Non-contour tooth card clothing

A carding needle, non-equal height technology, applied in the field of fixed opening parts and movable flats, can solve the problems of fiber and needle tooth damage, increased carding load, different states, etc., and achieves improved side-slip carding effect, Reduces carding damage and eases the effect of carding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

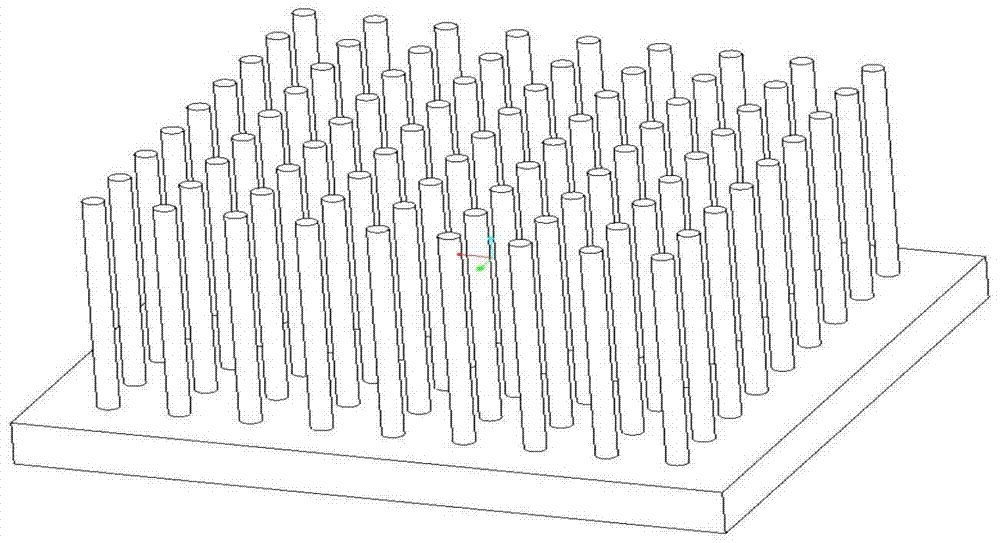

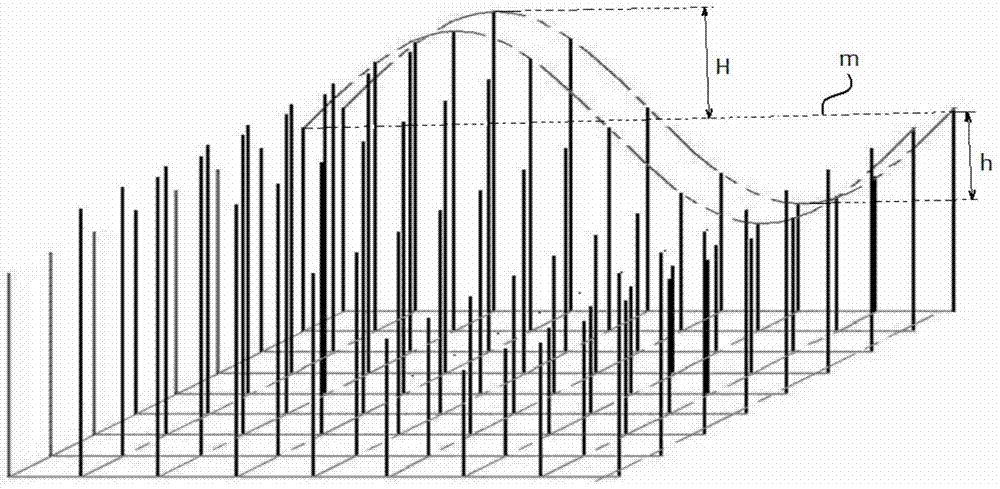

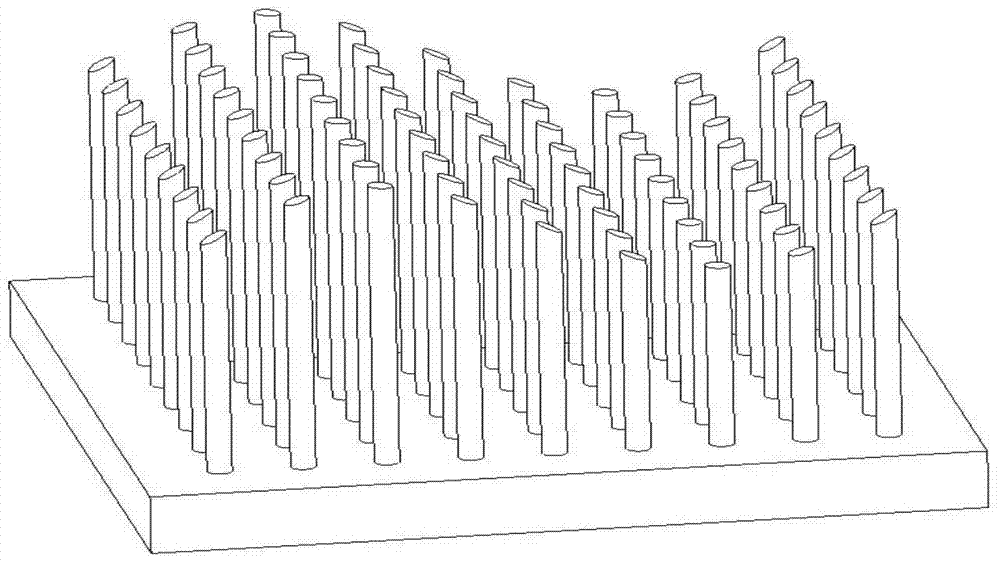

[0011] The non-contour tooth card clothing disclosed in the patent application of the present invention can be designed as a fixed carding part or a movable flat card clothing, and is widely used in carding parts such as cotton spinning, wool spinning, hemp spinning, non-woven fabrics, and silk spinning. This non-equal-tooth carding clothing is composed of non-uniform tooth-height clothing units arranged continuously. The wave direction between uniform tooth height clothing units is connected and continuous. For the amplitude of the wave direction, the maximum tooth height H and the minimum tooth height h are relative to the surface m formed by the tooth height of the conventional card clothing design. The standard tooth height surface has a maximum height difference of +3mm upward and - 3mm. The feature of the technical solution is only to limit the direction shape of the top surface of the tooth tops of the many needle teeth of the card clothing, and is not limited by the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com