Drive structure of nipper of comber

A driving structure and combing machine technology, which is applied in the direction of combing machines, textiles and papermaking, fiber processing, etc., can solve the problem of unsatisfactory nipper transmission mechanism and mode, affecting the service life of the action precision device, and the inertia of mechanical action Large and other problems, to achieve the effect of simple structure, increased driving power, avoiding running inertia and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

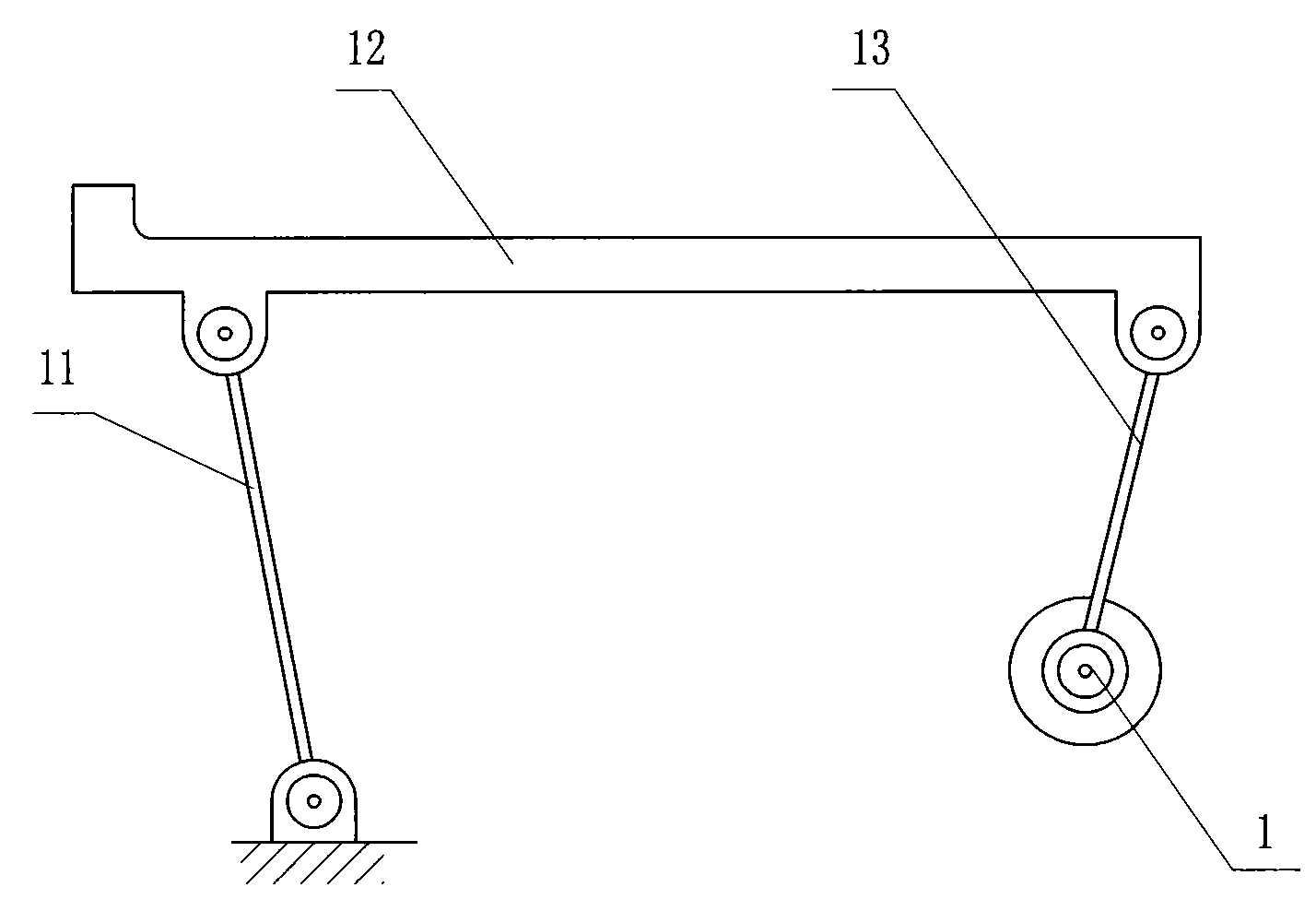

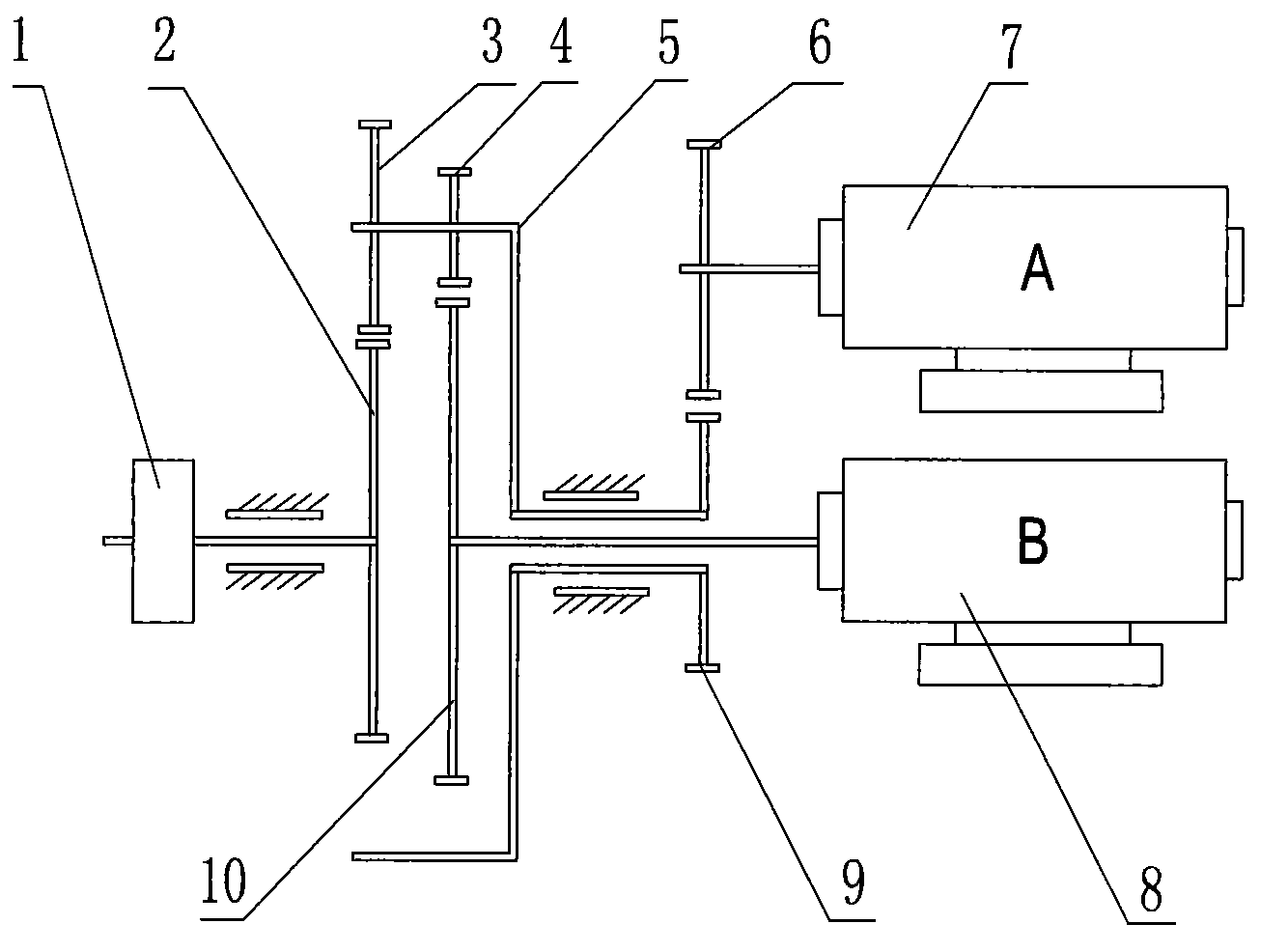

[0027] A driving structure for the nipper of a combing machine. One fulcrum of the nipper 12 is rotatably connected to a support rod 11 which is rotatably connected to a base at the lower part, and another fulcrum of the nipper 12 is rotatably connected to another support rod 13 at the lower part to support The lower end of the rod 13 is fixedly connected to the swing wheel 1 of the servo motor mechanism. The servomotor mechanism is two servomotors, wherein one A servomotor 7 meshes with the planet carrier gear 9 of a planetary gear through the A servomotor gear 6, and the other B servomotor 8 meshes with the sun gear 10 of the planetary gear. The rear planetary gear 4 meshes, and the front planetary wheel 3 meshes with the output gear 2, and the output gear 2 is coaxially connected to the swing wheel 1.

[0028] A servo motor 7 and B servo motor 8 are synthesized on an output gear 2 through a planetary gear mechanism, which not only improves the power to drive the nipper 12, ...

Embodiment 2

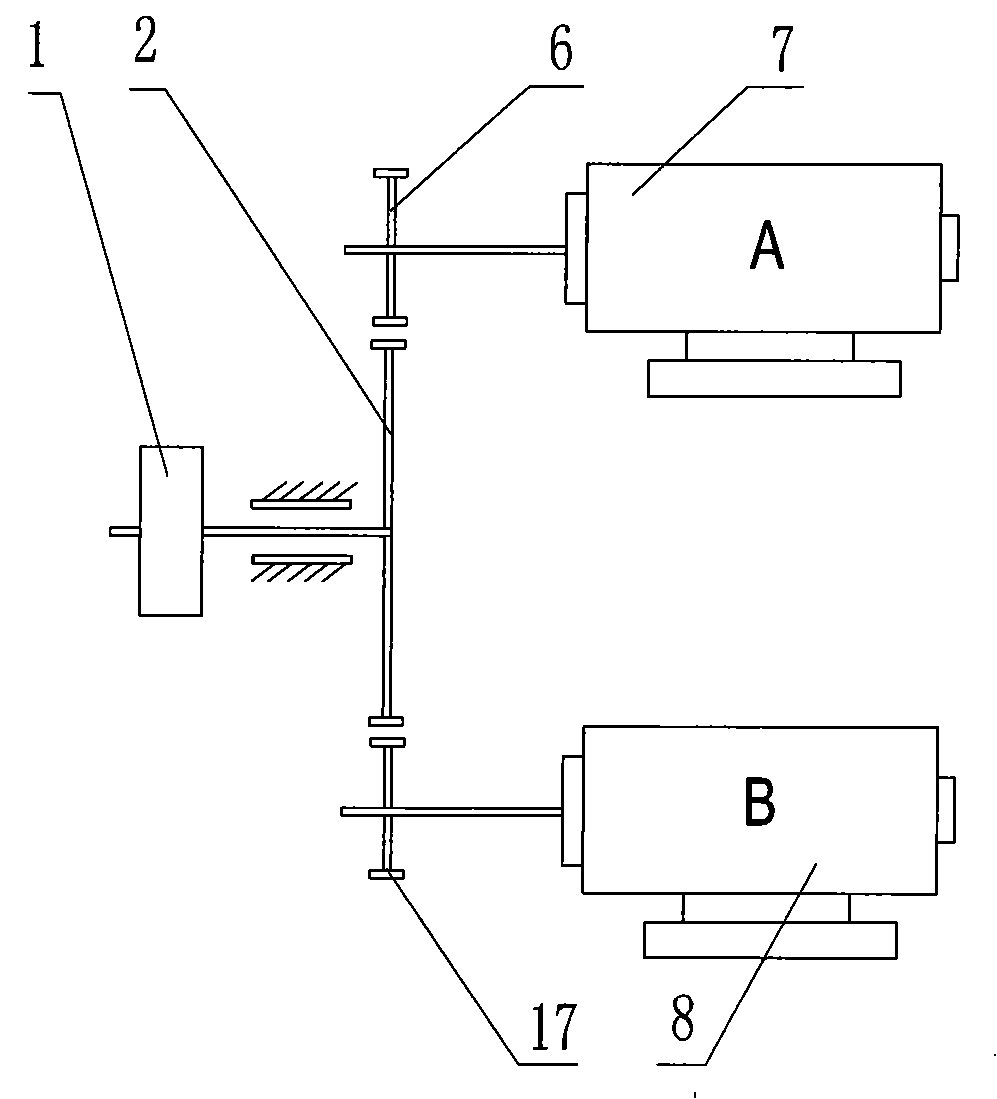

[0030] A driving structure for the nipper of a combing machine. One fulcrum of the nipper 12 is rotatably connected to a support rod 11 which is rotatably connected to a base at the lower part, and another fulcrum of the nipper 12 is rotatably connected to another support rod 13 at the lower part to support The lower end of the rod 13 is fixedly connected to the swing wheel 1 of the servo motor mechanism. The servo motor mechanism is that the A servo motor gear 6 and the B servo motor gear 9 of the two servo motors are both meshed with the coaxial output gear 2 of the swing wheel 1 .

[0031] A servo motor 7 and B servo motor 8 two servo motors directly mesh to drive an output gear 2, and the rotation of the output gear 2 rotates through the eccentric wheel 18 to connect another fulcrum of the nipper 12 to realize the swing operation of the nipper 12. The two servo motors have both improved the power to drive the nipper 12, and are driven by computer programming to drive and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com