Ironing table and garment steamer using ironing table

An ironing rack and ironing board technology, applied in the field of garment ironing machines, can solve the problems of inconvenient operation, comfort, inconvenient transportation, storage, inconvenient transportation and storage, etc., so as to improve ironing efficiency and ironing quality, and facilitate Storage and transportation, and the effect of improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

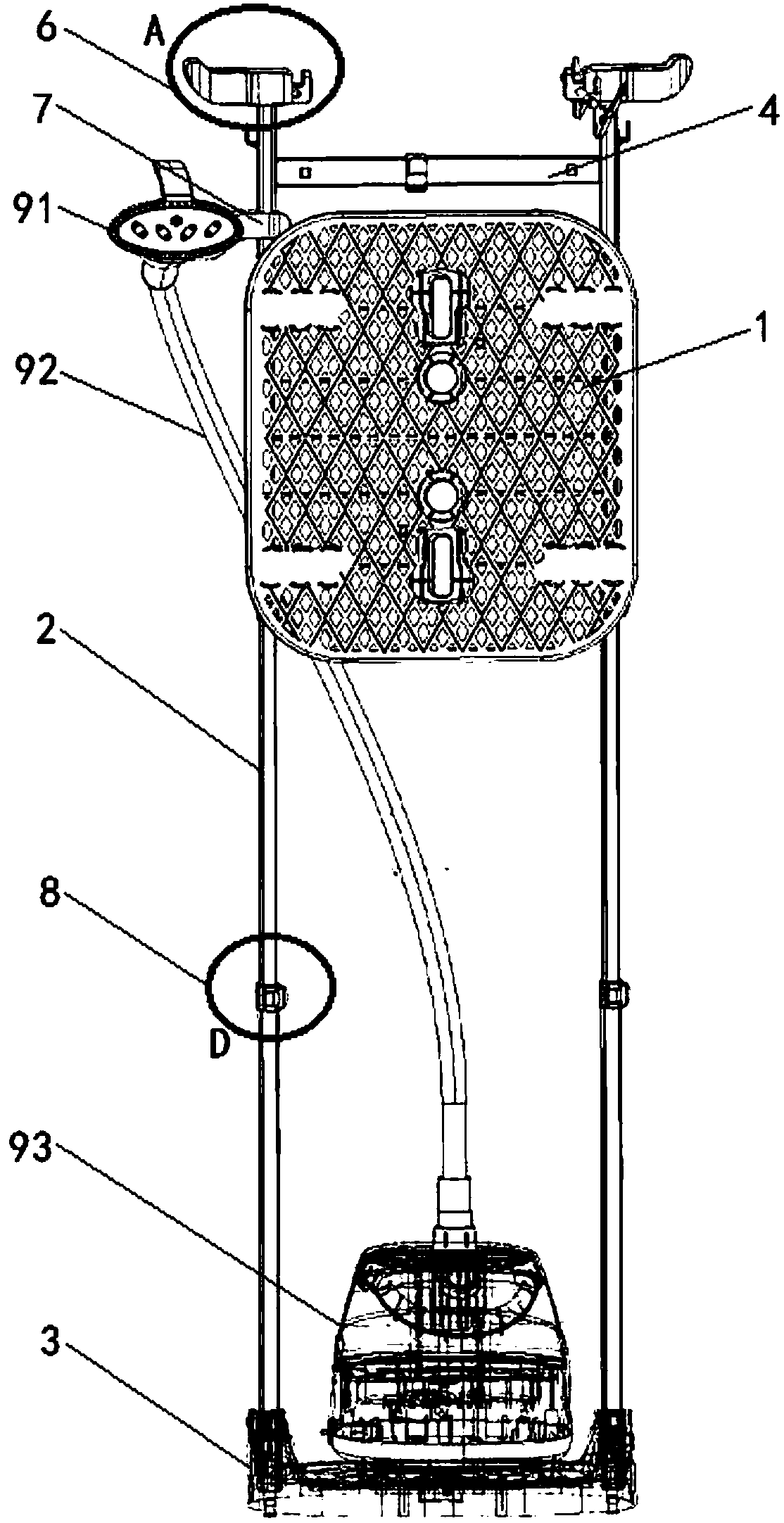

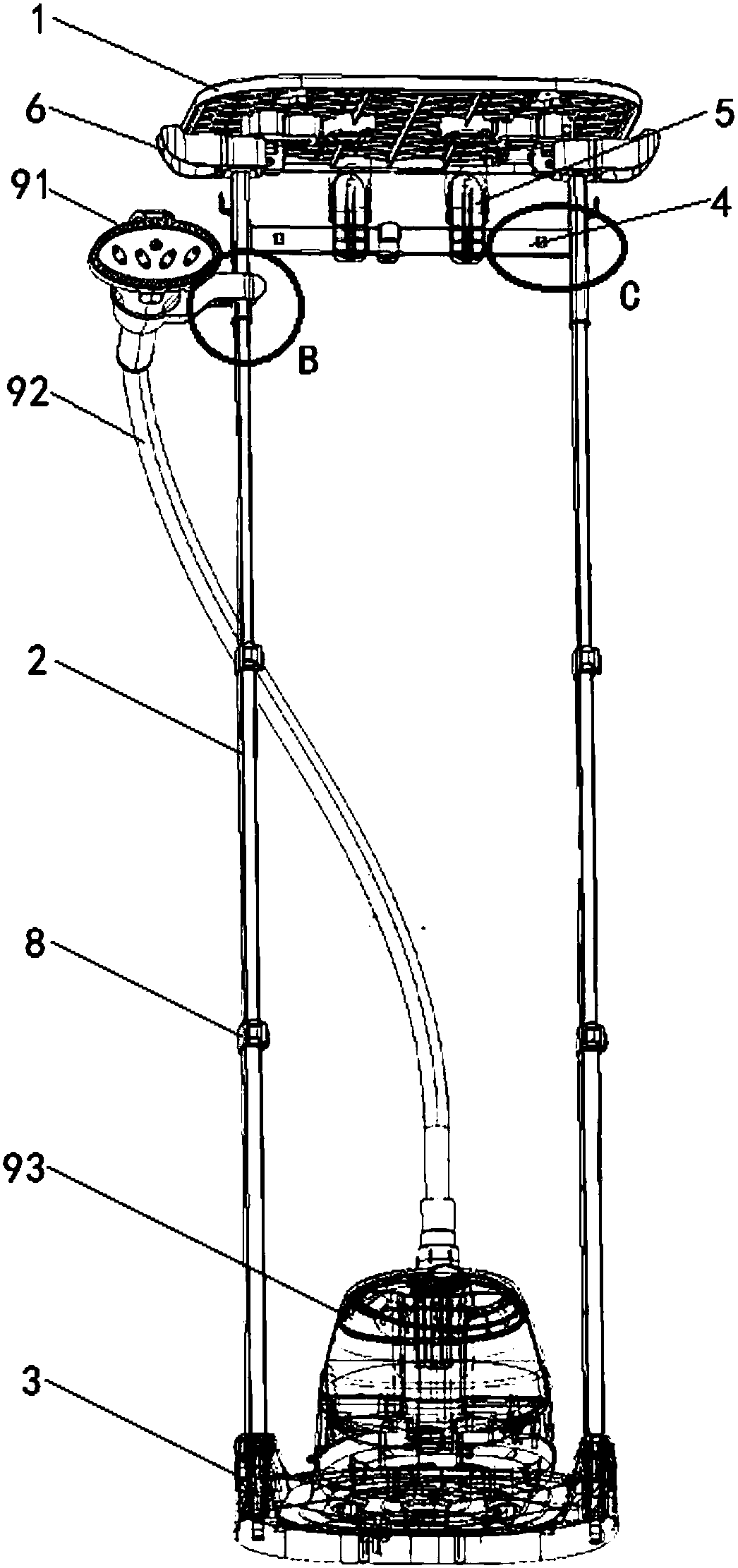

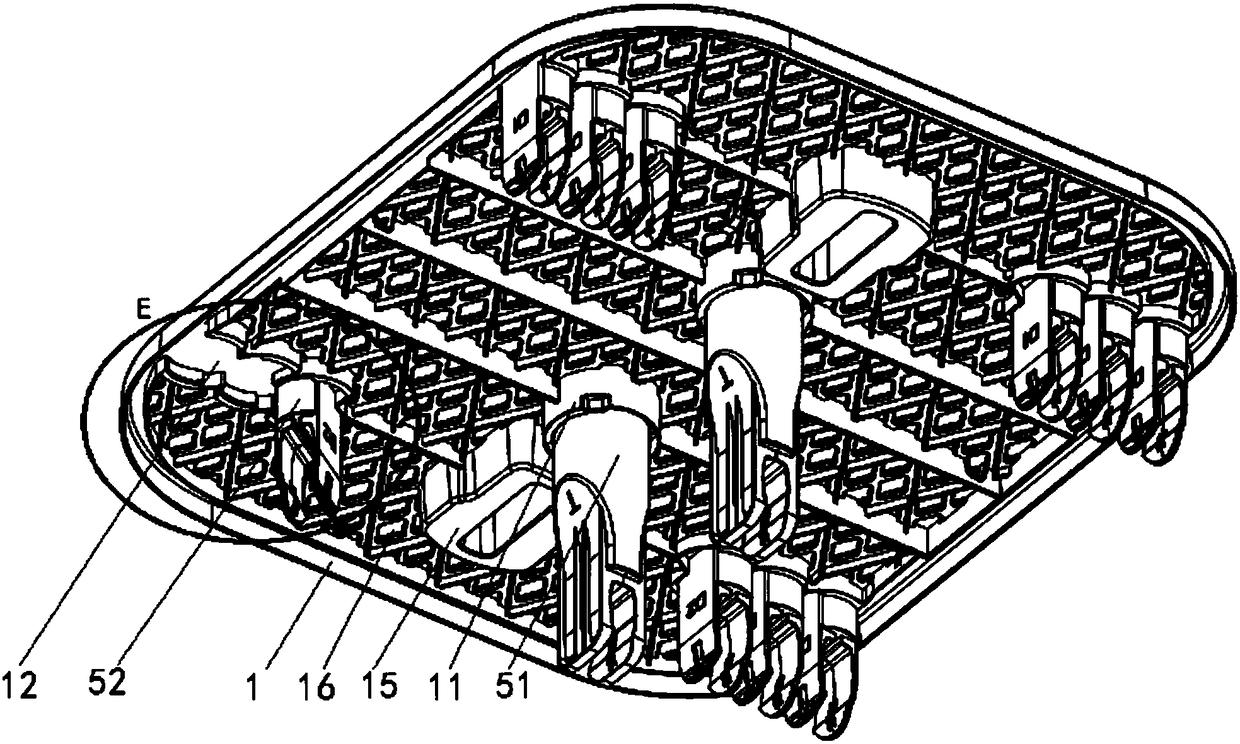

[0057] Such as figure 1 , figure 2 and image 3 As shown, an ironing stand provided by the present invention includes an ironing board 1 and a support frame for supporting the ironing board 1, the ironing board 1 includes an ironing surface and a supporting surface, and the supporting surface is provided with There is an elastic clip 5 and an annular installation groove for installing the elastic clip 5, the elastic clip 5 includes a connection end and a clamping end, and the connection end is detachably connected to the ironing board 1 through the installation groove ; The clamping end can be clamped on the support frame to realize the detachable connection between the ironing board 1 and the support frame.

[0058] The support frame includes a base 3, a plurality of uprights 2 vertically fixed to the base 3, and a cross bar 4 connected and fixed between the plurality of uprights 2; Crossbar 4, so that the ironing board 1 is fixed on the top of the support frame to form a...

Embodiment 2

[0082] The ironing stand of this embodiment is basically the same as that of Embodiment 1, the difference is that the clamping end of the elastic clip 2 is provided with a non-slip mat (not shown), and the two elastic splints 55 at the clamping end are opposite to each other. Both sides are provided with anti-skid pads, and the anti-skid pads are used to increase the friction between the vertical bar 2 and the cross bar 4 and the elastic splint 55, preventing the vertical bar 2 and the cross bar from 4 out of the clip end. The side of the elastic splint 55 opposite to the clamping surface is provided with a plurality of vertical reinforcing ribs (not shown), and the reinforcing ribs increase the strength of the elastic splint so that the elastic splint is not easy to break.

Embodiment 3

[0084] The ironing stand of this embodiment is basically the same as that of Embodiment 1, the difference is that the installation hole 32 of the base 3 is provided with a device that increases the stability of the pole 2 and prevents the pole 2 from shaking, such as Figure 12 As shown, the mounting hole 32 is provided with an elastic member 37, and an opening is provided in the middle of the elastic member 37, and the bottom end of the pole 2 is inserted into the opening, and the elastic member 37 is used to fasten the The pole 2 reduces the shaking of the pole 2, thereby increasing the stability of the support frame.

[0085] Preferably, the inner wall of the elastic member 37 is provided with a plurality of convex strips 38 along the circumference, and the convex strips 38 are used to increase the friction between the vertical rod 2 and the elastic member 37, and increase the vertical The stability of the assembly of the rod 2 with the mounting hole 32. Appropriately incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com