Nonuniform-tooth density carding cloth

A technology of carding needles and unequals, which is applied in the field of textile machinery carding equipment, can solve the problems of difficult to achieve high-quality and high-efficiency carding, and difficult to achieve high carding output, and achieve the effect of effective carding and improved carding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

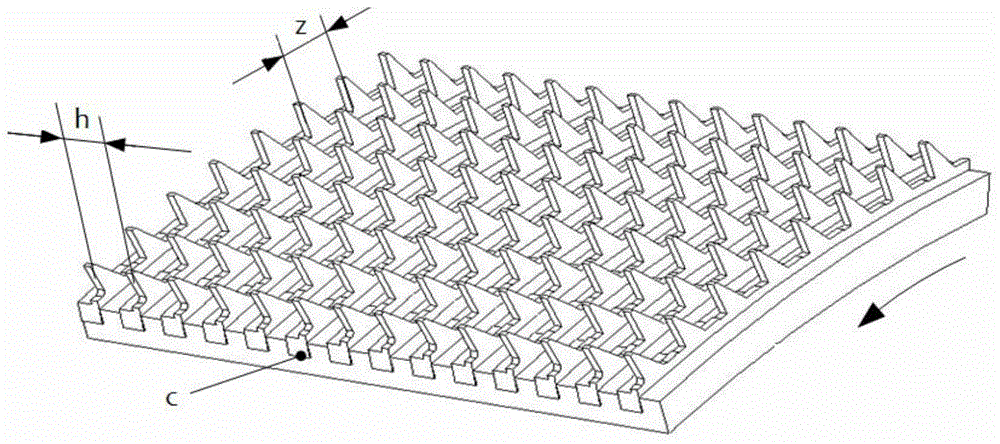

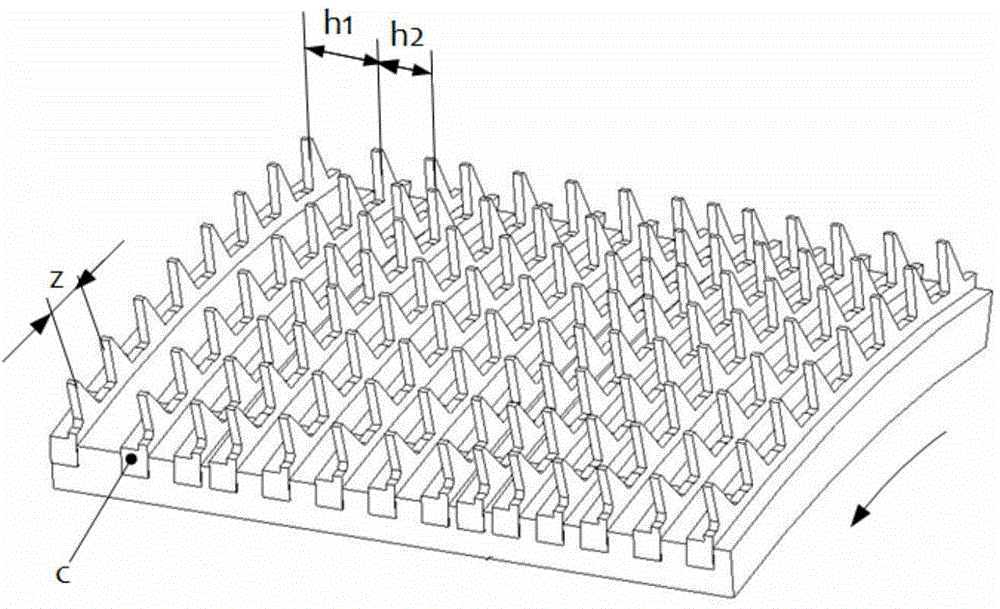

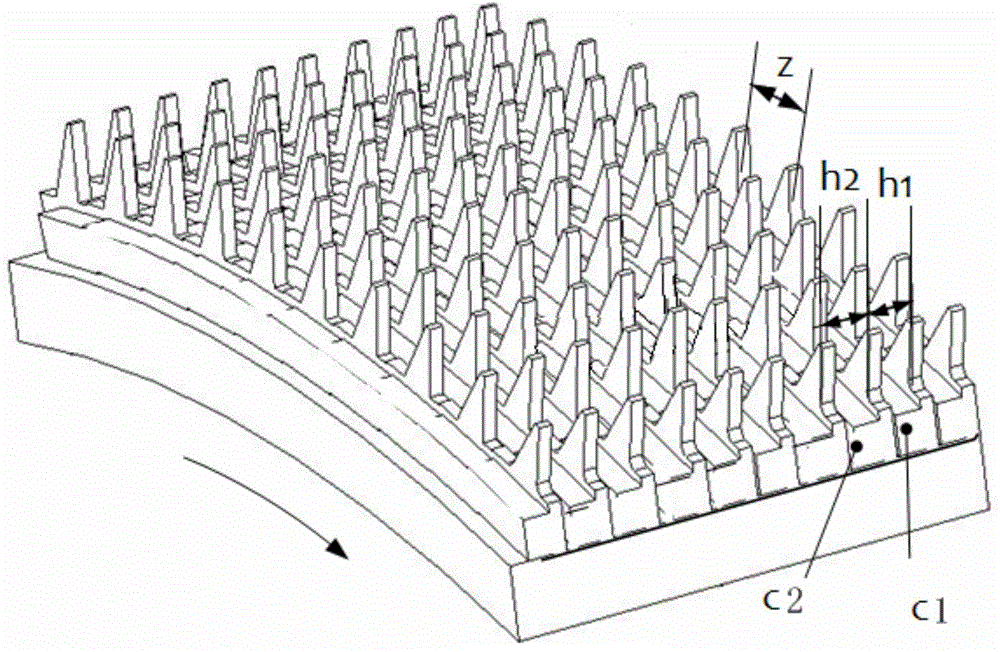

[0013] The unequal tooth density carding clothing provided by the patent application of the present invention can be widely used in grooved card clothing, wrapping card clothing, planting needle clothing, grooved planting clothing, and card clothing spacer type clothing. And other specific structure types of clothing. In this unequal tooth dense carding card clothing, the horizontal tooth spacing of the card clothing needle teeth is not equidistantly set, and the horizontal tooth spacing h distance of each row of needle teeth is selected and set unequally in the range of 0.5-6mm. The unequal spacing of the transverse teeth includes an arrangement structure in which each row of the card clothing is completely unequally spaced; it can also be an unequal spacing arrangement including the transverse tooth spacing of each row of needle teeth in a local area; It can also be: a plurality of unequal tooth densely arranged units are continuously arranged to form a card clothing, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com