Humidifying and carding device of twisting machine

A twisting machine and combing technology, which is applied in the field of twisting machines, can solve the problems affecting the quality of finished yarn, affecting the appearance quality of finished products and the economic benefits of enterprises, and the increase of hairiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

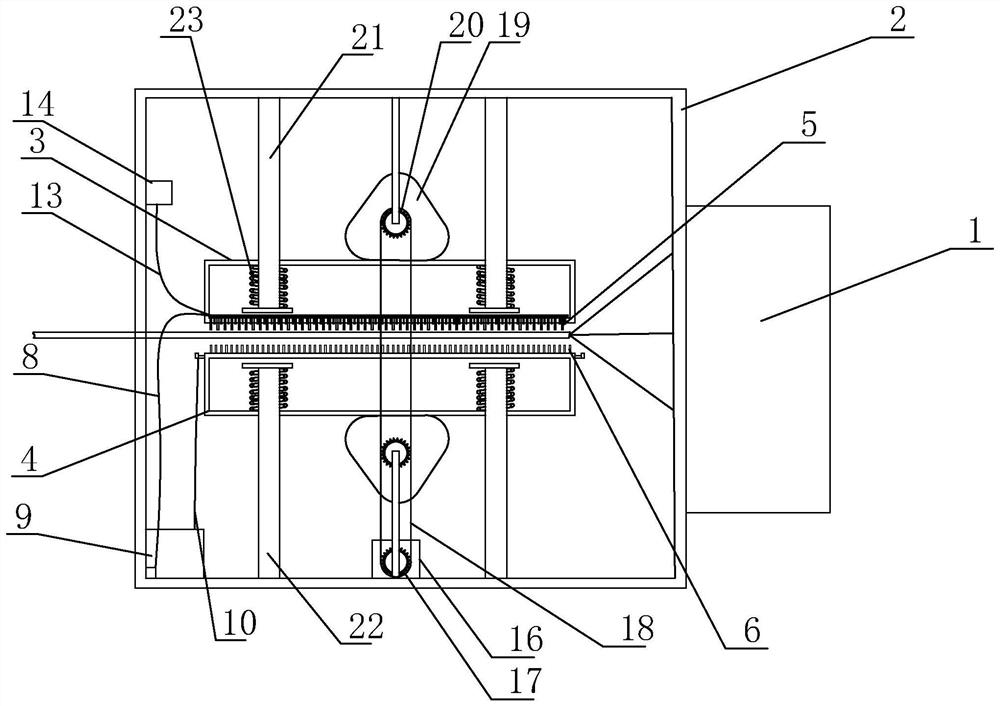

[0021] The present invention is described in further detail below:

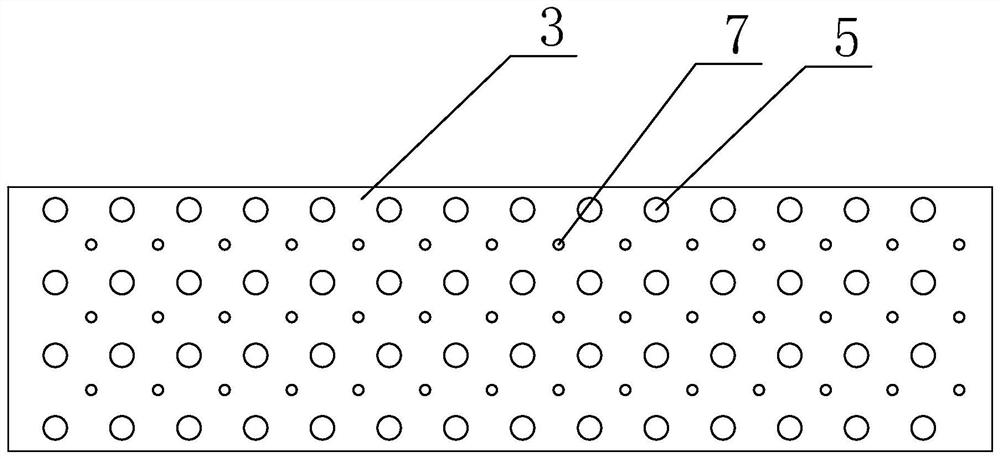

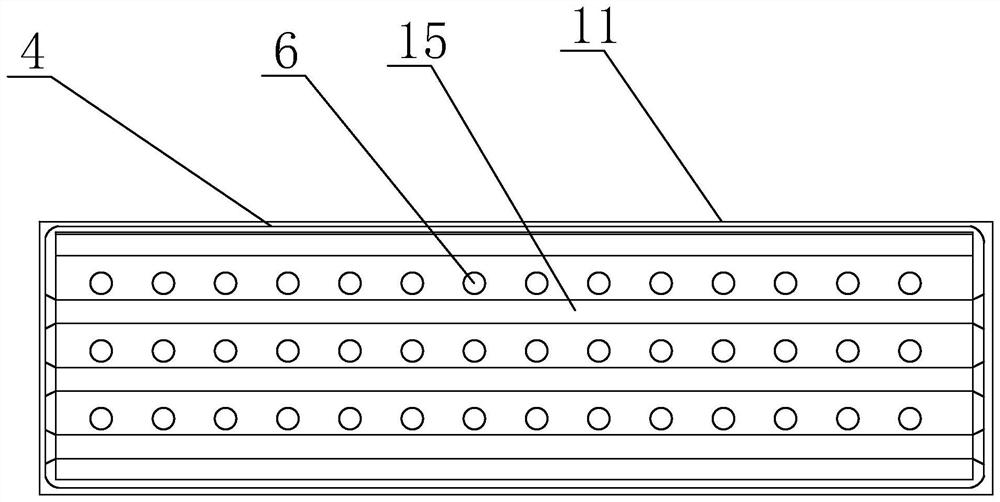

[0022] For details, see Figure 1 to Figure 4 :

[0023] A kind of humidifying carding device of twisting machine, it comprises the installation frame 2 that is fixed on the twisting machine frame 1, and described installation frame 2 is provided with and can comb the yarn of twisting triangular area and increase twisting triangular area Humidifying and combing device, the humidifying and combing device includes an upper movable frame 3, a lower movable frame 4, a first comb 5, a second comb 6, an atomizing nozzle 7, a spray pipe 8, an atomizing pump, a water tank 9, and a water pipe 10. Water collection plate 11, filter screen and driving mechanism, the upper movable frame 3 and the lower movable frame 4 are fixed in the middle of the mounting frame 2 in parallel through the driving mechanism, and the upper movable frame 3 and the lower movable frame are driven by the driving mechanism 4 can move away from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com