A high-efficiency metal saw blade for licker-in

A licker-in and saw blade technology, applied in the textile field, can solve the problems of unfavorable sawtooth utilization, difficulty in carding the cotton layer, and affecting carding quality, etc., to reduce channelization, ensure carding efficiency, and increase the probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

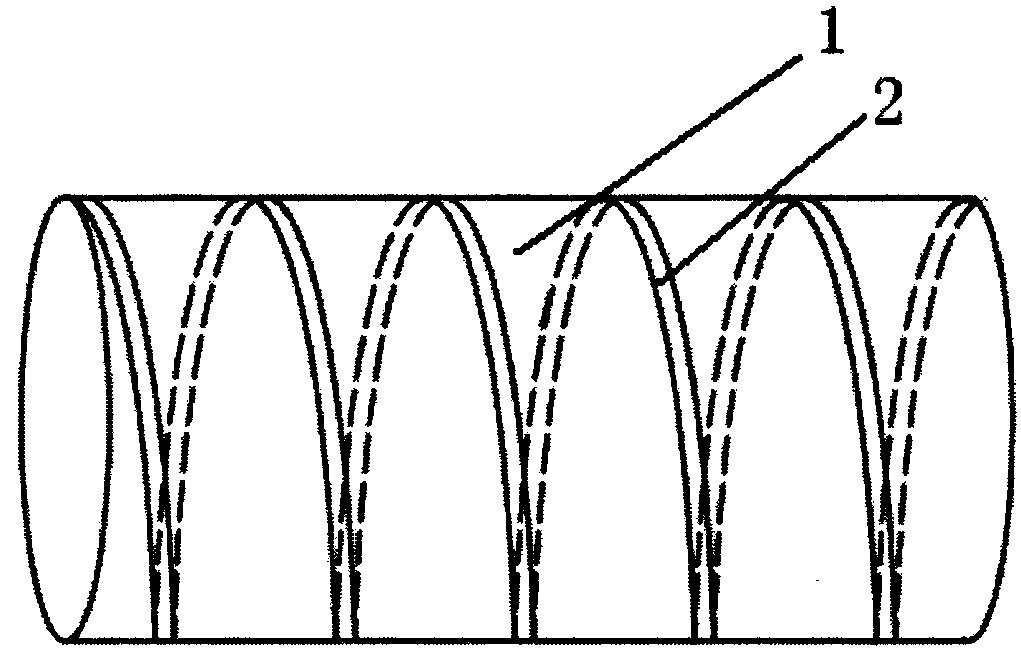

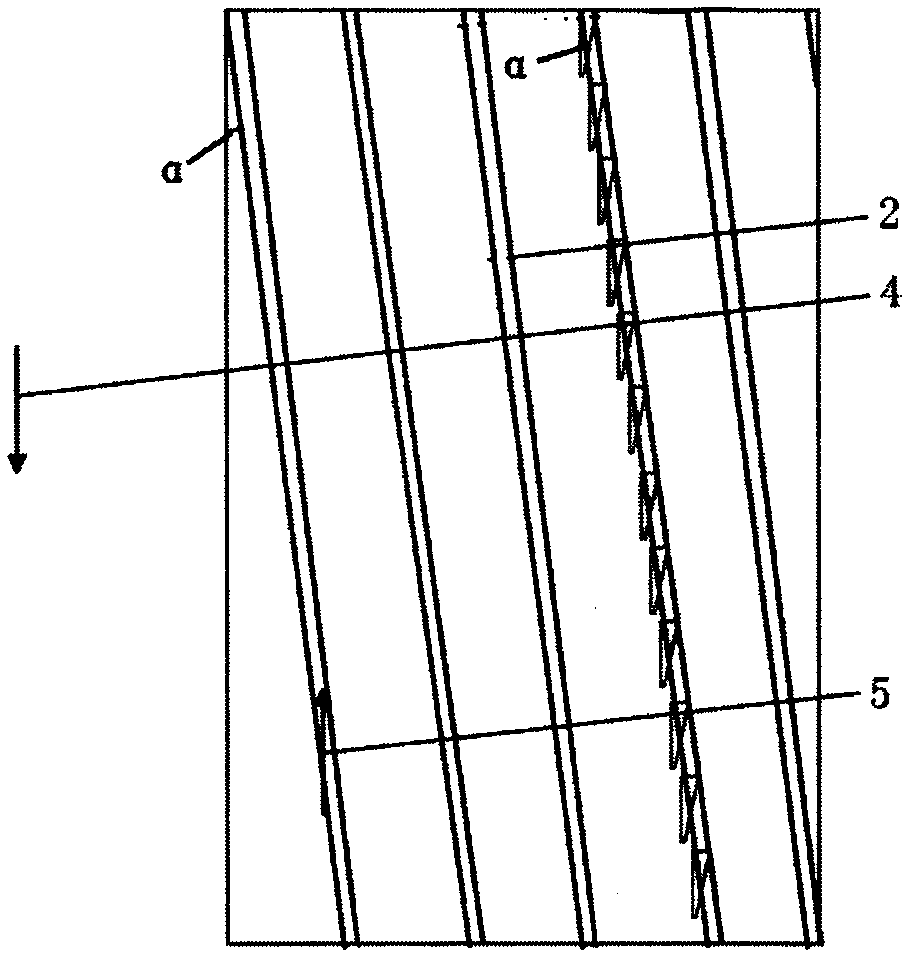

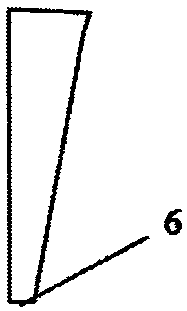

[0017] Such as Figure 1a and Figure 1b As shown, when the rack 2 is coated on the surface of the licker-in roller 1, it forms an angle α with the edge, so that as Figure 1b The saw teeth 3 on the toothed rack 2 are also shown to produce a lateral angle α. As a result, when the transverse cotton layer is carded, the sawtooth 3 that should be completely facing the face 6 has adopted the sawtooth side with a side angle α for carding. The side angle α blunts the sharpness that the sawtooth 3 should have on the cotton layer, and the cotton layer does not get the maximum carding of the licker-in roller sawtooth, but the side of the sawtooth beats the cotton layer, which also affects the cotton layer. Tearing has occurred, and the incomplete carding of the gripped cotton layer will lead to an increase in fiber linters and fragmentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com