Tufting hat ironing machine

A cap ironing machine and flocking technology, which is applied in the field of semi-automatic flocking cap ironing equipment, can solve the problems of high labor intensity, difficult to guarantee ironing quality, low efficiency, etc., so as to reduce labor intensity, improve ironing quality, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

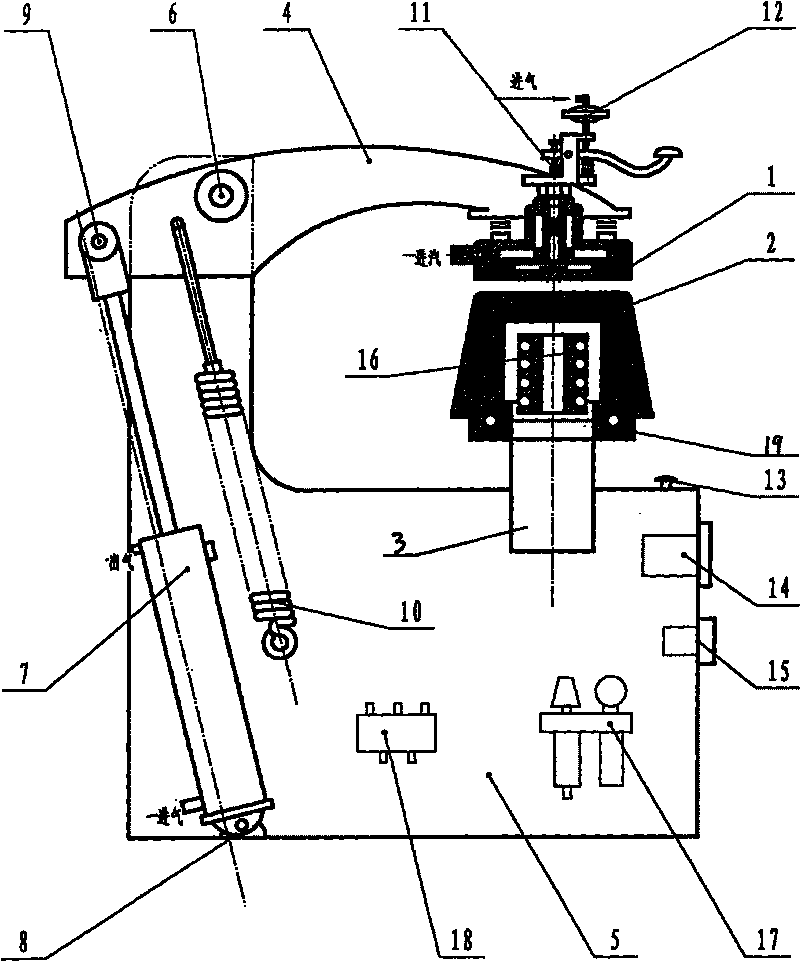

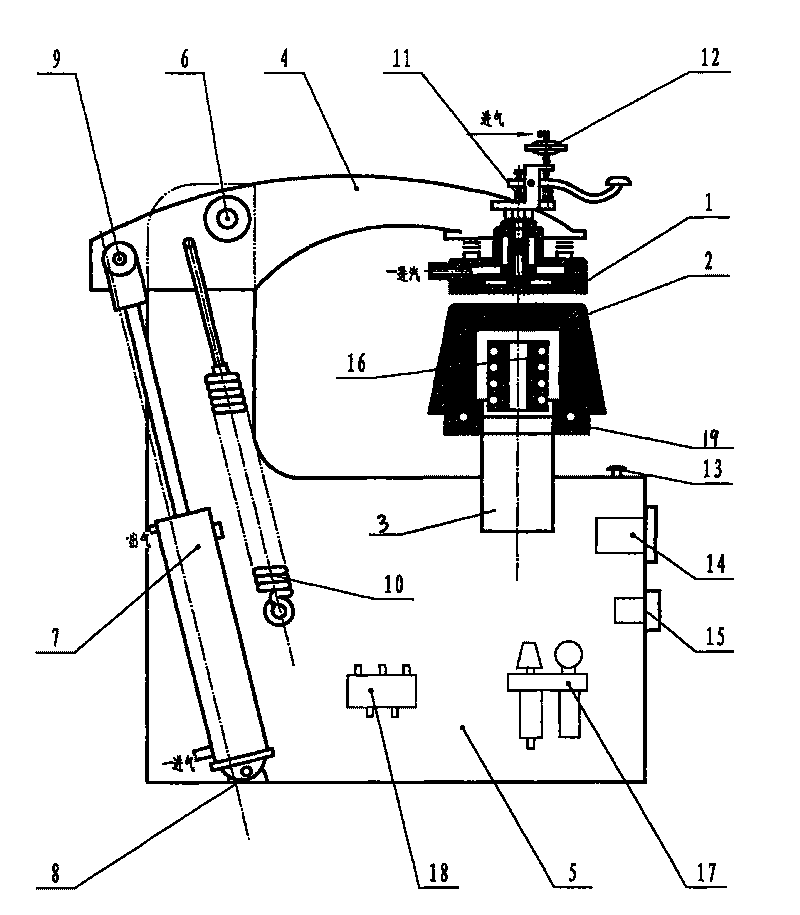

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0008] As shown in the drawings, the tufted cap finishing ironing machine in this embodiment includes an upper ironing head (1), a lower ironing head (2), an ironing head seat (3), a frame (5), a button switch (13 ), time relay (14), temperature controller (15), air pressure regulator (17) and solenoid valve (18), wherein: it also includes main arm (4), main shaft (6), large cylinder (7), Extension spring (10), steam valve (11), small cylinder (12), heating plate (16) and ball bearing (19); Ironing head seat (3) is contained on the frame (5) platen, heating plate ( 16) Set on the end face of the iron seat (3), the ball bearing (19) is set on the upper part of the iron seat (3), the lower end of the lower iron (2) is mounted on the ball bearing (19) and the heating plate (16) Located in the cavity of the lower iron (2), the upper iron (1) is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com