Energy-saving electric iron employing electromagnetic heating

An electric iron, high-frequency electromagnetic technology, applied in the direction of hand irons, washing devices, textiles and papermaking, etc., can solve the quality of insulation materials and the threat to the personal safety of aging users, low thermal conductivity of insulation materials, and fluctuations in ironing temperature, etc. problems, to achieve the effect of improving ironing quality, improving use safety, and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

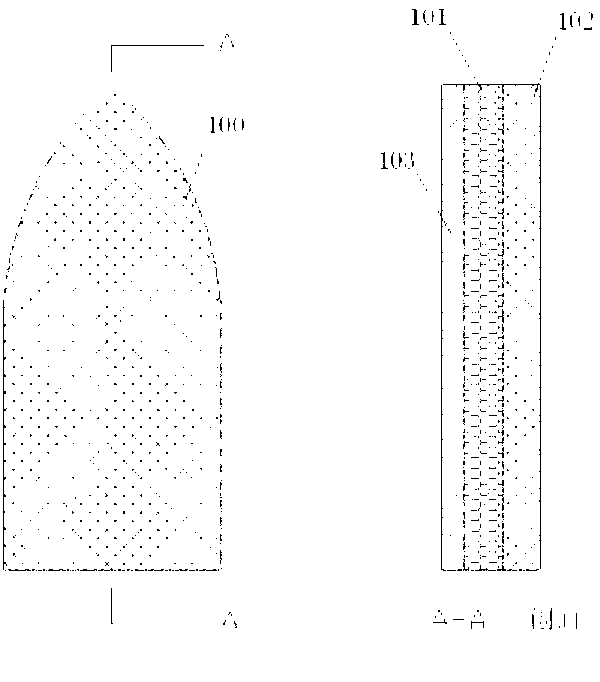

[0019] Such as figure 1 As shown, the circuit part is designed and manufactured with reference to the working principle of the induction cooker, including power supply circuit, high-power high-frequency pulse electromagnetic conversion circuit, infrared temperature measurement circuit, automatic control circuit, equipment casing and other components. The main part of the present invention is the base plate (100) of the electric iron device, which is composed of an electromagnetic power output coil (102), an insulating base plate (101) and a heating plate (103).

[0020] The circuit part converts the electric energy provided by the input power supply into a high-power high-frequency pulse, and the electromagnetic power output coil (102) converts it into electromagnetic power and sends it out. The heating plate (103) receives the high-frequency pulse electromagnetic power and generates heat.

[0021] The insulating bottom plate (101) needs to be made of a certain strong heat-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com