Outer tooth milling machine

A gear milling machine and gear milling technology, which is applied in the field of workpiece processing, can solve the problems that the turntable cannot support the workpiece, the positioning of the gear milling equipment is difficult, and the processing quality is affected, and the processing process is smooth, the structure is simple, and the processing efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

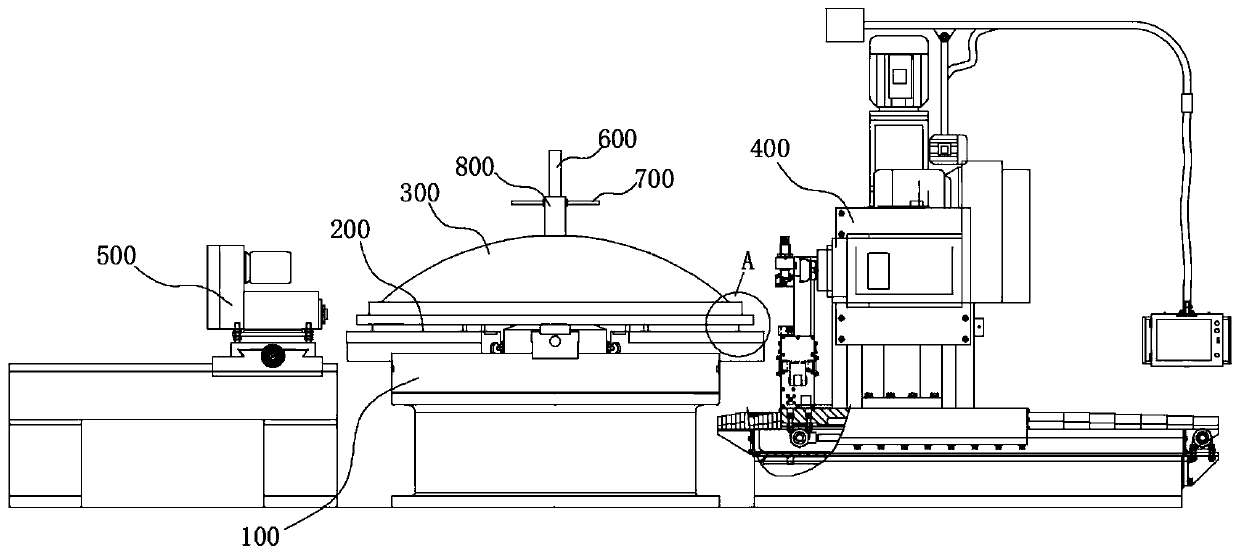

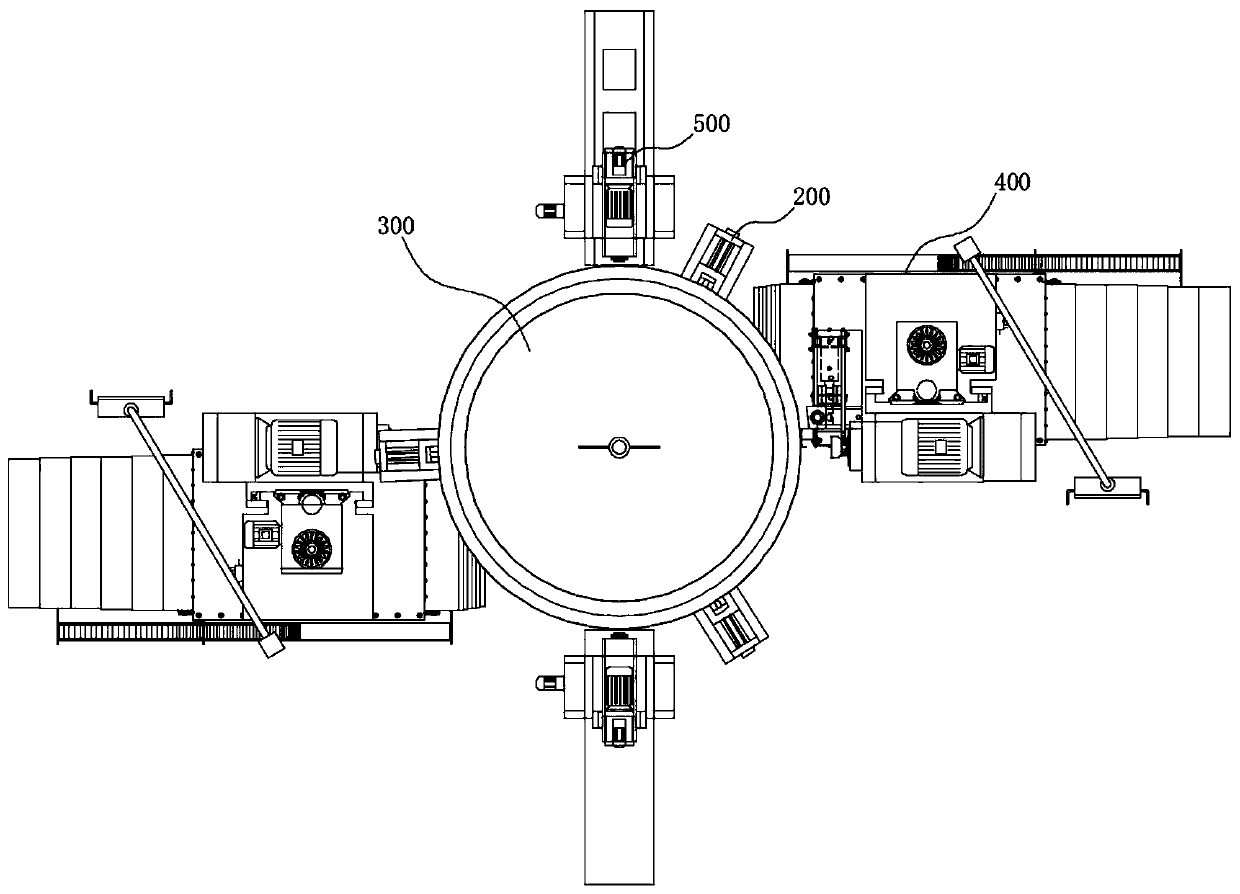

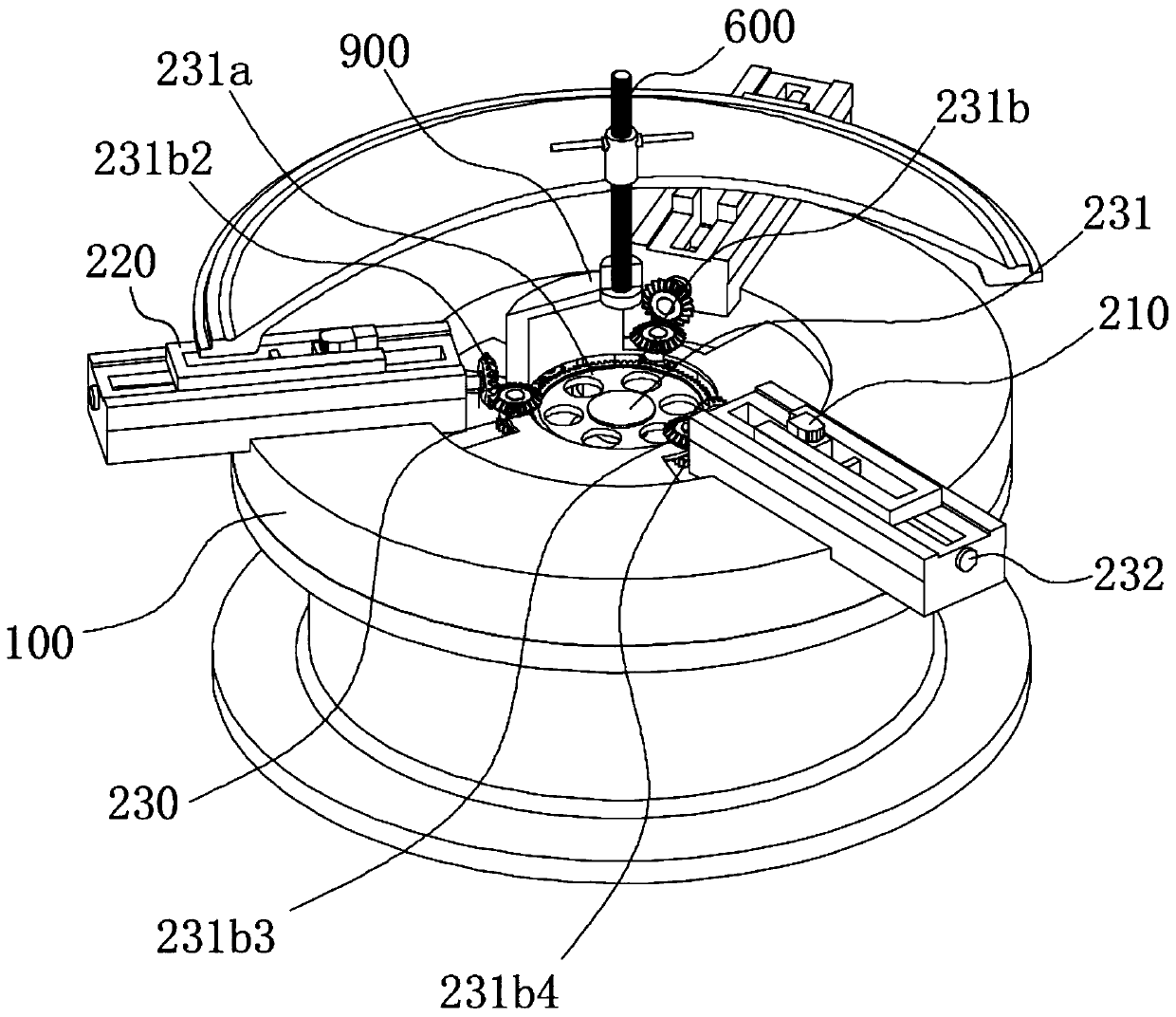

[0037] refer to Figure 1-5 , in the embodiment of the invention, an external gear milling machine is proposed, including a frame, a turntable 100 is installed on the frame, a gear milling device 400 and a vent groove processing device 500 are arranged around the turntable 100, and a clamping device is installed on the turntable 100 200 , the clamping device 200 is used for positioning and clamping the corresponding workpiece 300 and making the outer ring wall of the workpiece 300 to be processed in a state that can be processed.

[0038] Through the setting of the clamping device 200, the workpiece can be positioned first, and the workpiece can be positioned to the position where the center line of the workpiece is in line with the rotation axis of the turntable and the workpiece can be clamped, which is convenient for high-speed milling processing of the workpiece , for workpieces of different sizes, the clamping device 300 can make the outer ring wall of the workpiece to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com