Hand push type grass comber

A lawn comber and hand-push technology, applied in lawn growth, horticulture, botany equipment and methods, etc., can solve the problems of heavy equipment, unsuitable for small lawns, etc., and achieve the effect of improving carding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

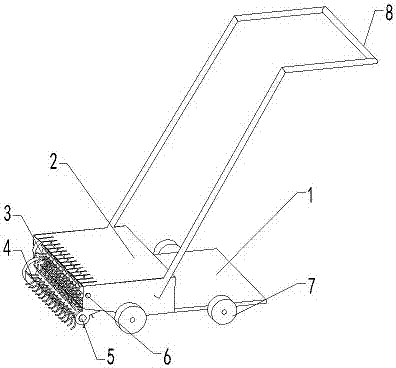

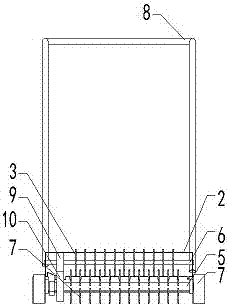

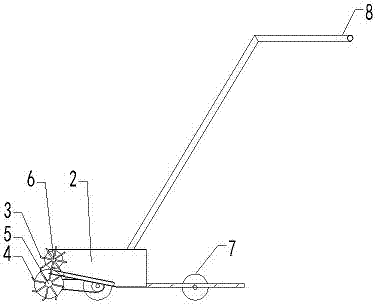

[0025] Examples such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a hand-push grass comber includes a chassis 1,

[0026] A collection device is provided near the front end of the chassis 1. The front end of the collection device is provided with a rotating device for combing and harvesting grass. The bottom of the chassis 1 is provided with a wheel device for moving. The wheel device is connected to the rotating device in transmission. The position near the rear end is provided with a push handle 8 for promoting the grass comber to move, and the push handle 8 is pushed to make the grass comber move forward, and the wheel device rotates to drive the rotating device to send debris such as dead leaves in the collection device.

[0027] The chassis 1 is rectangular, and the collection device includes a collection channel 2 for holding sundries. Garbage bags can be installed near the collection channel 2 at the rear of the chassis 1. When dead leaves and other debri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com