Garment ironing equipment

A technology for ironing equipment and garments, which is applied to ironing boards, ironing machines, washing devices, etc., can solve the problems of inability to fold, occupy a large area, and waste space, and achieves increased practicability, reduced space occupation, and good control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

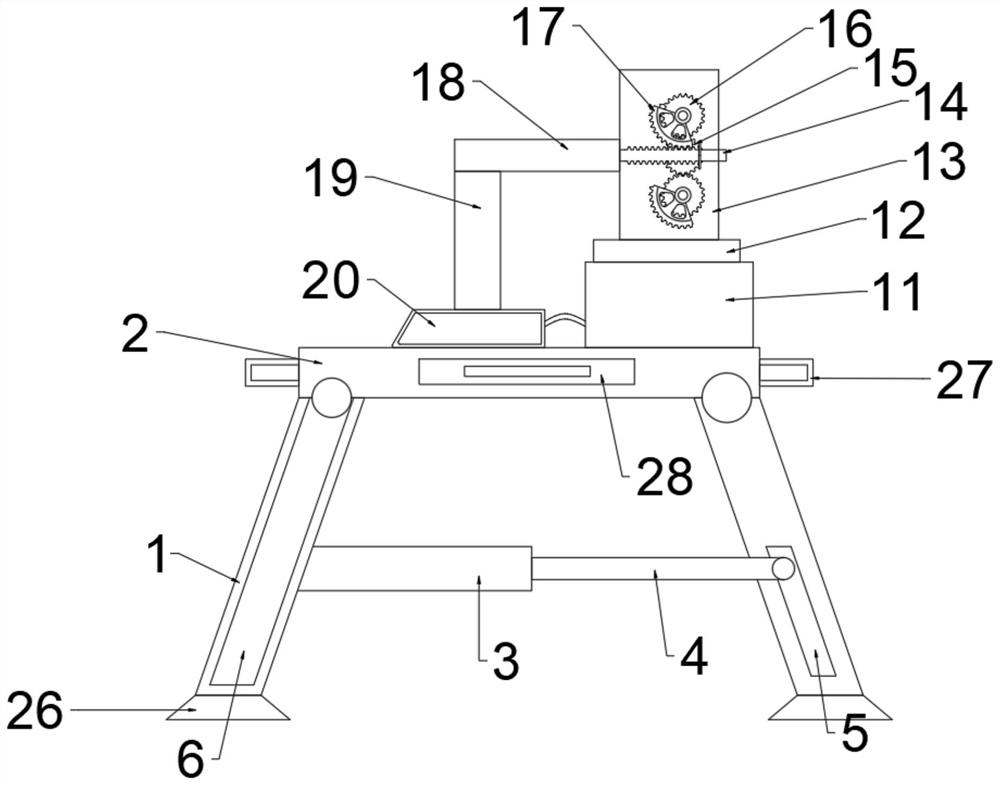

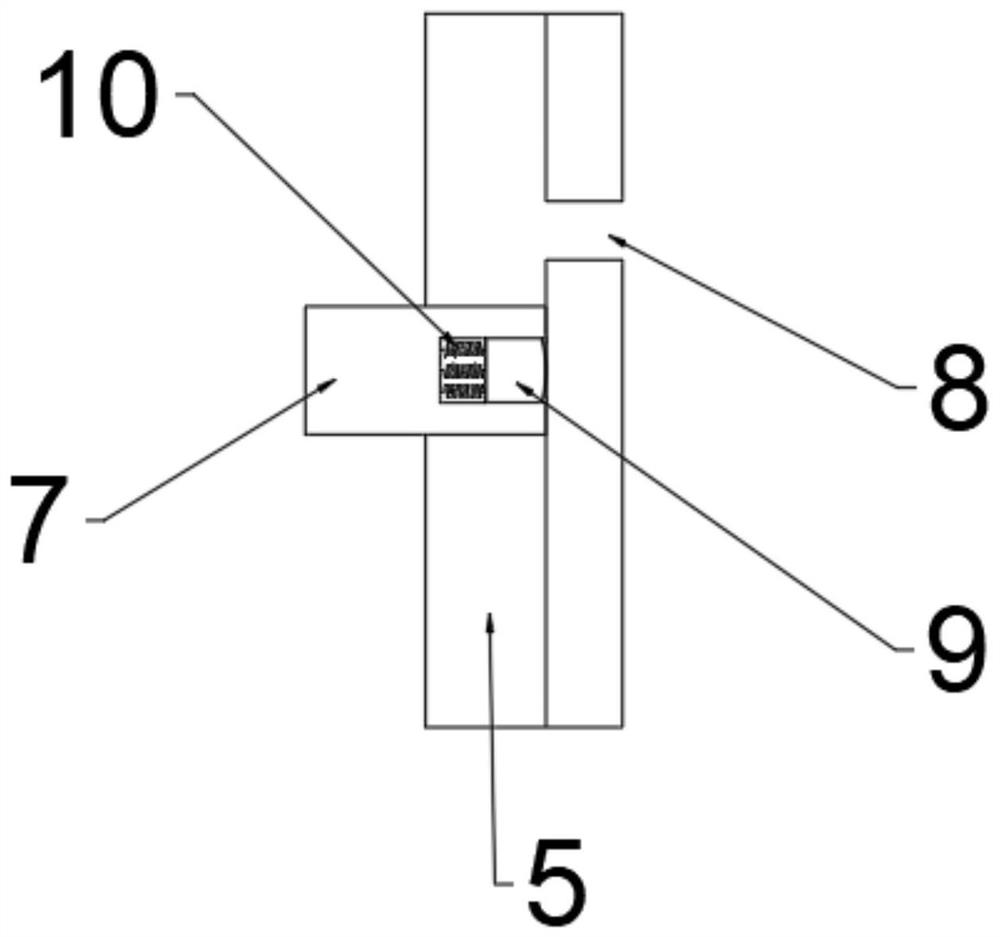

[0030] refer to Figure 1 ~ Figure 2 , an ironing device for garments, comprising an ironing board 2, legs 1 are connected by bolts at the left and right ends of the bottom of the ironing board 2, an ironing mechanism is arranged above the ironing board 2, and an ironing mechanism is arranged on the left side leg 1 There is a second chute 6, the first chute 5 is provided on the right leg 1, the rear of the left leg 1 is rotatably connected with a connecting pipe 3, and the end of the connecting pipe 3 far away from the left leg 1 is plugged and connected with a The drawing pipe 4, the left end of the ironing board 2 and the end of the drawing pipe 4 away from the connecting pipe 3 are bolted to a sliding post 7, and the first chute 5 and the second chute 6 are slidably connected to the sliding post 7. The inside of the column 7 is provided with a groove, and the limit rod 9 is slidably connected in the groove, and the end of the limit rod 9 near the groove is bolted to a sprin...

Embodiment 2

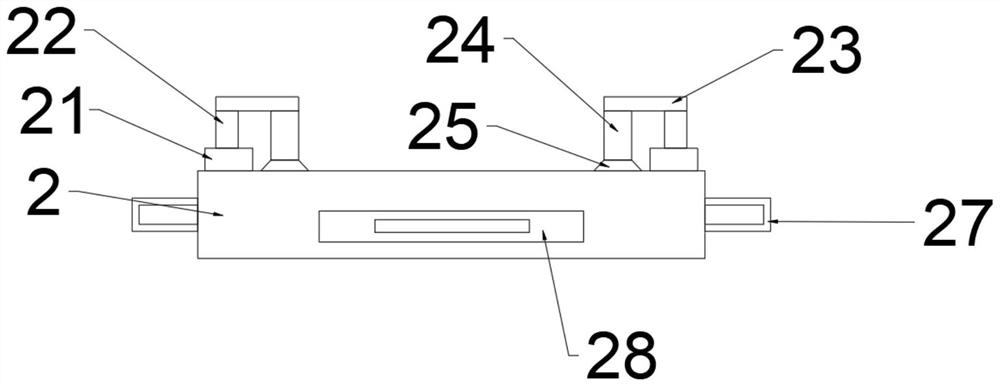

[0038] refer to Figure 3 ~ Figure 4 , an ironing device for garments. Compared with Embodiment 1, the four corners of the ironing board 2 are connected with the second hydraulic pipe 21 by bolts, and the upper part of the second hydraulic pipe 21 is connected with the second telescopic pipe. 22. The end of the second telescopic tube 22 away from the second hydraulic tube 21 is bolted to the second connecting plate 23, and the bottom of the second connecting plate 23 away from the second telescopic tube 22 is bolted to the second connecting rod 24. The second connection One end bolt of the rod 24 away from the second connecting plate 23 is connected with a pressing plate 25, the pressing plate 25 is disc-shaped, when the clothes are put into the top of the ironing board 2, the second hydraulic pipe 21 is activated, so that the first Two telescoping tubes 22 drive the second connecting plate 23 to move down, and then the second connecting rod 24 drives the pressing plate 25 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com