Dislocated metallic card clothing

A technology of metal card clothing and dislocation arrangement, which is applied in deburring devices, textiles and papermaking, fiber processing, etc., and can solve problems such as carding of fine fiber bundles, deterioration of carding quality, and fiber short pile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

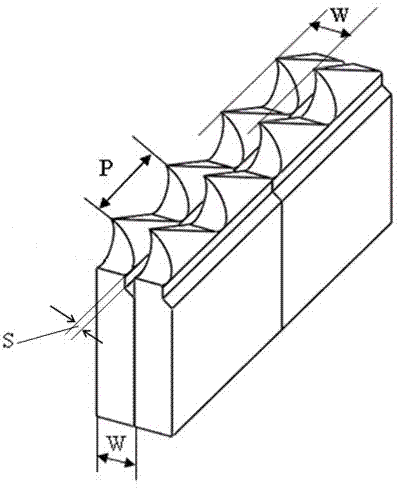

[0020] like figure 2 As shown, it is a three-dimensional effect diagram of two dislocated metal card clothings. The two dislocated metal card clothings include bases 1 arranged side by side, and a row of needle teeth 2 is distributed on the top of each base 1. This kind of dislocated metal card clothings can be needle Roll saw blade, also can be cylinder, doffer card clothing. The base width W and the longitudinal pitch P of the offset metal card clothing of the present invention are the same as those of the existing metal card clothing. The tips of the needle teeth 2 are arranged in a dislocation along the length direction of the base 1, with two needle teeth as a repeating unit.

[0021] like Figure 8 As shown, it is the front view of the two misplaced metal card clothings. In the repeating unit, the needle point of the first needle tooth 2 is located on the leftmost vertical line of the base 1, and the needle point of the second needle tooth 2 is located on the leftmost...

Embodiment 2

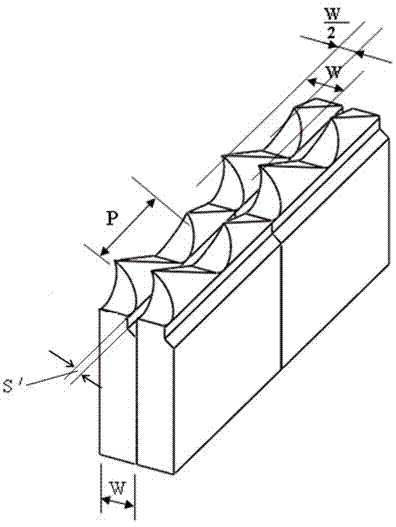

[0023] A three-dislocation metal card clothing includes bases 1 arranged side by side, and a row of needle teeth 2 is distributed on the top of each base 1. This kind of dislocation metal card clothing can be a licker-in saw blade, or a cylinder or doffer card clothing. The base width W and the longitudinal pitch P of the offset metal card clothing of the present invention are the same as those of the existing metal card clothing. The tips of the needle teeth 2 are arranged in a dislocation along the length direction of the base 1 , with three repeating units.

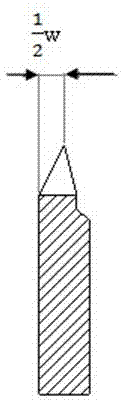

[0024] like Figure 9 As shown, it is the front view of the three-dislocation metal card clothing. In the repeating unit, the tip of the first pin tooth 2 is located on the leftmost vertical line of the base 1, and the tip of the second pin tooth 2 is located on the left side of the base 1. On the vertical line at the position of the side 1 / 3 of the width of the base 1 , the needle tip of the third needle tooth 2 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com