Ironing device for processing novel textile fabric

A technology for textile fabrics and ironing devices, which is applied in the directions of textiles and papermaking, fabric surface trimming, etc., can solve the problems of not reducing labor intensity, improving production efficiency, and inability to dry fabrics, etc. Processing cost, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

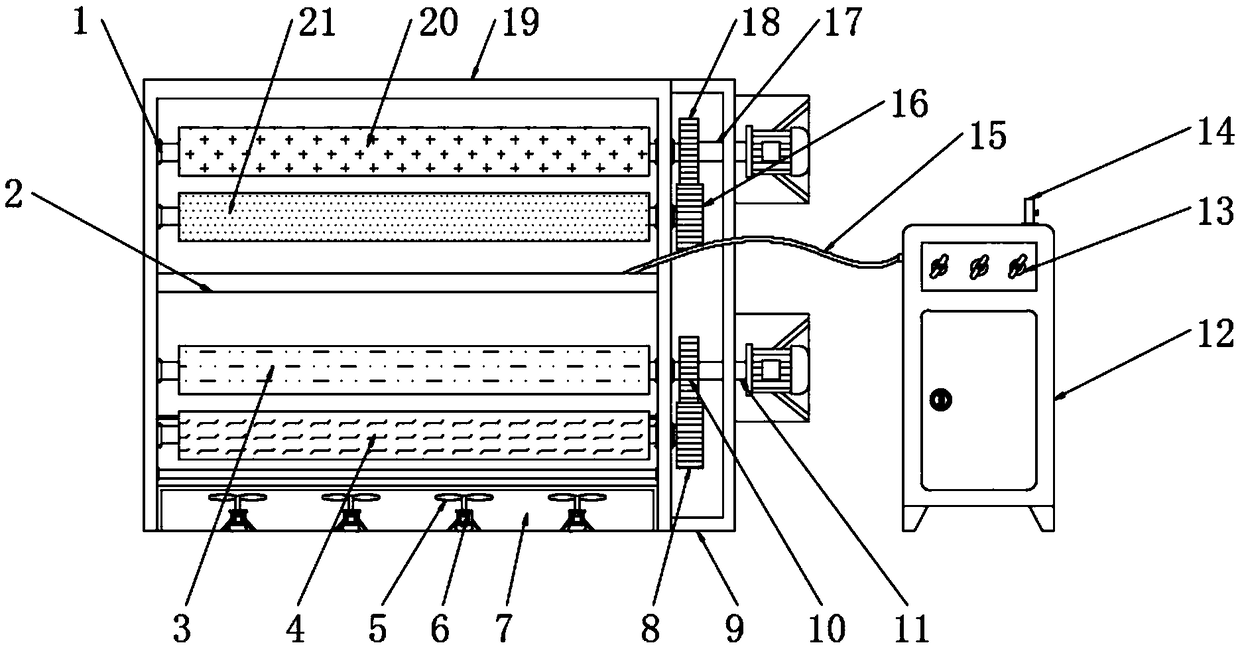

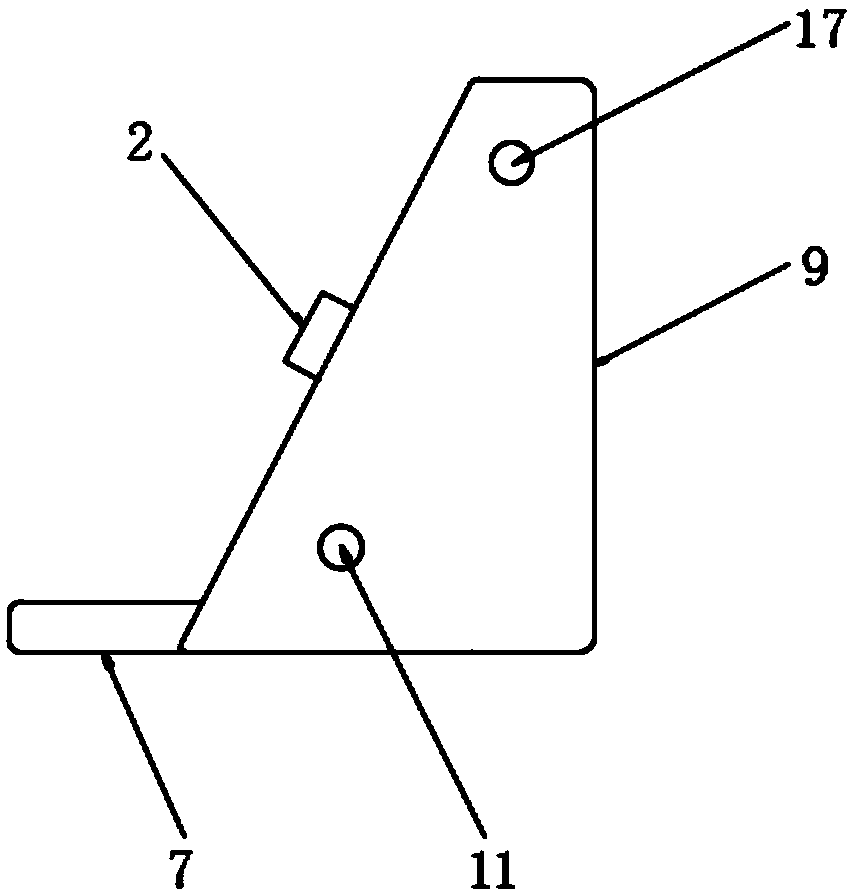

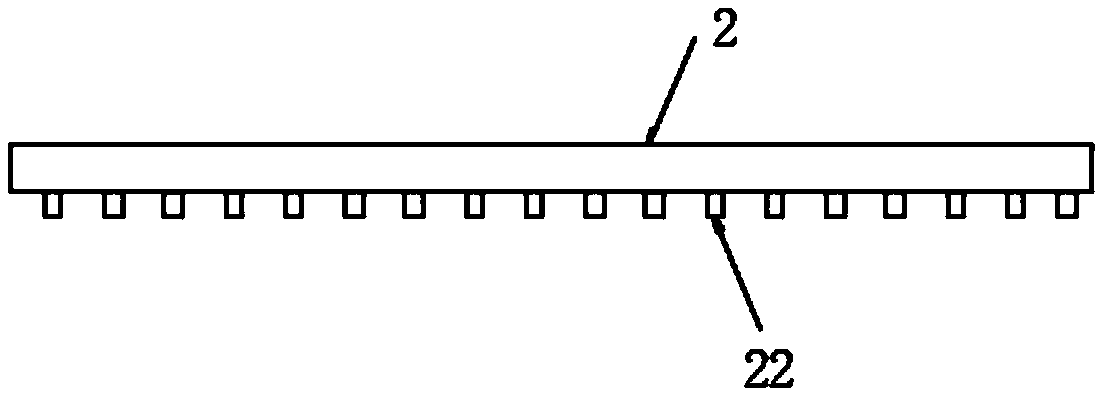

[0017] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a novel ironing device for textile fabric processing, comprising a frame 19, the front side of the bottom of the frame 19 is fixedly connected with a dehumidifier 7, and the inner bottom of the dehumidifier 7 is provided with a Motor 6, the top of motor 6 is connected with fan blade 5 in rotation, the inside of frame 19 is provided with second carding roller 4 near the upper position of dehumidifier 7, and the top of second carding roller 4 is provided with first carding roller 3, and One end of the second carding roller 4 is equipped with a carding driven gear 8, and the top of the carding driven gear 8 near one end of the first carding roller 3 is meshed with a carding driving gear 10, and one side of the carding driving gear 10 is provided with a carding main shaft 11, the outer side of the frame 19 is located at the outer position of the carding driven gear 8, and a protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com