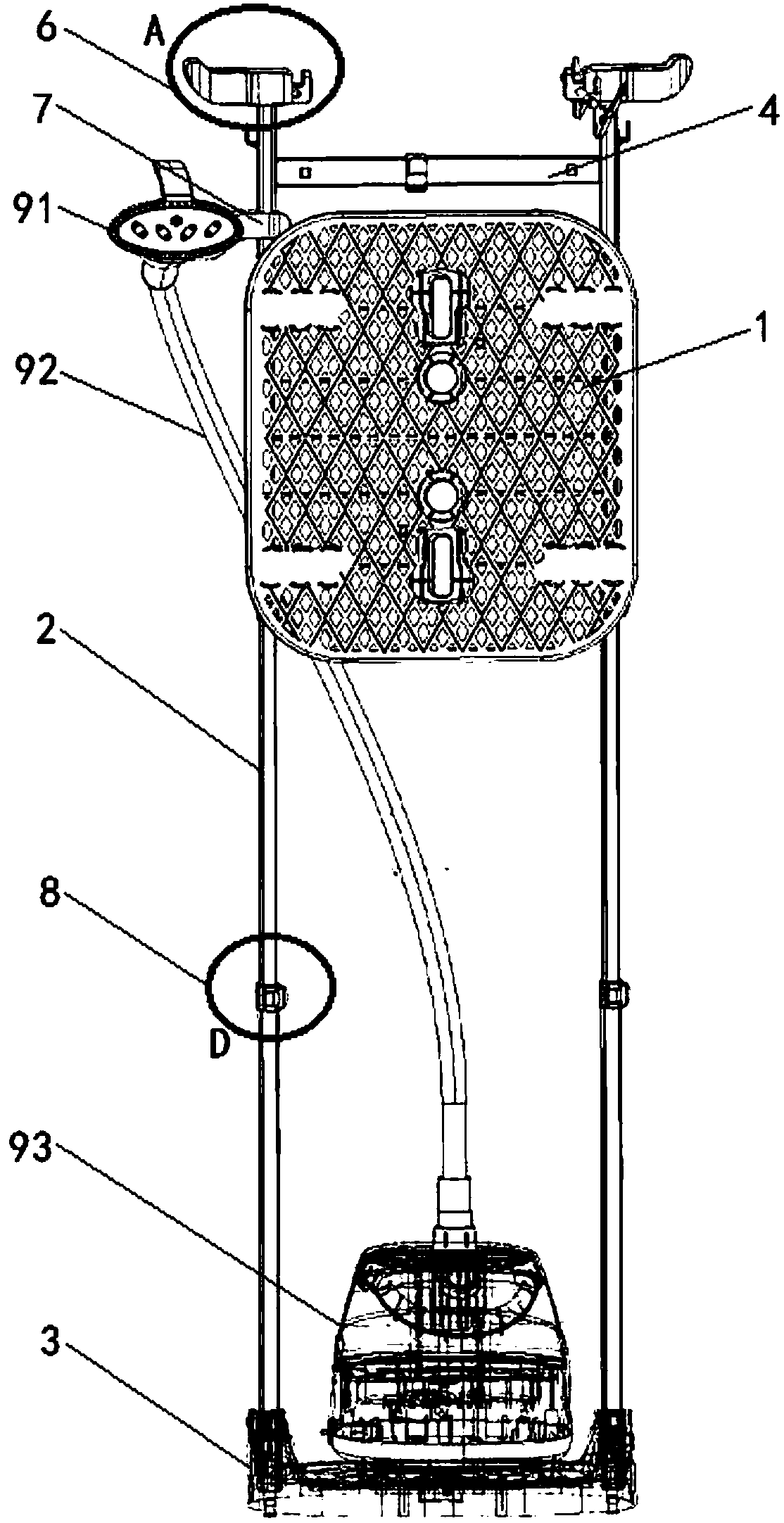

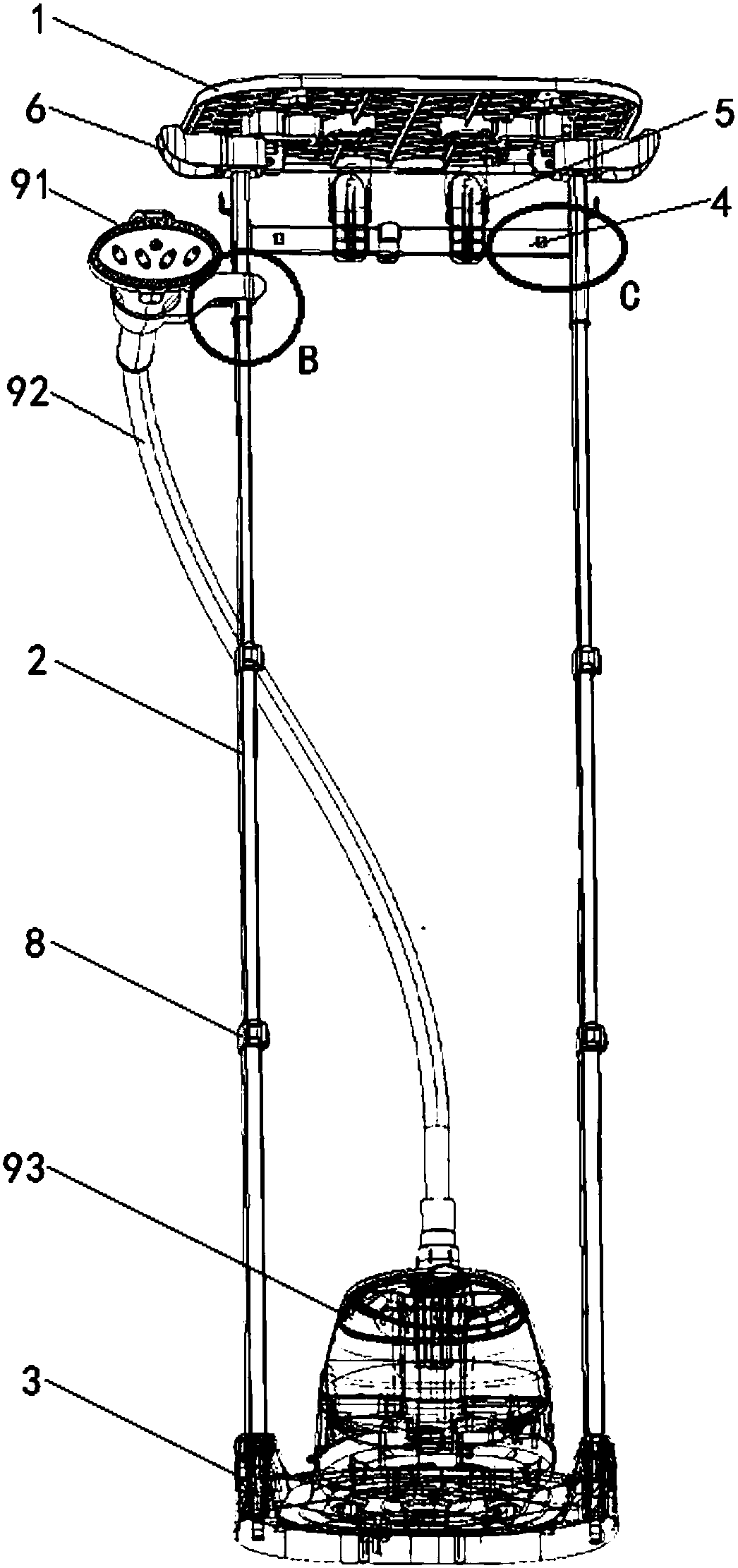

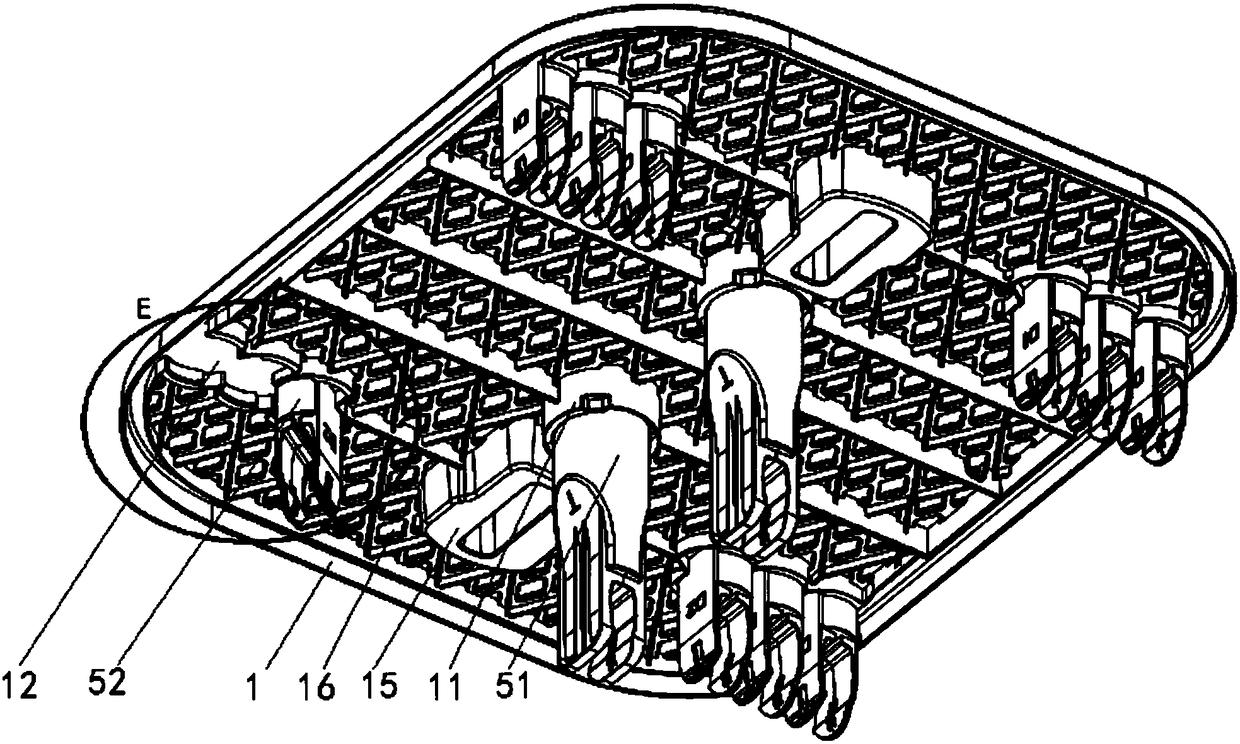

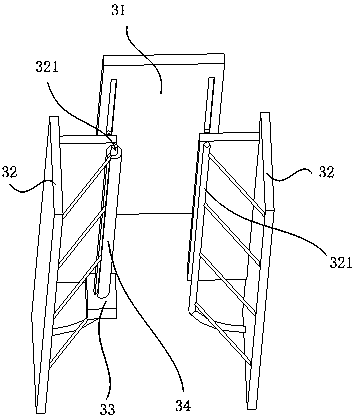

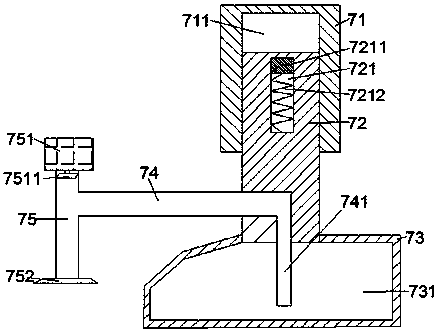

Ironing table and garment steamer using ironing table

PendingCN108118517AEasy to storeEasy to transportIroning boardsIroning apparatusEngineeringSupport plane

The invention discloses an ironing table. The ironing table comprises an ironing board and a support frame used for supporting the ironing board, wherein the support frame comprises a base, a plurality of upright rods and transverse rods; the upright rods are vertically fixed on the base; the transverse rods are fixedly connected among the plurality of upright rods; a supporting block and an elastic clamp are arranged on one side, which faces the support frame, of the ironing board; the elastic clamp is detachably connected with the ironing board surface; the elastic clamp comprises a first elastic clamp and a second elastic clamp; the first elastic clamp is clamped on the transverse rods, and the supporting block pops up the top ends of the upright rods, so that the ironing board is fixedon the top of the support frame so as to a flat ironing support plane; and the second elastic clamp is clamped on the upright rods, so that the ironing board is fixed on the side part of the supportframe so as to form a hanging ironing support plane. The ironing table disclosed by the invention integrates flat ironing and hanging ironing functions into a whole, and ironing requirements in multiple aspects of users are met. Moreover, the ironing board is in detachable connection with the elastic clamp and the support frame, and the ironing table is convenient to contain and transport.

Owner:SUZHOU GAMANA ELECTRIC APPLIANCE CO LTD

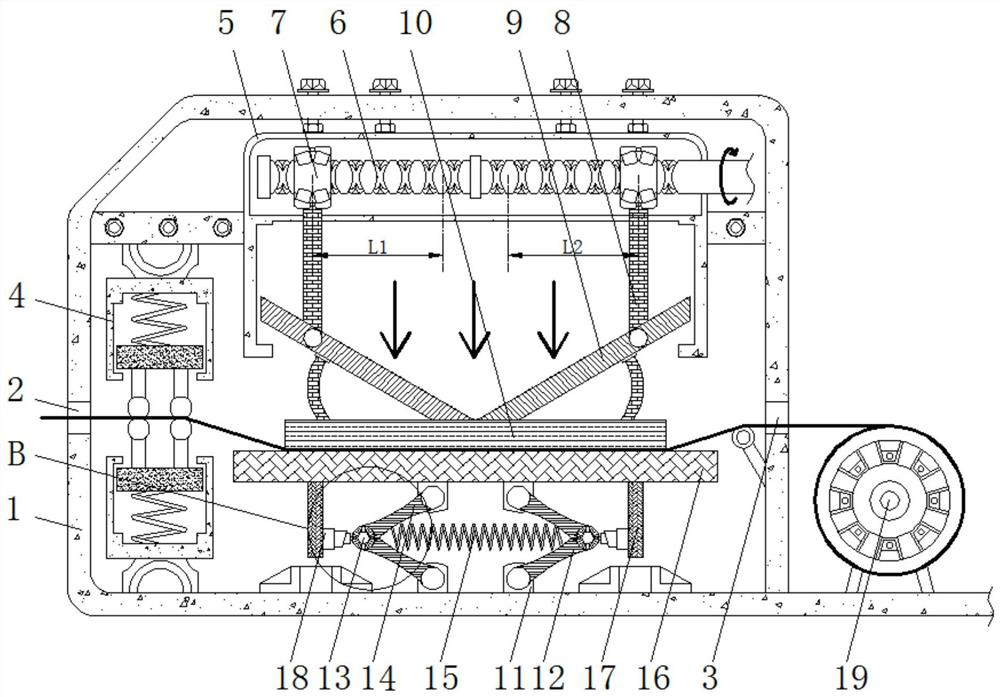

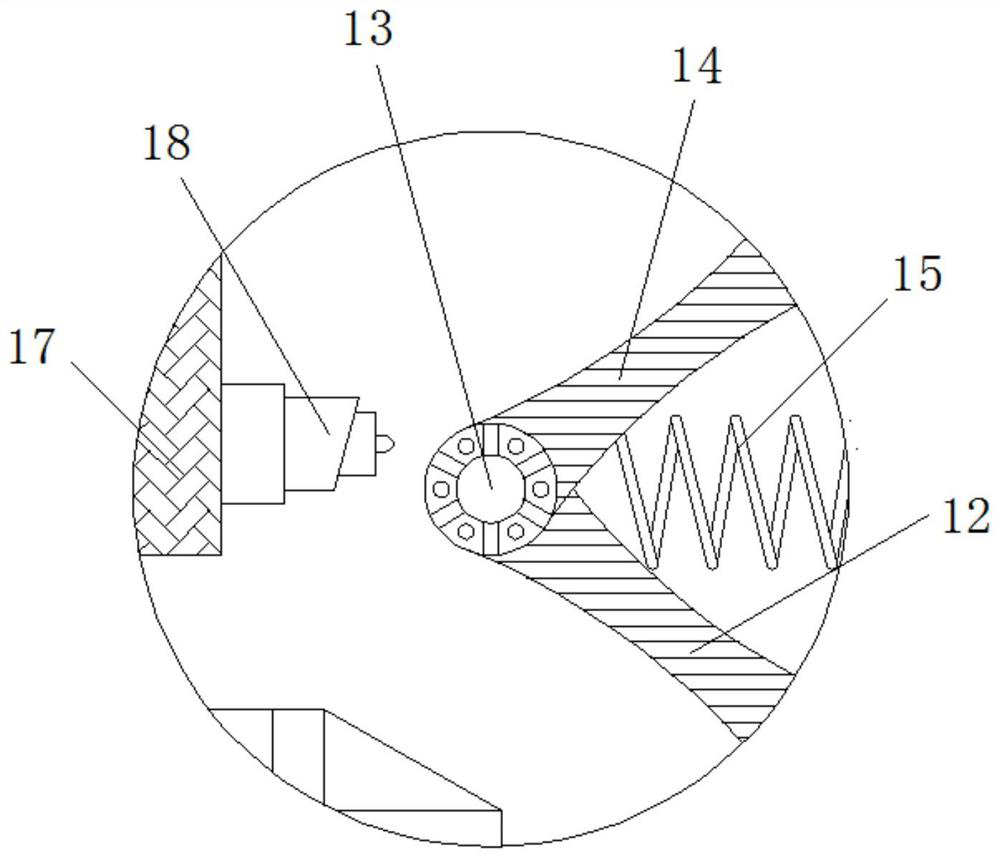

Intermittent ironing and winding device capable of avoiding insufficient ironing and achieving automatic flattening

InactiveCN112478869AAvoid quality problemsImprove automationTextile shapingWebs handlingTextile manufacturingMechanical engineering

The invention relates to the technical field of textile manufacturing equipment, and discloses an intermittent ironing and winding device capable of avoiding insufficient ironing and achieving automatic flattening. The intermittent ironing and winding device comprises a shell, a feeding opening is formed in the left side of the shell, a discharging opening is formed in the right side of the shell,and flattening mechanisms are arranged on the left side in the shell. A device box is arranged at the top end in the shell, and a lead screw is movably connected in the device box. According to the intermittent ironing and winding device capable of avoiding insufficient ironing and achieving automatic flattening, through cooperative use of the flattening mechanisms and a pressing plate, textile cloth can become level through the flattening mechanisms when entering the device from the feeding opening; and through cooperative use of a rolling wheel and a steam plate, in the ironing process of the steam plate, after the rolling wheel stops rotating and the steam plate breaks away from ironing, the rolling wheel starts to rotate to convey cloth, automation is improved, the ironing efficiencyand the ironing quality are greatly improved, and the quality problem caused by wrinkles is avoided.

Owner:中山亿铭网络科技有限公司

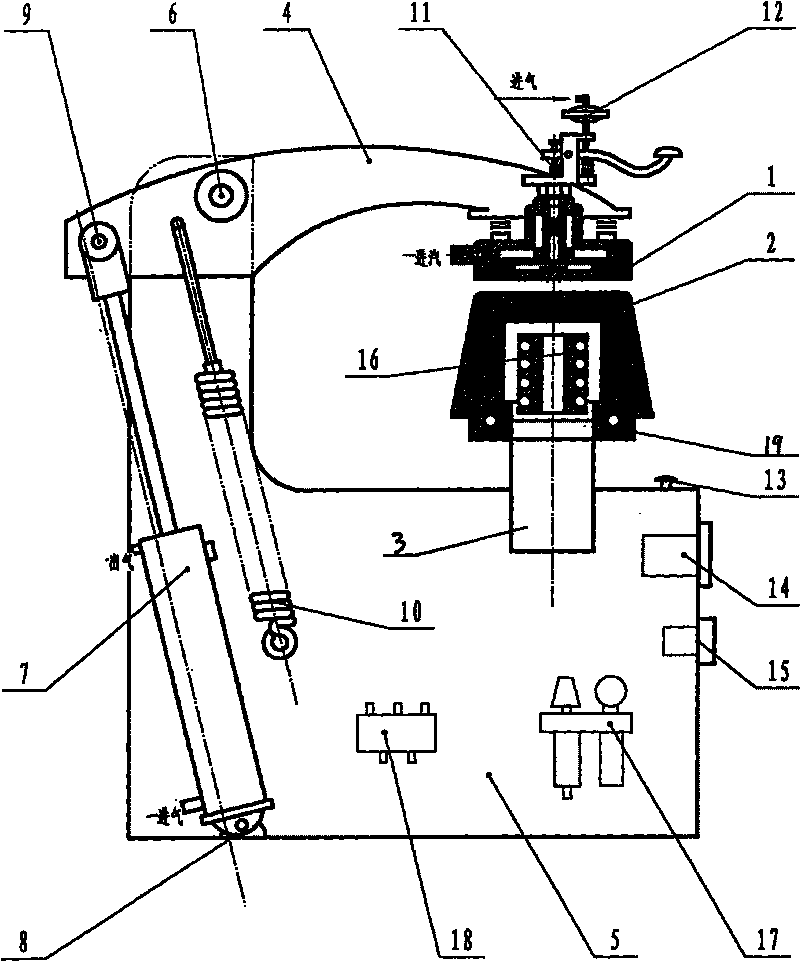

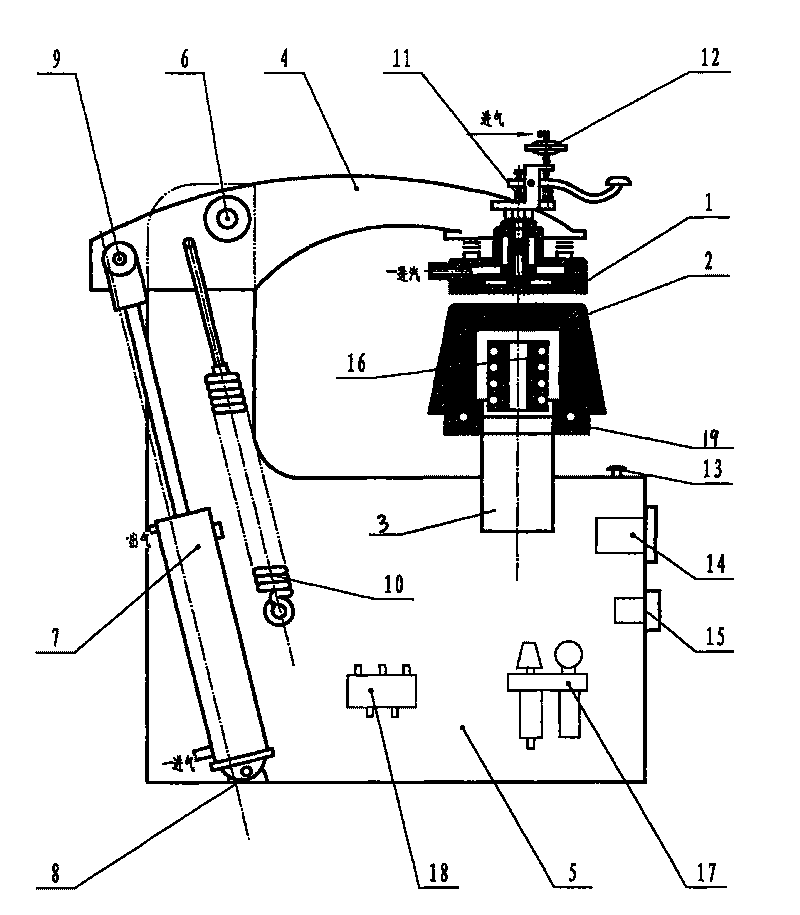

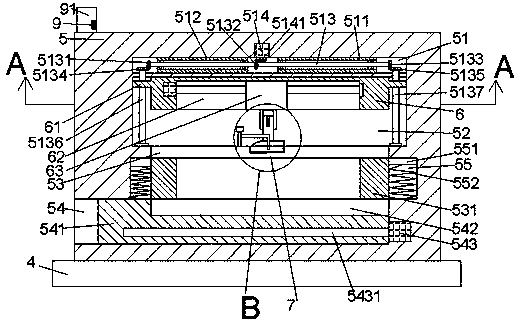

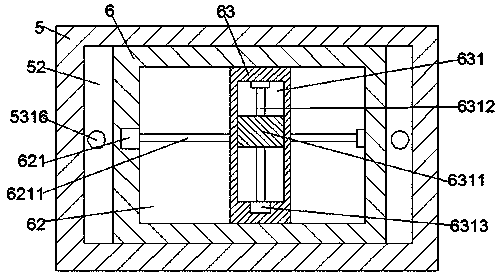

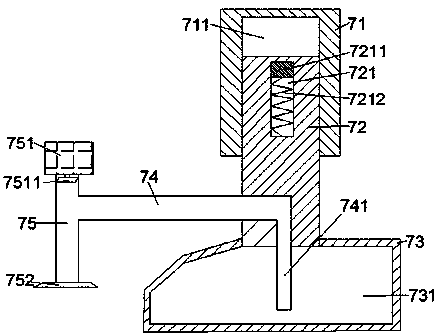

Tufting hat ironing machine

The invention relates to a tufting hat ironing machine, which belongs to semi-automatic tufting hat ironing equipment. The tufting hat ironing machine mainly solves the technical problems of high labor strength, low efficiency and difficulty in ensuring the ironing quality in the prior art. The invention adopts a technical scheme that: the tufting hat ironing machine comprises an upper ironing head, a lower ironing head, an ironing head seat, a frame, a button switch, a time relay, a temperature controller, a gas-pressure regulator and an electromagnetic valve; the tufting hat ironing machine also comprises a main arm, a main shaft, a big air cylinder, a tension spring, a steam valve, a small air cylinder, a heating plate and a ball bearing; the ironing head seat is arranged on a bedplate of the frame; the heating plate is arranged on an end surface of the ironing head seat; a lower end of the lower ironing head is arranged on the ball bearing and makes the heating plate positioned in a cavity of the lower ironing head; the upper ironing head is arranged in a front end of the main arm and is connected with the main arm by a bolt; the upper part of the upper ironing head is provided with the steam valve and the small air cylinder; the main arm is arranged on the upper part of an upright post of the frame by the main shaft; and an end part of a piston rod of the big air cylinder is connected with a rear end of the main arm by a connecting shaft.

Owner:JIHUA 3534 CLOTHING

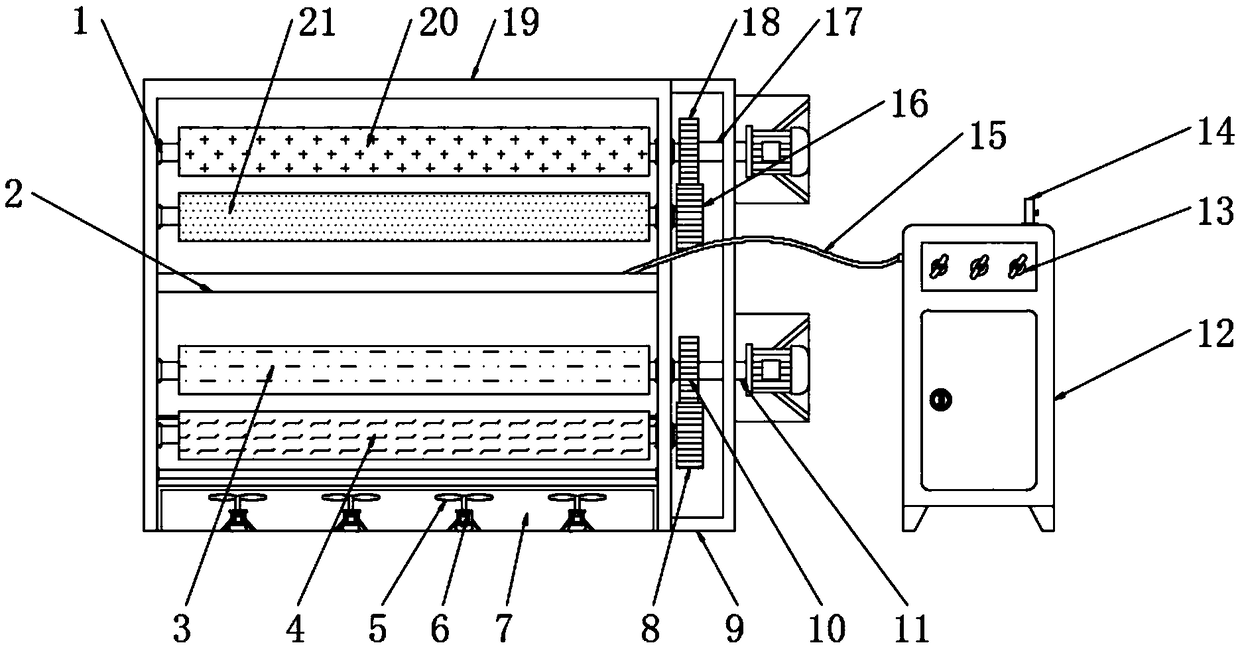

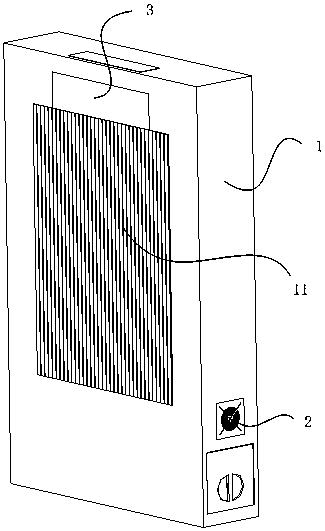

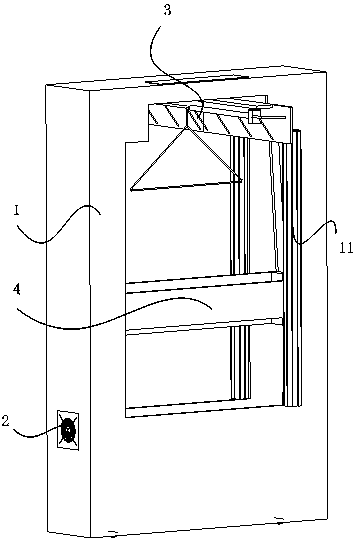

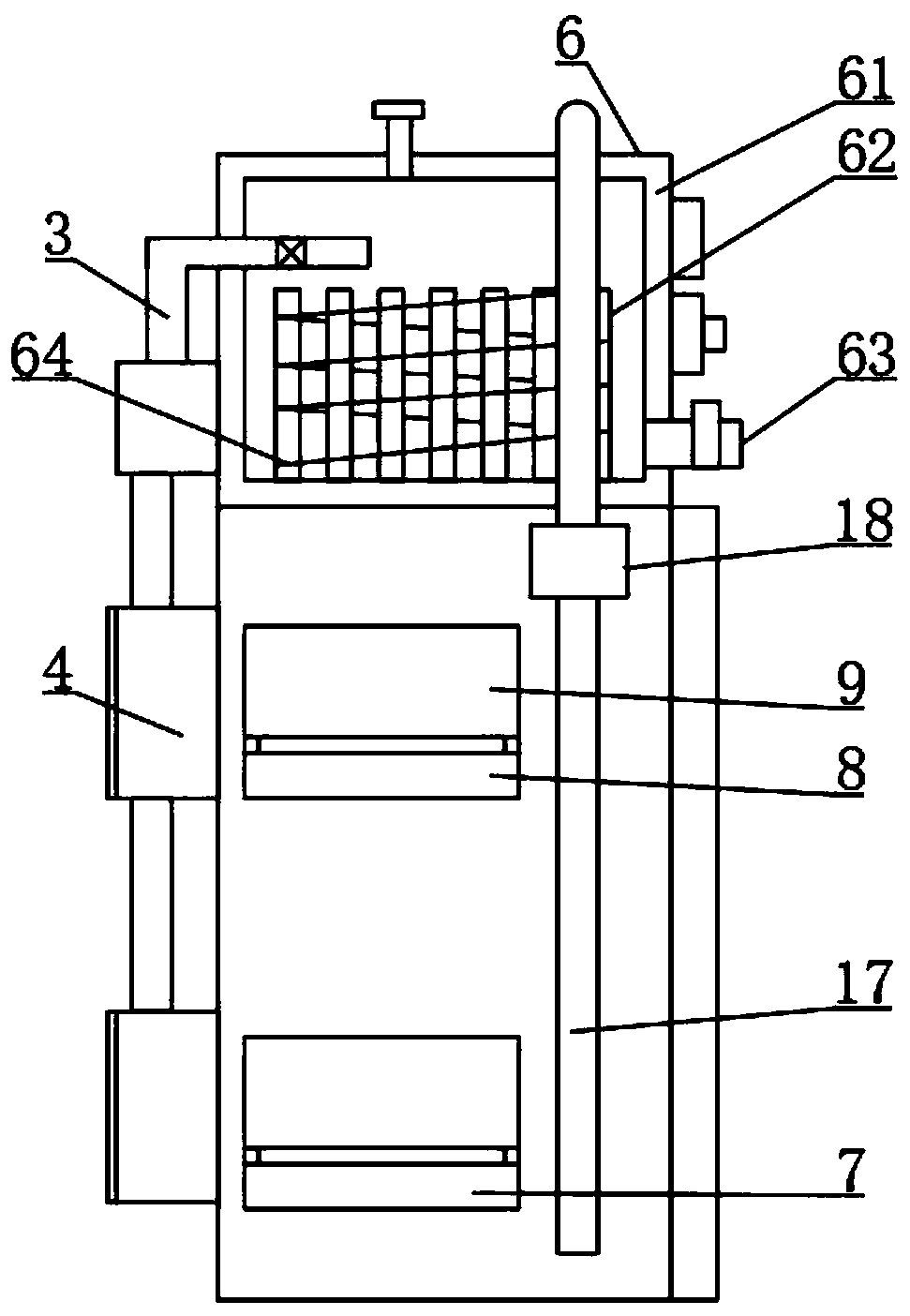

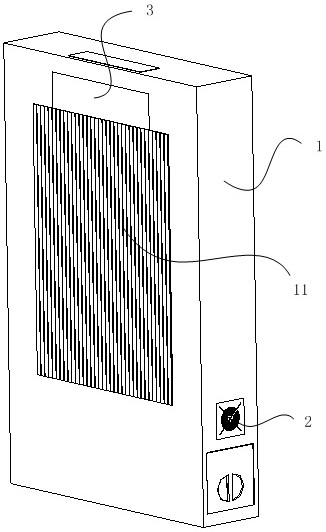

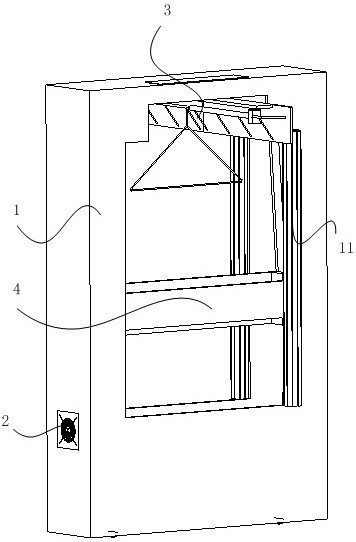

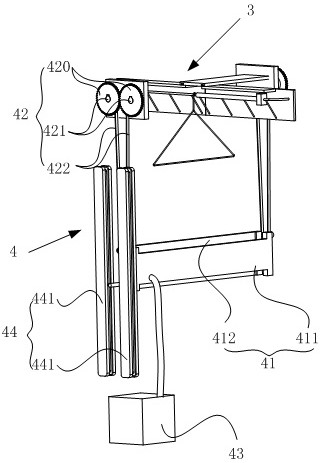

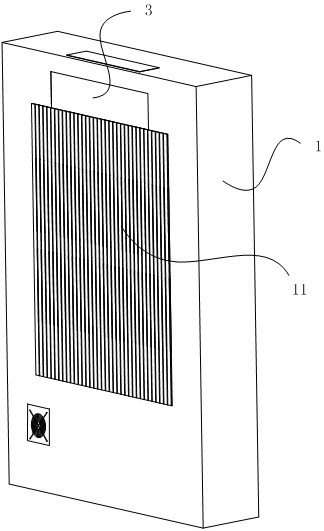

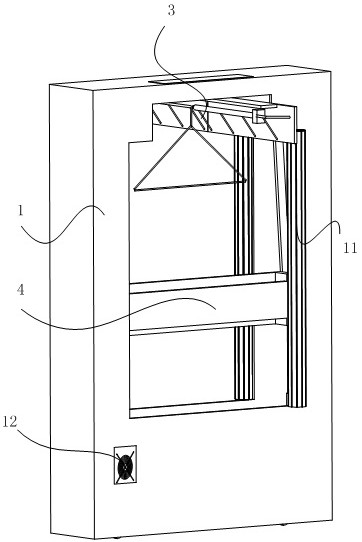

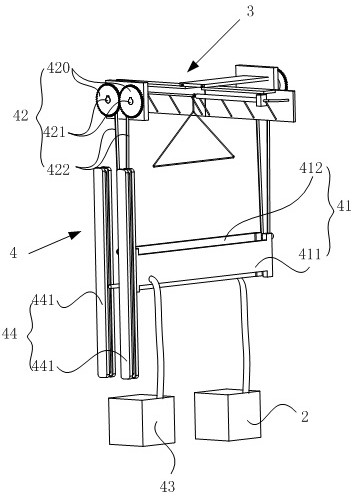

Automatic ironing clothes drying equipment and control method thereof

ActiveCN111663312AImprove experienceImprove ironing qualityIroning apparatusTextiles and paperManufacturing engineeringMechanical engineering

The invention discloses automatic ironing clothes drying equipment and a control method thereof. The automatic ironing clothes drying equipment comprises a cabinet body, wherein a clothes hanging rackis arranged in the cabinet body; the automatic ironing clothes drying equipment also comprises an automatic ironing mechanism; the automatic ironing mechanism comprises an ironing head, an ascendingand descending assembly, a steam generating module and a guide assembly; the ironing head comprises two ironing plates in opposite arrangement; an ironing space is formed between the two ironing plates; a plurality of steam spray openings are formed in the inner surface of one ironing plate; the steam generating module is used for supplying steam to the steam spraying openings; the ascending and descending assembly is used for driving the two ironing plates to do vertical synchronous circulation movement; and the guide assembly is used for guiding the two ironing plates to approach to each other when upwards moving to the top, and is also used for guiding the two ironing plates to leave far away from each other when downwards moving to the bottom. The goal of automatically performing ironing treatment on clothes while drying the clothes by the automatic ironing clothes drying equipment is achieved; the manual ironing by a user is not needed; and the user experience is improved.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

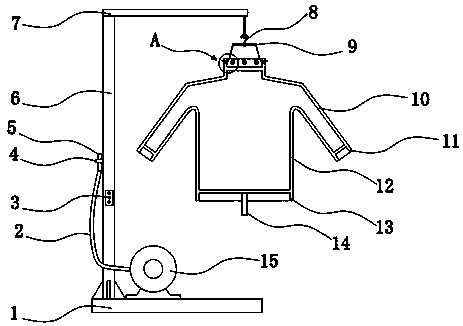

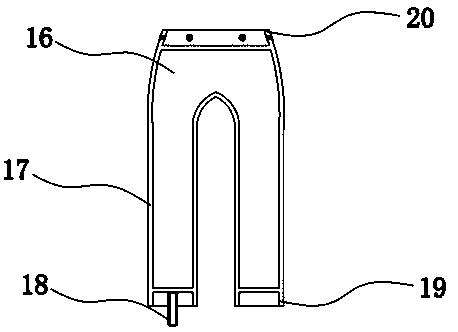

Ironing auxiliary device used for keeping body shape of clothies

InactiveCN108221327AAvoid wrinklesEasy to useIroning apparatusTextiles and paperPulp and paper industryAir blower

The invention discloses an ironing auxiliary device used for keeping the body shape of clothes, comprising a support rod and a clothes mainbody air bag, a clothes wherein the bottom of the support rodis welded and fixed on a base, at least one cross rod is welded and fixed at the top end of the support rod, a fixed ring is hooked at one end of the cross rod by a first hook, an air blower is arranged on the base, the output end of the air blower is connected with an insertion pipe by an air duct; two sides of the clothes mainbody air bag are cooled and fixedly connected with cuff air bags after fusing, a neckline extension part is integrally arranged at the top of the clothes mainbody air bag, and a first inflation hole is integrally formed in the bottom of the clothes mainbody air bag. According to the invention, corresponding air bag is selected according to the type of clothes, the air bag is hung on the cross rod, and the clothes is completed supported by the air bags and is ironed, and therefore, wrinkling caused in ironing can be effectively prevented, use is convenient and ironing quality is high.

Owner:盛红龙

Automatic clothes ironing, pressing and drying equipment and control method thereof

ActiveCN110318233AImprove experienceImprove ironing qualityTextiles and paperHome appliance efficiency improvementAir cycleClothes hanger

The invention discloses automatic clothes ironing, pressing and drying equipment and a control method thereof. The automatic clothes ironing, pressing and drying equipment comprises a cabinet body, aheating module, a draught fan and an automatic ironing and pressing mechanism, a clothes hanger is arranged in the cabinet body, the draught fan is used for achieving air circulation inside and outside the cabinet body, and the heating module is used for heating air entering the cabinet body to form hot air; the automatic ironing and pressing mechanism comprises an ironing and pressing head, a lifting assembly and a steam generation module; the ironing and pressing head comprises an ironing and pressing plate and a clamping plate which are arranged oppositely, an ironing and pressing space isformed between the ironing and pressing plate and the clamping plate, and several steam spraying ports are formed in the inner surface of the ironing and pressing plate; the steam generation module isused for supplying steam to the steam spraying ports, and the lifting assembly is used for driving the ironing and pressing head to move up and down. The automatic clothes ironing, pressing and drying equipment dries clothes and automatically irons and presses the clothes at the same time, manual ironing and pressing of a user is not needed, and the user experience is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

Woven fabric ironing and method with steam recovery

InactiveCN111549477AIroning on both sidesImprove ironing qualityTextile treatment machine arrangementsTextile treatment by spraying/projectingWorkbenchMaterials science

The invention discloses woven fabric ironing with steam recovery and belongs to the technical field of woven fabric ironing. The woven fabric ironing comprises a base. A shell is fixedly arranged in the center of the top of the base. A guide roller I is arranged in the middle of the outer wall of the left side of the shell through a support. A transverse block is transversely arranged in the middle of an inner cavity of the shell. Pressing pieces with the same structure are correspondingly arranged on the inner wall of the top of the shell and the inner wall of the bottom of the transverse block. An ironing mechanism attached to the top of a workbench II is arranged at the bottom of the pressing piece on the top. According to the woven fabric ironing with steam recovery, the pressing pieces and the ironing mechanism are correspondingly arranged on a workbench I and the workbench II, and the woven fabric is guided through the cooperation of the guide roller I and a guide roller II; andafter the woven fabric is subjected to top surface ironing through the workbench I, the pressing piece at the bottom and the ironing mechanism, ironing of the other side is carried out through the pressing piece on the top and the ironing mechanism, the double-surface ironing of the woven fabric is achieved, the ironing quality of the woven fabric is improved greatly, and the working efficiency isimproved.

Owner:苏州留白服饰有限公司

Automatic ironing machine

ActiveCN112030501AImprove the quality and efficiency of ironingImprove user experienceIroning apparatusTextiles and paperProcess engineeringElectric heating

The invention discloses an automatic ironing machine. The automatic ironing machine comprises a cabinet body, a clothes hanging mechanism and an automatic ironing mechanism; the clothes hanging mechanism is mounted on the cabinet body and used for hanging to-be-ironed clothes; the automatic ironing mechanism comprises an ironing head, a lifting module and a steam generation module, the ironing head comprises a steam spraying plate and an electric heating plate which are oppositely arranged, and an ironing area used for ironing the clothes is formed between the steam spraying plate and the electric heating plate; and the lifting module is used for driving the ironing head to move up and down in the cabinet body, and the steam generation module is used for generating steam and spraying the steam into the ironing area through the steam spraying plate. The automatic ironing machine automatically irons the clothes without manual ironing by a user, so that the user experience is improved.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

Automatic ironing device

InactiveCN108486843AImprove ironing qualityImprove work efficiencyIroning boardsHand ironEngineering

The invention discloses an automatic ironing device. The automatic ironing device comprises a base and an ironing machine body fixedly arranged at the top of the base; a first cavity is formed in theironing machine body, a second cavity, a third cavity and a fourth cavity which are located on the lower side of the first cavity are sequentially communicated in the ironing machine body from top tobottom, a first fixed block and a second fixed block which correspond are fixedly arranged on the left side and the right side inside the first cavity, a first rotating shaft extending left and rightis rotationally and cooperatively connected inside the first fixed block and the second fixed block, and penetrates through the left end faces and the right end faces of the first fixed block and thesecond fixed block, a second bevel gear and a fourth bevel gear are fixedly arranged at the extending tail end of the left side and the extending tail end of the right side of the first rotating shaft, and a third bevel gear located between the first fixed block and the second fixed block is fixedly arranged on the first rotating shaft section. The automatic ironing device is simple in structure and convenient to operate, and the ironing efficiency and effect are improved.

Owner:陈军

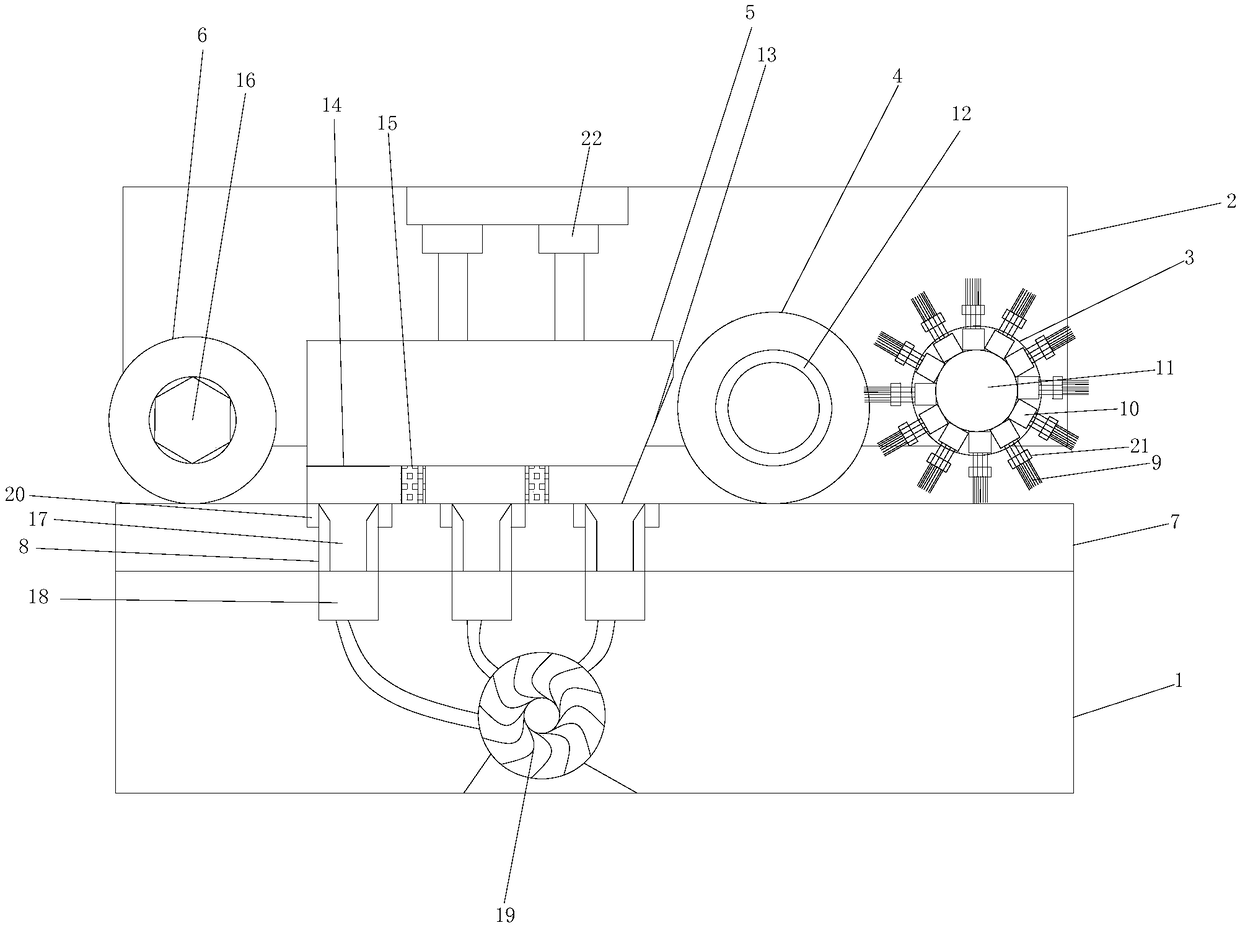

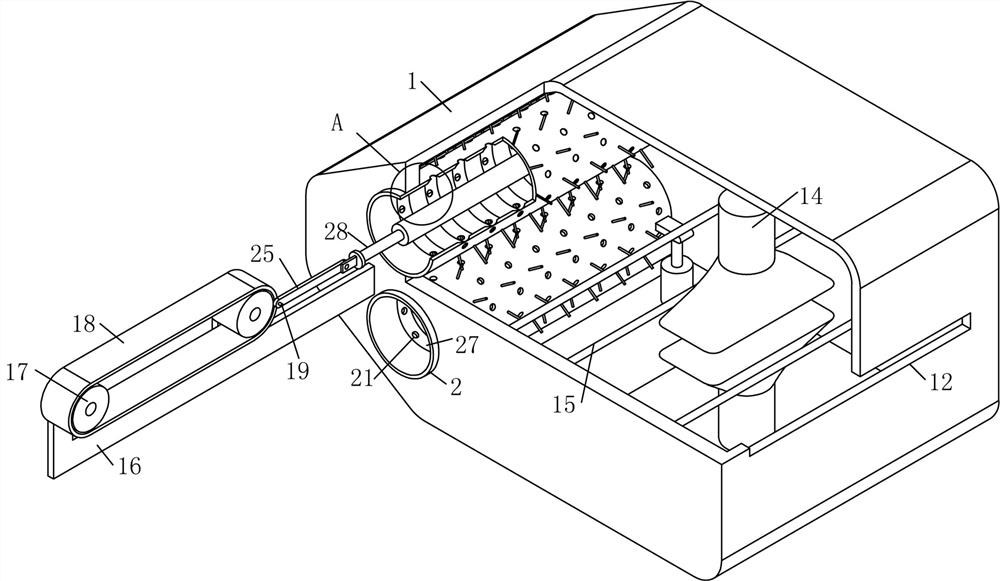

Textile fabric rapid carding equipment and working method thereof

InactiveCN112227047AImprove patencyImprove adsorption capacityMechanical cleaningPressure cleaningBristleStructural engineering

The invention belongs to the technical field of textile equipment, and particularly relates to textile fabric rapid carding equipment and a working method thereof. The textile fabric rapid carding equipment comprises a machine body; a feeding hole and a discharging hole are formed in the two sides of the machine body correspondingly; a pair of circular pipes are rotatably connected to the side, close to the feeding hole, in the machine body through a bracket; one end of each circular pipe is fixedly connected with a hollow clearing roller, and the other ends of the circular pipes communicate with negative pressure devices; and a group of negative pressure holes are uniformly distributed at the periphery of each clearing roller, and a group of bristles are circumferentially and uniformly distributed at the position, between the adjacent negative pressure holes, of each clearing roller. The ends, away from the circular pipes, of the clearing rollers penetrate through the machine body andextend out of the machine body, and pushing rods are arranged in the clearing rollers; brush plates are arranged at the ends, located in the clearing rollers, of the pushing rods; supporting seats are fixedly connected to the position, corresponding to the clearing rollers, of the machine body, and a pair of rollers is arranged on each supporting seat; and a conveying belt is arranged between theevery two rollers in a sleeving mode, one side of each conveying belt is fixedly connected with a rotating pin, and the rotating pins are hinged to the pushing rod through connecting rods. Accordingto the textile fabric rapid carding equipment, the brush plates are driven by the conveying belts to continuously scrape the inner walls of the clearing rollers, and the carding efficiency of cloth isimproved.

Owner:沈足金

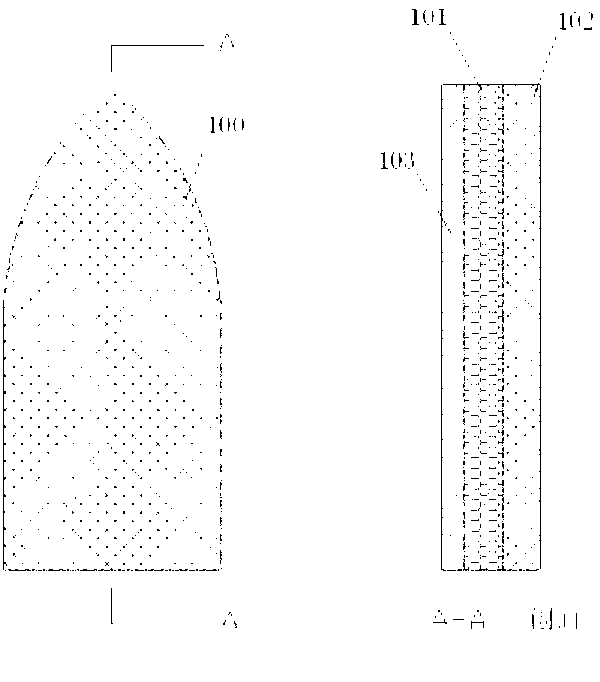

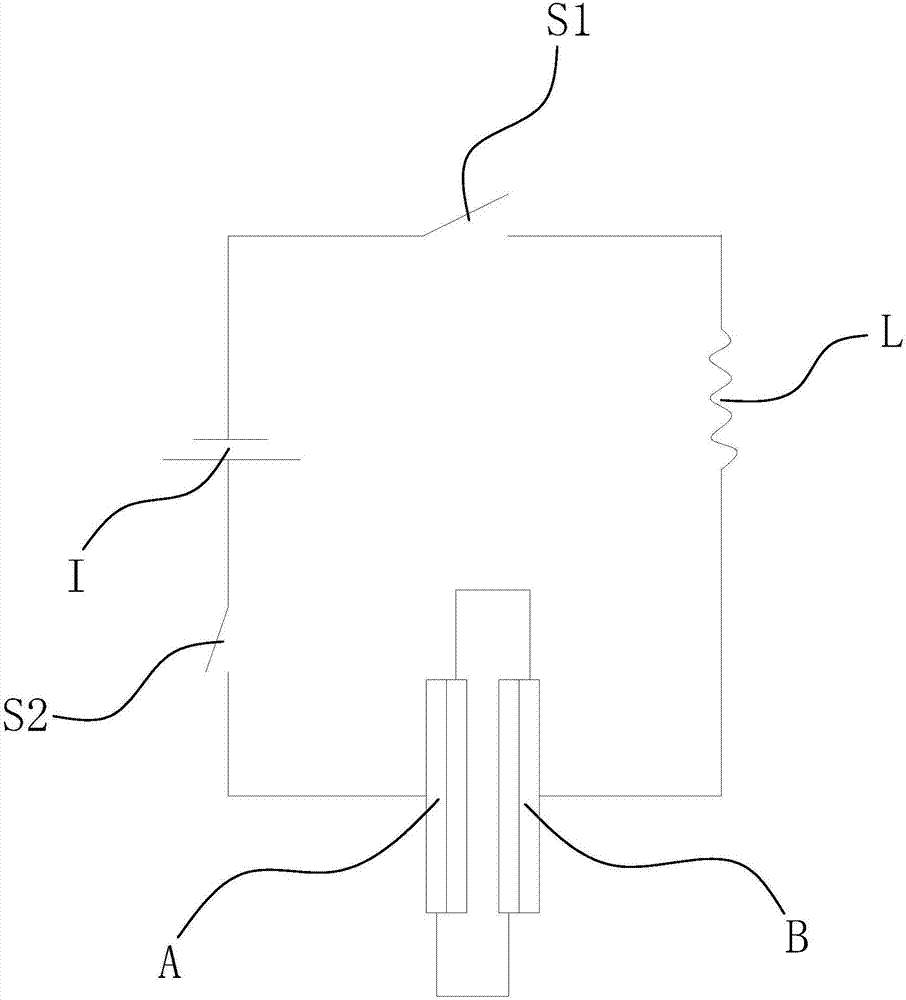

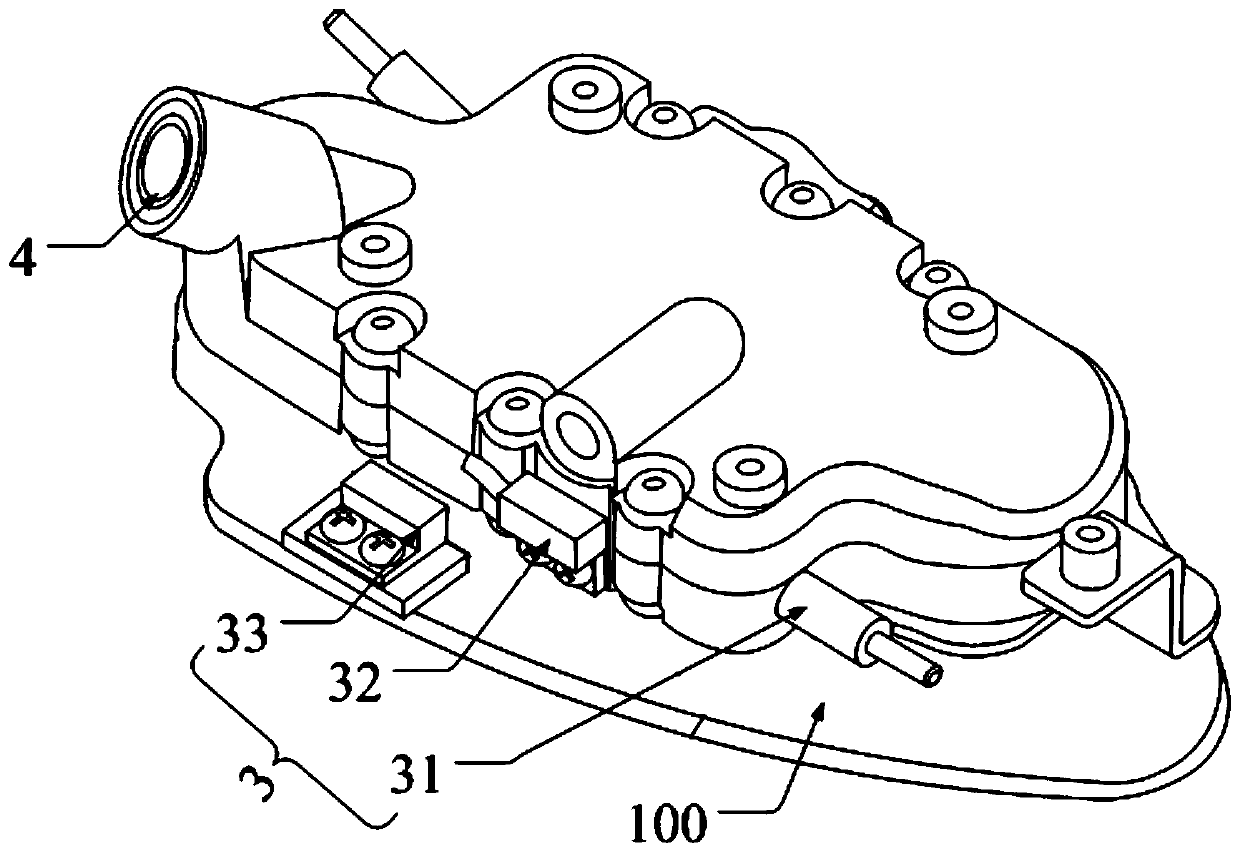

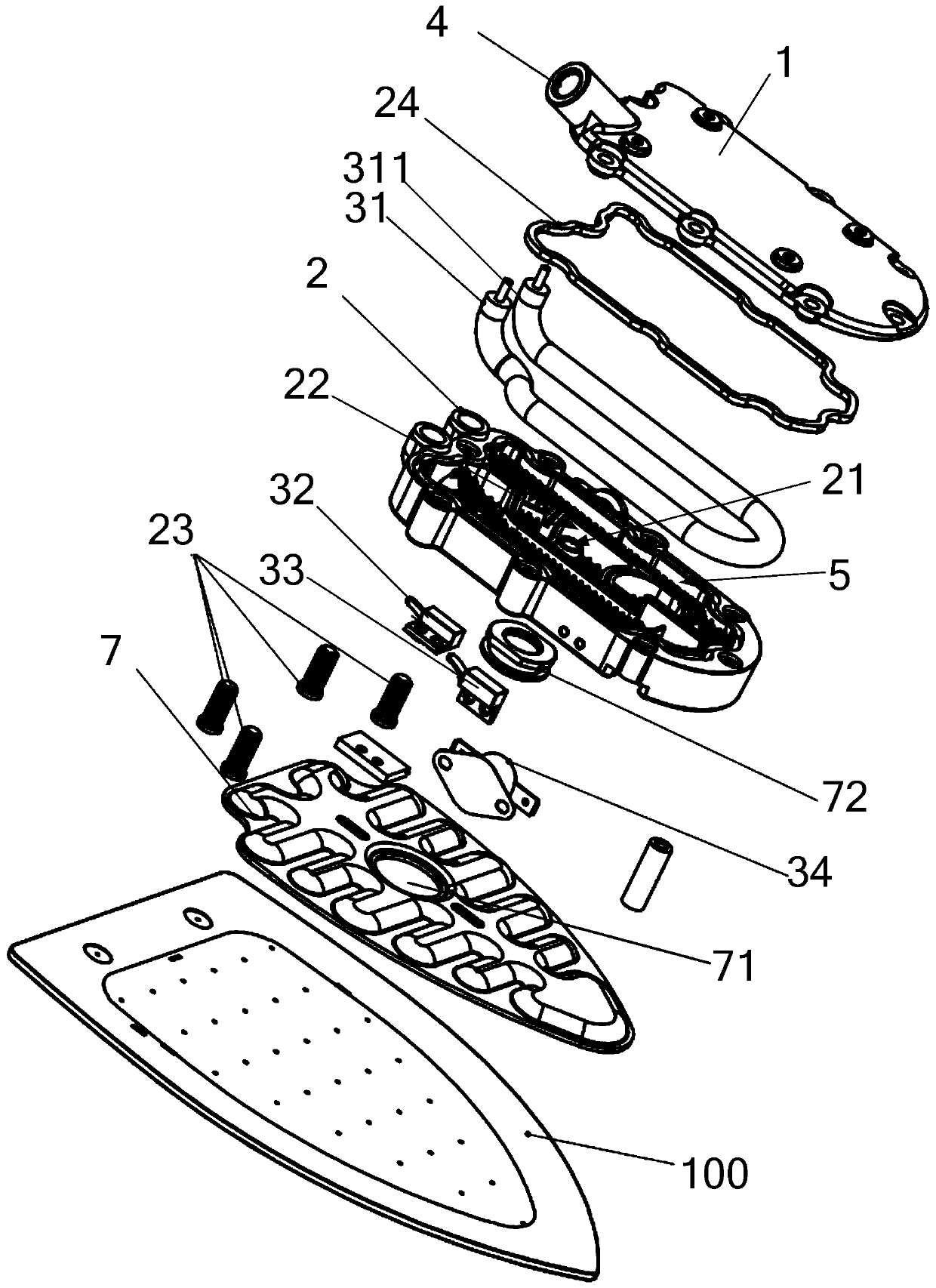

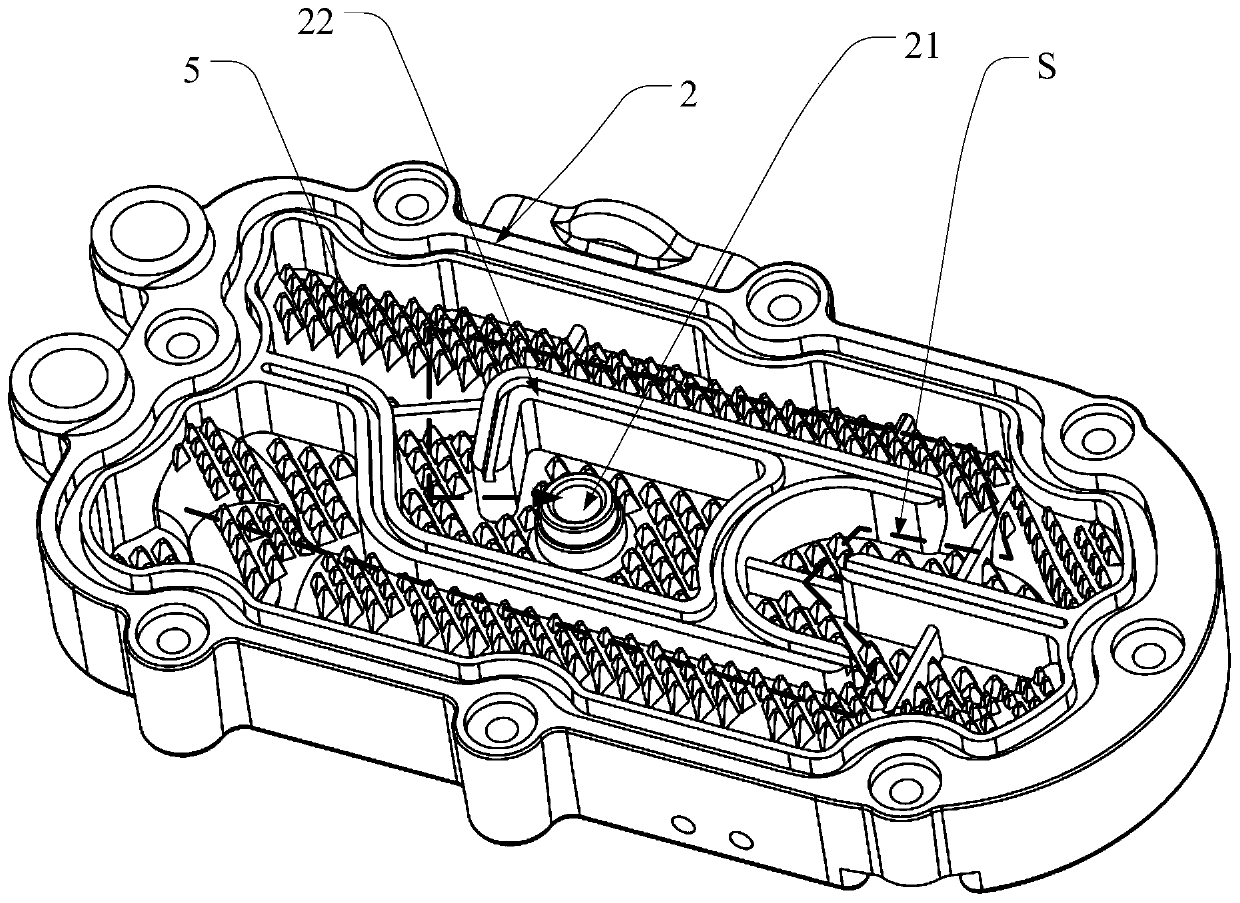

Energy-saving electric iron employing electromagnetic heating

InactiveCN102839529AExtend your lifeImprove the safety of useHand ironTextiles and paperElectricityAutomatic control

The invention discloses a safe and energy-saving electric iron which is particularly applicable to use places with requirements on energy saving and safety. The electric iron comprises a circuit part, an equipment casing and a bottom plate (100), wherein the bottom plate (100) consists of an electromagnetic power output coil (102), an insulating base (101) and a heating plate (103); and the heating plate (103) is made of metal material with magnetic conductivity and metal material with high heat conductivity, a small amount of material is used for manufacturing the heating plate, so that the heating plate has smaller thermal capacity, and the effects of saving energy and reducing cost are realized. The temperature of the electric iron is adjustable, and the electric iron is controlled by an automatic control circuit to stably operate within the preset temperature. The working bottom plate of the electric iron is completely isolated from the mains supply by the insulating base (101), and the safety on power utilization is guaranteed. A tickle-type microswitch is arranged on an operating handle, and a user can enable the electric iron to operate by slightly holding the handle and enable the electric iron to stop heating by loosening the handle. The electric iron also can be used for wetting clothes by spraying water and is convenient to use.

Owner:李文忠

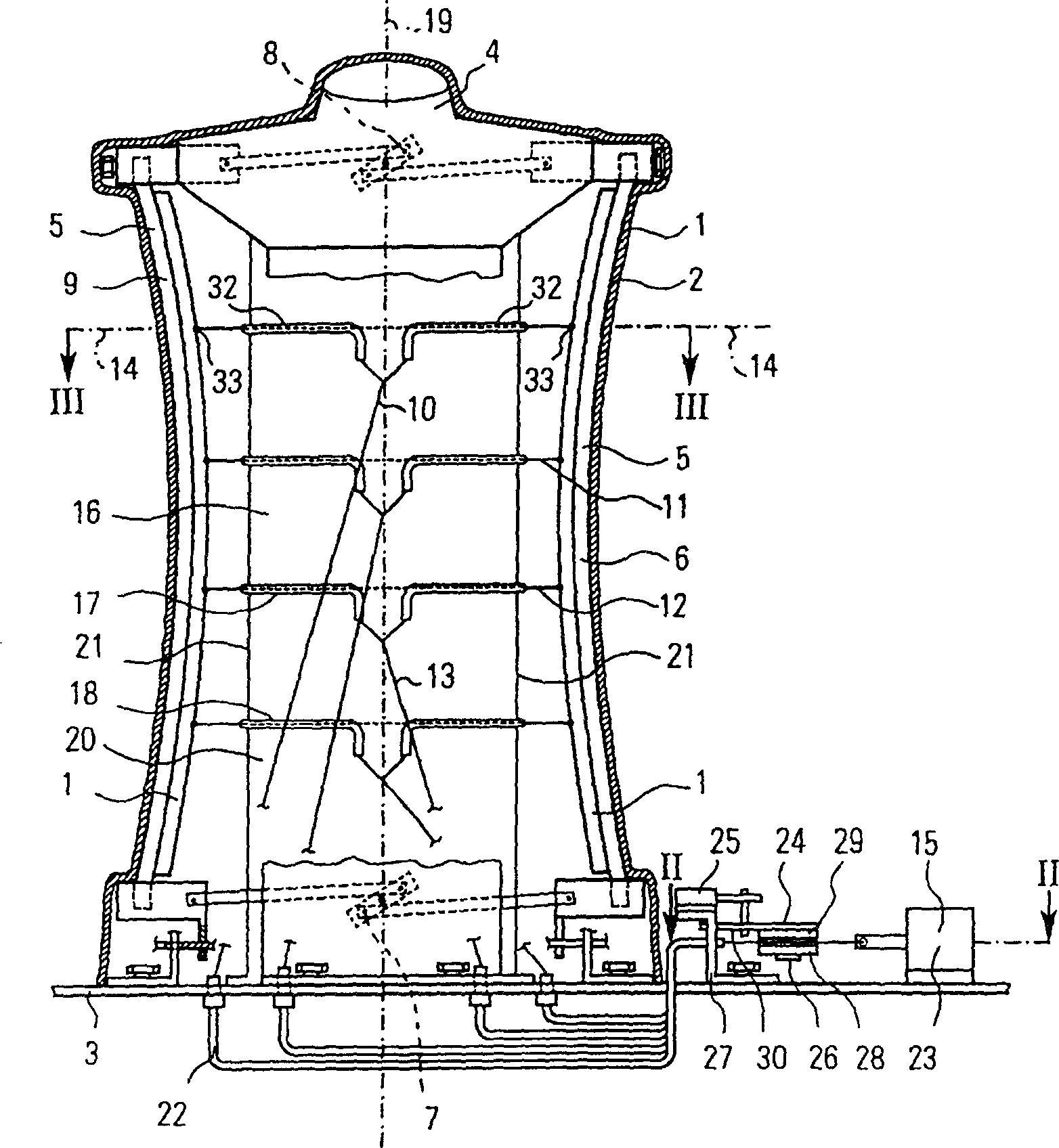

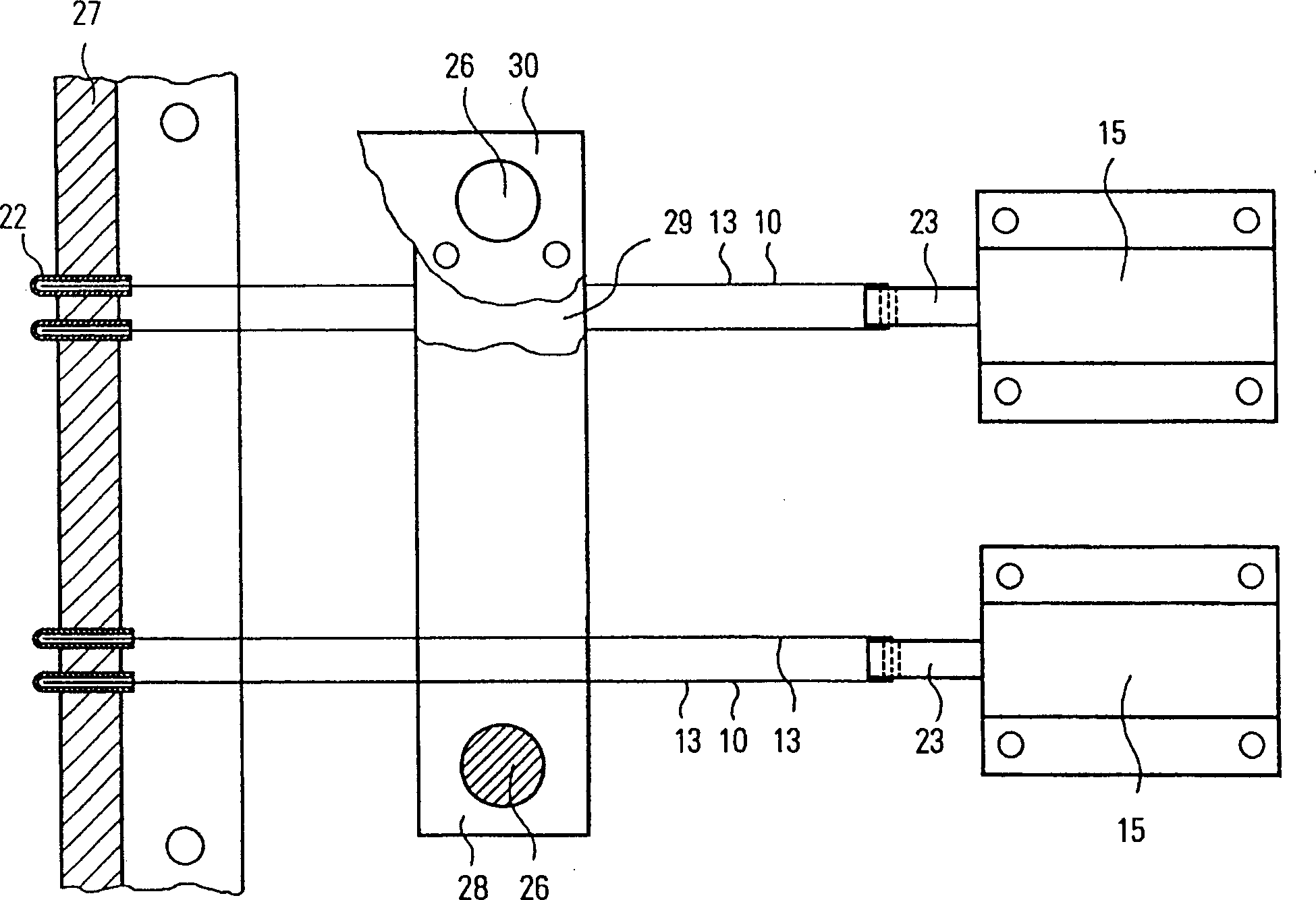

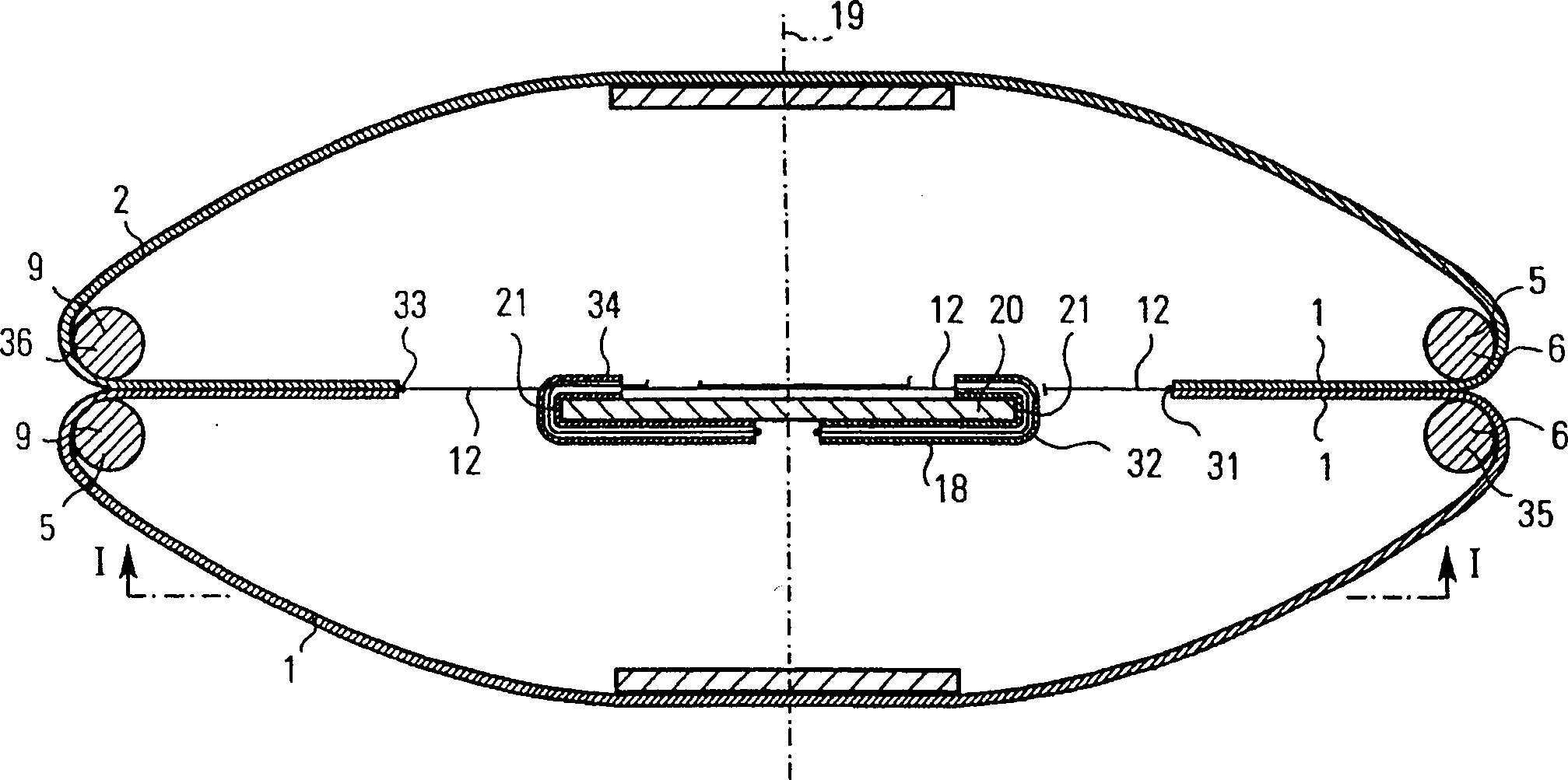

Ironing device

InactiveCN1282788CImprove ironing qualityAvoid wrinklesIroning apparatusTextiles and paperEngineeringLaundry

The invention relates to an ironing device with an inflatable pocket with a breathable outer shell, the periphery of which can be adjusted by means of an adjustment device and adapted to the inner contour of the garment to be placed over the pocket. The device should be modified in such a way that no creases are formed between the garment to be ironed and the pocket when the outer periphery of the housing is reduced. This is achieved by arranging at least one deflecting element inside the pocket, around which the housing is drawn into the interior. The peripheral size of the shell is reduced by transferring the shell material on the surface of the pocket, and thus matches the different sizes of the clothes to be ironed, but does not affect the passage of steam through the shell to the clothes. Expansion of the garment to be ironed is avoided by providing an adjusting device which produces a defined contraction of the housing by means of the clamping device.

Owner:WIJIE

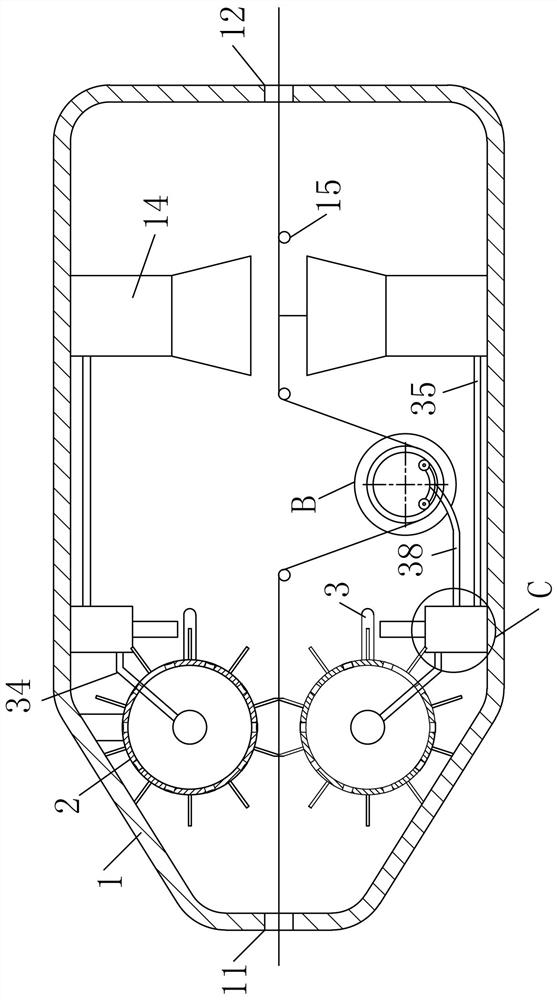

Textile fabric ironing device

InactiveCN107385736ARealize automatic ironingSolve efficiency problemsSucessive textile treatmentsTextile treatment machine arrangementsEnergy analysisTextile

The invention discloses a textile fabric ironing device, which comprises two sets of support plates arranged in parallel, two sets of feeding rollers are installed along the vertical direction on the sides where the two sets of support plates are close to each other, and one side of the two sets of feeding rollers is There are two sets of spraying pipes arranged vertically. A rotating shaft fixedly connected to the support plate is installed above the two groups of spraying pipes away from the feed pipe. The outer side of the rotating shaft is movably socketed with a swing rod, which is far away from the rotating shaft. A tensioning roller is installed at one end, two sets of ironing mechanisms arranged vertically are installed on the side of the rotating shaft far away from the spraying pipeline, and two sets of outlets arranged vertically are installed on the side away from the rotating shaft. There is a material drum, and a suction cover is installed directly above the two sets of ironing mechanisms. The invention has a compact structure, integrates cloth humidification, tensioning and ironing, realizes automatic cloth ironing, improves the efficiency and quality of cloth ironing, and effectively improves the utilization rate of energy.

Owner:CHANGXING DEHONG MACHINERY CO LTD

Automatic household ironing device

ActiveCN108049139AImprove ironing qualityImprove work efficiencyIroning machinesTextiles and paperIncreased ironBevel gear

The invention discloses an automatic household ironing device. The automatic household ironing device comprises a base and an ironing device body arranged at the top of the base and is characterized in that a first cavity is arranged in the ironing device body, a second cavity, a third cavity and a fourth cavity located on the lower side of the first cavity are sequentially arranged in the ironingdevice body from top to bottom in a communicated manner, a first fixing block and a second fixing block are correspondingly fixedly arranged on the left side and the right side inside the first cavity, a first rotary shaft extending leftwards and rightwards is connected into the first fixing block and the second fixing block in a running fit manner, the first rotary shaft penetrates the left andright end faces of the first fixing block and the second fixing block, the left extending tail end and the right extending end of the first rotary shaft are respectively fixedly provided with a secondbevel gear and a fourth bevel gear, and a third bevel gear located between the first fixing block and the second fixing block is arranged on the first rotary shaft. The automatic household ironing device is simple in structure, convenient to operate and capable of increasing ironing efficiency and effect.

Owner:苏州联台针纺织有限公司

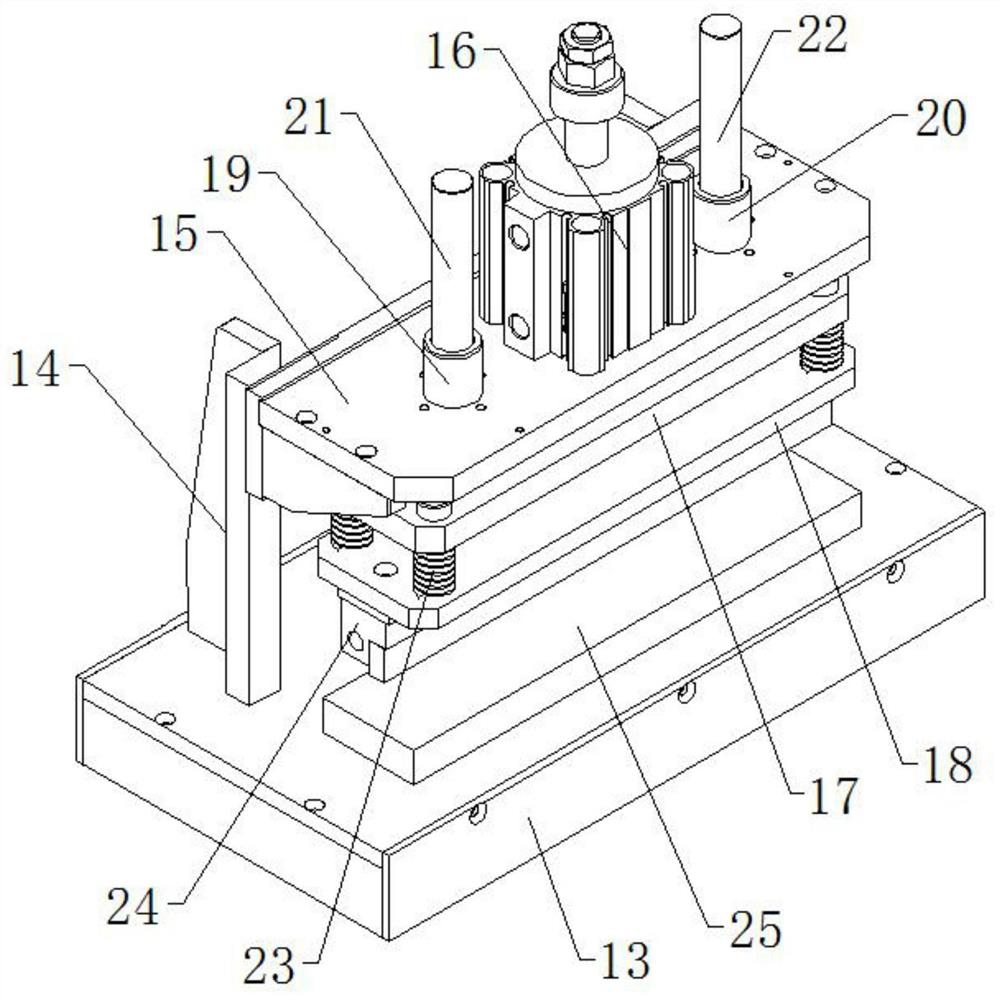

Ironing equipment for garment manufacturing

PendingCN112111901AImprove ironing efficiencyReduce volumeTextile shapingStructural engineeringMechanical engineering

The invention relates to the technical field of garment manufacturing equipment, in particular to ironing equipment for. The ironing equipment comprises an ironing base, wherein a mounting frame is arranged on the upper side of the ironing base, and driving fluted discs are arranged at the right ends of a first lower clamping and conveying roller and a second lower clamping and conveying roller inthe length direction. A limiting transverse rod is arranged on the mounting frame and located on the right side of a cloth unwinding roller in the length direction, limiting plates are arranged at two ends of the limiting transverse rod in the length direction, limiting adjusting plates are arranged on the lower sides of the limiting plates, and an ironing assembly is arranged on one side close to the second lower clamping and conveying roller, of the base surface of the ironing base; and the ironing assembly comprises a bearing base, supporting vertical plates, an upper bearing base, a push-up air cylinder, an upper mounting plate, a lower mounting plate, a first positioning sleeve, a second positioning sleeve, a first positioning guide column, a second positioning guide column, spring columns, an ironing square pipe and an ironing plate. The ironing equipment is small in size, and can perform ironing on the cloth of garment automatically. Ironing quality and efficiency are high.

Owner:夏梦意杰服饰有限公司

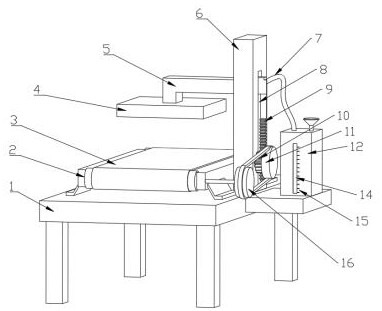

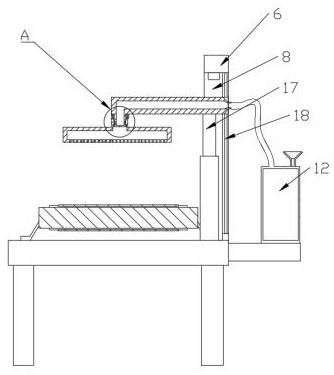

Temper mill for clothing industry

The invention is applicable to the technical field of garment processing, and provides a temper mill for the clothing industry. The temper mill for the clothing industry comprises a workbench fixedlyconnected with a mounting frame, an ironing plate, a lifting driving part and a steam generation box. the ironing plate is slidably arranged on the mounting frame through a connecting frame, a plurality of air holes are formed in the lower surface of the ironing plate, and the ironing plate is used for ironing; the lifting driving part is installed on the workbench, connected with the connecting frame and used for driving the ironing plate to ascend and descend; the steam generation box is installed on the workbench, communicates with the ironing plate and is used for forming steam; and a rotating roller is rotationally arranged on the workbench, a conveying belt is arranged on the rotating roller in a matched manner, the connecting frame is connected with an insection rod, a one-way gearis rotationally arranged on the mounting frame, and the one-way gear is connected with the rotating roller through a transmission piece. The temper mill has the advantages of being simple in structure, convenient to operate, large in operation space, energy-saving, good in synchronism and convenient to popularize and implement.

Owner:义乌市皓祺服饰有限公司

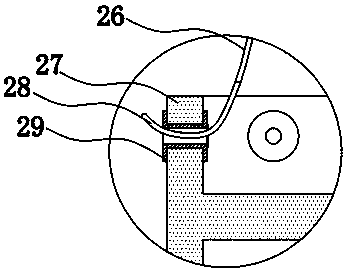

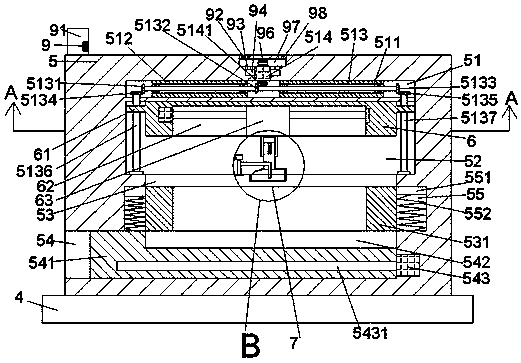

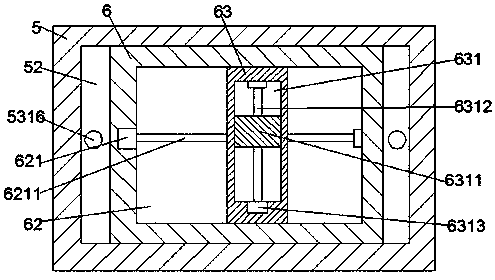

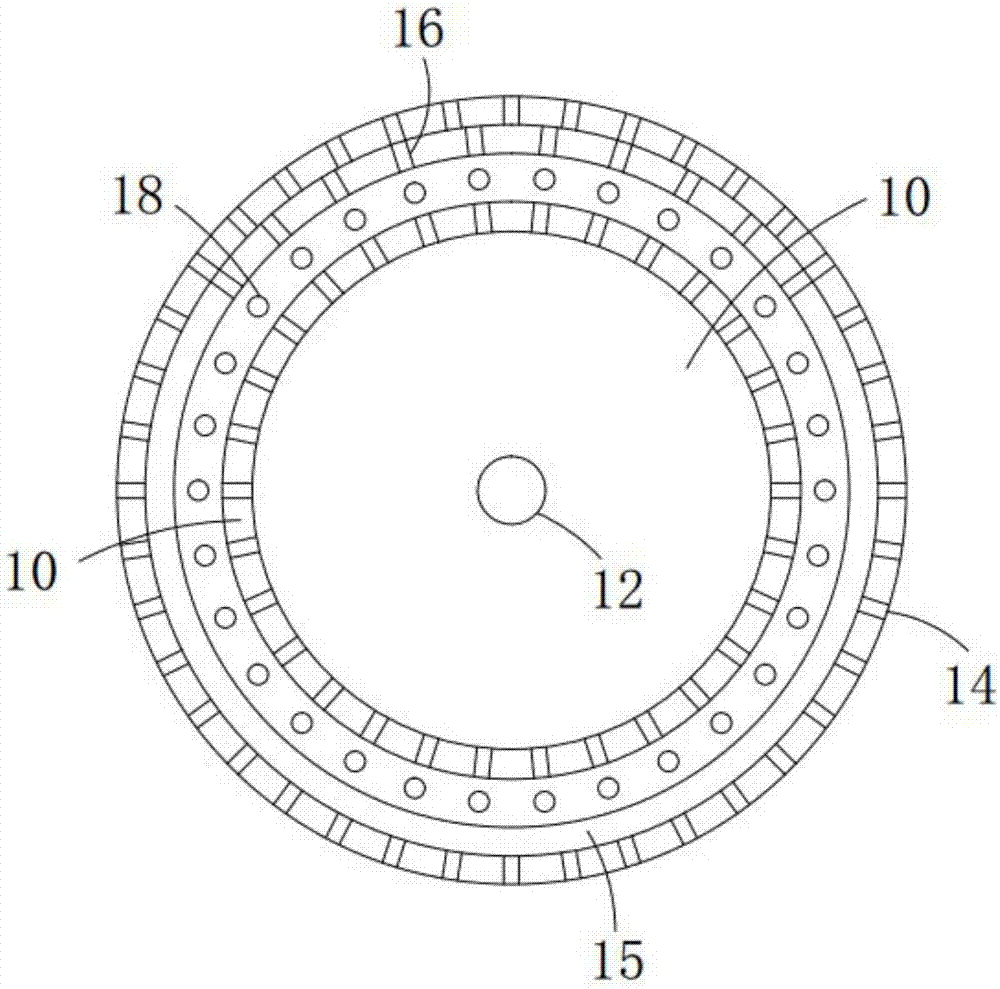

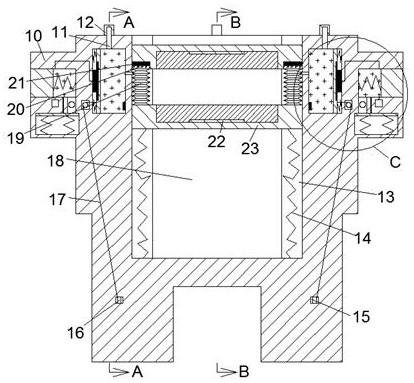

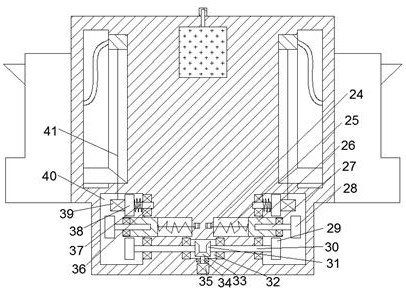

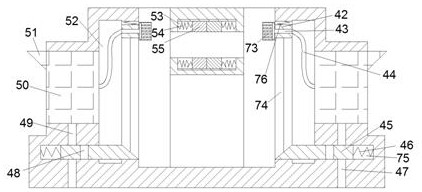

Peristaltic pump self-lubrication structure for clothes pressing and shaping machine

ActiveCN107034651APrevent discolorationAvoid damageHand ironTextiles and paperImpellerPeristaltic pump

The invention provides a peristaltic pump self-lubrication structure for clothes pressing and shaping machine, belongs to the technical field of garment manufacturing and sales. The technical problems of short service life of the old peristaltic pumps and the like are solved. The peristaltic pump self-lubrication structure for the clothes pressing and shaping machine is characterized in that the peristaltic pump is arranged on the body of the shaping machine, and a center shaft is arranged fixedly inside an output shaft, a lubrication chamber is arranged in the middle of the center shaft and the output shaft, an impeller composed of several evenly spaced blades is arranged fixedly on one end of the output shaft, lead pillars one-to-one corresponding to the blades are arranged in the middle of the center shaft and the output shaft, the two ends of the lead pillar are respectively connected with the internal wall of the output shaft and the external wall of the center shaft, arc panels one-to-one corresponding to the lead pillars are arranged in the lubrication chamber, the two ends of the pull spring are respectively fixedly connected with the center shaft and the curved panels, and a tubular structure dividing the lubrication chamber into two parts is formed of all the arc panels under the impact of the spring tension. The peristaltic pump self-lubrication structure for the clothes pressing and shaping machine has the advantages of long service life and the like.

Owner:吴江天星纺织有限公司

Garment ironing equipment

InactiveCN112458721ASmall footprintImprove practicalityIroning boardsIroning machinesStructural engineeringMechanical engineering

The invention discloses garment ironing equipment. The garment ironing equipment comprises an ironing plate, supporting legs are arranged at the left end and the right end of the lower part of the ironing plate, an ironing mechanism is arranged above the ironing plate, a second sliding groove is formed in the left supporting leg, a first sliding groove is formed in the right supporting leg, a connecting pipe is arranged behind the left supporting leg, a drawing pipe is arranged at the end, away from the left supporting leg, of the connecting pipe, sliding columns are arranged at the left end of the ironing plate and the end, away from the connecting pipe, of the drawing pipe, and the first sliding groove and the second sliding groove are slidably connected with the sliding columns. When the garment ironing equipment is unfolded, the right supporting leg is fixed, the left supporting leg is pulled, a limiting rod can be clamped in a limiting hole under the action of a spring, and garment can be placed on the upper part of the ironing plate and ironed through the ironing mechanism; and when the garment ironing equipment is stored, only the limiting rod needs to be pressed, so that the limiting rod is disengaged from the limiting hole, the sliding columns can slide in the first sliding groove and the second sliding grooves to be folded and stored, the occupied space is reduced, and the garment ironing equipment is suitable for large-scale popularization.

Owner:桃江县鹏翔制衣有限公司

Steam iron and heating device thereof

PendingCN110205789AImprove reheating efficiencyPrevent heat lossHand ironTextiles and paperEngineeringHeating efficiency

Owner:深圳汉明威智能设备有限公司

Clothing vapor ironing device with double-side ironing function

InactiveCN111705490AQuality improvementEase of mass productionIroning apparatusTextiles and paperStructural engineeringMechanical engineering

Owner:ZHUJI PANDA TEXTILE TECH CO LTD

Automatic clothes ironing and drying equipment

ActiveCN112030494AImprove the quality and efficiency of ironingImprove user experienceTextiles and paperLaundry driersManufacturing engineeringAir drying

The invention discloses automatic clothes ironing and drying equipment. The automatic clothes ironing and drying equipment comprises a cabinet body, a clothes hanging mechanism, an air drying mechanism and an automatic ironing mechanism; the clothes hanging mechanism is mounted on the cabinet body and used for hanging to-be-ironed clothes; the air drying mechanism is provided with an air suction opening and an air exhaust opening, and the air drying mechanism is used for sucking wet air in the cabinet body through the air suction opening, drying and heating the wet air and then exhausting dryhot air into the cabinet body through the air exhaust opening; the automatic ironing mechanism comprises an ironing head, a lifting module and a steam generation module, the ironing head comprises a steam spraying plate and a supporting plate which are oppositely arranged, an ironing area used for ironing the clothes is formed between the steam spraying plate and the supporting plate, and the lifting module is used for driving the ironing head to move up and down in the cabinet body; and the steam generation module is used for generating steam and spraying the steam into the ironing area through the steam spraying plate. The automatic clothes ironing and drying equipment automatically irons and dries the clothes, and the user experience is improved.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com