Ironing equipment for garment manufacturing

A clothing manufacturing and equipment technology, applied in the field of ironing equipment for clothing manufacturing, can solve problems such as hidden dangers to operator safety, reduce production costs, and be unfavorable to enterprises, and achieve the effect of high ironing quality and efficiency and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

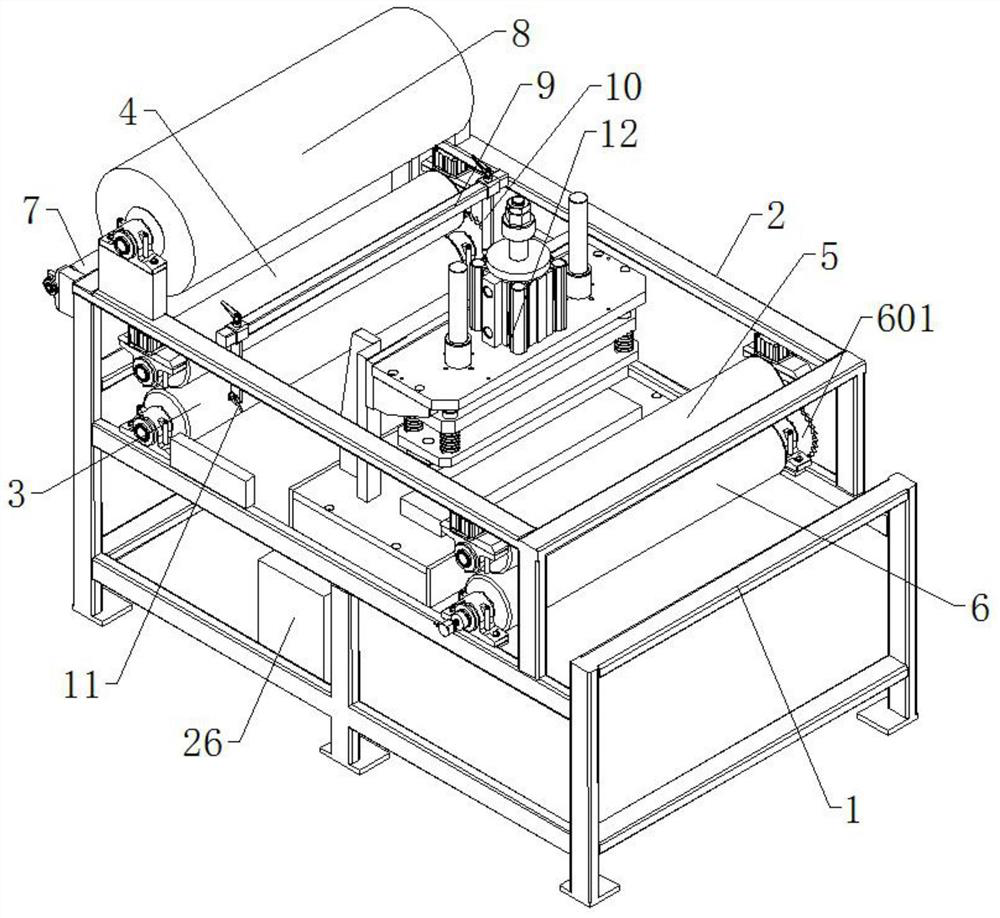

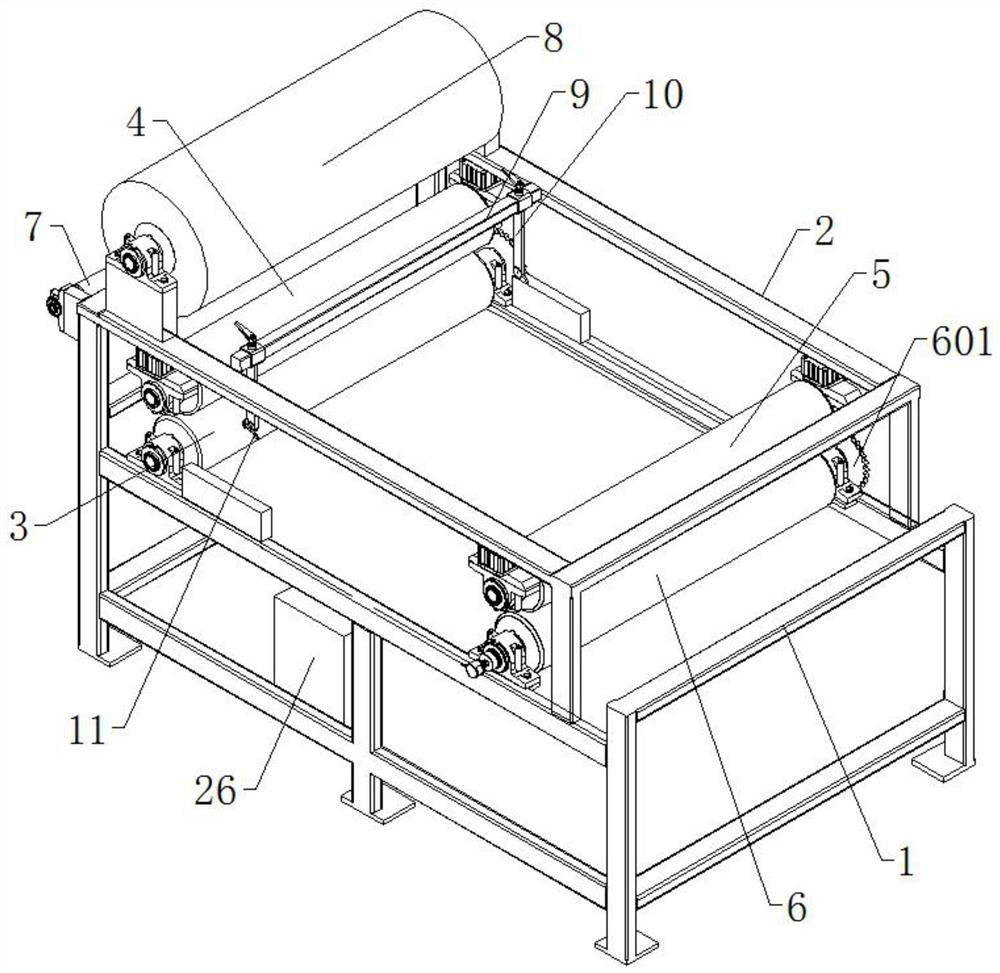

[0028] Example: see figure 1 , the first lower pinch roller 3, the ironing plate 25, and the second lower pinch roller 6 are arranged at the same level, so that the cloth in the cloth ironing process can be at the passing level, and the efficiency of cloth ironing is higher .

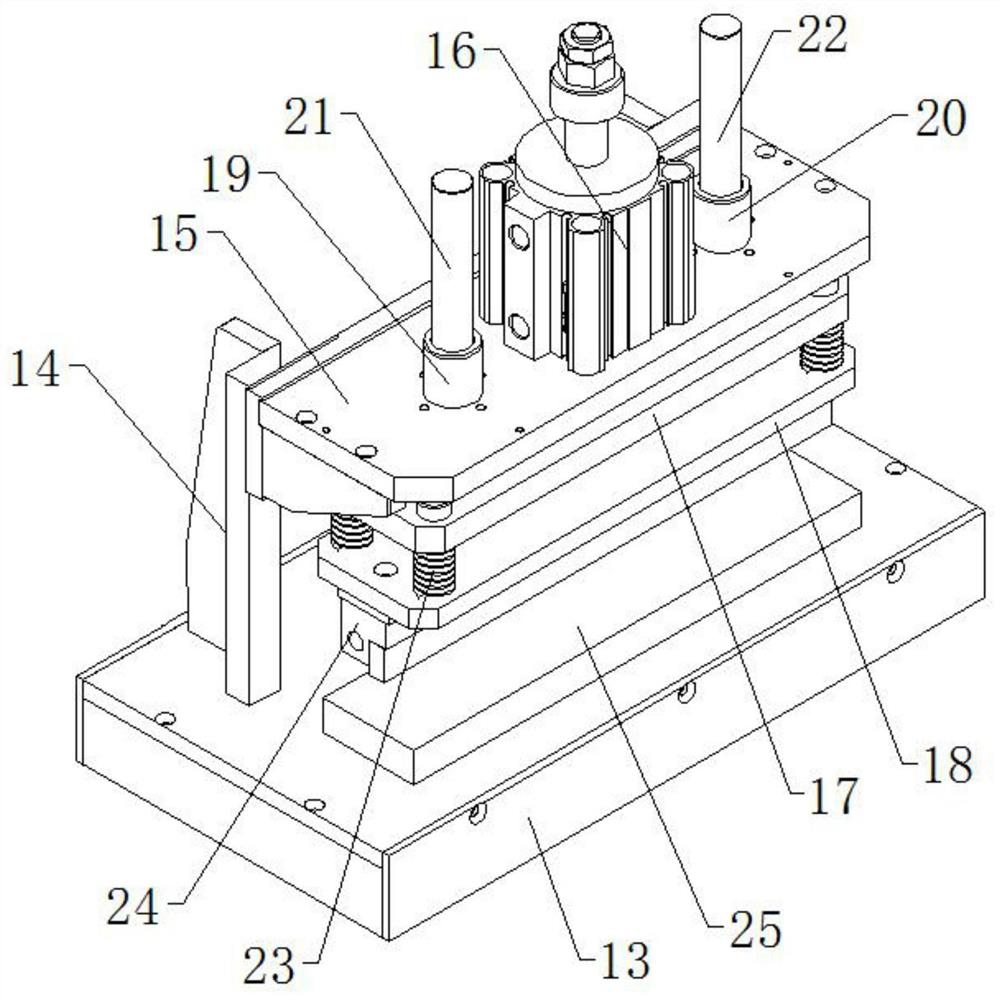

[0029] Embodiment: Please refer to 3-4, the upper mounting plate 17 is slidably connected with the upper bearing seat 15 through the first positioning guide column 21 and the second positioning guide column 22 through the first positioning sleeve 19, the second positioning sleeve 20 and the upper bearing seat 15, supporting Riser 14 is positioned at the upper side of bearing base 13 and is provided with two left and right symmetrically along the length direction, by setting, the stability of ironing can be made higher through the first positioning guide column 21, the second positioning guide column 22 that is provided.

[0030]The working process of the present invention: when in use, the external dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com