Cashmere opening and carding line production system and process thereof

A flow-line operation and carding technology, which is applied in the field of cashmere textiles, can solve the problems of low automation of carding machines, increased material and manpower input, and unadjustable carding machines, so as to improve the efficiency of carding and impurity removal, and achieve a high degree of automation , Improve the effect of carding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

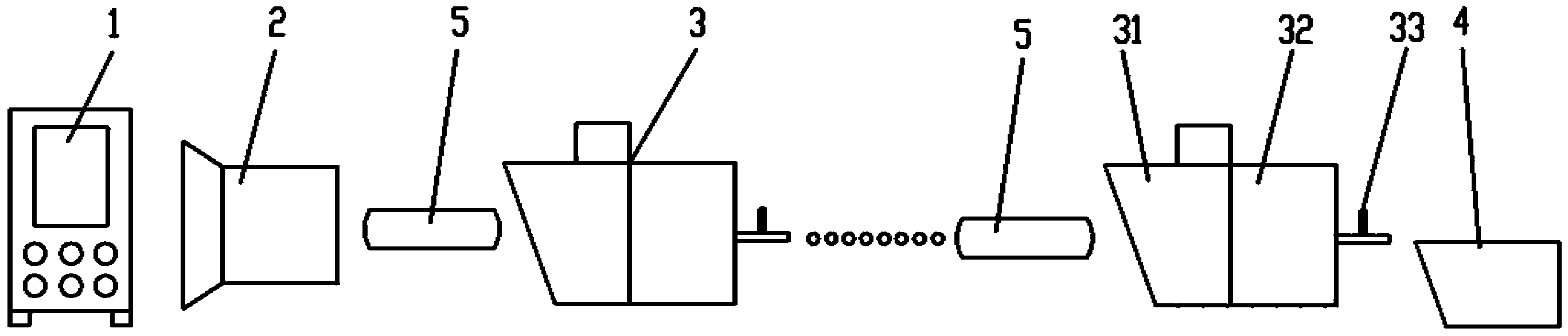

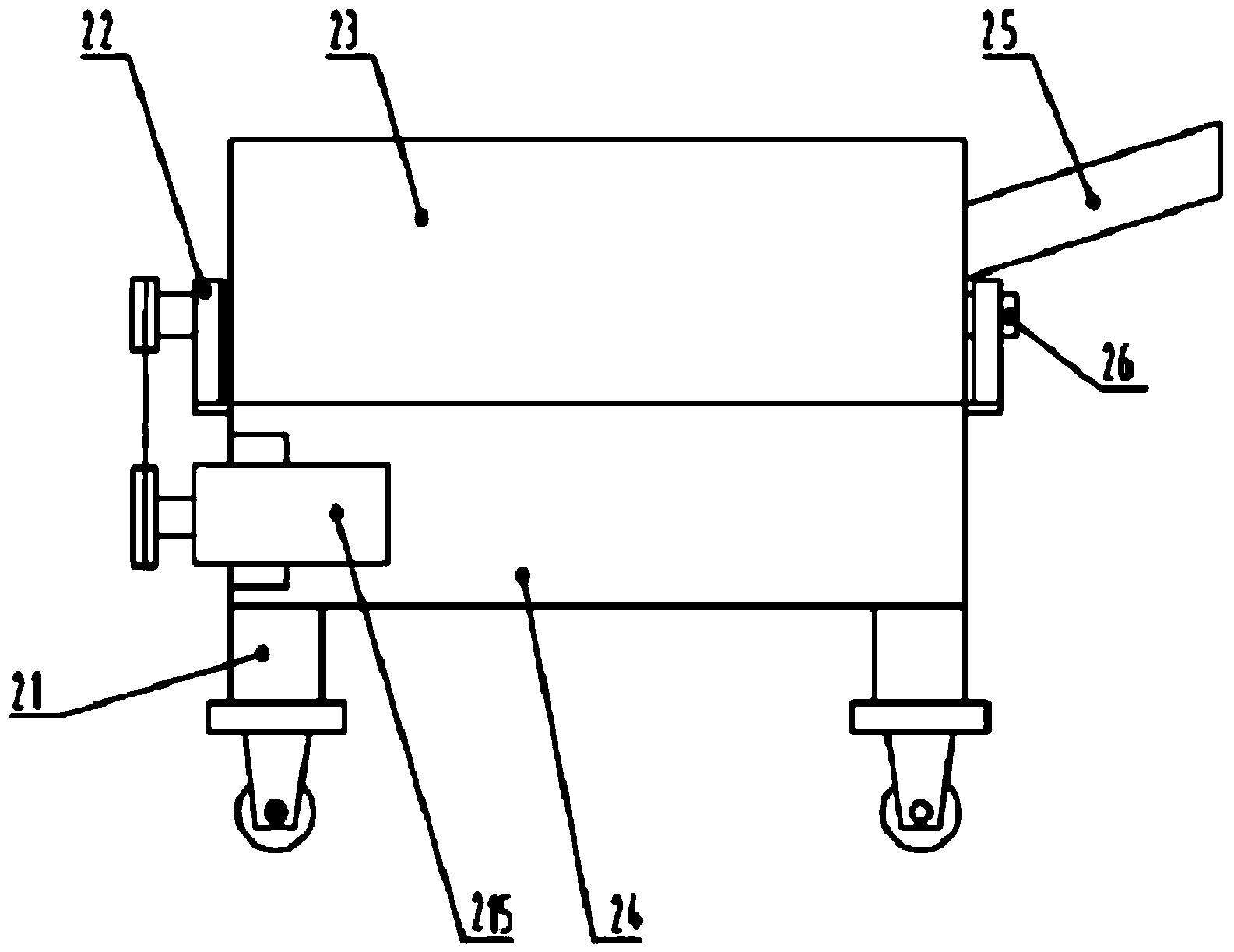

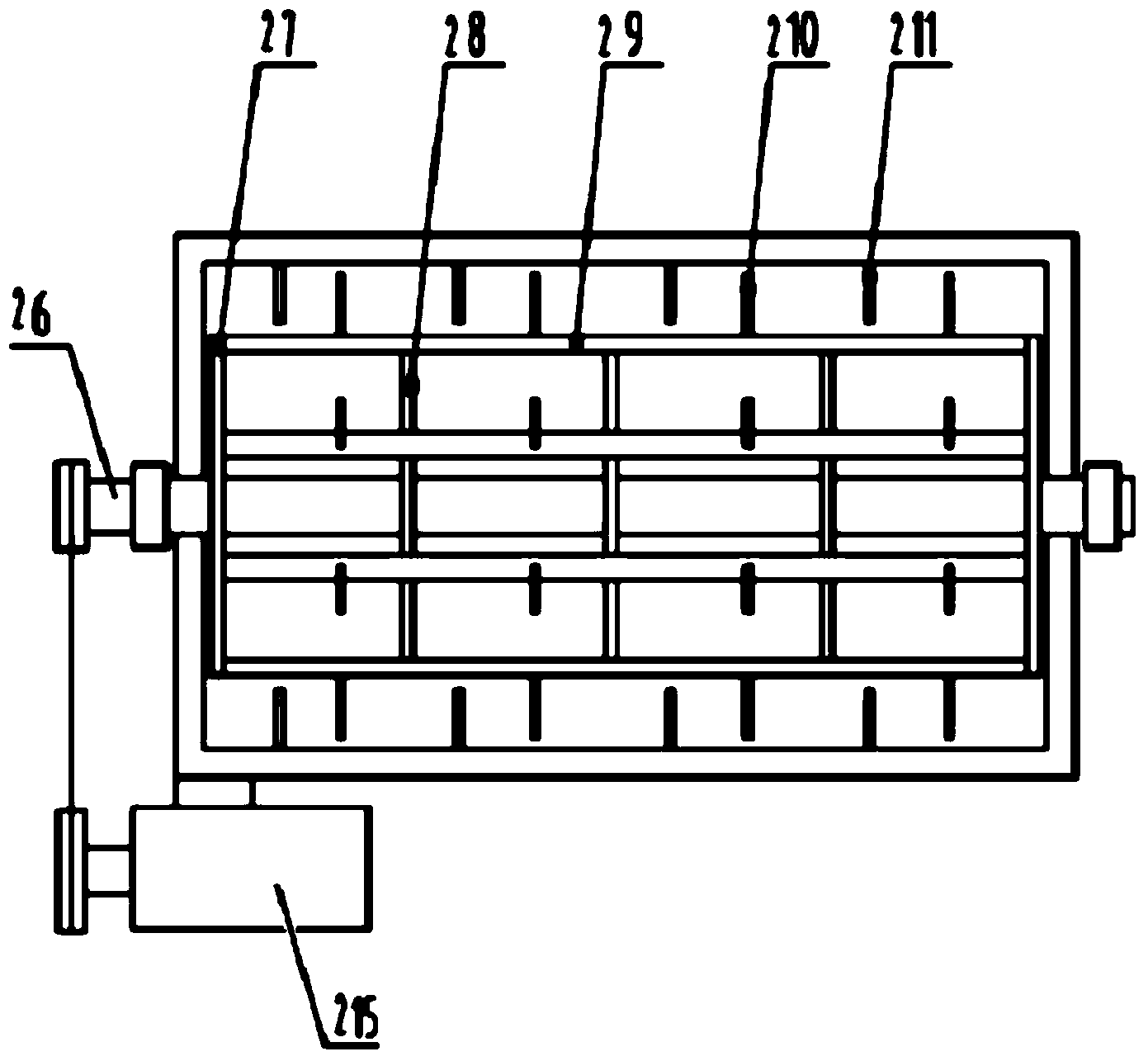

[0034]Referring to the accompanying drawings, the structure of a specific embodiment of the present invention includes an industrial computer 1, an opening machine 2 and 12 carding machines 3 arranged end-to-end in sequence, and the industrial computer 1 monitors the opening machine 2 and the carding machine in real time. 3 and carry out automatic control; the opening machine 2 and the first carding machine 3 are provided with a conveying flat belt 5, and a cashmere conveying flat belt 5 is provided between every two carding machines 3, and the last carding machine 3 The receiving hopper 4 is arranged at the end of each carding machine; each carding machine 3 includes the cashmere feeding mechanism 31 that transports the cashmere into the carding main frame 32, the carding main frame 32 that performs the carding operation, and the cashmere through the carded cashmere in sequence. Moisture regaining mechanism 33 for water spraying and moisture regaining operation; the cashmere f...

Embodiment 2

[0038] With reference to accompanying drawing, working principle of the present invention is:

[0039] A. The cleaned cashmere enters the opening machine 2 to complete the opening and mixing;

[0040] B. The loosened and mixed cashmere enters into 12 carding machines 3 in turn through the conveying flat belt 5, and strictly controls the sequence of the carding machines 3 to ensure that the first carding machine always performs the first carding operation. The X carding machine carries out the X road carding operation all the time; The control parameter of industrial computer 1 is set so that the feeding speed of the latter carding machine 3 cashmere feeding mechanism 31 is 1.1 times of the previous one; Determine the control parameters of the industrial computer 1, for the first and the second carding machine 3, the water spray volume of the second carding machine 3 moisture regain mechanism 33 is 0.14 times of the first carding machine; for the second carding machine After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com