Streamlined equipment for silk spinning production

A streamlined and silk spinning technology, applied in textiles and papermaking, fiber processing, carding machines, etc., can solve problems such as poor error tolerance, excessive equipment, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

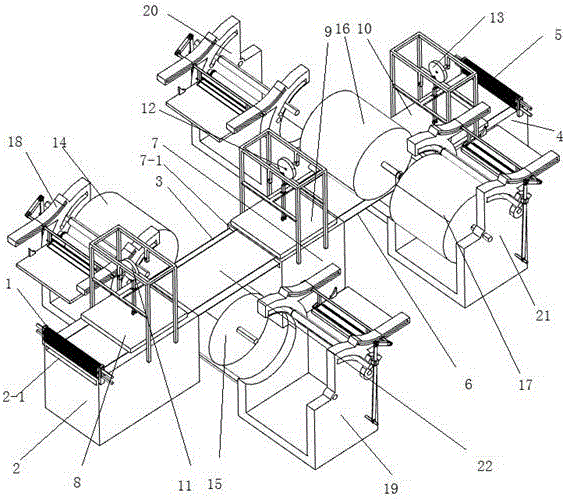

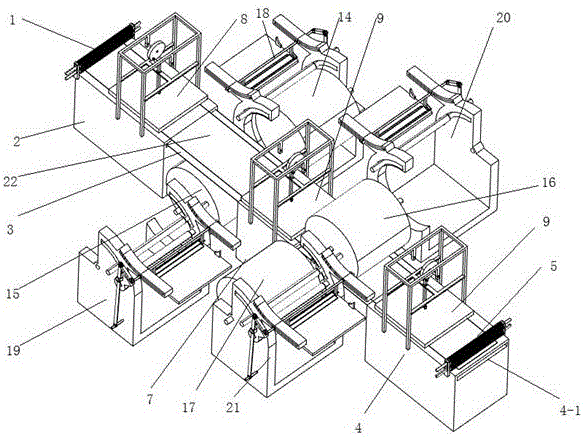

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0018] The invention provides a streamlined equipment for silk spinning production, which greatly simplifies the original silk spinning mechanism, saves the middle cutter, attached splint, simplifies the circular comb, improves production efficiency, and is convenient for manufacturers to cut and process arbitrary lengths cotton.

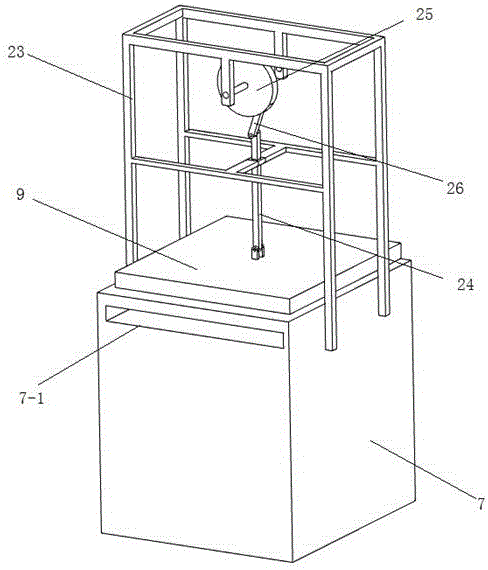

[0019]As an embodiment of the present invention, the present invention provides a streamlined equipment for silk spinning production, including input roller 1, transfer platform, smooth baffle, output roller 5, press plate, press plate lifting mechanism, carding cylinder and automatic doffing device, the transfer station has three transfer stations one 2, two transfer stations 4 and middle transfer station 7, the middle transfer station 7 is between the transfer station one 2 and the second transfer station 4, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com