Patents

Literature

37results about How to "Improve carding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

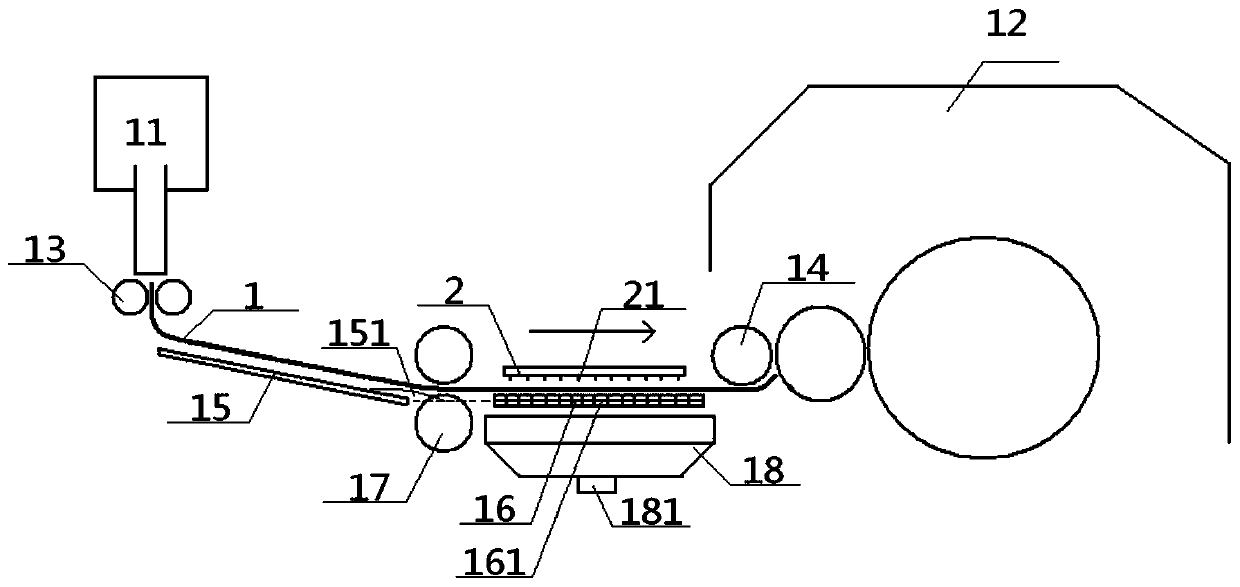

Method for improving properties of yarns formed by rotor spinning

InactiveCN102634894AImproved yarn performanceLow bending stiffnessContinuous wound-up machinesOpen-end spinning machinesWoolFlexural rigidity

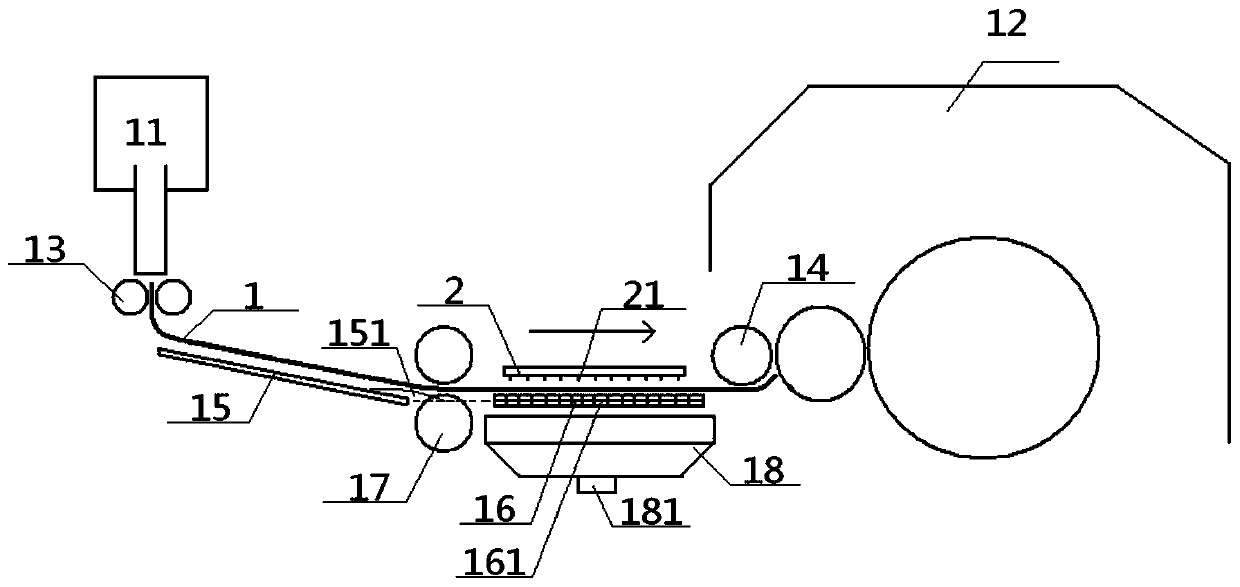

The invention relates to a method for improving the properties of yarns formed by rotor spinning by reducing fiber modulus and rigidity on line, belonging to the field of textile processing. The method has the following advantages that the fiber modulus and bending rigidity of rotor spun fiber strands are quickly reduced on line by adopting a three-stage parallel softening treatment method, thus improving the fiber combing quality of the combing roller, improving torsion easiness and internal and external transfer properties when the fibers undergo rotor spinning, improving the rotor spun yarn surface twist line clarity and yarn strength and substantially elevating the capability of spinning high count yarns through rotor spinning; the key problems that the rotor spun yarn surface fibers are loose, the twist lines are not clear and the method is not suitable for spinning the high count yarns can be effectively solved; the quality of the yarns formed by rotor spinning of fibers is substantially improved; and the method is especially suitable for high-quality spinning of textile fibers with high rigidity (such as ramie) and high elasticity (such as wool) on the rotor spinning machine.

Owner:WUHAN TEXTILE UNIV

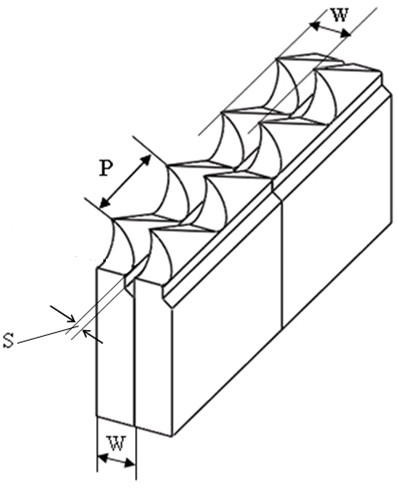

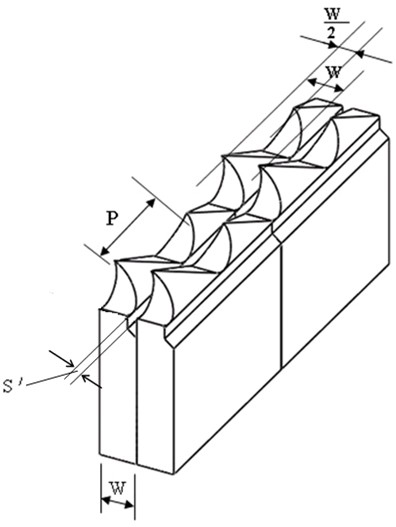

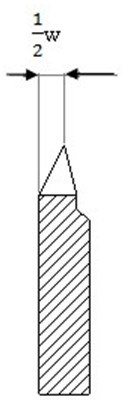

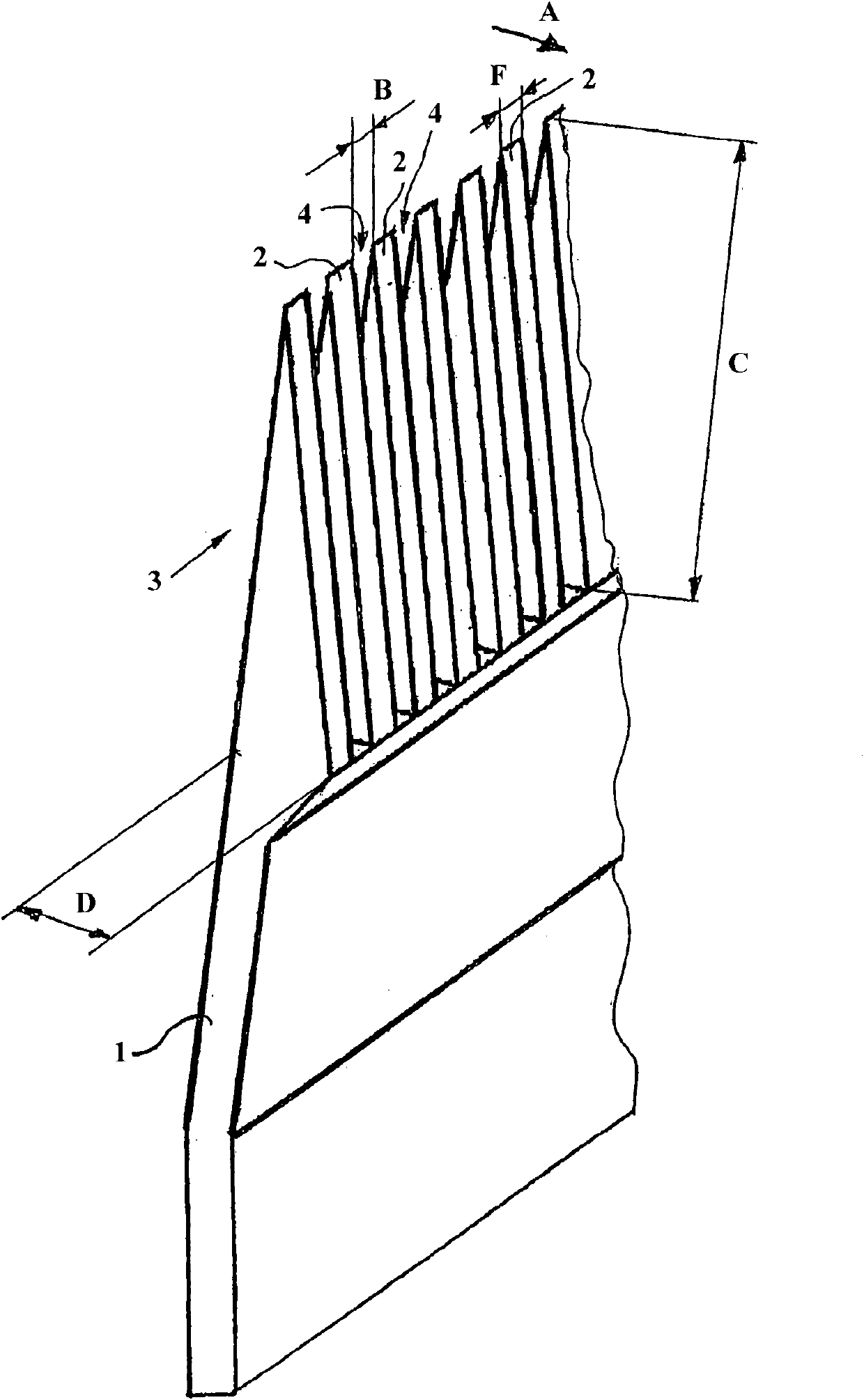

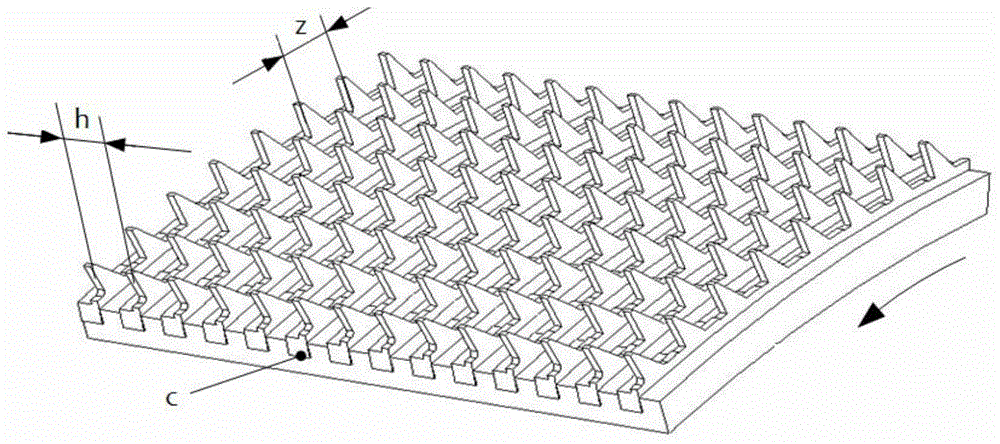

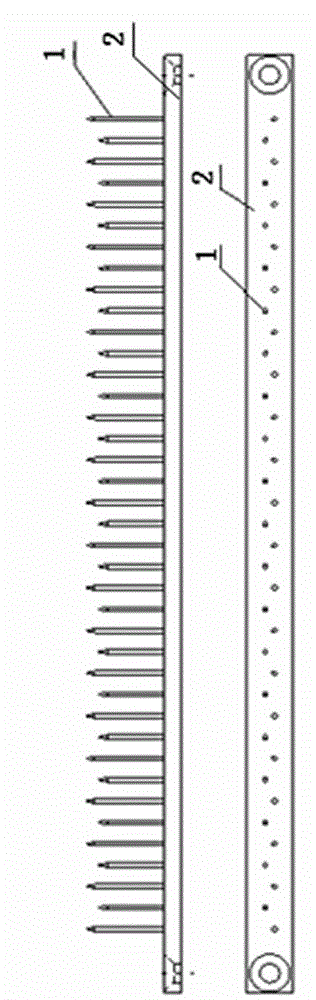

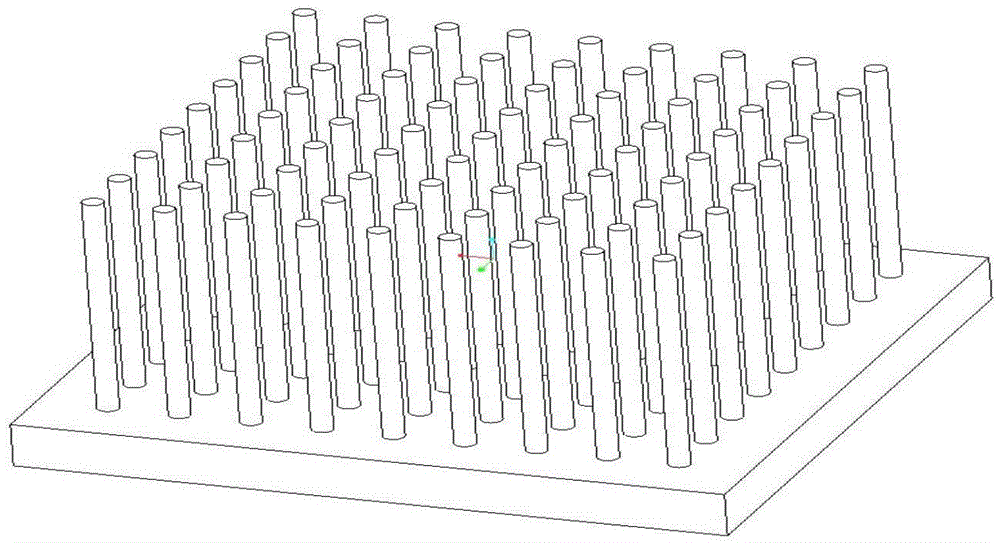

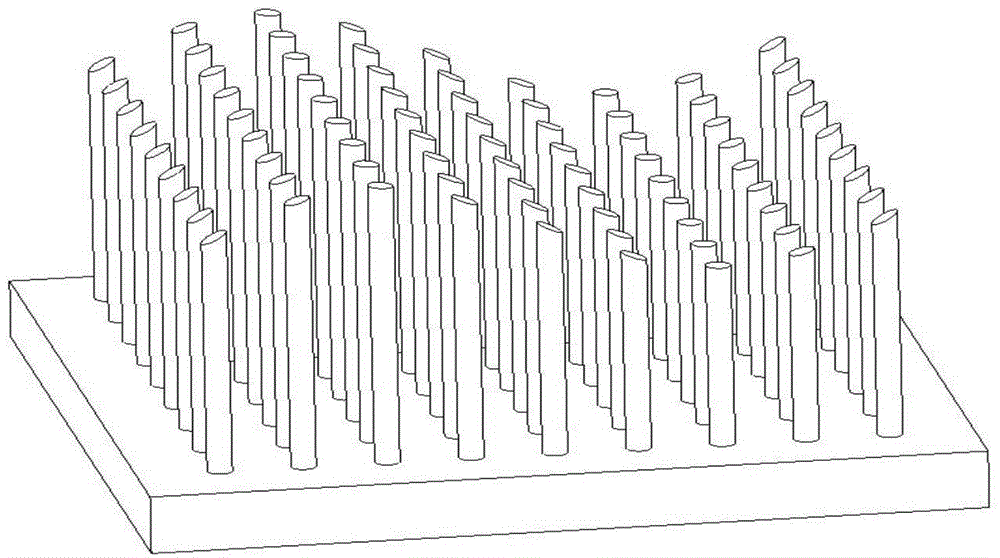

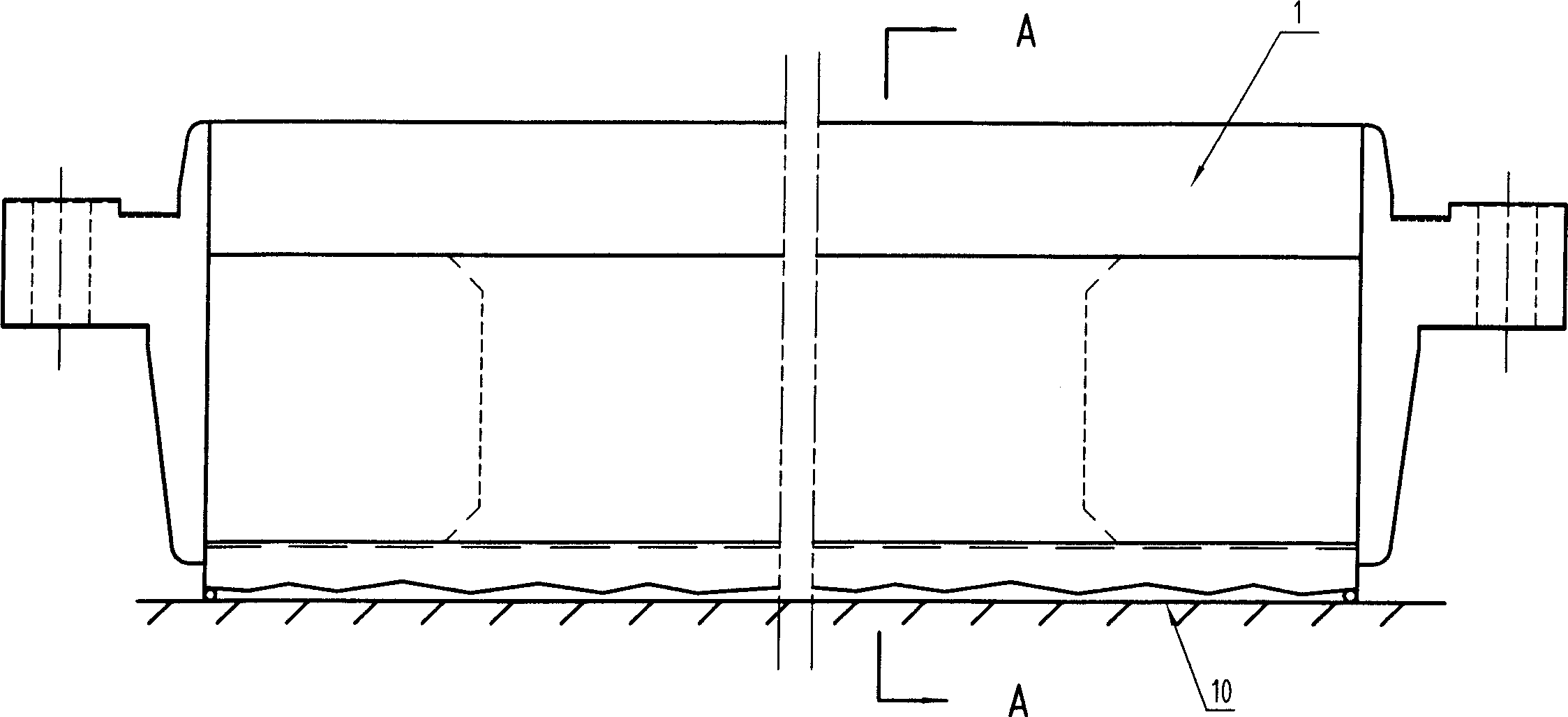

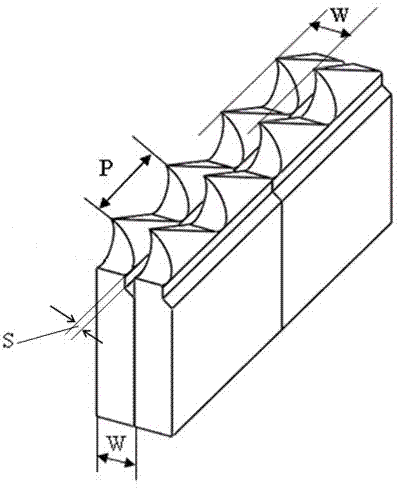

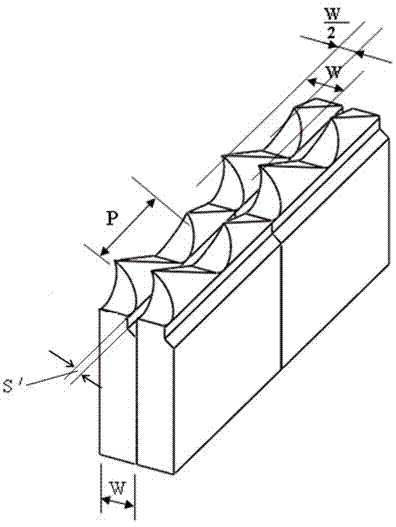

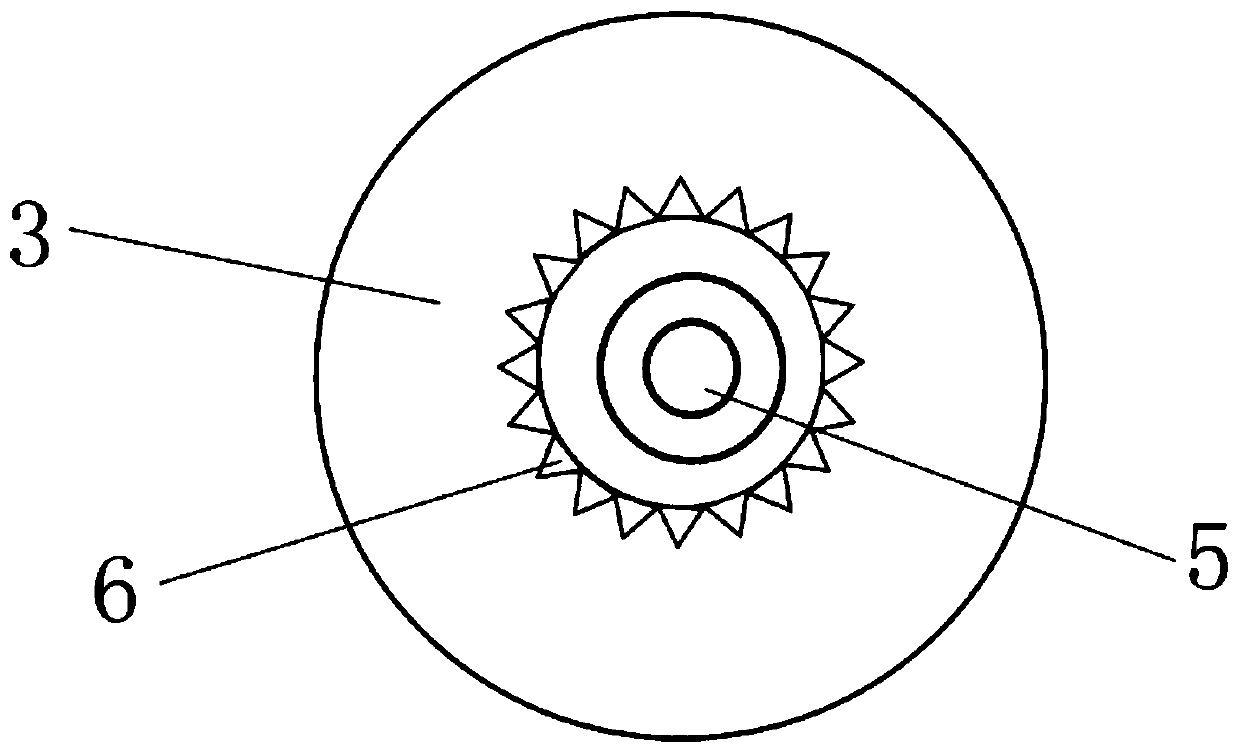

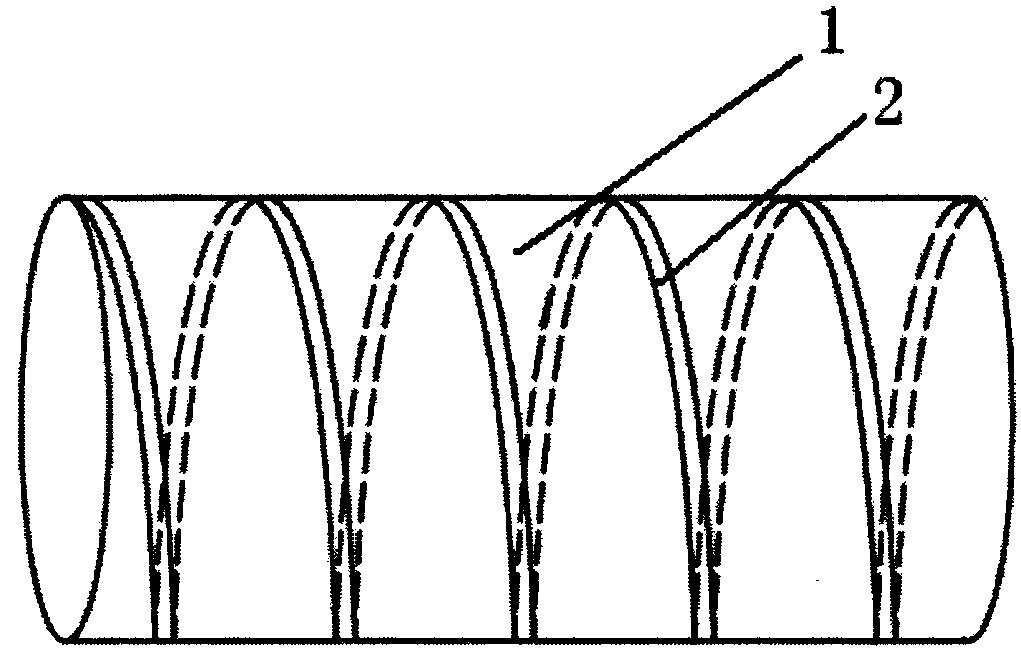

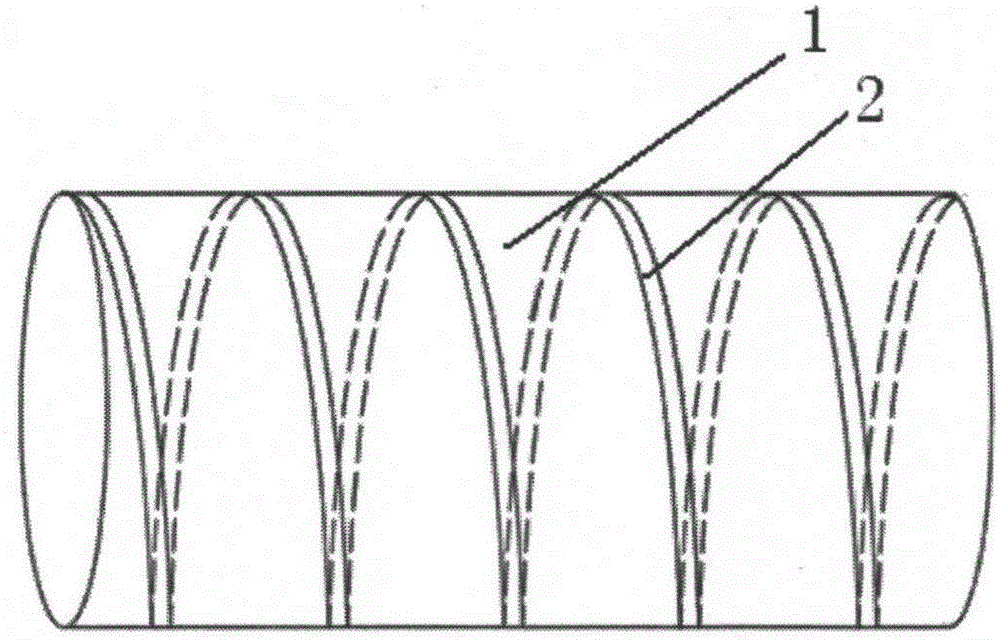

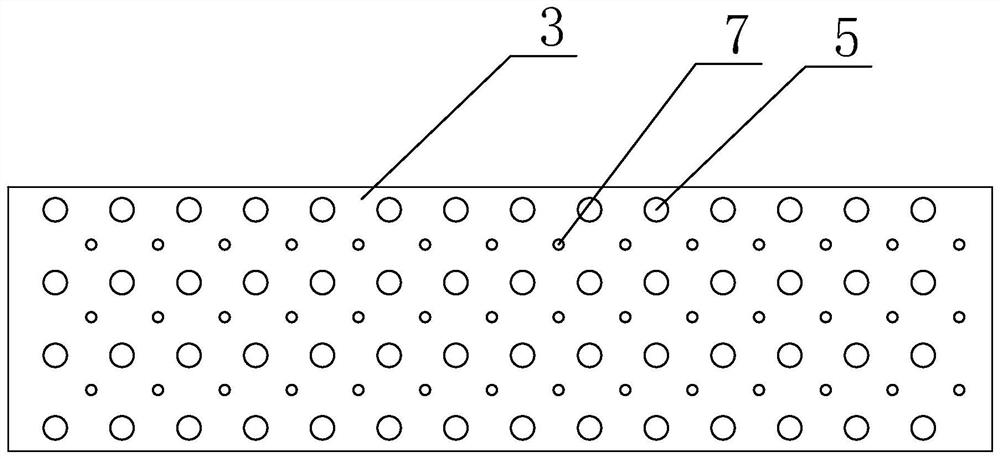

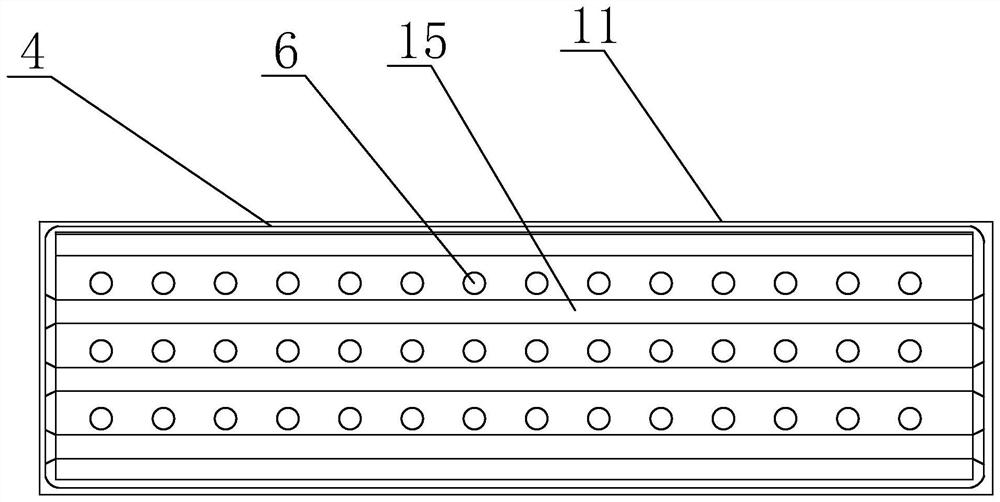

Dislocated metallic card clothing

The invention relates to dislocated metallic card clothing which comprises base parts arranged side by side, wherein needle teeth in a row are distributed at the top end of each base part, and the needle teeth are characterized in that the needle points of the needle teeth are in dislocated arrangement in the length direction of the base part. The dislocated metallic card clothing is capable of effectively reducing the transverse relative gaps of the needle teeth, effectively increasing the carding probability of fiber fines bundles in the carding process, improving the carding quality, reducing fiber damage, improving the card sliver quality, and being used for carding card slivers for producing fine yarns and extra fine yarns. The dislocated metallic card clothing can be applied to manufacturing of licker-in wires and also cylinders and doffer card clothing, and is suitable for reformation of old machines such as the existing cotton carding machines, wool carding machines and hemp carding machines and suitable for equipment of new machines.

Owner:DONGHUA UNIV +1

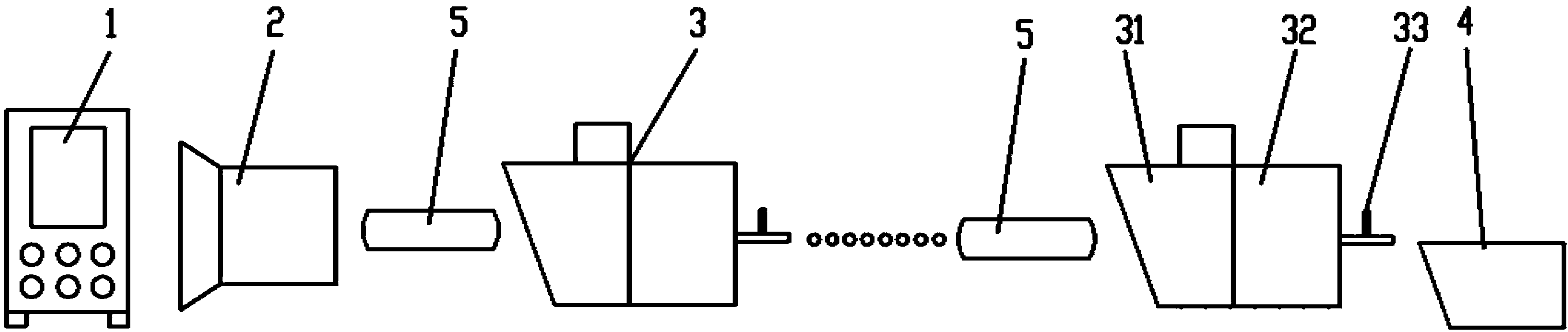

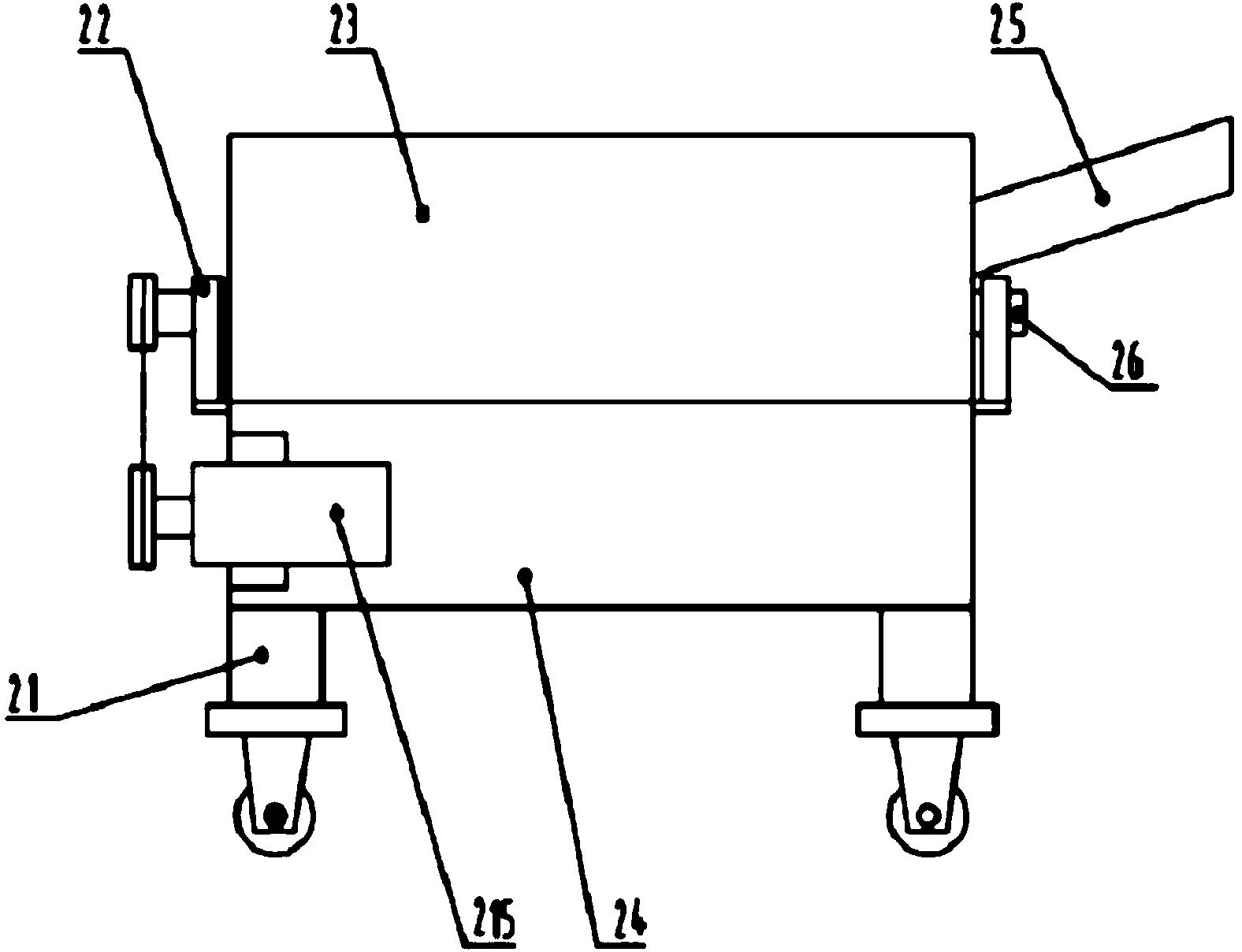

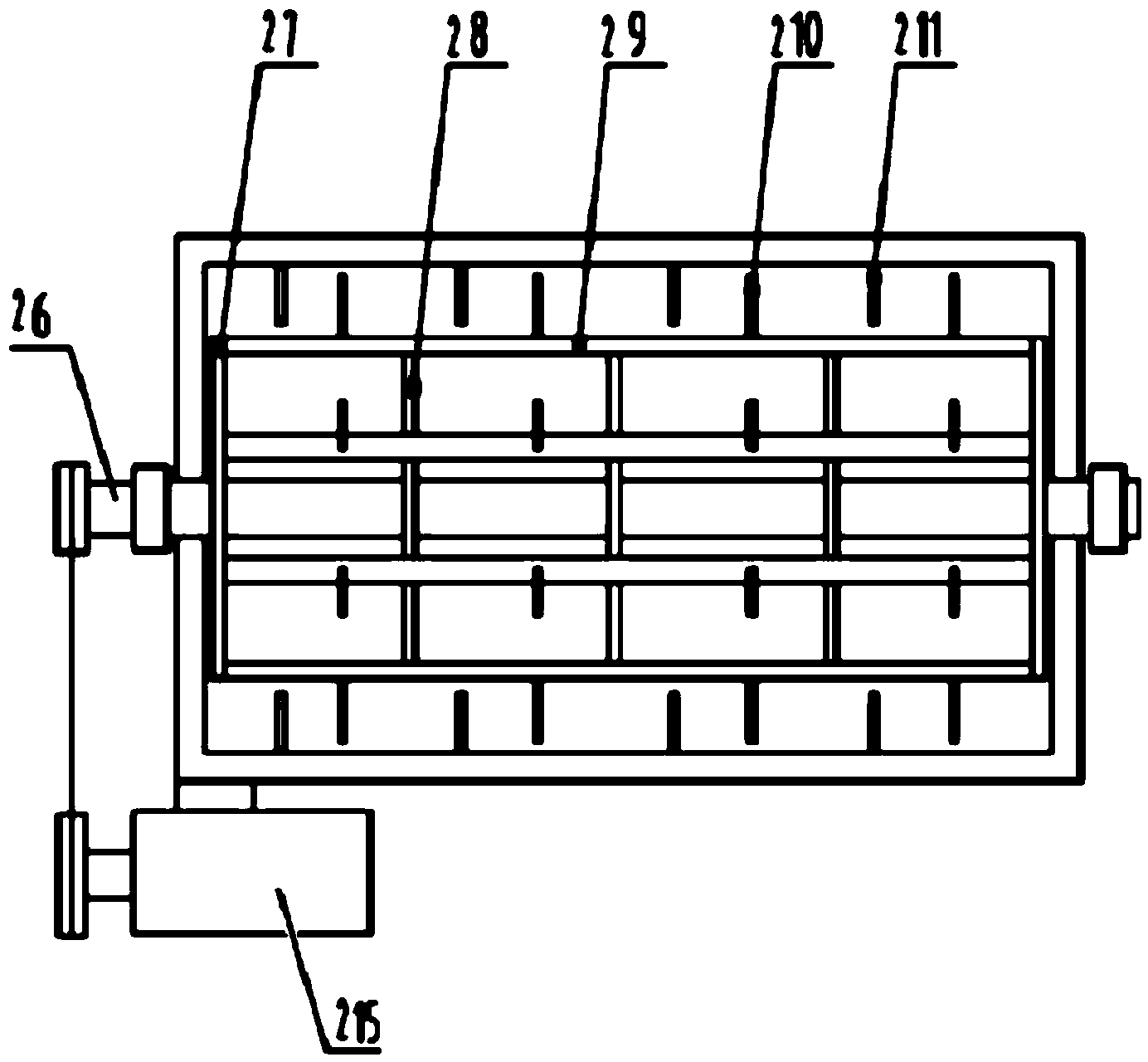

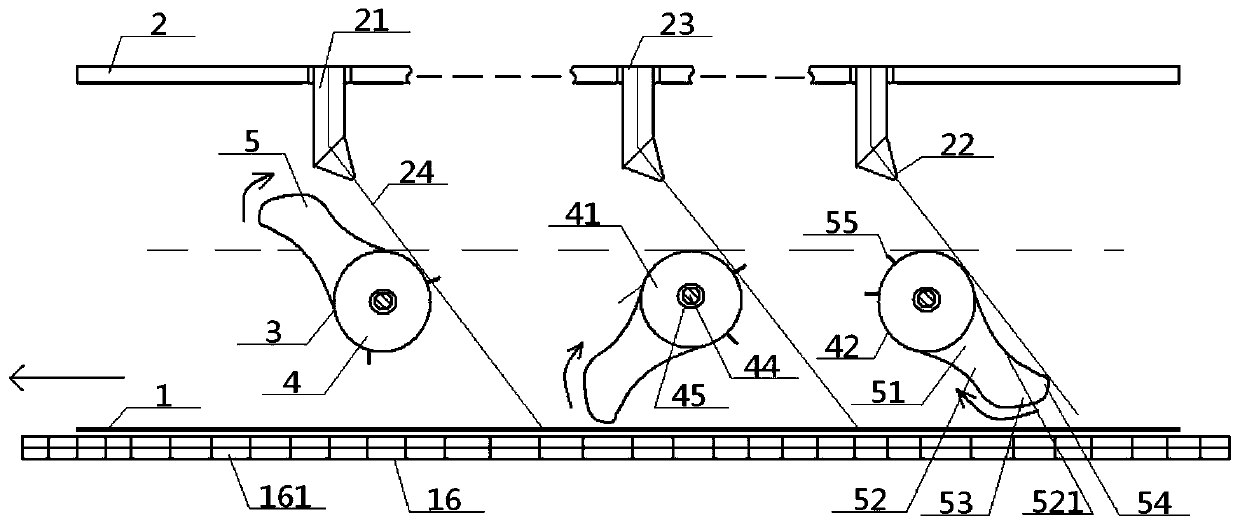

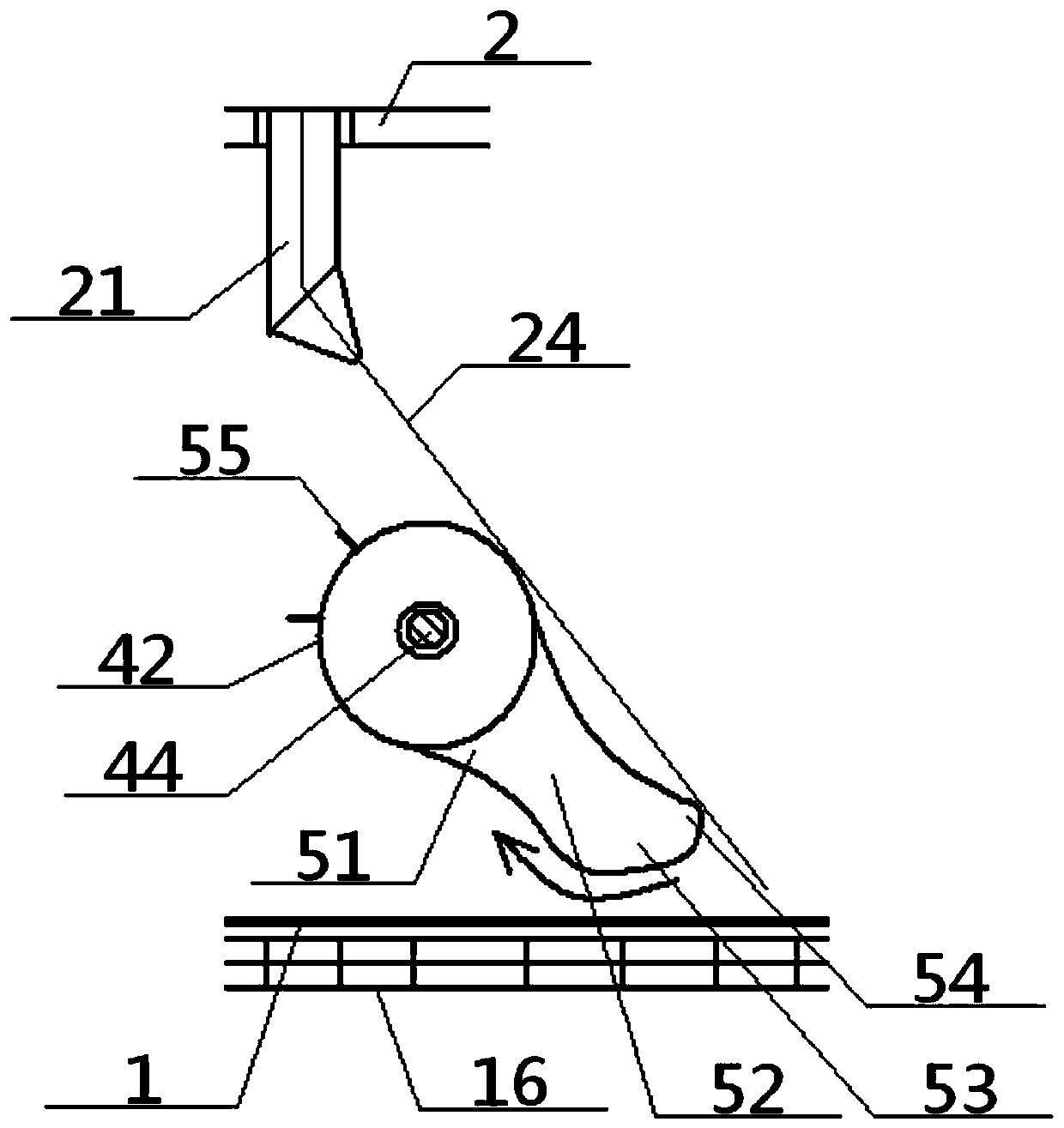

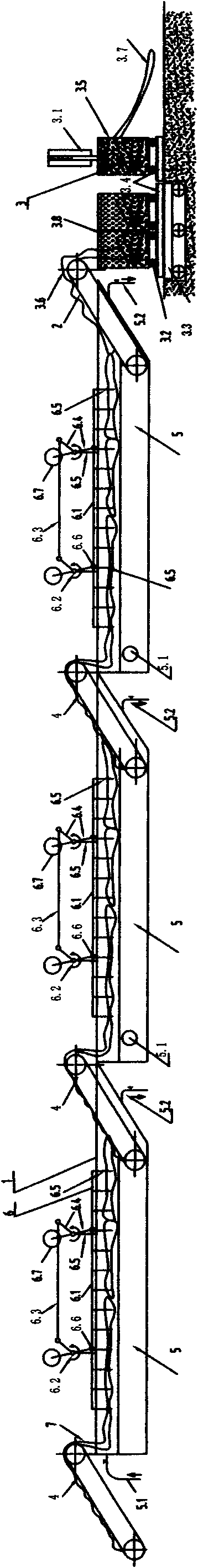

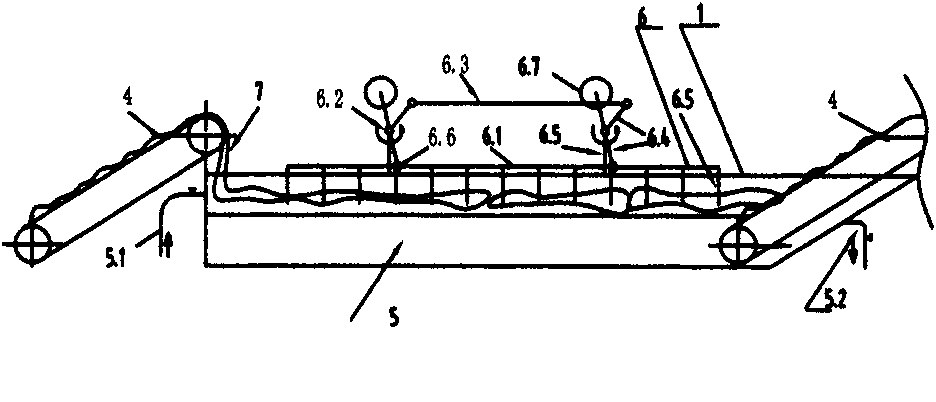

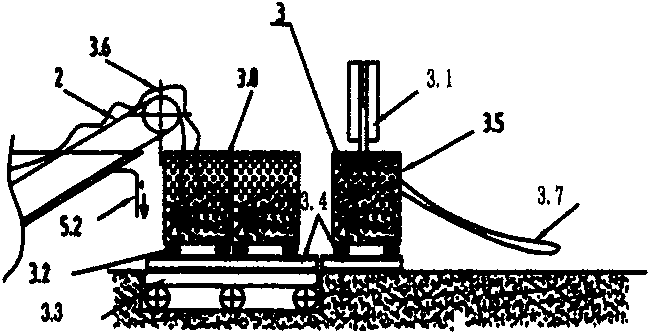

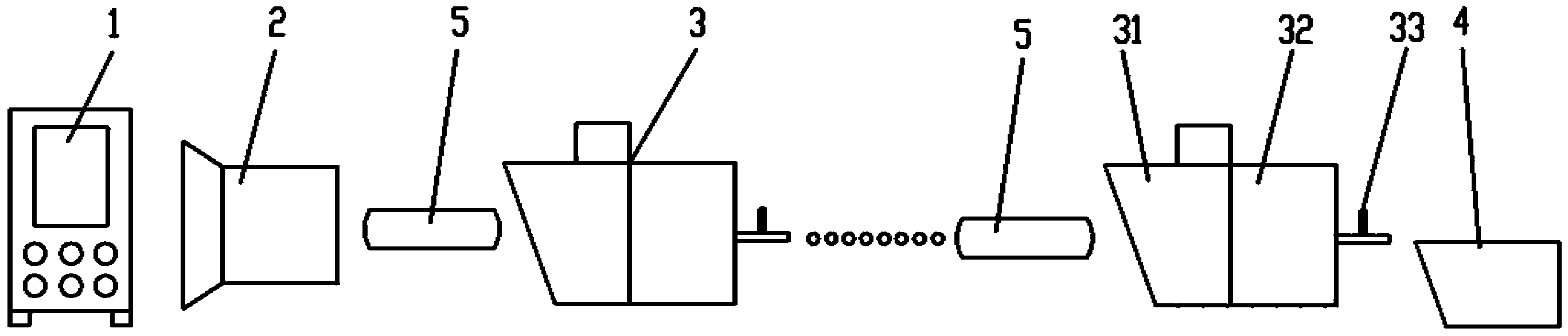

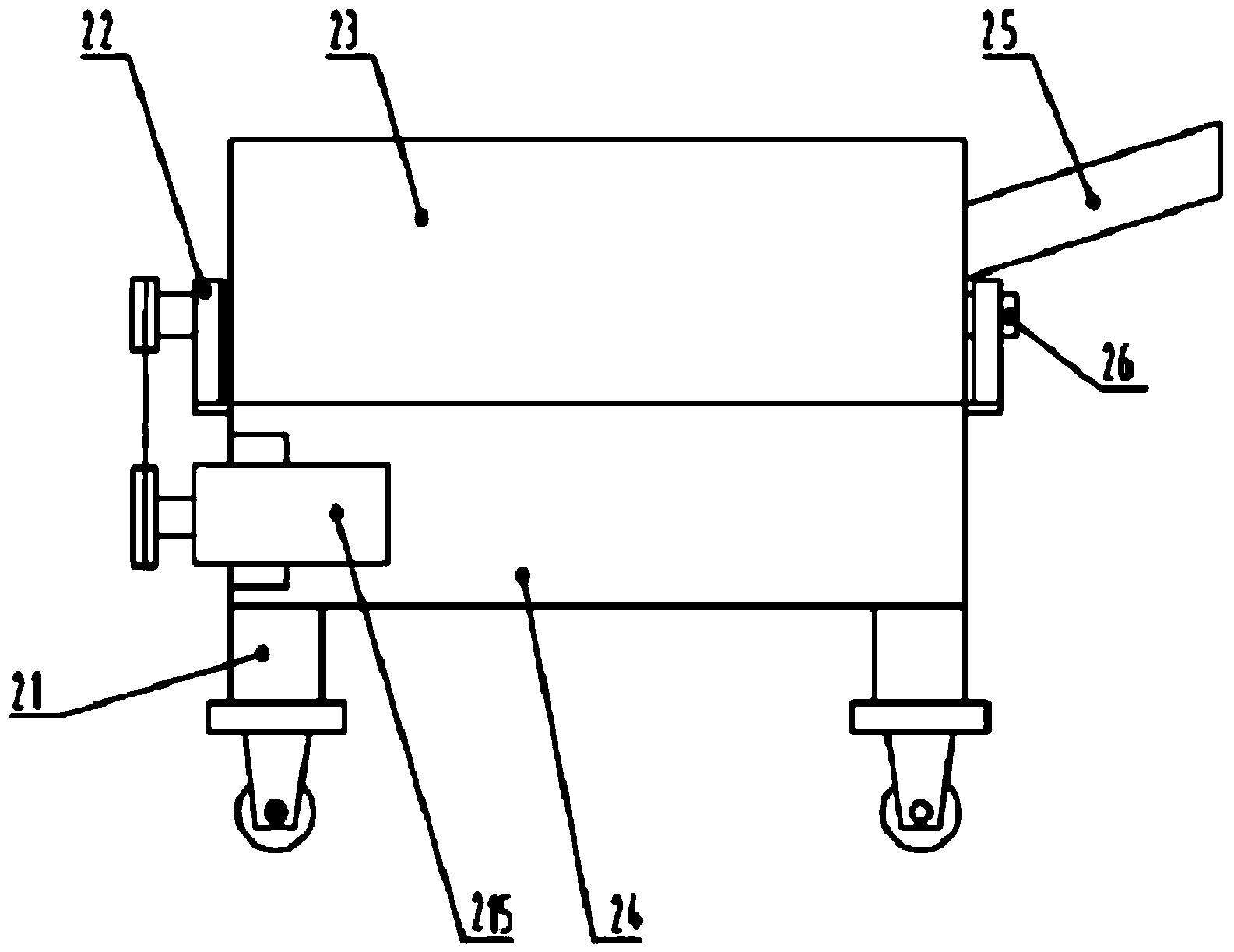

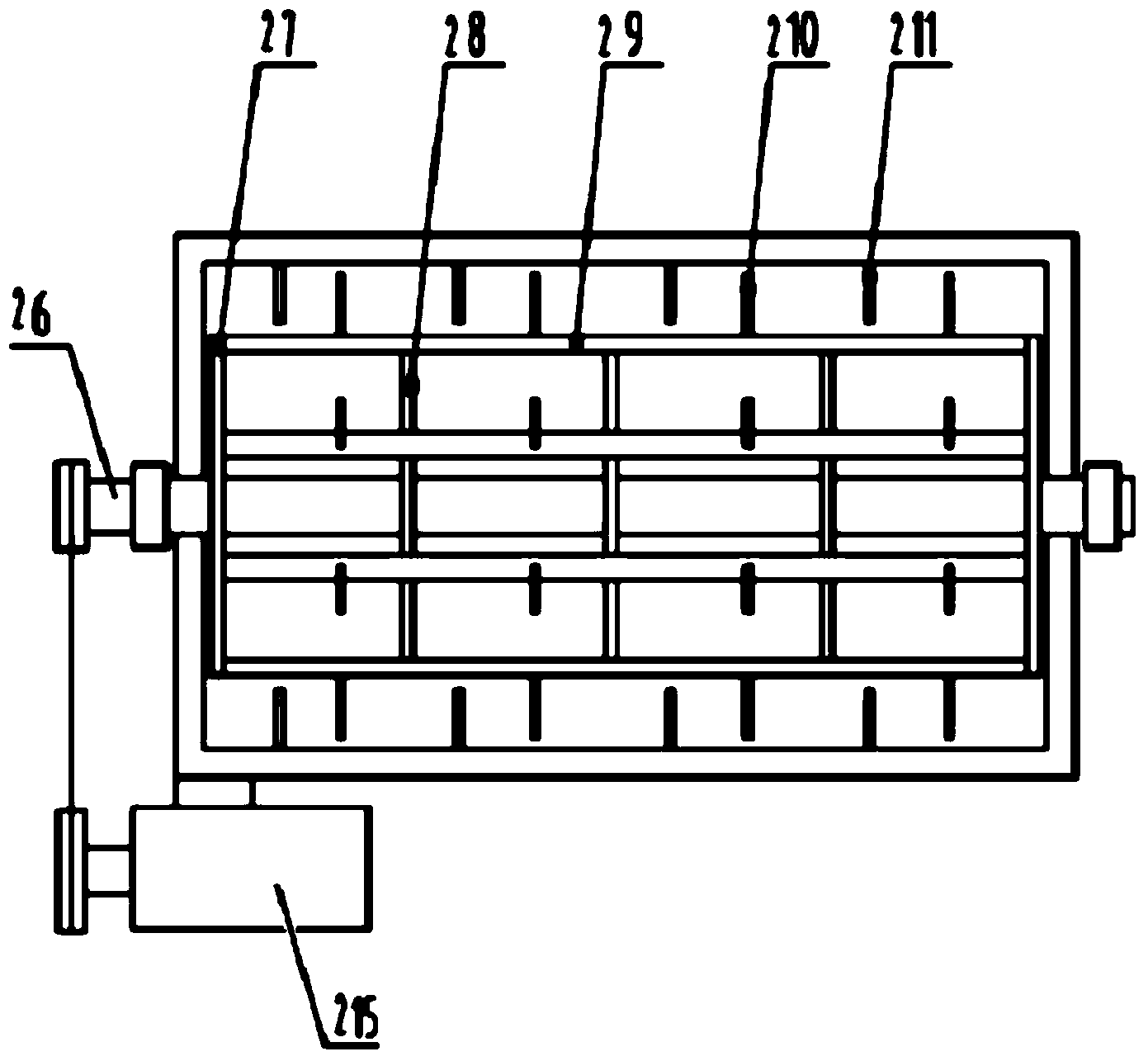

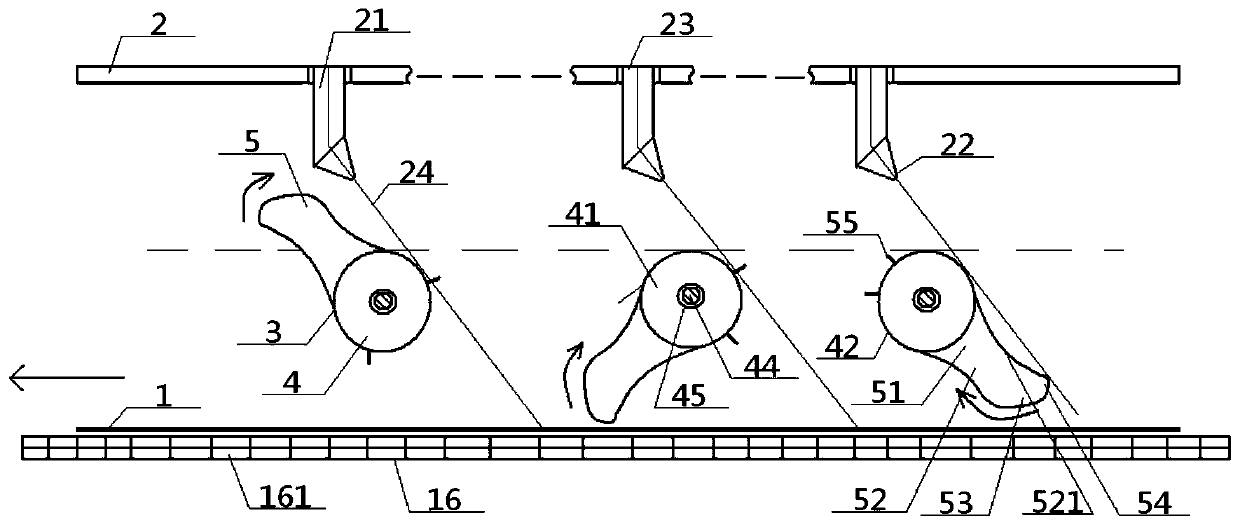

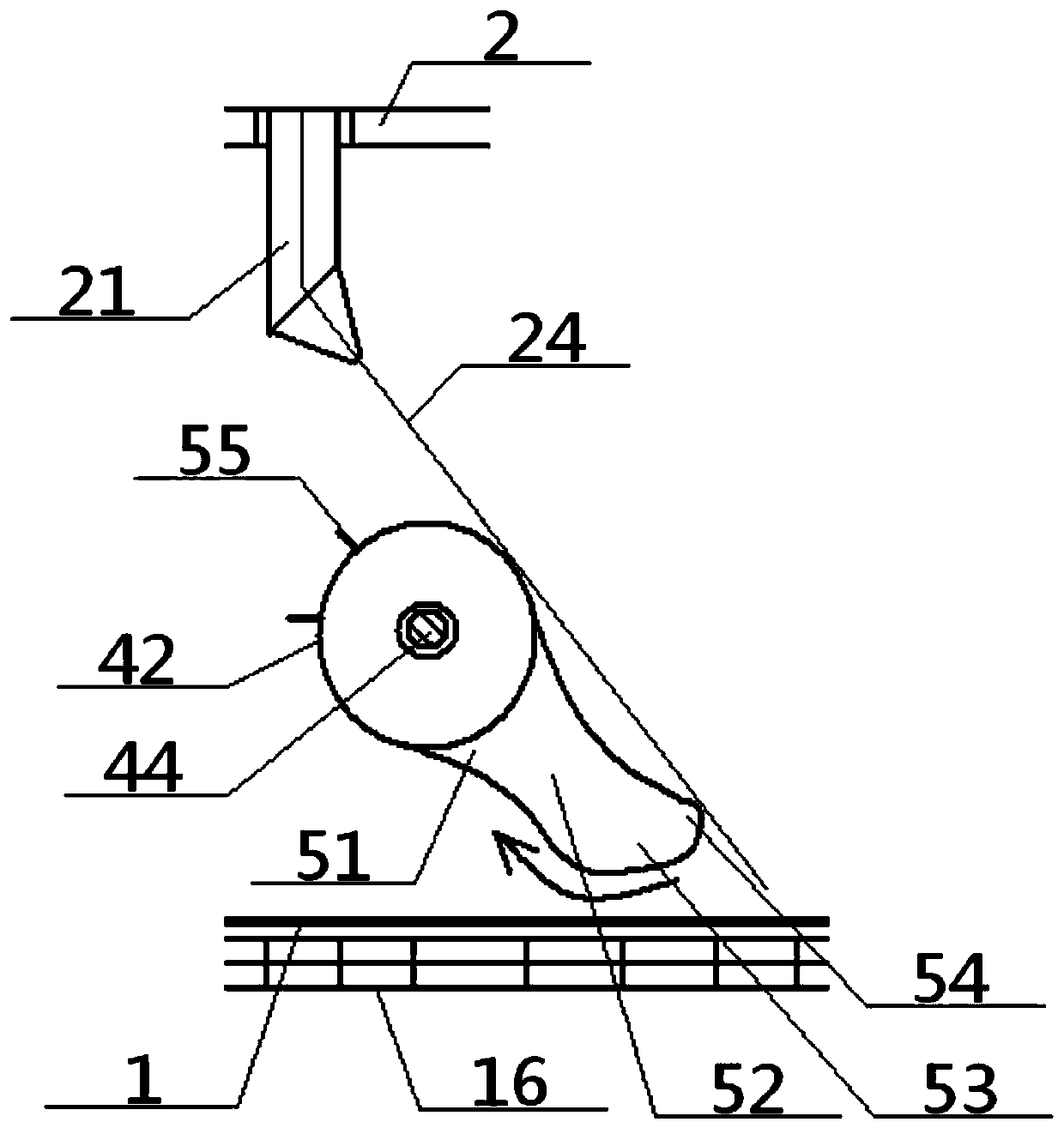

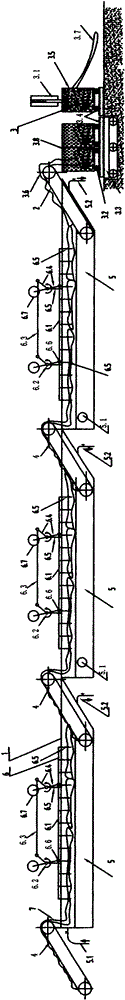

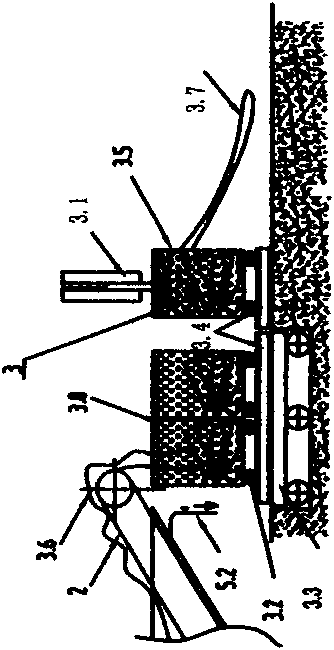

Cashmere opening and carding line production system and process thereof

ActiveCN103451781AImprove carding efficiencyImprove carding qualityContinuous processingFibre feedersAutomatic controlMoisture regain

The invention discloses a cashmere opening and carding line production system, which structurally comprises an industrial control computer, an opener and 8-16 carding machines sequentially, wherein the 8-16 carding machines are connected end to end and are arrayed in sequence, and the industrial control computer is used for monitoring the operation states of the opener and the carding machines in real time and performing automatic control; according to the line production sequence, each carding machine comprises a cashmere feeding mechanism used for conveying and feeding cashmere to a carding host, the carding host used for carrying out carding operation, and a moisture regain mechanism used for carrying out water spray moisture regain operation on carded cashmere sequentially. According to the cashmere opening and carding line production system and the process thereof, when opened and mixed cashmere enters each carding machine sequentially by virtue of conveying flat belts, the arrangement sequence of the carding machines are strictly controlled so as to ensure that the Xth carding machine is always used for carrying out the Xth carding operation, and the opening and carding operation can be efficiently finished. The feed quantity, the carding speed and the moisture regain rate of the carding machines can be automatically adjusted according to different properties of raw materials, and accordingly, the carding efficiency and quality of the cashmere can be improved.

Owner:HONGYE CASHMERE

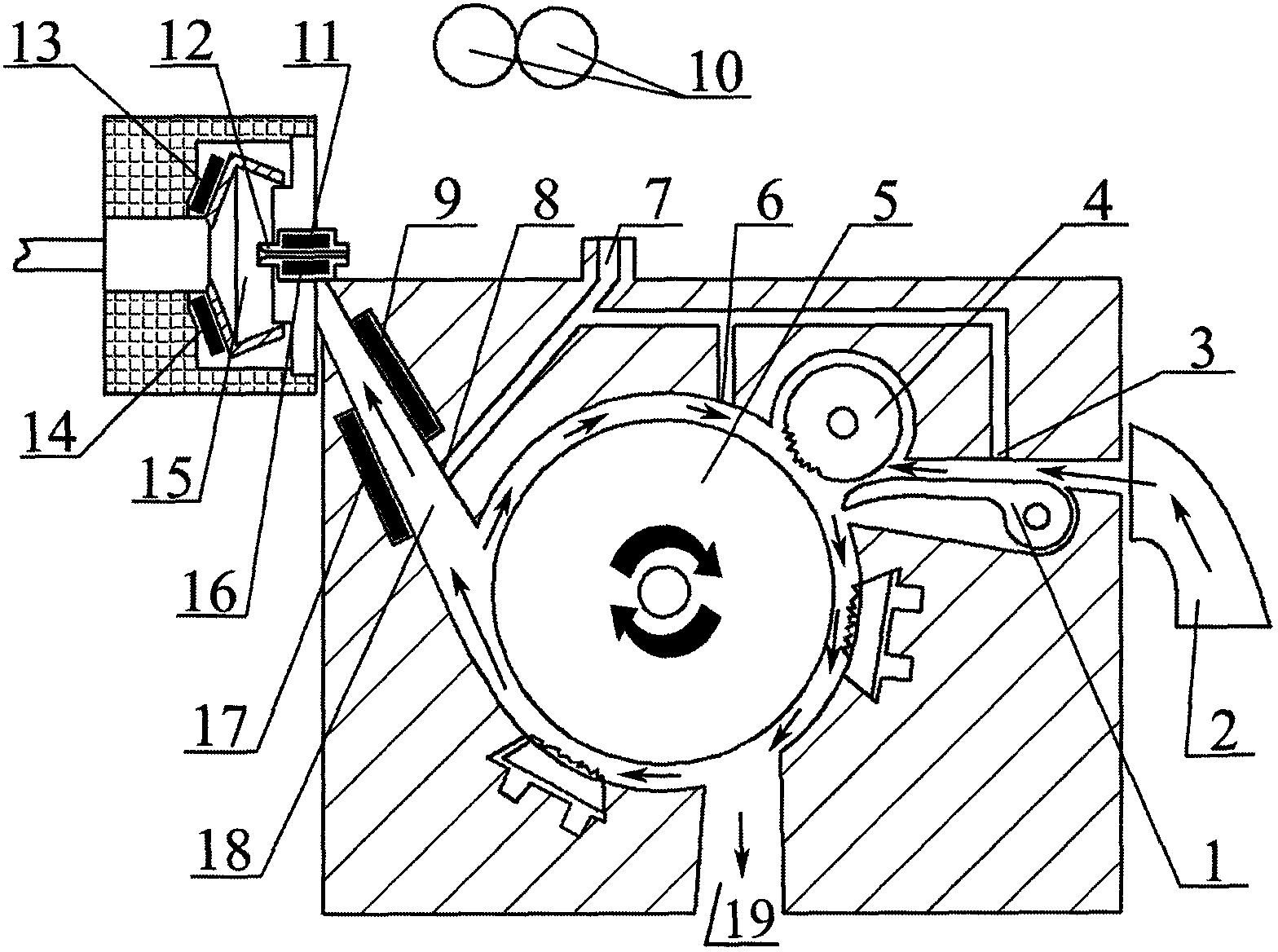

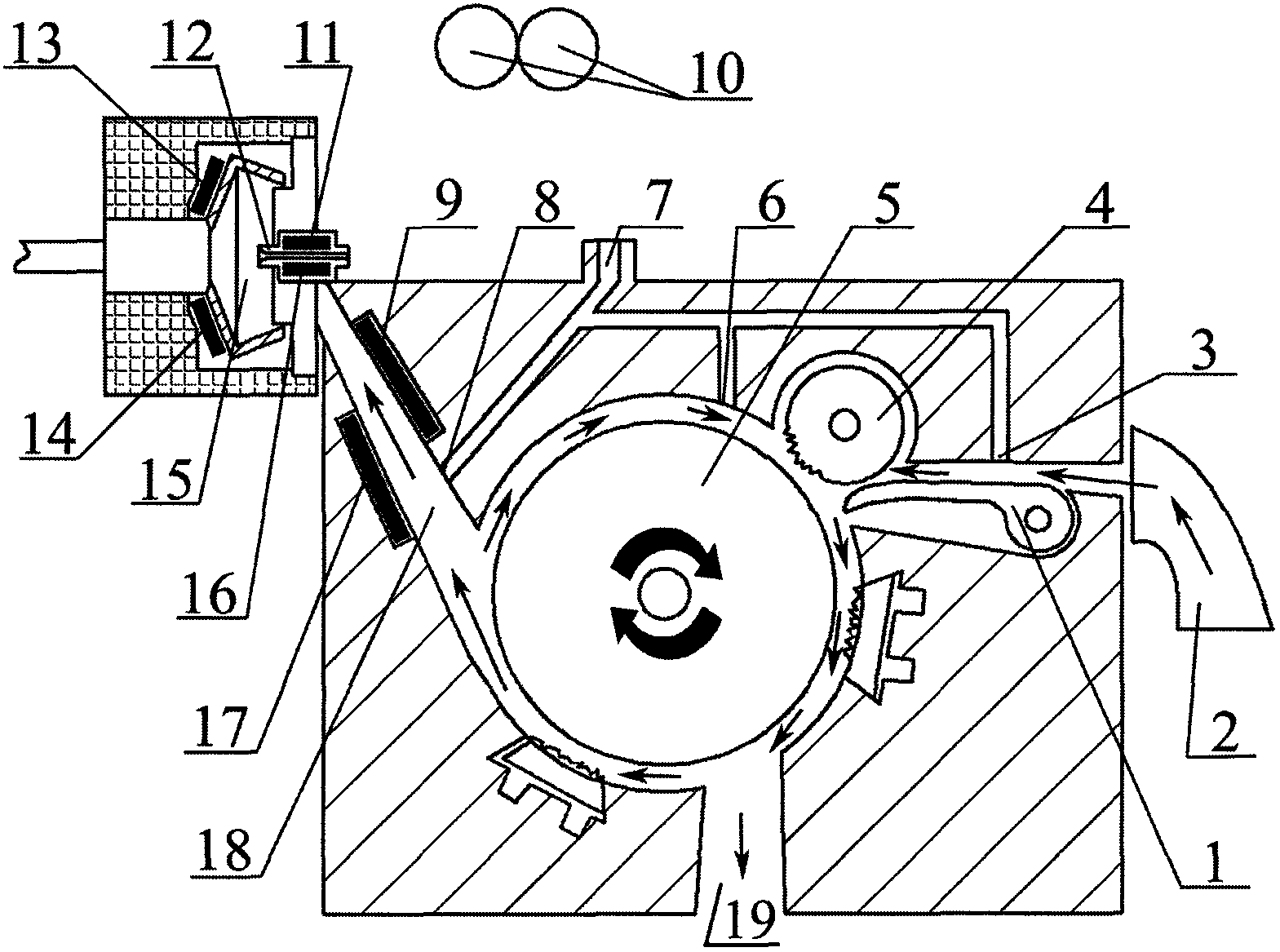

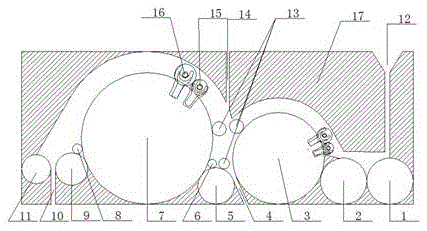

Novel multi-layer transfer carding machine

InactiveCN105568438AImprove carding qualityImprove combing effectCarding machinesMaster cylinderTextile

The invention relates to the technical field of spinning of textiles, in particular to a novel multi-layer transfer carding machine. The novel multi-layer transfer carding machine comprises a cotton feeding roller, a taker-in roller, a breast cylinder, a second cotton outlet, a doffer, a master cylinder, a master doffer, a third cotton outlet, a condensing roller, a cotton feeding opening, a first cotton outlet, stripping rollers, working rollers and a case body; the cotton feeding roller, the taker-in roller, the breast cylinder, the second cotton outlet, the doffer, the master cylinder, the master doffer, the third cotton outlet and the condensing roller are sequentially arranged at the bottom inside the case body from right to left; the cotton feeding opening is formed above the cotton feeding roller, the breast cylinder and the master cylinder are each provided with one stripping roller and one working roller, and the first cotton outlet is formed above the portion between the breast cylinder and the master cylinder. By means of the novel multi-layer transfer carding machine, carding of a three-layer veil can be achieved, and a better carding effect can be achieved.

Owner:广西玉林市汉龙环保科技有限公司

Toothed cloth for a comb piece of a combing machine

InactiveCN102002775AImprove efficiencyIncrease combing speedDrafting machinesCombing machinesEngineeringErbium lasers

The invention relates to a toothed cloth for a comb piece of a combing machine, comprising a large amount of teeth arranged in parallel and forming at least one tooth row that is oriented transverse to a working direction of the teeth. The teeth row comprises more than 35 teeth per cm when viewed transverse to the working direction. Preferably, the teeth of the tooth row are integrated, wherein the teeth space between two adjacent teeth extending along the working direction is formed in aid of a laser.

Owner:GROB & CO AG

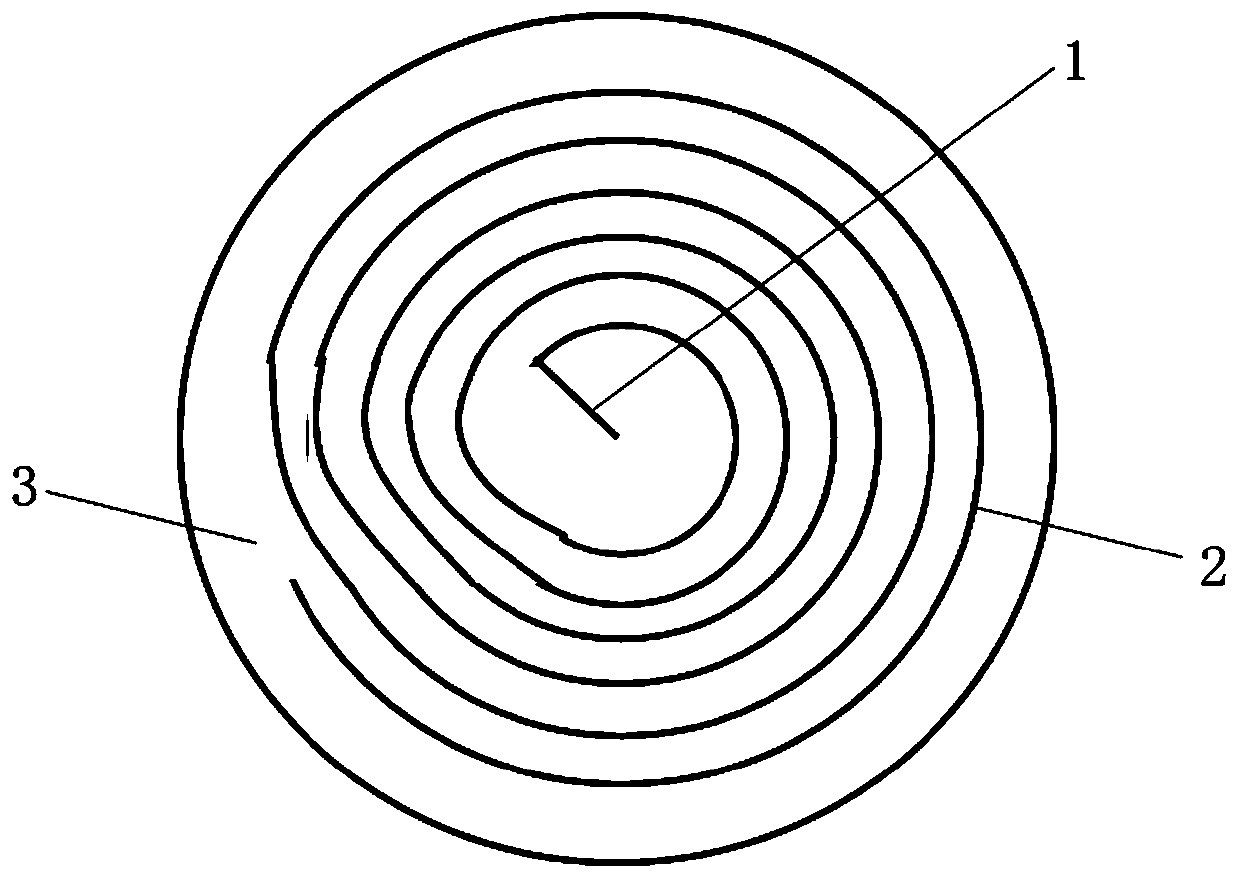

Nonuniform-tooth density carding cloth

InactiveCN104805541AEvenly distributedHomogeneous densification of the wires enables full distributionCarding machinesCardingFiber bundle

The application of the invention provides a nonuniform-tooth density carding cloth. The technical characteristic of the nonuniform-tooth density carding cloth is that the horizontal intertooth spaces of carding cloth teeth are arranged at unequal distances. The technical scheme can fully take the carding of fiber bundles and fiber polymers with random sizes, forms and distributions into consideration, ensures that each tooth and adjacent teeth can sufficiently play a carding role, and overcomes the technical problem that the carding effect of a uniform-tooth space random sizes, forms and distributions and uniform-tooth density carding cloth on the nonuniform fiber flow of fiber bundles with random sizes, forms and distributions is limited, the carding quality is improved, and conditions for the increase of carding output are created.

Owner:孙鹏子

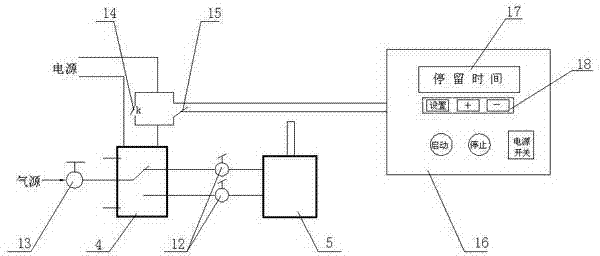

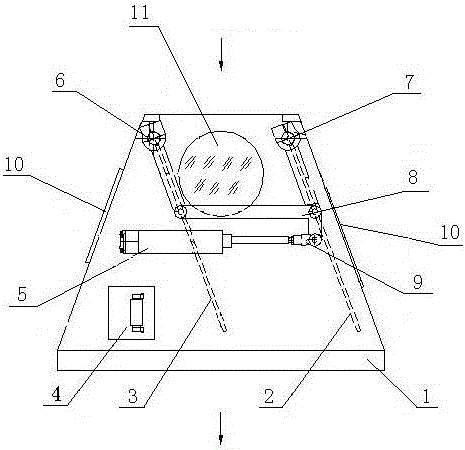

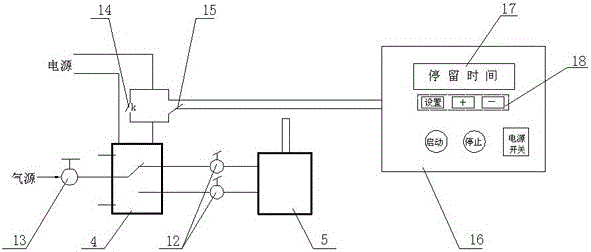

Device for evenly distributing cotton

ActiveCN104746185AContinuous and even cotton supplyImprove carding qualityFibre mixingFibre feedersEngineeringControl valves

The invention provides a device for evenly distributing cotton. The device for evenly distributing the cotton is characterized by being arranged inside a pipeline at a raw material inlet of a cotton storage bin. The device for evenly distributing the cotton is provided with a first rocking plate and a second rocking plate, a first shaft sleeve and a second shaft sleeve are arranged in the width direction of the top of the device for evenly distributing the cotton, and one end of the first rocking plate and one end of the second rocking plate are movably connected with the first shaft sleeve and the second shaft sleeve respectively. The two ends of a connecting rod are fixed to the middle of the first rocking plate and the middle of the second rocking late respectively, an air cylinder is fixed to one side, in the width direction, of the device for evenly distributing the cotton, a piston rod of the air cylinder is in parallel with the width direction of the device for evenly distributing the cotton, the top end of the piston rod is hinged to one end of the connecting rod, an air inlet and outlet port of the air cylinder is connected with a control valve, the air inlet end of the control valve is connected with an air source, and the electric appliance control end of the control valve is connected with a controller. Stretching and retracting of the piston rod of the air cylinder are used for controlling the rocking plates to swing back and forth, the rocking plates poke the raw materials to be distributed in the transverse direction, and therefore the raw materials are evenly distributed in the transverse direction inside the cotton storage bin.

Owner:QINGDAO HONGDA TEXTILE MACHINERY

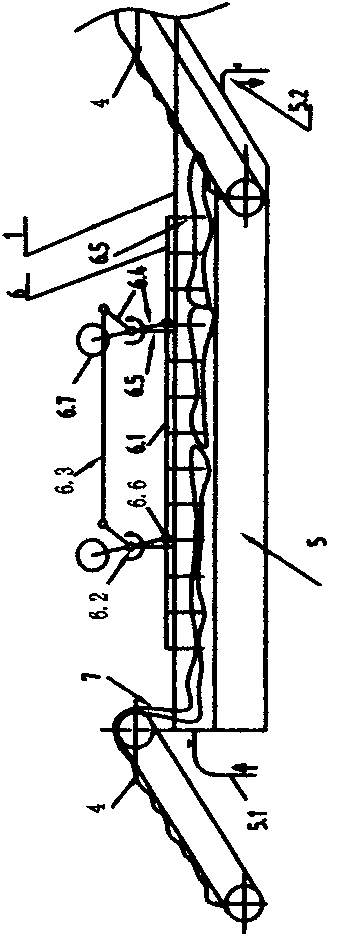

Roll type undaria pinnatifida stem combing equipment

ActiveCN104146291AImprove processing efficiencyImprove carding qualityFood shapingFood preparationFiberRoller chain

The invention relates to roll type undaria pinnatifida stem combing equipment which comprises a needle plate movement device and a combing main body device, and is characterized in that the needle plate movement device comprises a needle plate motor, a coupler, a lead screw, a guide rod device, a needle plate seat and a needle plate; the combing main body device comprises an undaria pinnatifida roll, an undaria pinnatifida roll shaft, a roller chain, a chain wheel, an undaria pinnatifida stem clamping device, an undaria pinnatifida stem clamping device fixing device, a support, a coder, a tensioning wheel, a bracket, a motor installing seat and a motor. According to the roll type undaria pinnatifida stem combing equipment, undaria pinnatifida stems are combed through the needle plate along the fiber direction of the undaria pinnatifida stems. The roll type undaria pinnatifida stem combing equipment is simple in structure and easy to operate, the angle and position of the needle plate is adjustable, the technical level of operating personnel is not required, the damage of the existing shredding machine to the undaria pinnatifida stems can be overcome, the processing efficiency of the undaria pinnatifida stems is high, the labor intensity can be reduced, the production cost can be lowered, and the combing quality of the undaria pinnatifida stems can be improved.

Owner:烟台宋和宋智能科技股份有限公司

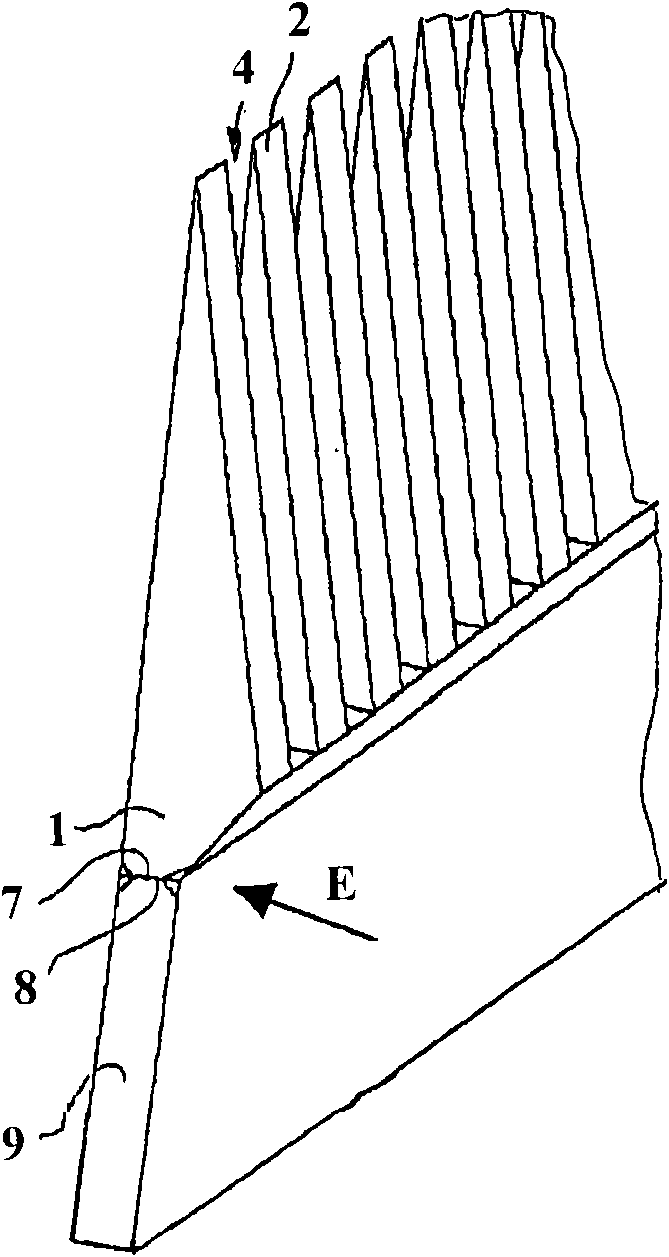

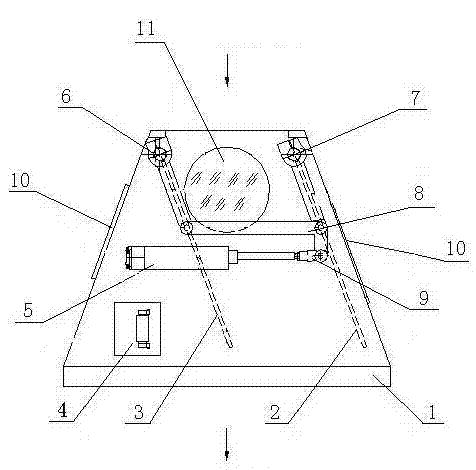

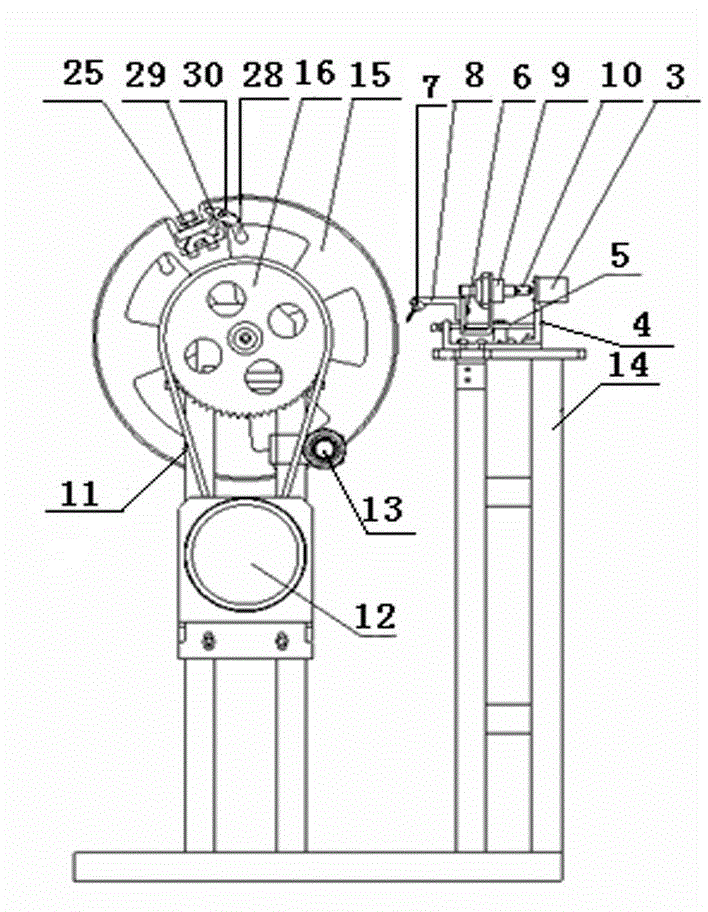

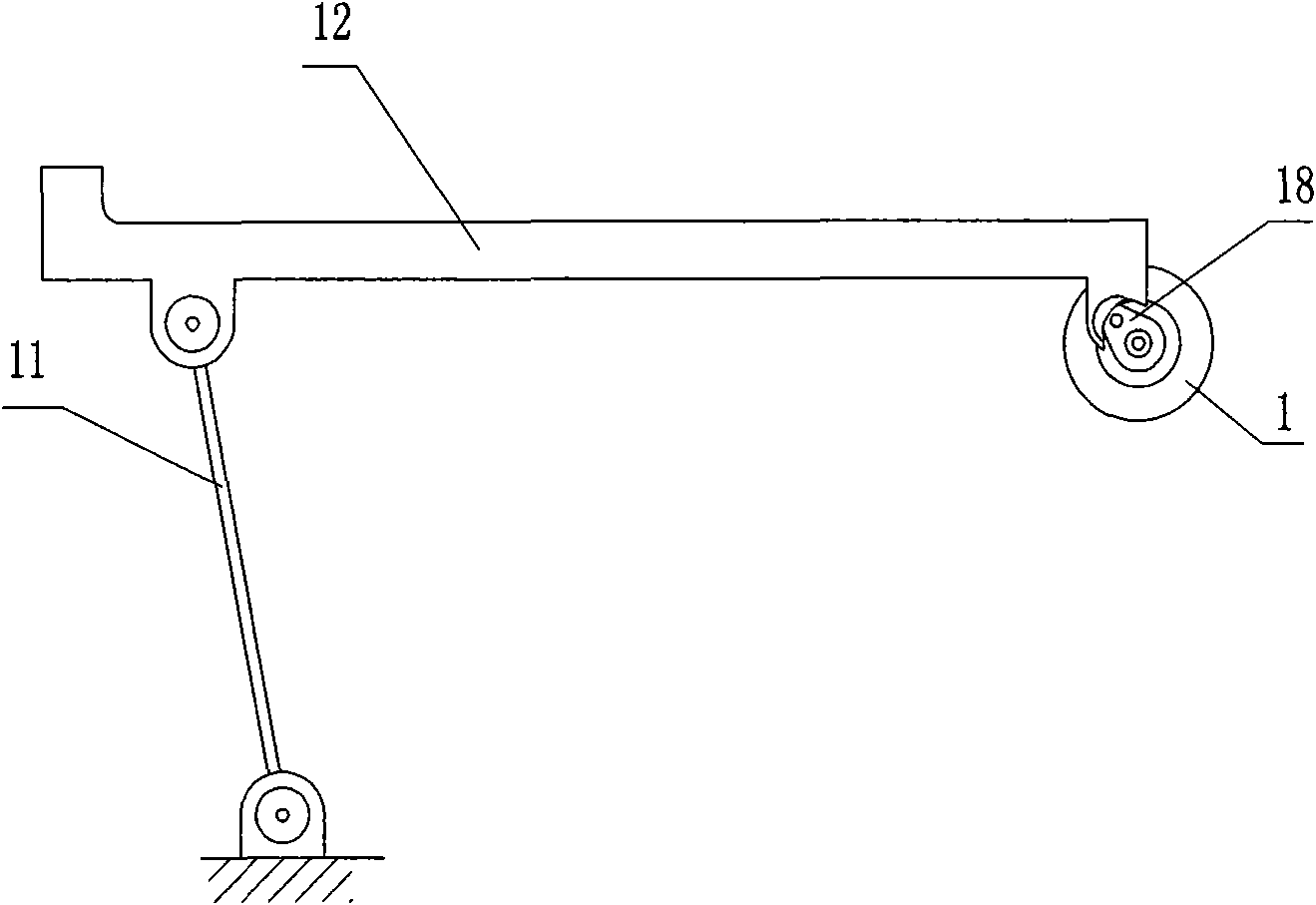

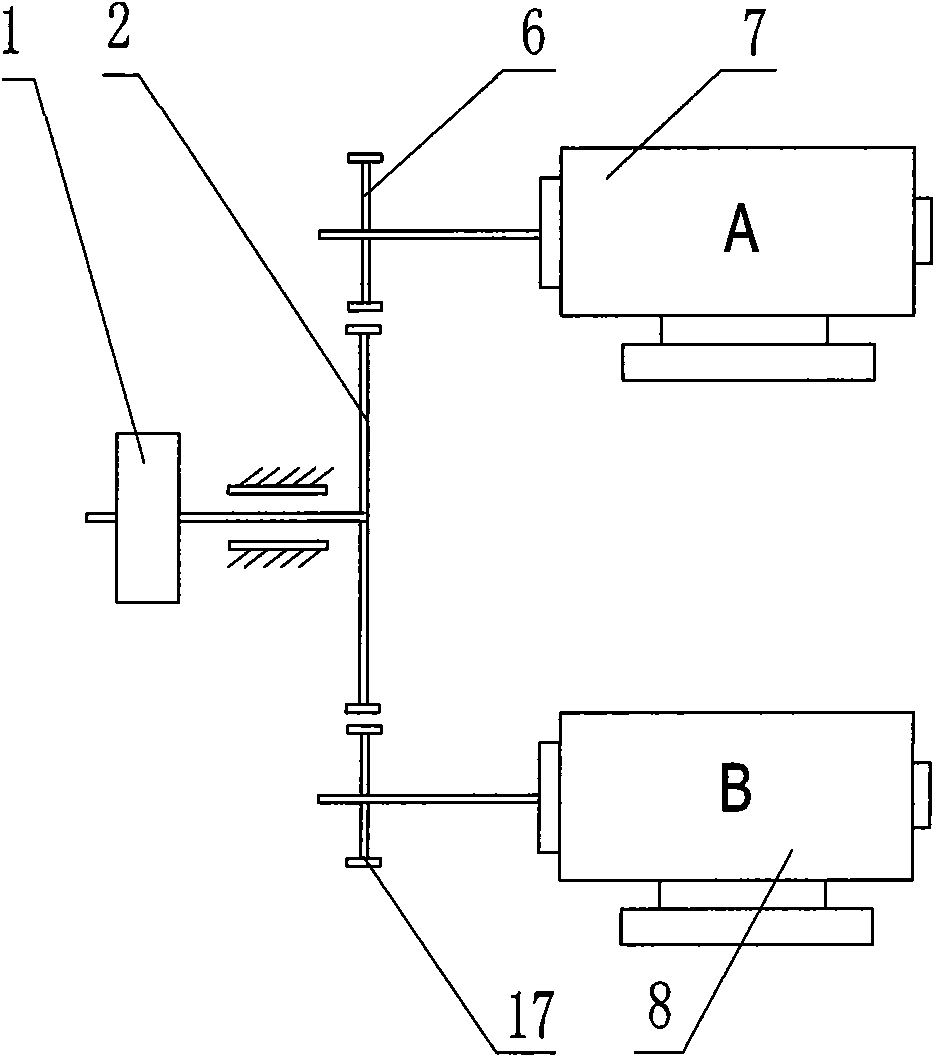

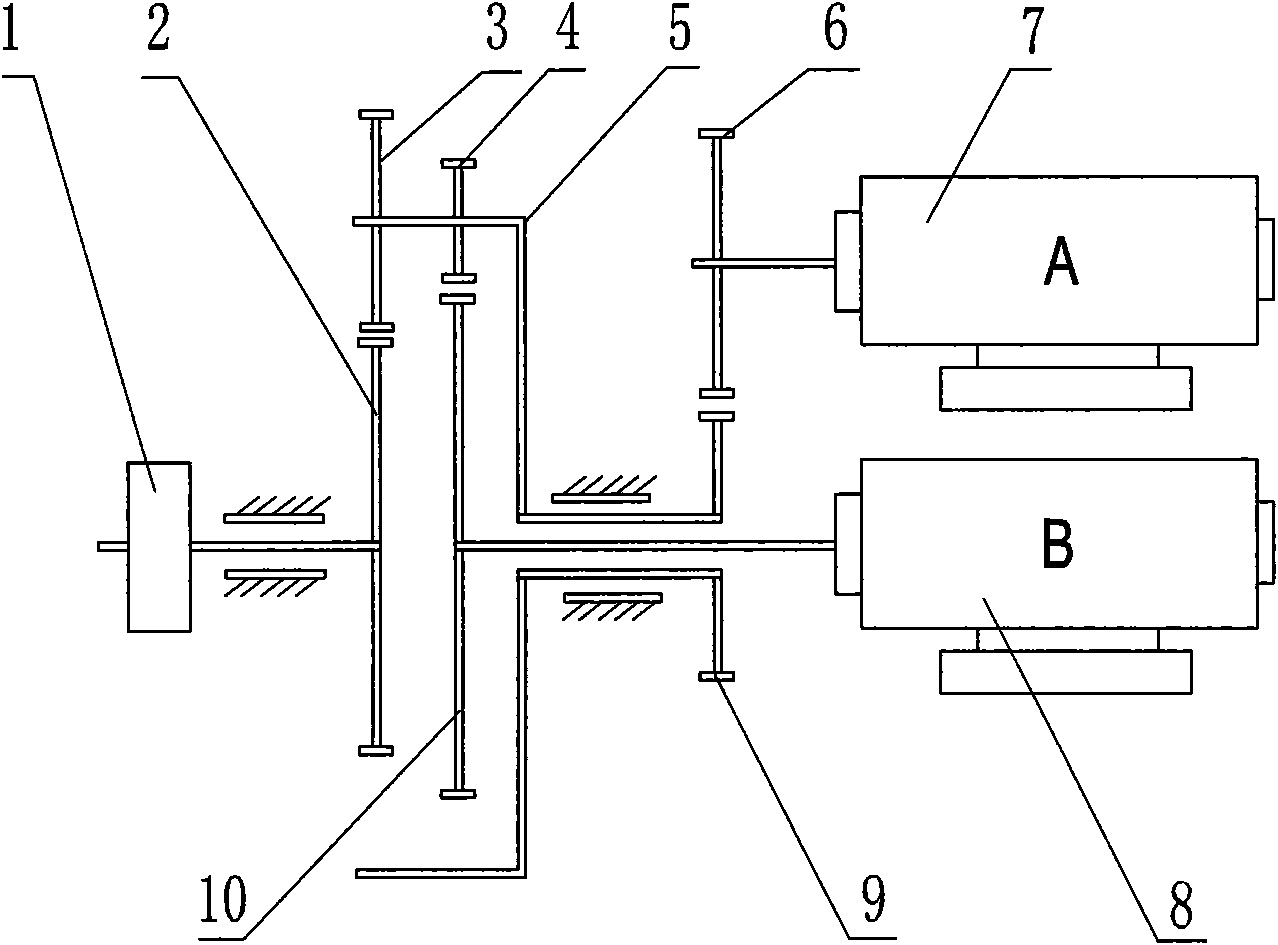

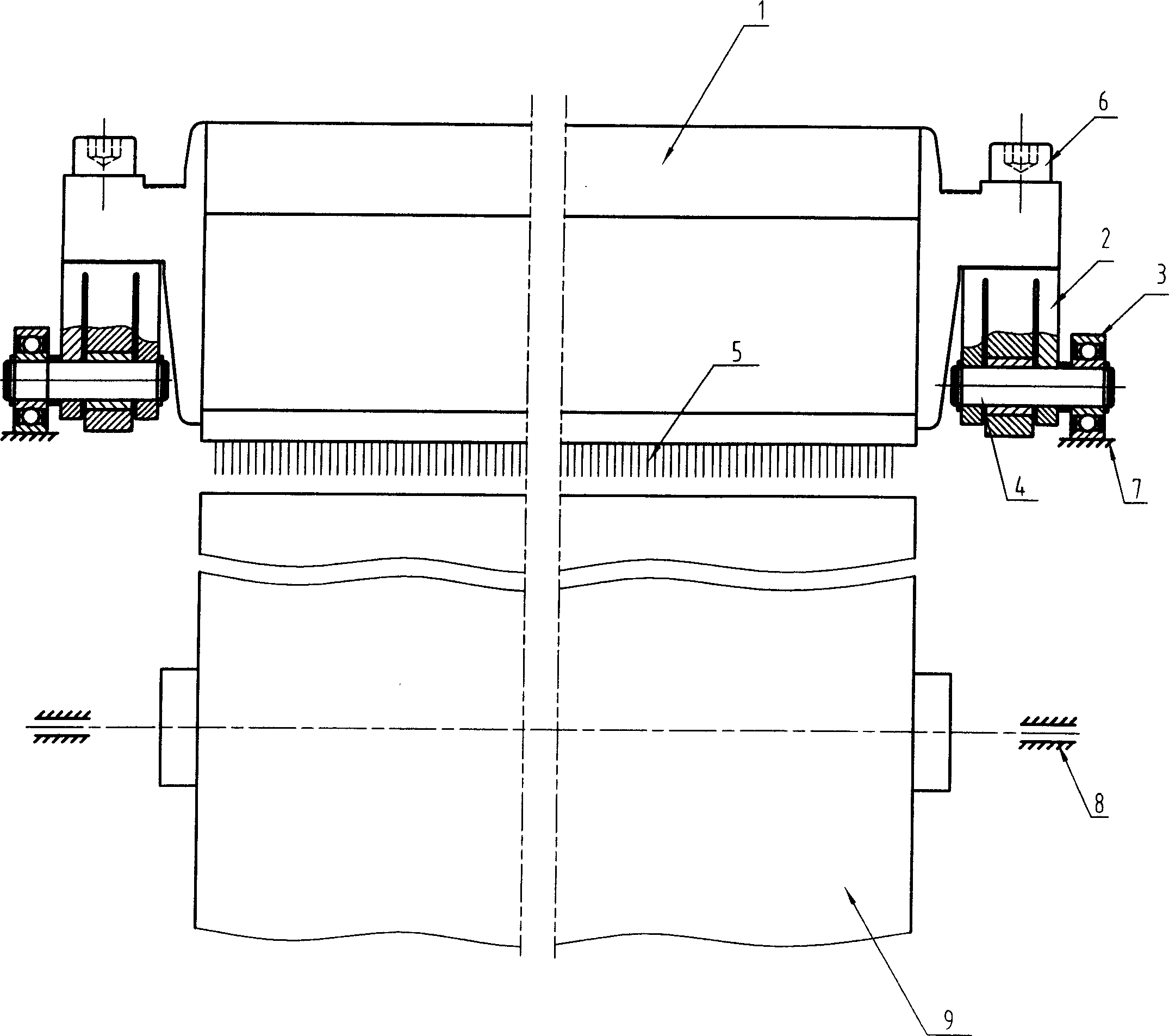

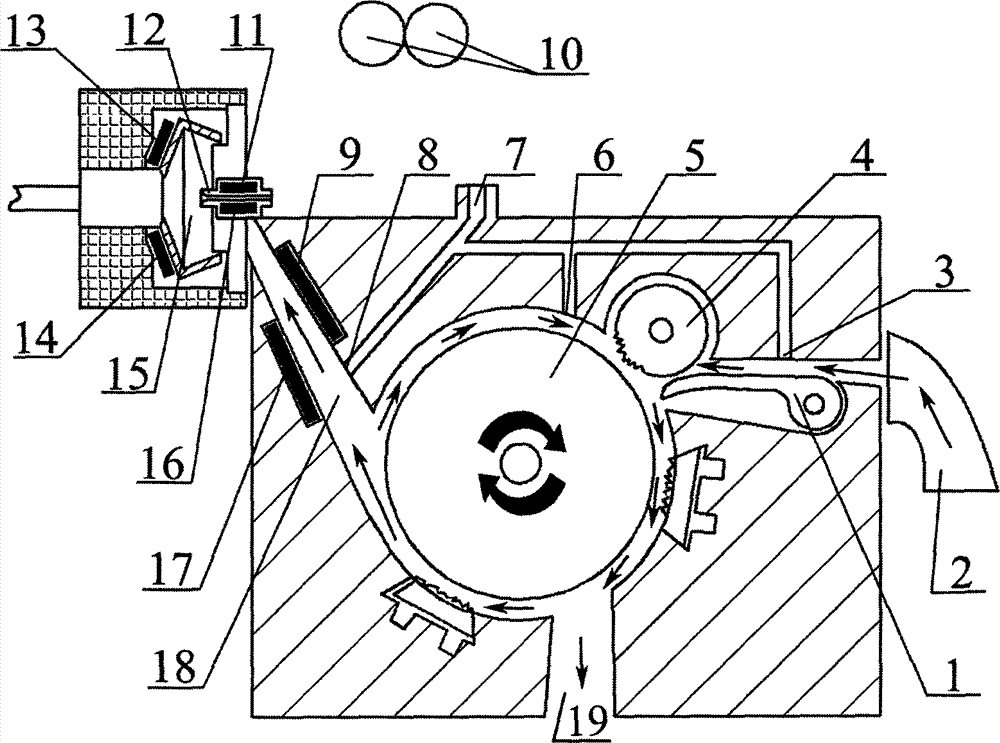

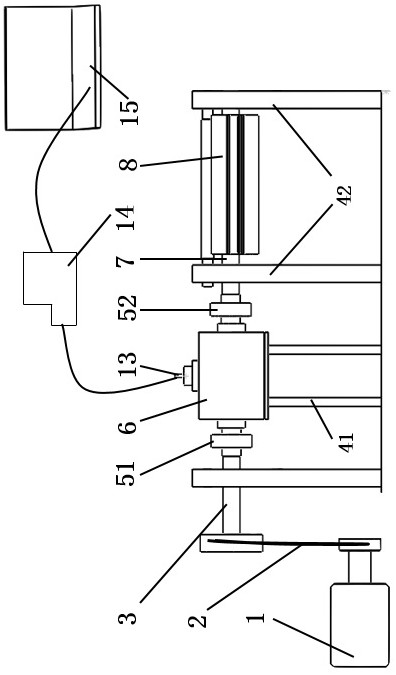

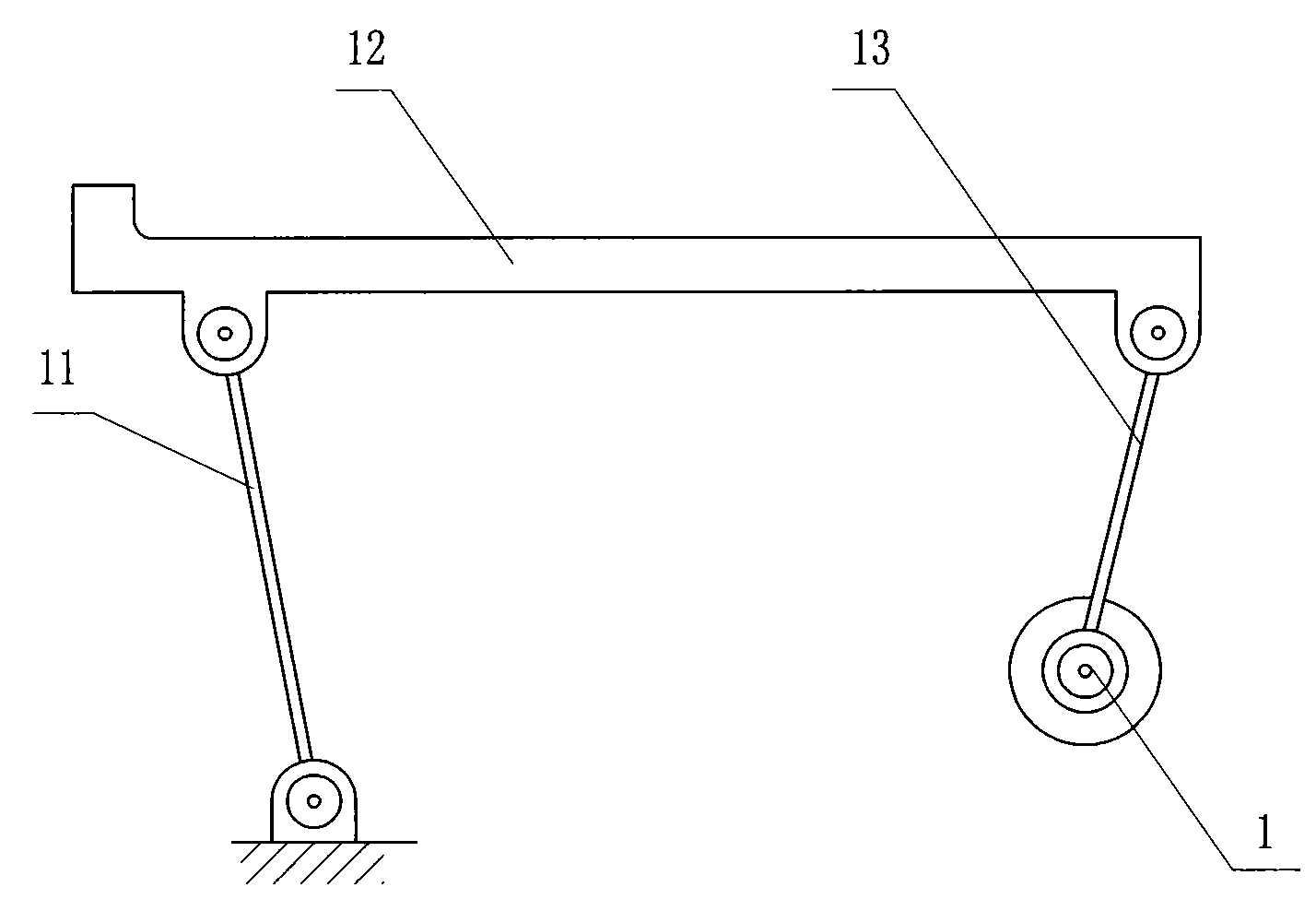

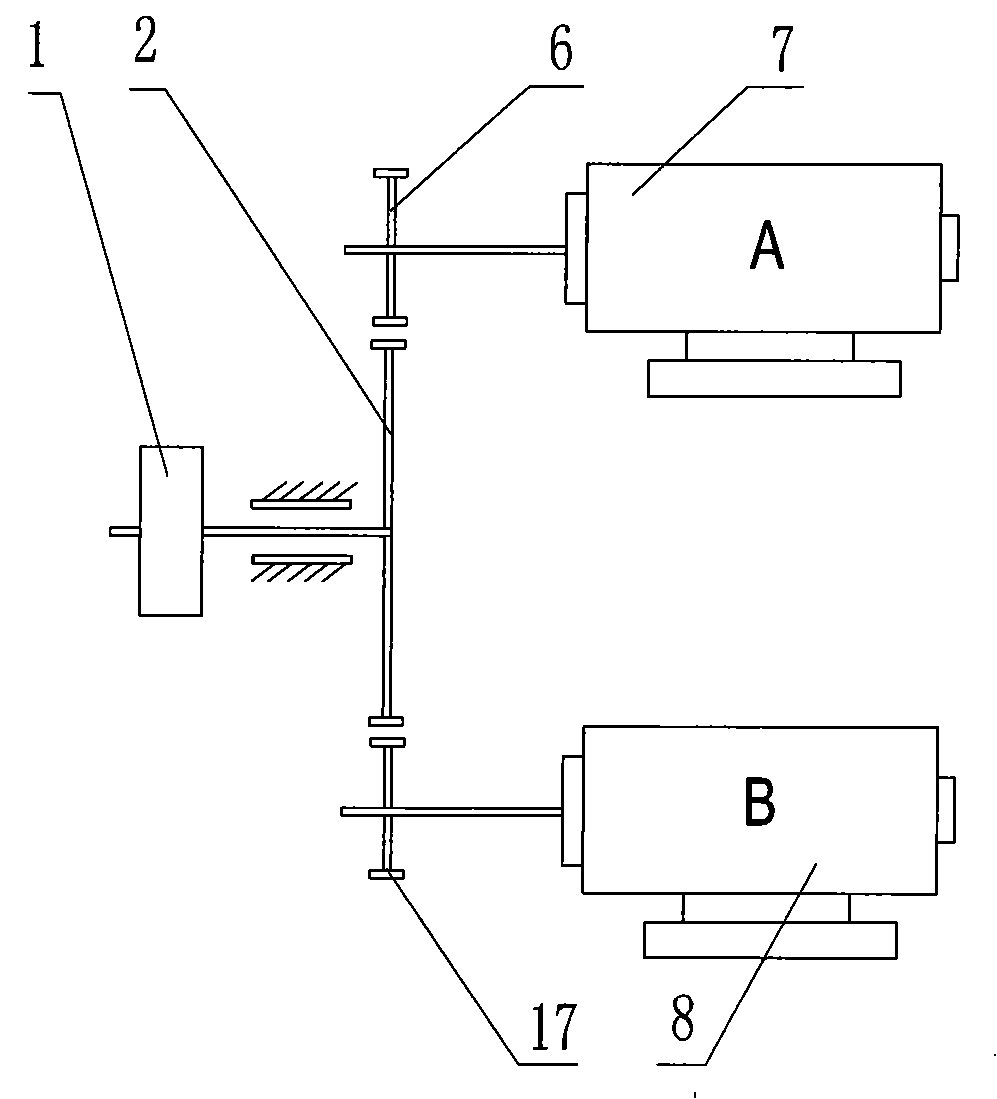

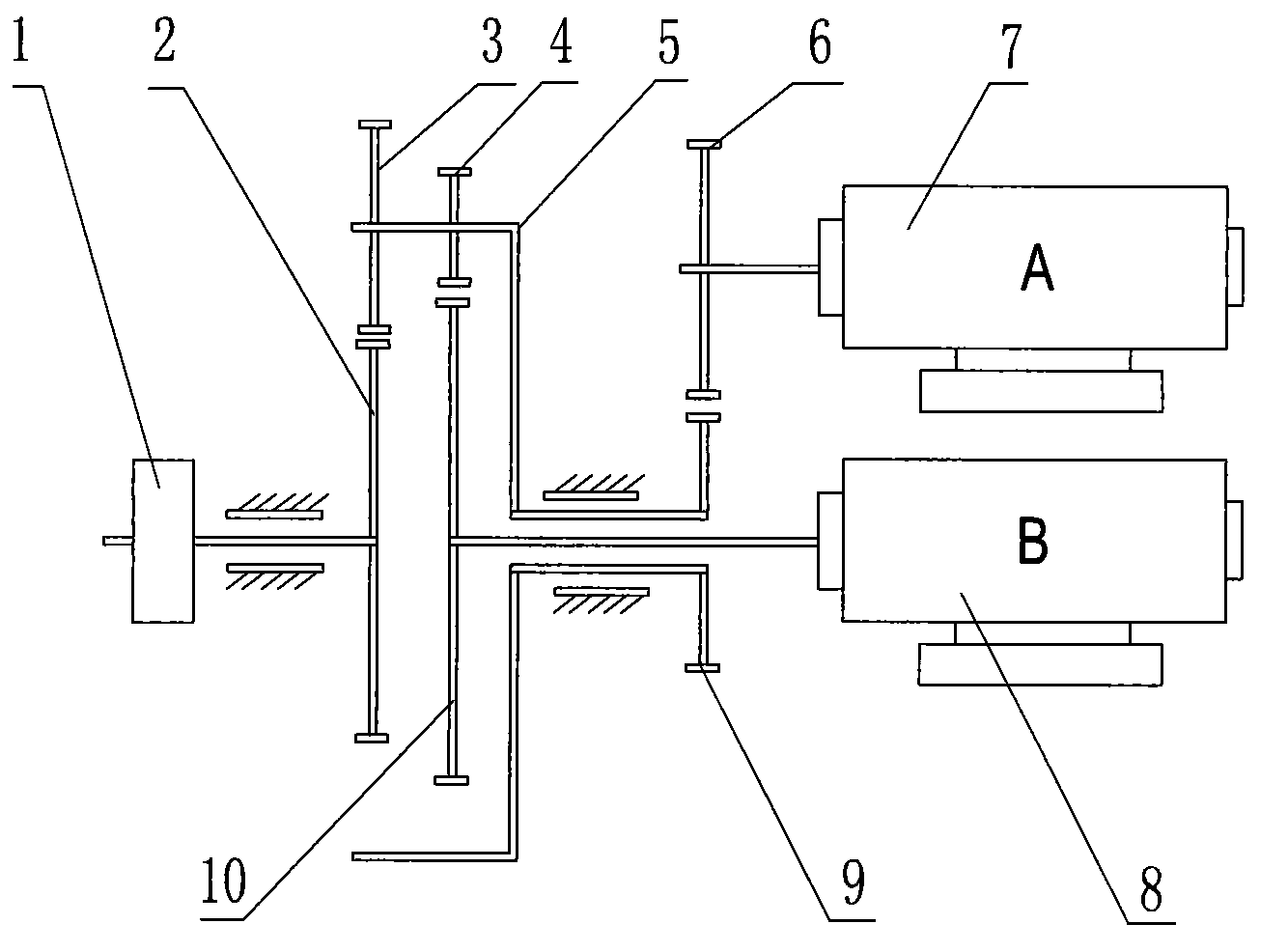

Transmission structure of nipper of comber

InactiveCN101654816ASatisfy exercise power needsEasy to driveCombing machinesElectric machineryControl theory

The invention relates to a power transmission mode and a structure of a nipper of a comber. In the transmission structure of the nipper of the comber, a pivot of the nipper (12) is rotatablely connected with a support bar (11) which is positioned on the lower part and is rotatablely connected with a base. A rotating wheel (1) of a servo motor mechanism is connected with the other pivot of the nipper (12) by an eccentric wheel (18) in an eccentrically rotating manner. A servo motor A (7) of two servo motors is meshed with a planetary carrier gear (9) of a planetary gear by a gear (6) of the servo motor A, and the other servo motor B (8) is meshed with a rear planetary gear (4) by a central gear (10) of the planetary gear. A front planetary gear (3) is meshed with a drive output gear (2) which is coaxially connected with the rotating wheel (1). The gear (6) of the servo motor A and a gear (9) of the servo motor B can be both meshed with a coaxial output gear (2) of the rotating wheel (1). The motion trail of the nipper is adjustable, thus conducing to optimizing the nipper motion, simplifying the structure and conducing to improving the speed of the comber and the combing quality.

Owner:SHANGHAI TEXTILE MACHINERY COMPLEX

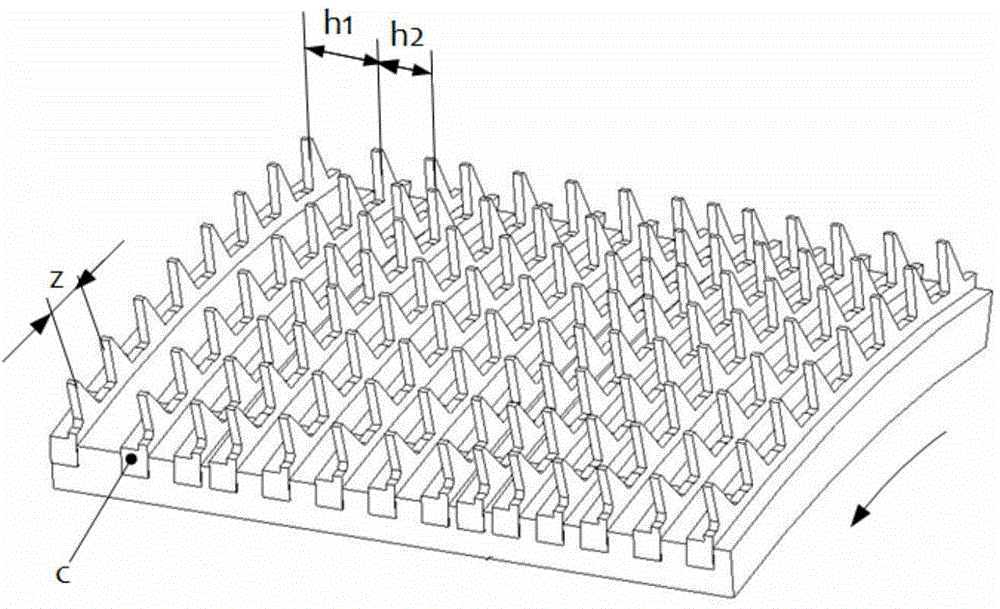

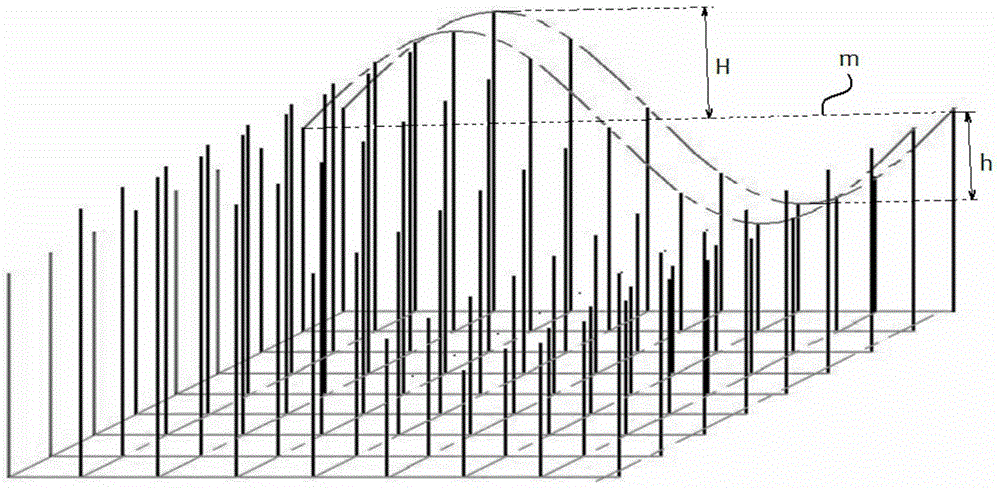

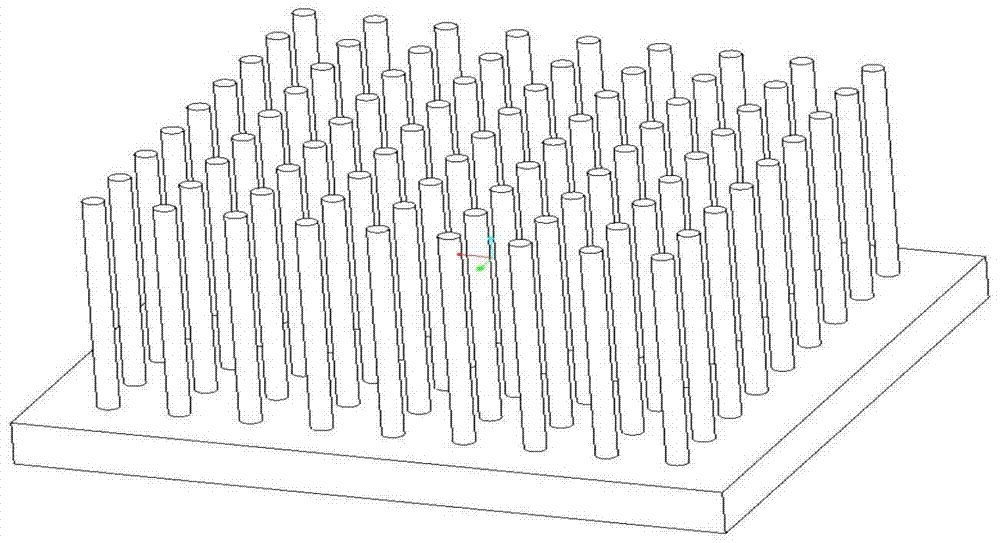

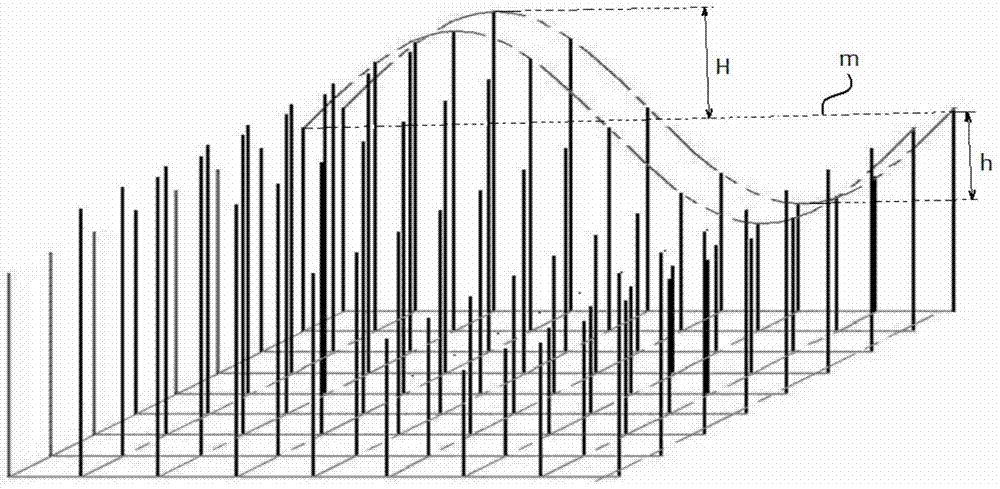

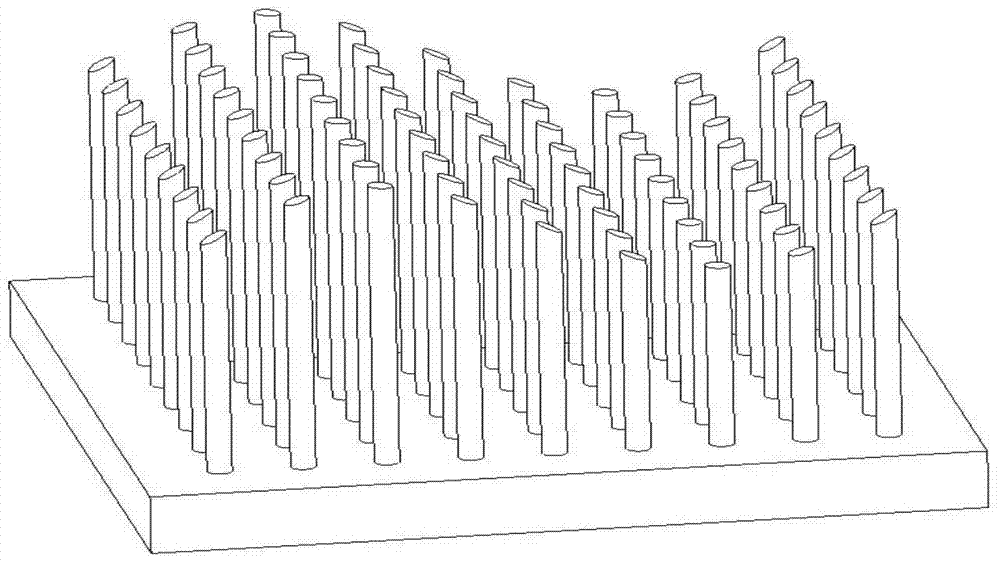

Unequal-height tooth carding cloth

ActiveCN104805542AMinimizes carding damageAffect quality efficiencyCarding machinesCardingEngineering

The invention provides an unequal-height tooth carding cloth, which consists of unequal-height tooth carding cloth units, wherein the surface of the tooth top of the carding cloth of each unequal-height tooth carding cloth unit is in a wavy way. By adopting the technical scheme, the unequal-height tooth carding cloth has the advantages that the carding and loosening functions are realized, the carding damage to fibers is reduced, the amount of short fibers is reduced, the carding quality is improved, the stereo multi-layer surface carding state is formed, and the technical purposes of high carding yield and high carding quality are realized.

Owner:EASTERN LIAONING UNIV

Cover board bar of carding engine cylinder and leveling gum adding method

InactiveCN1884646AGap stabilityGuaranteed straightnessCarding machinesEngineeringMechanical engineering

The invention discloses a mobile lid rod of cotton machine cylinder and extending method, which consists of T-shaped bar-shaped body and bottom plane, wherein the flat glue layer is set on the bottom plane, which is adhered on the bottom plane stickly to improve flatness of bottom. The rod stabilizes gap among cloth and cylinder, which improves carding machine quality cardinally.

Owner:SAURER CHANGZHOU TEXTILE MACHINERY CO LTD

Dislocated metallic card clothing

The invention relates to dislocated metallic card clothing which comprises base parts arranged side by side, wherein needle teeth in a row are distributed at the top end of each base part, and the needle teeth are characterized in that the needle points of the needle teeth are in dislocated arrangement in the length direction of the base part. The dislocated metallic card clothing is capable of effectively reducing the transverse relative gaps of the needle teeth, effectively increasing the carding probability of fiber fines bundles in the carding process, improving the carding quality, reducing fiber damage, improving the card sliver quality, and being used for carding card slivers for producing fine yarns and extra fine yarns. The dislocated metallic card clothing can be applied to manufacturing of licker-in wires and also cylinders and doffer card clothing, and is suitable for reformation of old machines such as the existing cotton carding machines, wool carding machines and hemp carding machines and suitable for equipment of new machines.

Owner:DONGHUA UNIV +1

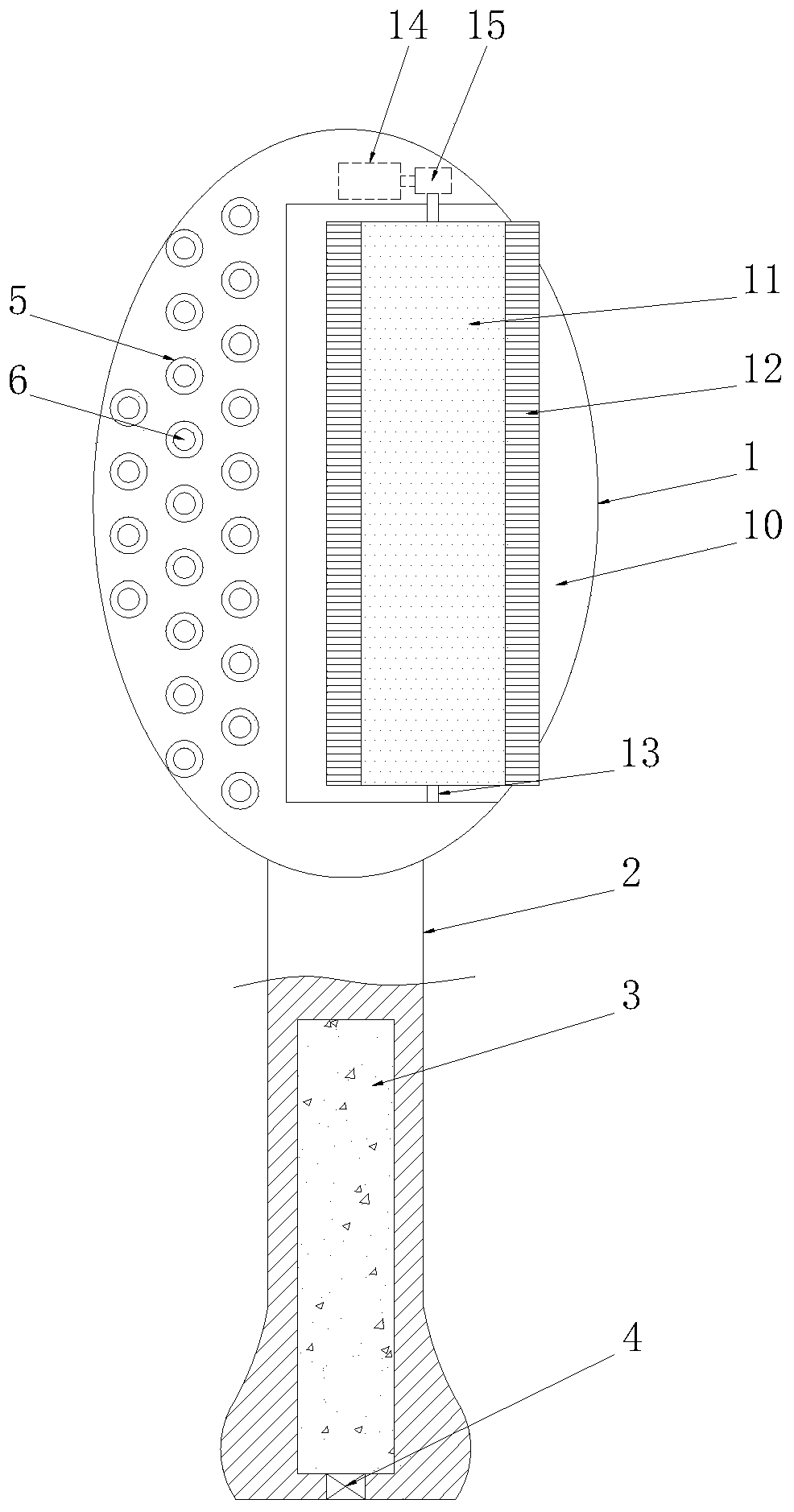

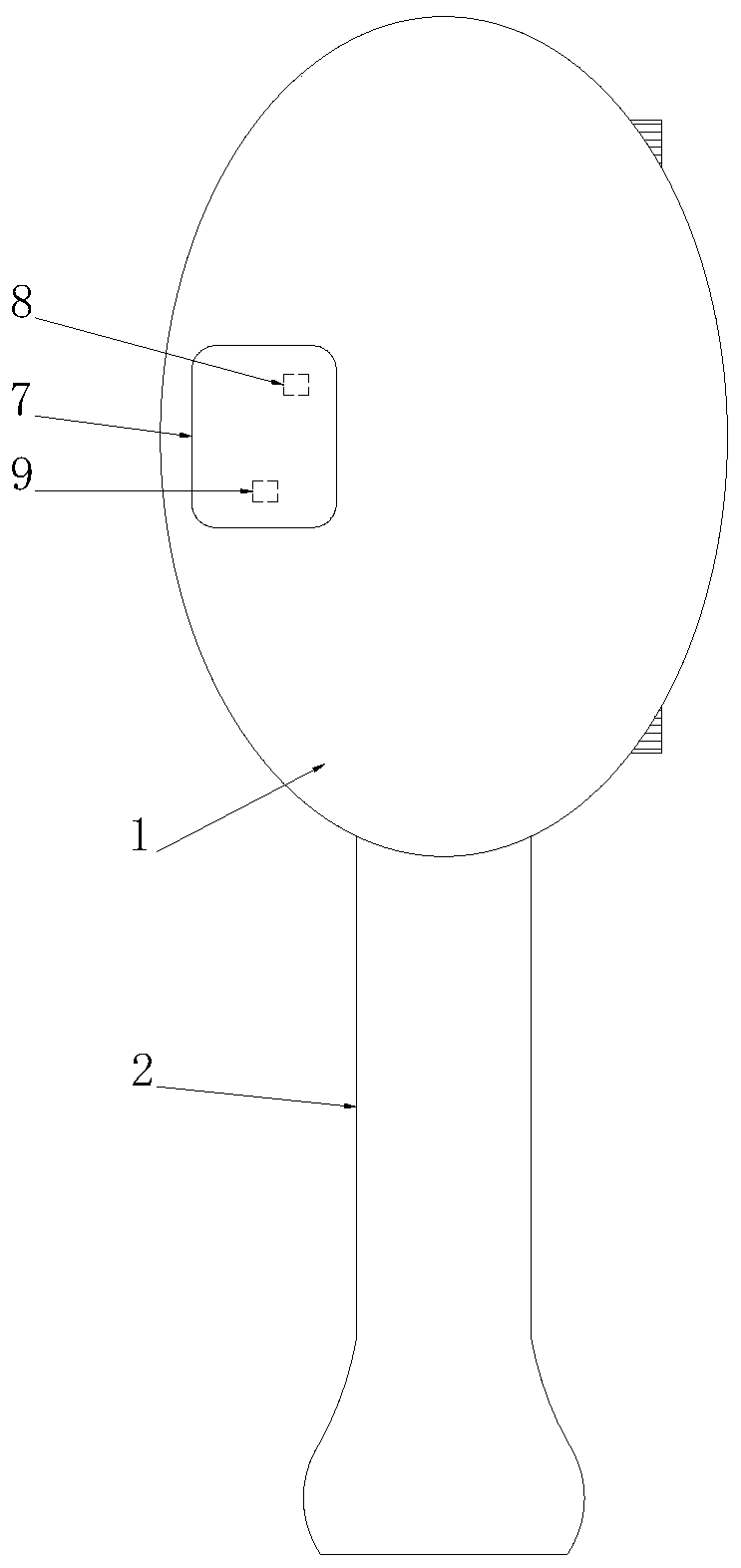

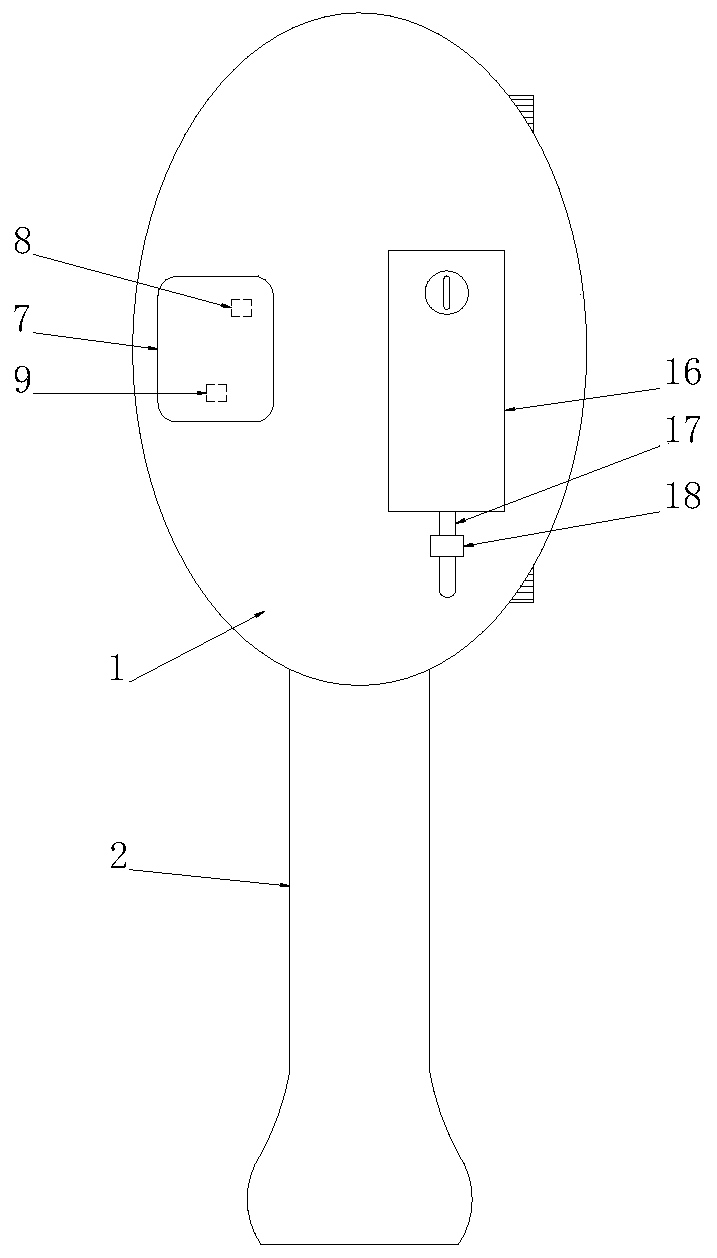

Animal parasite detection device

InactiveCN110301370AImprove carding qualityImprove carding efficiencyGeological measurementsGrooming devicesEngineeringBody surface

The invention discloses an animal parasite detection device. The animal parasite detection device comprises a comb head and a comb handle and is characterized in that one end of the comb head is fixedly connected with the comb handle, a storage battery is embedded into the comb handle, the front end face of the comb head is provided with a comb cavity and a plurality of fixed comb teeth, a detection probe is embedded into one end, away from the comb head, of each fixed comb tooth, and a touch display screen is arranged on one side of the back side of the comb head; a comb roller is arranged inthe comb cavity, the comb roller is rotatably connected to the comb cavity through a rotary shaft, a plurality of movable comb teeth are evenly arranged on the comb roller, and a motor and a reducerare arranged in one end, away from the comb handle, of the comb head. The animal parasite detection device has the advantages that whether parasites exist on the body surface of a pet or not is detected through the detection probes, an alarm module gives out a sound to remind a pet owner when parasites are detected, the number of the detected parasites is counted through a counting module, the conditions of the parasites are displayed through the touch display screen, and the pet owner can roughly observe the number of the parasites on the body surface of the pet through the touch display screen so as to decide whether to wash the pet with medicine and water or not to remove the parasites.

Owner:TARIM UNIV

Method for improving properties of yarns formed by rotor spinning

InactiveCN102634894BIncreased bending stiffnessImprove carding qualityContinuous wound-up machinesOpen-end spinning machinesTextile fiberThree stage

The invention relates to a method for improving the properties of yarns formed by rotor spinning by reducing fiber modulus and rigidity on line, belonging to the field of textile processing. The method has the following advantages that the fiber modulus and bending rigidity of rotor spun fiber strands are quickly reduced on line by adopting a three-stage parallel softening treatment method, thus improving the fiber combing quality of the combing roller, improving torsion easiness and internal and external transfer properties when the fibers undergo rotor spinning, improving the rotor spun yarn surface twist line clarity and yarn strength and substantially elevating the capability of spinning high count yarns through rotor spinning; the key problems that the rotor spun yarn surface fibers are loose, the twist lines are not clear and the method is not suitable for spinning the high count yarns can be effectively solved; the quality of the yarns formed by rotor spinning of fibers is substantially improved; and the method is especially suitable for high-quality spinning of textile fibers with high rigidity (such as ramie) and high elasticity (such as wool) on the rotor spinning machine.

Owner:WUHAN TEXTILE UNIV

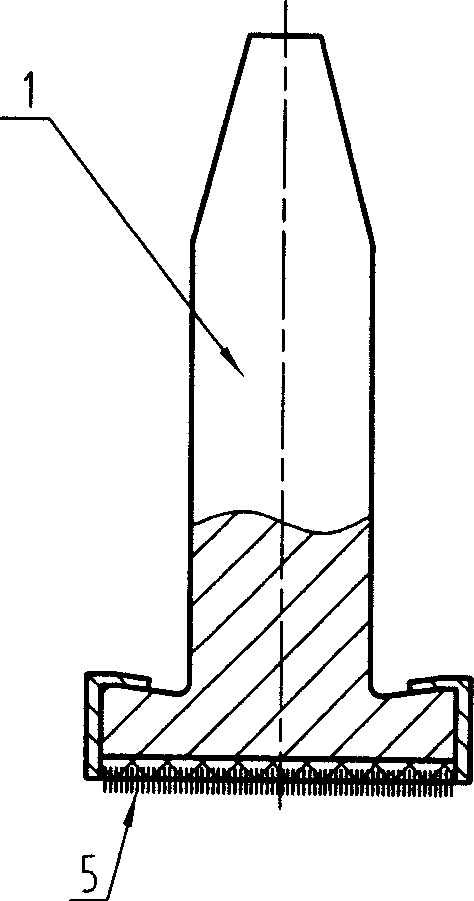

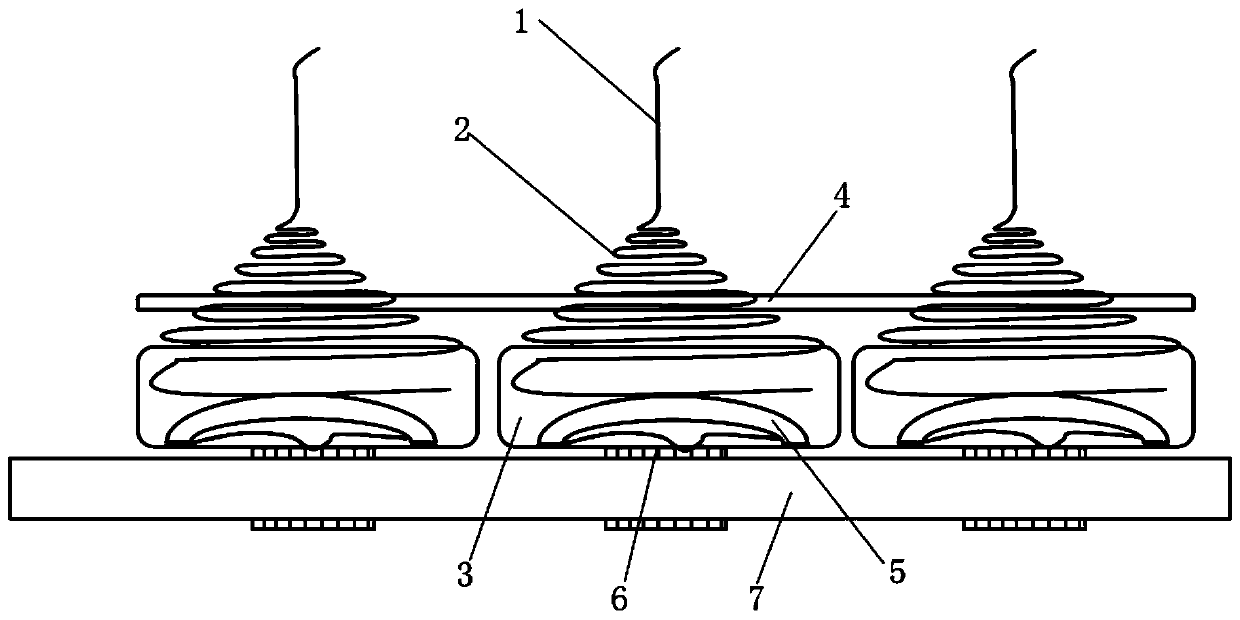

Spiral adjustable thermoelastic carding device, carding cover plate and carding machine

PendingCN110747541AReduce stiffnessImprove straightening parallelismCarding machinesFiberEngineering

The invention provides a spiral adjustable thermoelastic carding device, a carding cover plate and a carding machine. The spiral adjustable thermoelastic carding device comprises a carding needle, a spiral spring and a base, the carding needle is positioned above the spiral spring, the upper end of the spiral spring is connected with the bottom of the carding needle, the lower end of the spiral spring is fixed in the base, a base cloth is arranged above the base, the base cloth transversely penetrates through a spring gap of the spiral spring, an electric heating ceramic sheet is arranged inside the base, the electric heating ceramic sheet is connected with the spiral spring, and a transmission gear is arranged below the base. The spiral adjustable thermoelastic carding device has the beneficial effects that comb needles are heated through the electrothermal ceramic sheet, thus, when the comb needles comb fibers, the fibers soften and the rigidity is reduced, the carding efficiency andquality can be improved, and the fiber straightening parallelism can be improved; and the spiral spring is arranged at the lower ends of the comb needles, so that the action force of the fibers can be effectively buffered by the comb needles in the combing process, and damage of the comb needles to the fibers is reduced.

Owner:WUHAN TEXTILE UNIV

A carding device for preparing para-aramid yarn and its application process

Owner:HUBEI FENGSHU THREAD MFG

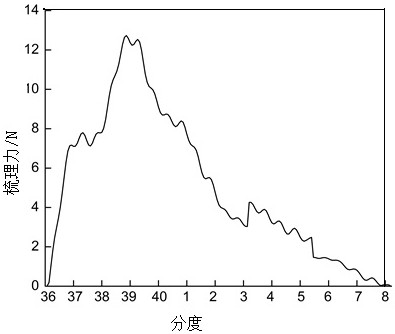

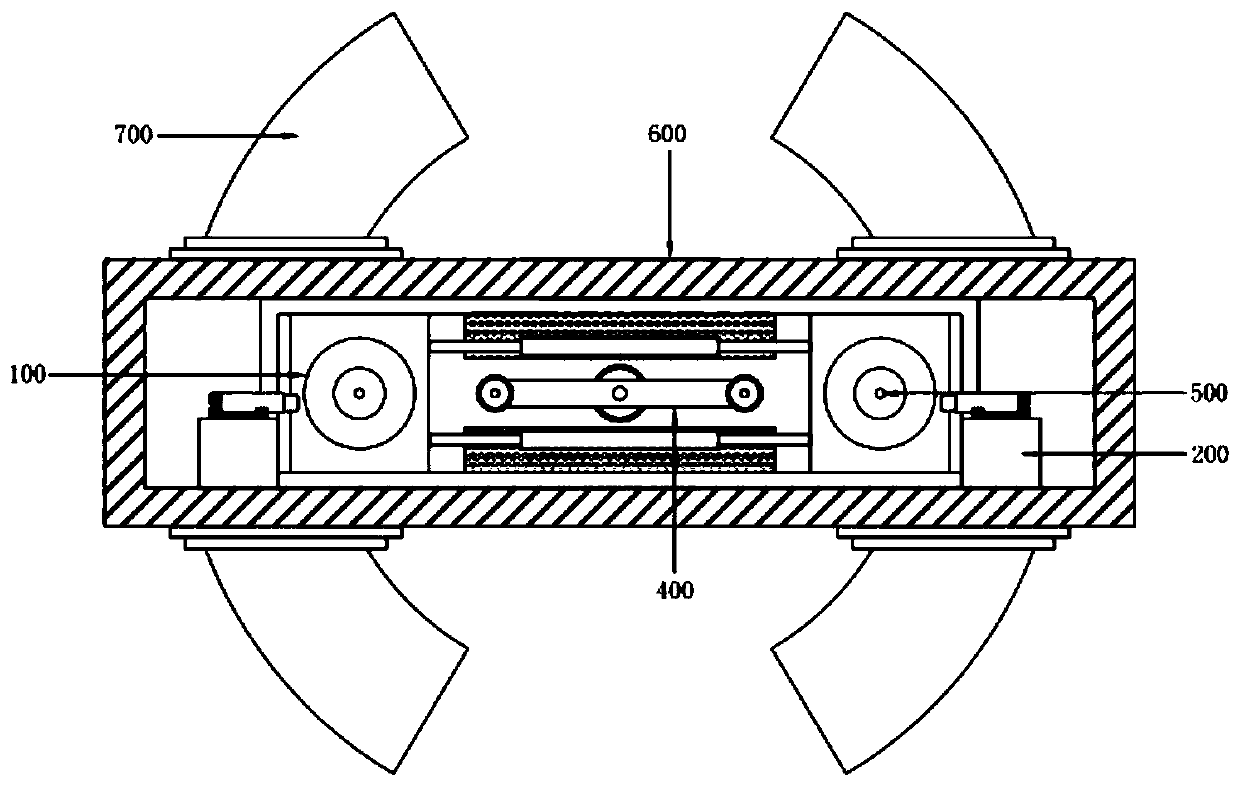

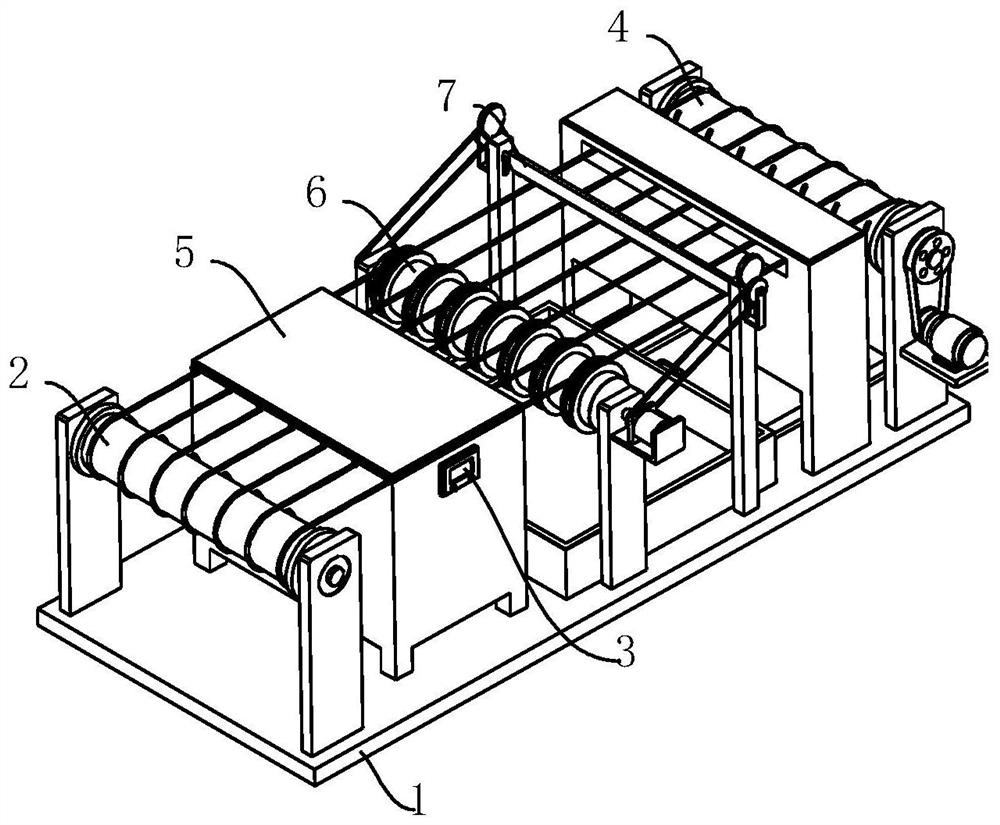

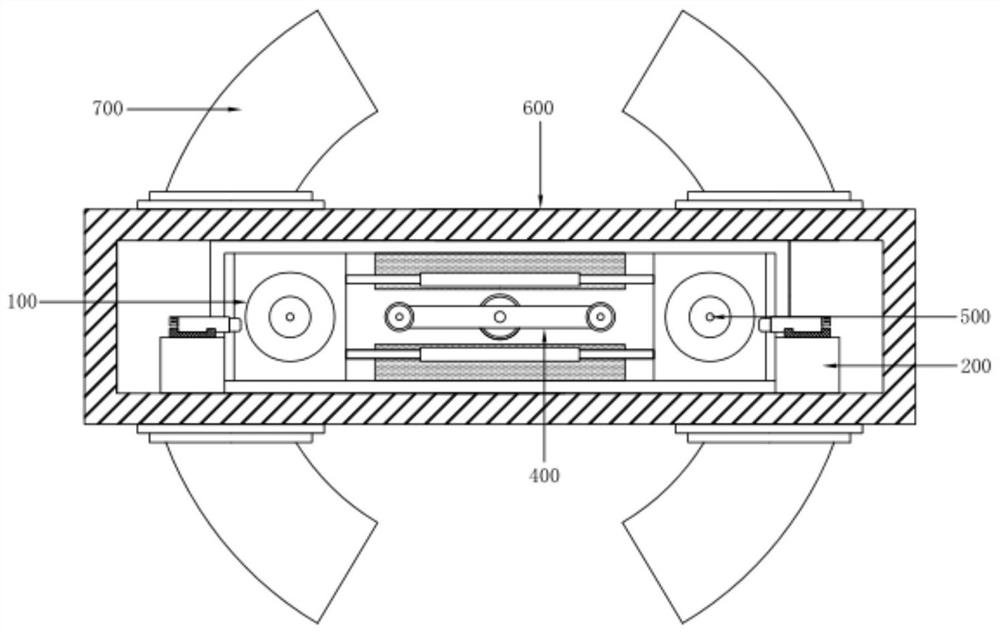

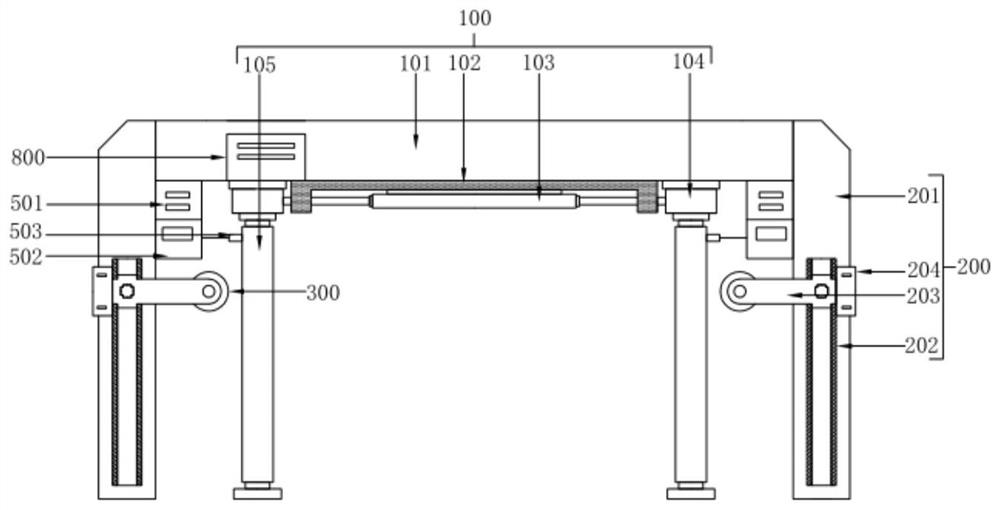

Carding force testing device of cylinder of cotton spinning combing machine

InactiveCN112195539AImprove carding qualityFast online detectionCombing machinesTorque sensorProcess engineering

The invention provides a carding force testing device of a cylinder of a cotton spinning combing machine. The carding force testing device is used for solving the technical problems that the carding effect and the fiber falling rate are easily influenced, an on-line detection function is lacked, and the testing precision is poor when a force sensor is arranged on a caliper plate of an existing device. The carding force testing device comprises a driving unit, a testing unit and a load unit which are connected in sequence, the testing unit comprises a torque sensor, the load unit comprises a cylinder shaft and a cylinder assembly, and the cylinder assembly is arranged on the cylinder shaft in a sleeving manner; and the two ends of the torque sensor are connected with the driving unit and the cylinder shaft through connecting pieces correspondingly, the torque sensor is connected with a data acquisition unit, and the data acquisition unit is connected with an intelligent terminal. According to the carding force testing device, the carding force in the combing machine cylinder carding process can be rapidly and accurately detected on line, the carding quality and the fiber falling rate are not influenced in the detection process, the overall structure is simple, the operation is easy, and the use is convenient.

Owner:ZHONGYUAN ENGINEERING COLLEGE

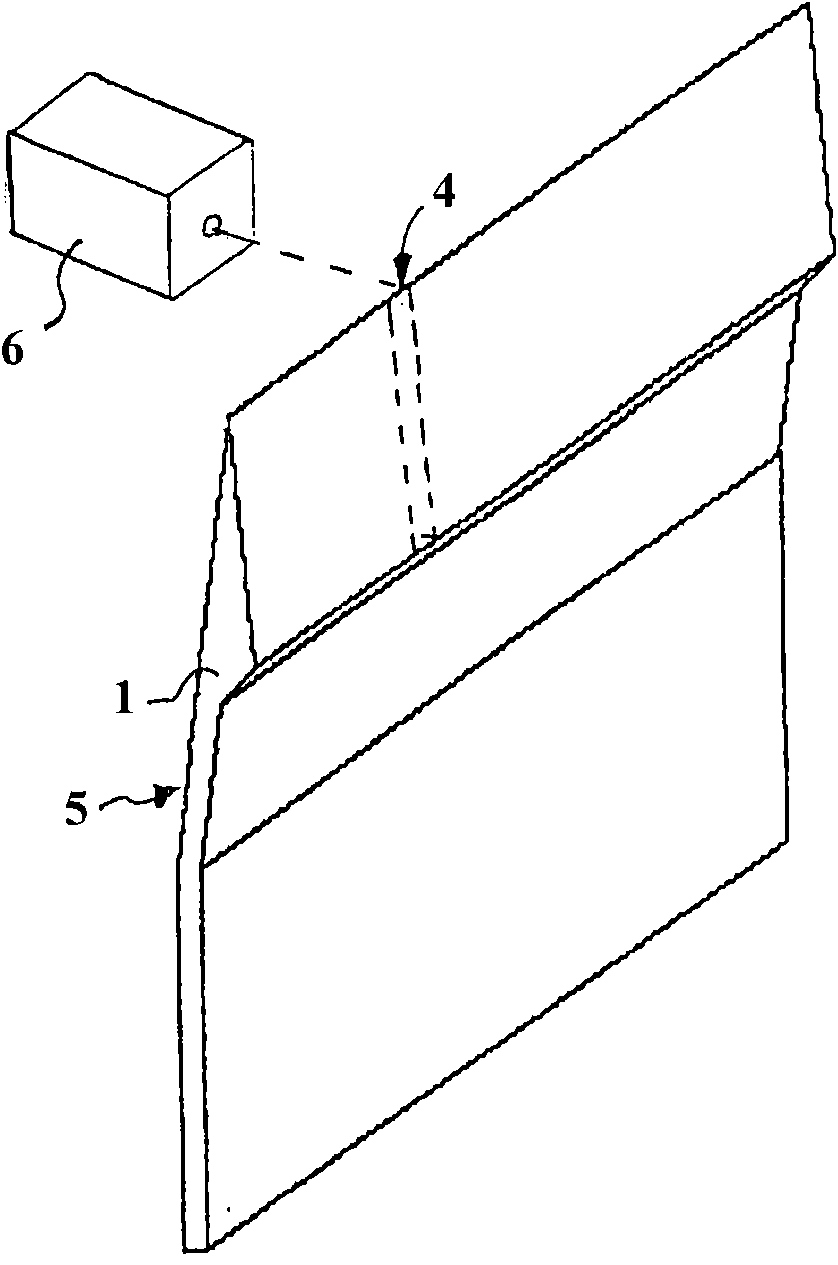

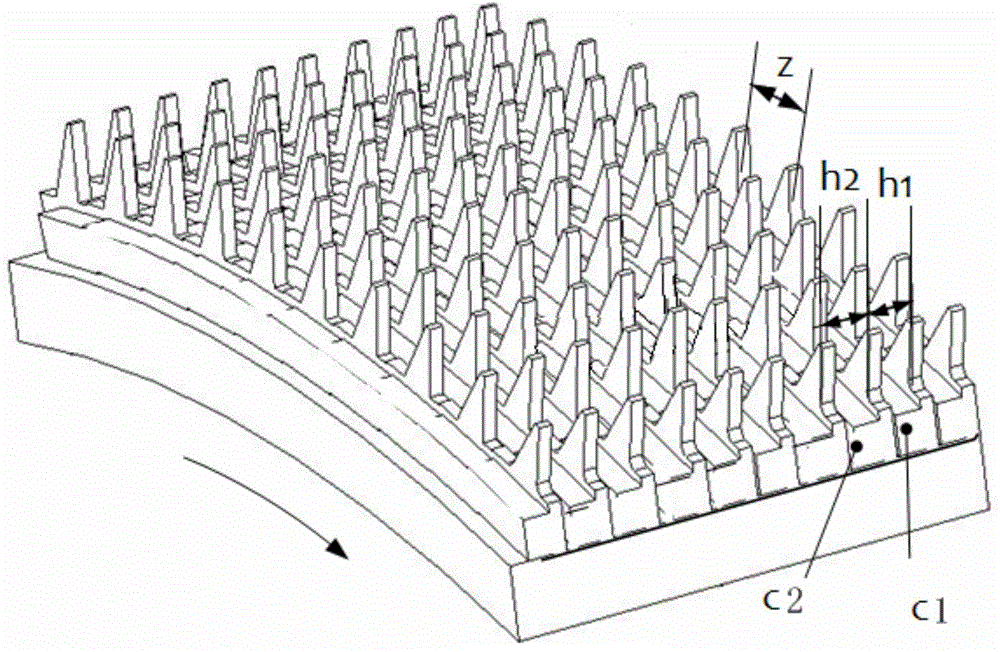

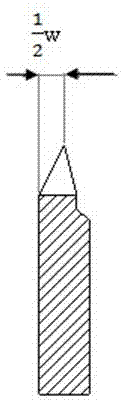

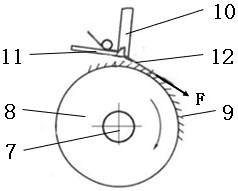

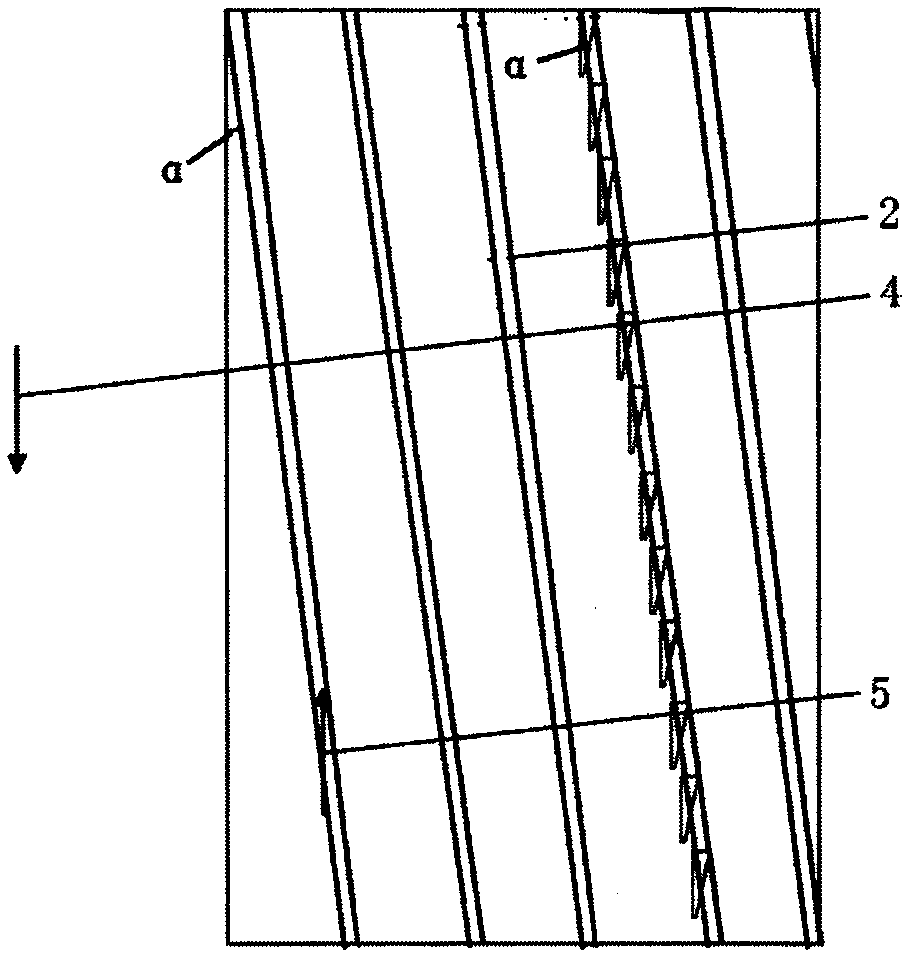

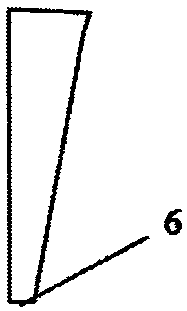

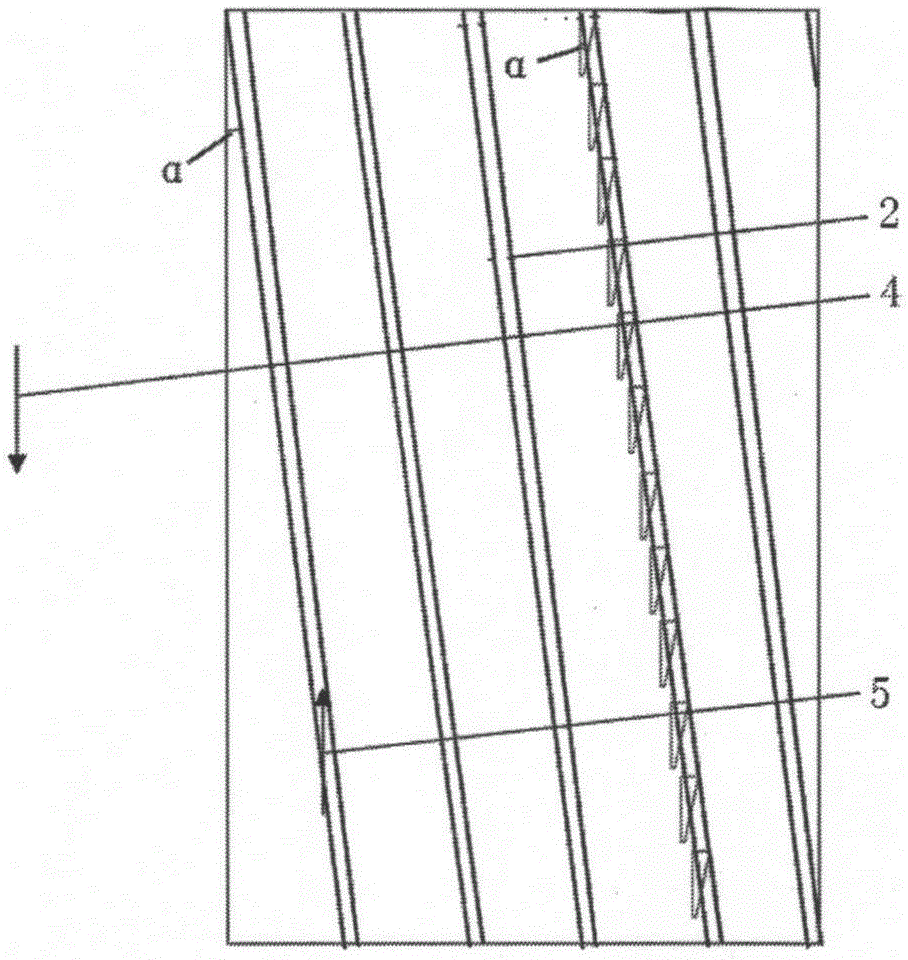

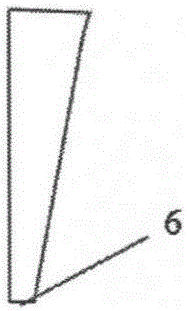

A high-efficiency metal saw blade for licker-in

The invention relates to a licker-in high efficiency metal saw blade; the saw blade wraps the surface of a licker-in, and forms an angle [alpha] with the licker-in edge; the saw blade comprises a base body; the base body bottom plane is vertical to the vertical plane; the base body is provided with saw teeth; the features are that the needle height plane of each saw tooth and the vertical plane form an angle [beta], wherein the angle [beat] equal to angle[alpha]. The high efficiency carding licker-in saw blade with certain angle is provided; compared with the prior art and under same saw teeth density, each saw tooth of the novel saw blade employs complete front edge carding, and abandons existing side angle carding problems, thus reducing channelizing phenomenon in carding fiber current, improving fiber (group) bundle effective carded probability, effectively improving carding quality, and maximumly reducing fiber damages.

Owner:DONGHUA UNIV +1

Licker-in high efficiency metal saw blade

The invention relates to a licker-in high efficiency metal saw blade; the saw blade wraps the surface of a licker-in, and forms an angle [alpha] with the licker-in edge; the saw blade comprises a base body; the base body bottom plane is vertical to the vertical plane; the base body is provided with saw teeth; the features are that the needle height plane of each saw tooth and the vertical plane form an angle [beta], wherein the angle [beat] equal to angle[alpha]. The high efficiency carding licker-in saw blade with certain angle is provided; compared with the prior art and under same saw teeth density, each saw tooth of the novel saw blade employs complete front edge carding, and abandons existing side angle carding problems, thus reducing channelizing phenomenon in carding fiber current, improving fiber (group) bundle effective carded probability, effectively improving carding quality, and maximumly reducing fiber damages.

Owner:DONGHUA UNIV +1

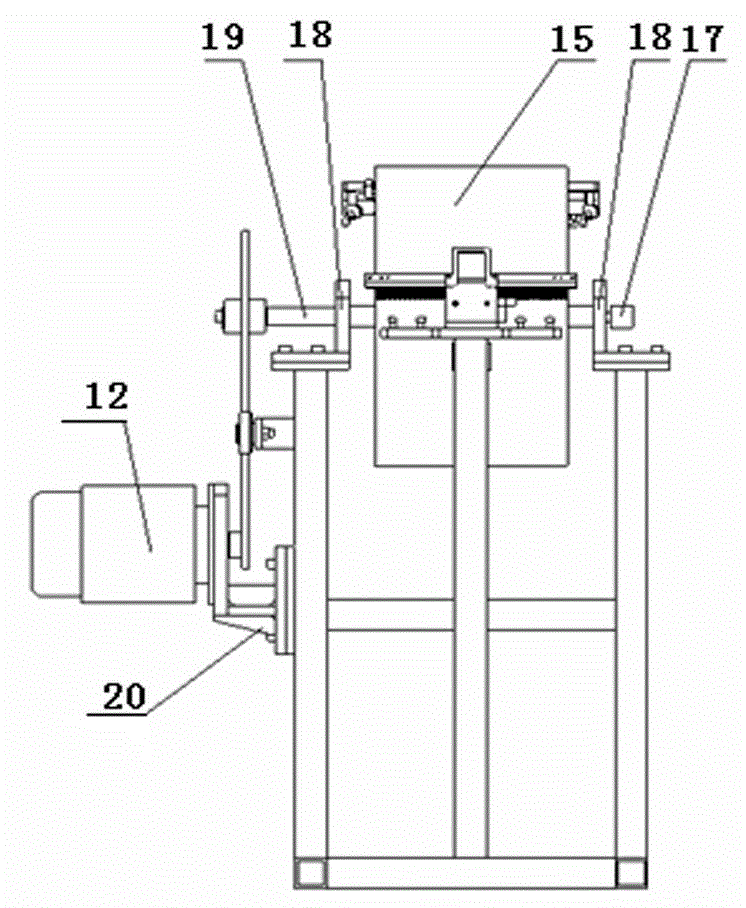

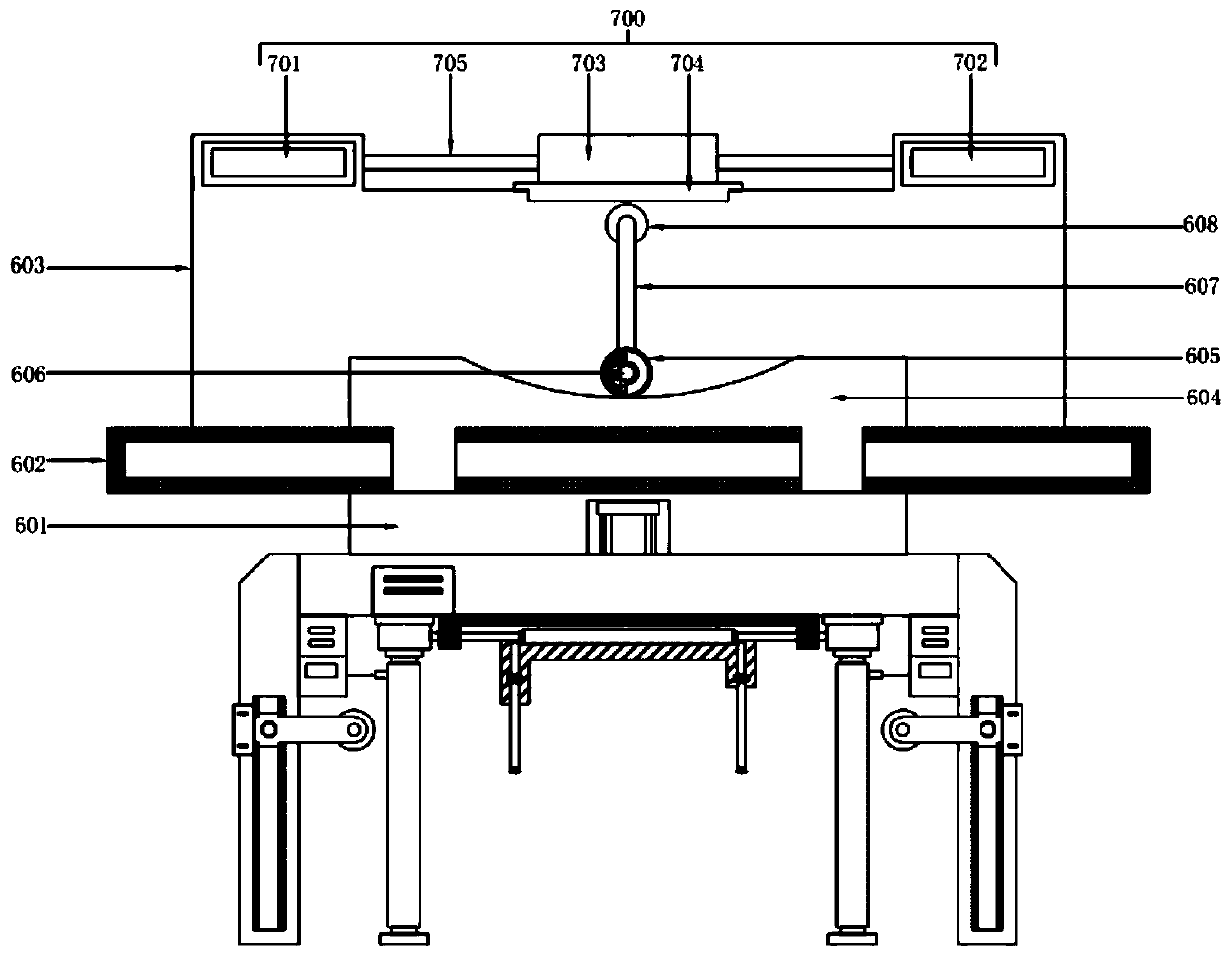

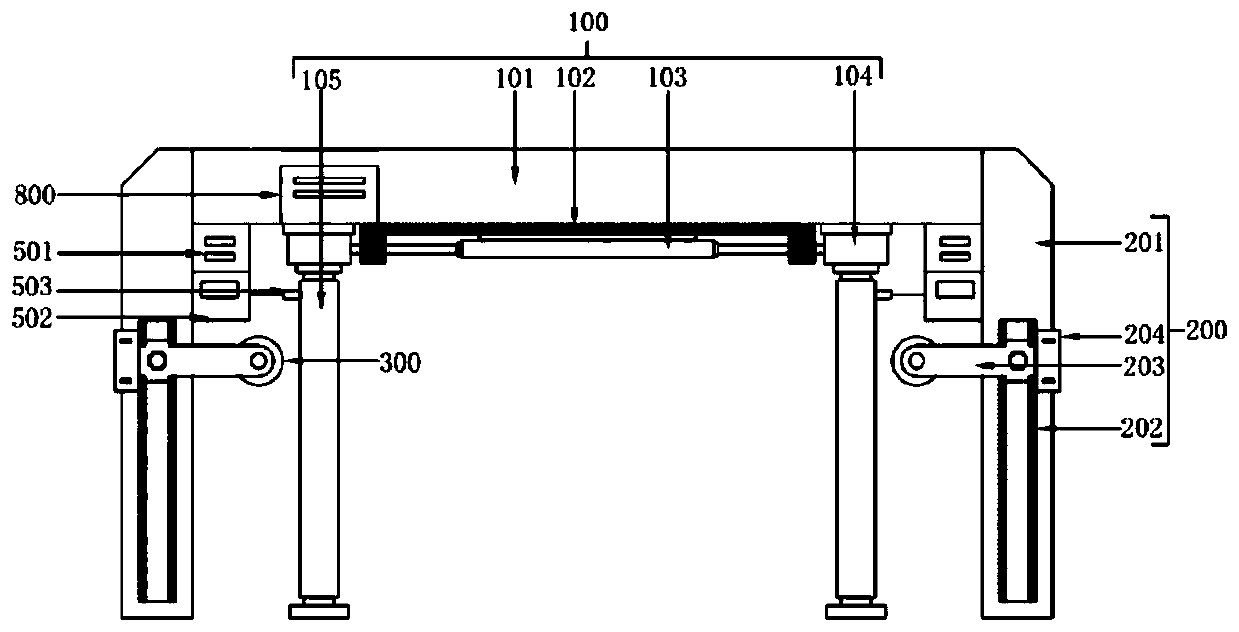

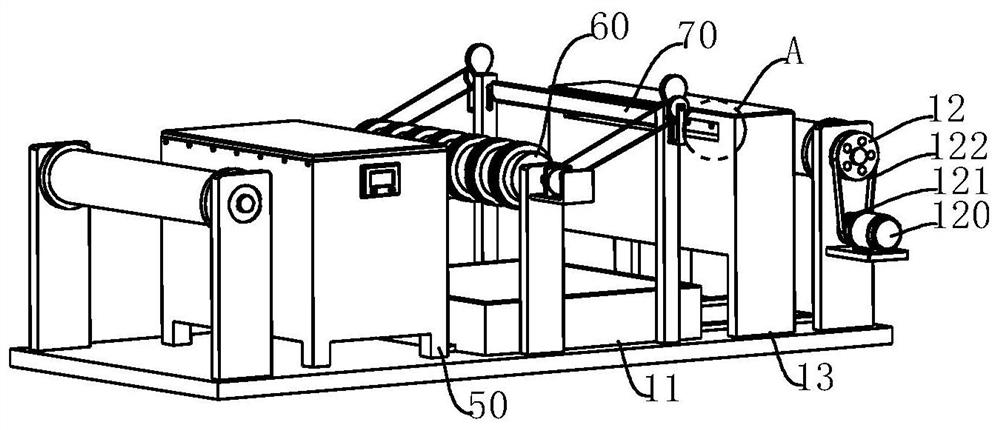

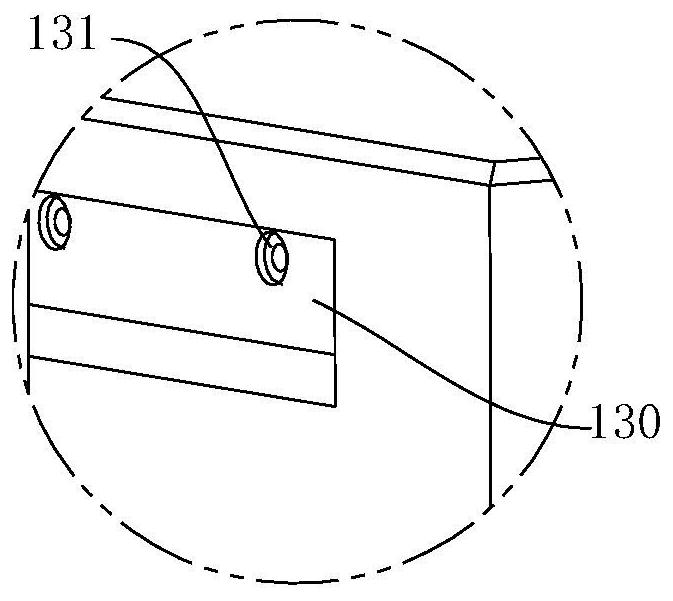

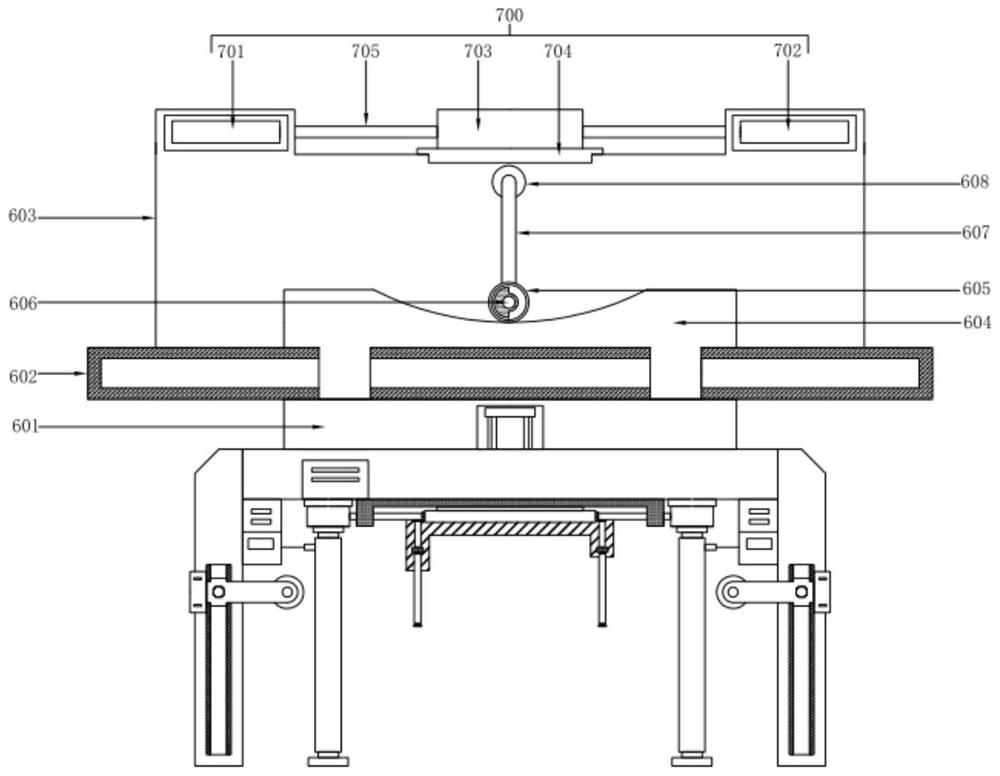

Double-roller type skein fluffing device and method

The invention discloses a double-roller type skein fluffing device and method, and belongs to the technical field of textiles. The double-roller type skein fluffing device comprises a double-roller assembly, moving assemblies are arranged on the two sides of the double-roller assembly, a shifting rod assembly is arranged on each moving assembly, and a stretching assembly is arranged on the front side of the double-roller assembly; and a vibration assembly is arranged on the side wall of each moving assembly, the double-roller assembly is movably installed on a transverse shaking assembly, thetransverse shaking assembly is movably installed on a vertical shaking assembly, and a control box is installed on the double-roller assembly. According to the device, operation is carried out throughalternate circulation of the transverse shaking assembly and the vertical shaking assembly, so that fluffing operation similar to manual operation on skein is achieved, manual labor intensity is reduced, and skein carding quality is improved; and overall tightness of skeins is reduced through the shifting rod assemblies and the vibration assemblies, the skeins are easier to shake and loosen, andskein carding efficiency is improved.

Owner:HEFEI C&P NONWOVEN PROD

Ramie bast fiber washing and fiber pressing linkage device

InactiveCN102071475APrevent hoardingSolve the flaws of messing aroundVegetable materialState of artEngineering

The invention provides a ramie bast fiber washing and fiber pressing linkage device, relating to the field of a ramie production processing device. The device solves the disadvantages that washing machines and dehydrators in the prior art are low in output, bad in production efficiency, high in energy loss and not beneficial for environment protection. The linkage device comprises a ramie washing device, a ramie outlet curtain and a pressing device, wherein the ramie washing device is joined with the pressing device through the ramie outlet curtain. The device is simple in structure, convenient in operation, low in improved investment cost, high in output, energy loss saving, work saving and material saving; the device further washes the ramie thoroughly and does not lead to disorder; and the device is suitable for popularization and application.

Owner:HUNAN MINGXING FIBER

Cashmere opening and carding line production system and process thereof

ActiveCN103451781BImprove carding efficiencyImprove carding qualityContinuous processingFibre feedersAutomatic controlMoisture regain

The invention discloses a cashmere opening and carding line production system, which structurally comprises an industrial control computer, an opener and 8-16 carding machines sequentially, wherein the 8-16 carding machines are connected end to end and are arrayed in sequence, and the industrial control computer is used for monitoring the operation states of the opener and the carding machines in real time and performing automatic control; according to the line production sequence, each carding machine comprises a cashmere feeding mechanism used for conveying and feeding cashmere to a carding host, the carding host used for carrying out carding operation, and a moisture regain mechanism used for carrying out water spray moisture regain operation on carded cashmere sequentially. According to the cashmere opening and carding line production system and the process thereof, when opened and mixed cashmere enters each carding machine sequentially by virtue of conveying flat belts, the arrangement sequence of the carding machines are strictly controlled so as to ensure that the Xth carding machine is always used for carrying out the Xth carding operation, and the opening and carding operation can be efficiently finished. The feed quantity, the carding speed and the moisture regain rate of the carding machines can be automatically adjusted according to different properties of raw materials, and accordingly, the carding efficiency and quality of the cashmere can be improved.

Owner:HONGYE CASHMERE

Carding device for preparing p-aramid fiber yarns and application process of carding device

The invention discloses a carding device for preparing p-aramid fiber yarns. The carding device comprises a cotton box, a cotton conveying roller, an inclined pallet, a horizontal pallet, a cotton feeding roller and a carding machine, a horizontal pressing plate parallel to the horizontal pallet is arranged above the horizontal pallet, a plurality of air flow sprayers are arranged in the horizontal pressing plate, a plurality of flow adjusting rotating spoons which are sequentially arranged are disposed between the air flow sprayers and the horizontal pallet, the flow adjusting rotating spoonsand the air flow sprayers are vertically arranged in a one-to-one corresponding manner, and each of the flow adjusting rotating spoons comprises a fixedly rotatable cylinder and a rotatable concave spoon which are connected with each other. According to the carding device, electrostatic removal effects are good, rigidity of the yarns can be reduced, smoothness of a cotton layer can be increased,adjustability is high, and treating efficiency is higher.

Owner:HUBEI FENGSHU THREAD MFG

Ramie bast fiber washing and fiber drying linkage equipment

InactiveCN102071475BPrevent hoardingSolve the flaws of messing aroundVegetable materialHigh energyEngineering

A ramie bast fiber washing and fiber drying linkage equipment, which relates to the field of ramie production and processing equipment, solves the problems of low output, poor production efficiency and high energy consumption that are not conducive to environmental protection in the prior art using washing machines and dehydrating machines. It includes a hemp washing device, a hemp outlet curtain and a drying device, and the hemp washing device is connected with the drying device through the hemp outlet curtain. The invention has the advantages of simple structure, convenient operation, low transformation input cost, high output, energy saving, labor saving, material saving, hemp cleaning is thorough, and it is not easy to cause mess, and is suitable for popularization and application.

Owner:HUNAN MINGXING FIBER

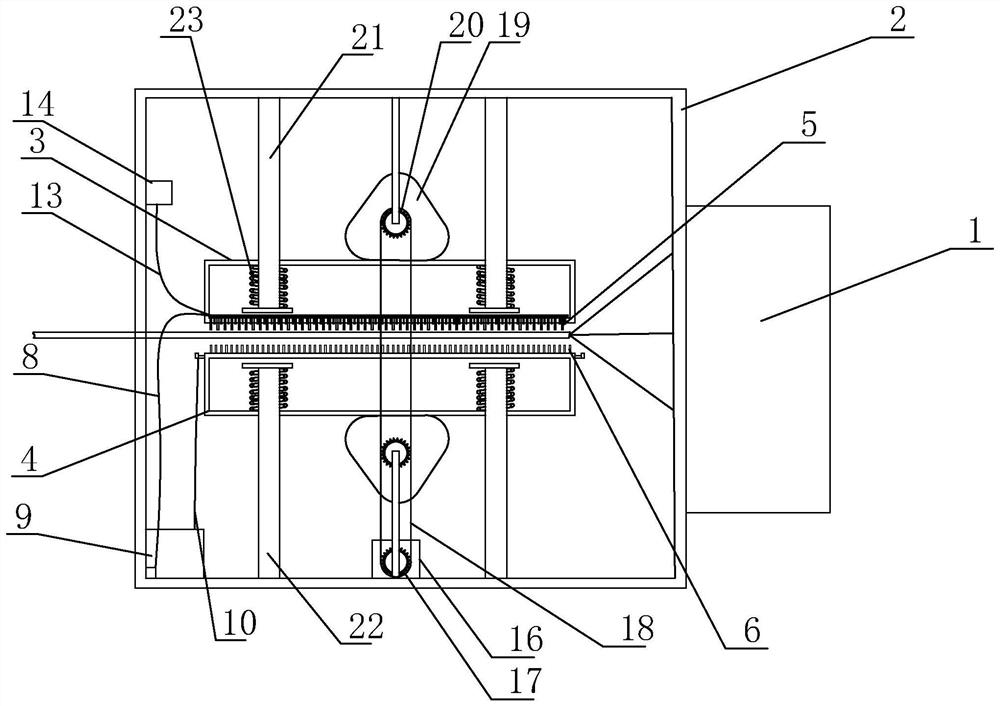

Humidifying and carding device of twisting machine

The invention aims to provide the humidifying and carding device of the twisting machine, and the carding device can humidify and comb yarns. The device comprises a mounting frame fixed on a frame of the twisting machine, and the mounting frame is provided with a humidifying and carding device capable of carding yarns in a triangular twisting area and increasing the humidity of the triangular twisting area. The humidifying and carding device comprises an upper movable frame, a lower movable frame, first comb teeth, second comb teeth, an atomizing nozzle, a spray pipe, an atomizing pump, a water tank, a water pipe, a water collecting plate, a filter screen and a driving mechanism, the upper movable frame and the lower movable frame are fixed to the middle of the mounting frame in parallel through the driving mechanism, and the first comb teeth are fixed to the lower surface of the upper movable frame; second comb teeth are fixed to the upper surface of the lower movable frame, and atomizing nozzles are fixed to the portions, between the adjacent first comb teeth, of the upper movable frame.

Owner:海宁市欧师达经编有限公司

Non-contour tooth card clothing

The invention provides an unequal-height tooth carding cloth, which consists of unequal-height tooth carding cloth units, wherein the surface of the tooth top of the carding cloth of each unequal-height tooth carding cloth unit is in a wavy way. By adopting the technical scheme, the unequal-height tooth carding cloth has the advantages that the carding and loosening functions are realized, the carding damage to fibers is reduced, the amount of short fibers is reduced, the carding quality is improved, the stereo multi-layer surface carding state is formed, and the technical purposes of high carding yield and high carding quality are realized.

Owner:EASTERN LIAONING UNIV

Drive structure of nipper of comber

InactiveCN101654817BMotion synchronizationIncrease drive powerCombing machinesControl theoryPower transmission

The invention relates to a power transmission mode and a structure of a nipper of a comber. In a drive structure of the nipper of the comber, a pivot of the nipper (12) is rotatablely connected with a support bar (11) which is positioned on the lower part and is rotatablely connected with a base. A wobble wheel (1) of a servo motor mechanism is connected with the other pivot of the nipper (12) byan eccentric wheel (18) in an eccentrically rotating manner. A servo motor A (7) of two servo motors is meshed with a planetary carrier gear (9) of a planetary gear by a gear (6) of the servo motor A, and the other servo motor B (8) is meshed with a rear planetary gear (4) by a central gear (10) of the planetary gear. A front planetary gear (3) is meshed with a drive output gear (2) which is coaxially connected with the wobble wheel (1). The gear (6) of the servo motor A and a gear (9) of the servo motor B can be both meshed with a coaxial output gear (2) of the wobble wheel (1). The motion trail of the nipper is adjustable, thus conducing to optimizing the nipper motion, simplifying the structure and conducing to improving the speed of the comber and the combing quality.

Owner:SHANGHAI TEXTILE MACHINERY COMPLEX

An anti-knotting device and working method for textile yarn carding

ActiveCN112877848BStable deliveryDoes not affect deliveryFibre cleaning/openingTextile technologyTextile yarn

The invention relates to the field of textile technology, in particular to a textile yarn carding anti-knotting device and a working method, including a base and a feeding roller, and also includes a controller, a receiving roller, an anti-deviation mechanism, a cleaning mechanism and a shaking mechanism, The anti-bias mechanism includes a support platform and a guide assembly. The cleaning mechanism includes a cleaning roller and several scraping assemblies. The shaking mechanism includes a contact rod and two pressing assemblies. The top of the base is symmetrically provided with two vertical rods. The contact The rod is rotatably arranged between two vertical rods, and each pressing assembly is sleeved between the cleaning roller and the contact rod, and the guide assembly is electrically connected to the controller. The invention relates to a textile The yarn carding anti-knotting device and working method have better carding effect and better cleaning effect, and at the same time have low power consumption, lower cost, and higher quality of the ex-factory yarn.

Owner:佛山市顺德区纺泰织带有限公司

Uniform cotton distribution device

ActiveCN104746185BSlow down the opening and closing momentumContinuous and even cotton supplyFibre mixingFibre feedersEngineeringControl valves

The invention provides a device for evenly distributing cotton. The device for evenly distributing the cotton is characterized by being arranged inside a pipeline at a raw material inlet of a cotton storage bin. The device for evenly distributing the cotton is provided with a first rocking plate and a second rocking plate, a first shaft sleeve and a second shaft sleeve are arranged in the width direction of the top of the device for evenly distributing the cotton, and one end of the first rocking plate and one end of the second rocking plate are movably connected with the first shaft sleeve and the second shaft sleeve respectively. The two ends of a connecting rod are fixed to the middle of the first rocking plate and the middle of the second rocking late respectively, an air cylinder is fixed to one side, in the width direction, of the device for evenly distributing the cotton, a piston rod of the air cylinder is in parallel with the width direction of the device for evenly distributing the cotton, the top end of the piston rod is hinged to one end of the connecting rod, an air inlet and outlet port of the air cylinder is connected with a control valve, the air inlet end of the control valve is connected with an air source, and the electric appliance control end of the control valve is connected with a controller. Stretching and retracting of the piston rod of the air cylinder are used for controlling the rocking plates to swing back and forth, the rocking plates poke the raw materials to be distributed in the transverse direction, and therefore the raw materials are evenly distributed in the transverse direction inside the cotton storage bin.

Owner:QINGDAO HONGDA TEXTILE MACHINERY

A double-roller skein fluffing device and method

The invention discloses a double-roller skein yarn fluffing device and method in the field of textile technology, which includes a double-roller assembly, moving assemblies are arranged on both sides of the double-roller assembly, and a driving lever assembly is arranged on the moving assembly. The front side of the double-roller assembly is provided with a stretching assembly, the side wall of the moving assembly is provided with a vibrating assembly, the double-roller assembly is movably installed on the horizontal shaking assembly, and the horizontal shaking assembly is movably installed on the vertical shaking assembly , the control box is installed on the double-roller assembly, and the present invention operates through an alternating cycle of a horizontal shaker assembly and a vertical shaker assembly, which realizes the loosening operation of the skein similar to manual manual operation, reduces the labor intensity, and improves the The carding quality of the skein is improved, and the overall tightness of the skein is reduced through the lever assembly and the vibration assembly, so that the skein is easier to shake and the carding efficiency of the skein is improved.

Owner:HEFEI C&P NONWOVEN PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com