Toothed cloth for a comb piece of a combing machine

A technology of combs and carding machines, applied in the field of tooth card clothing, to achieve good carding effect and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

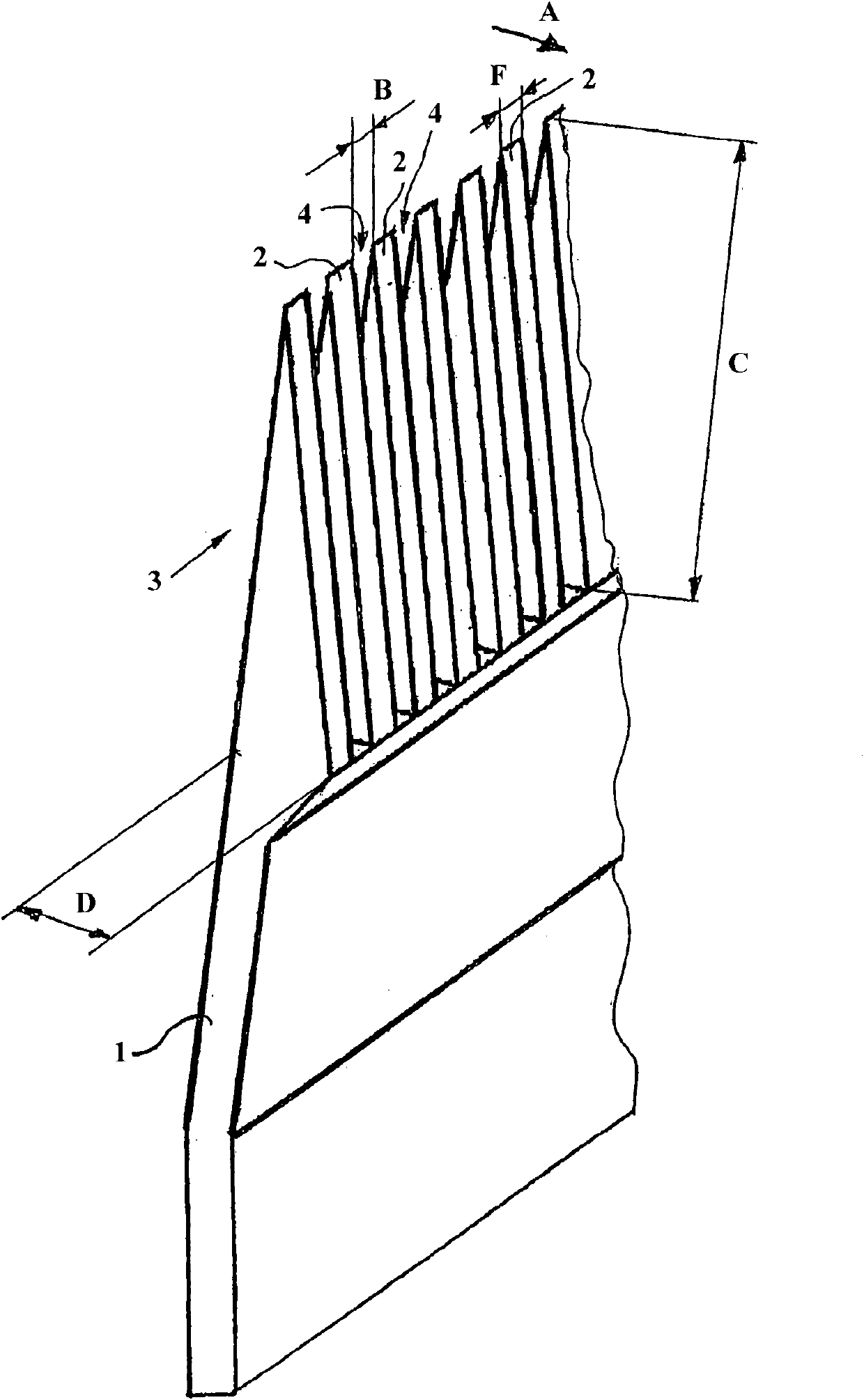

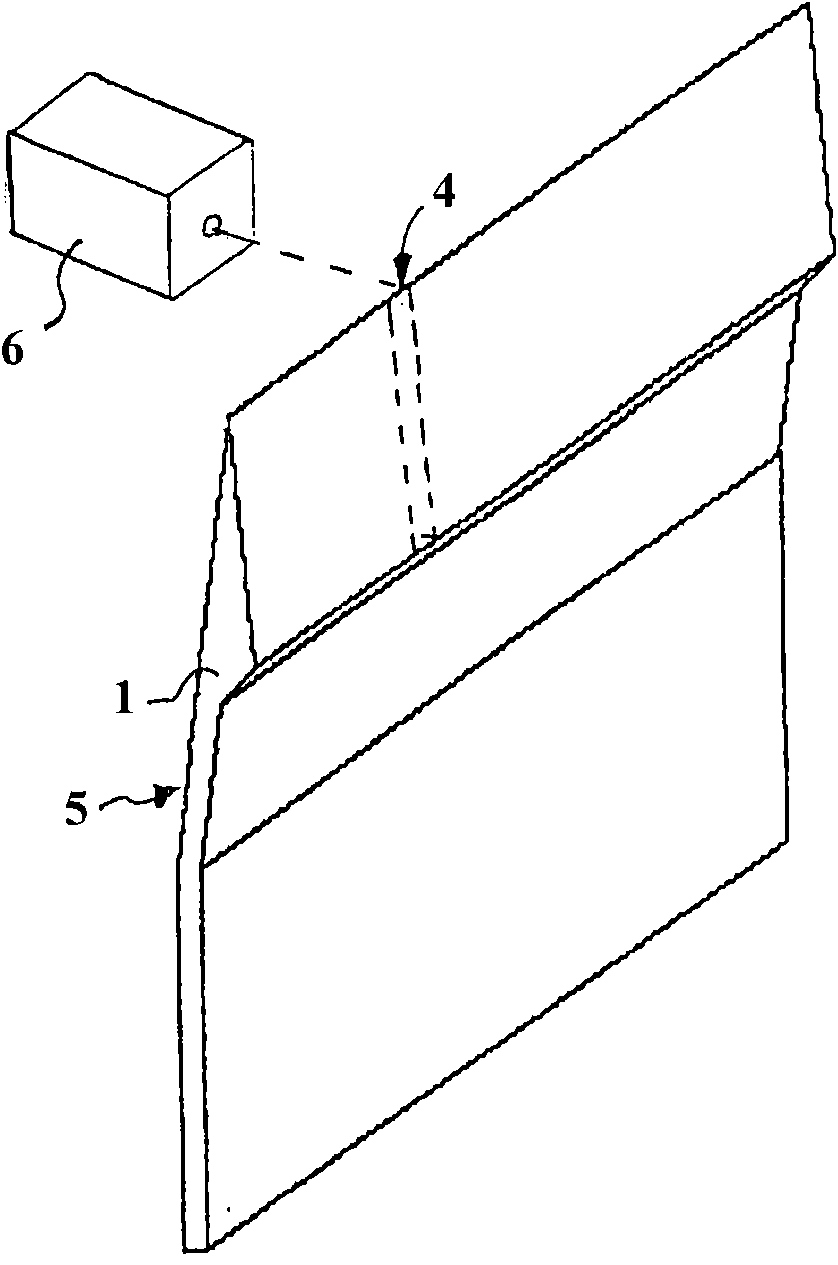

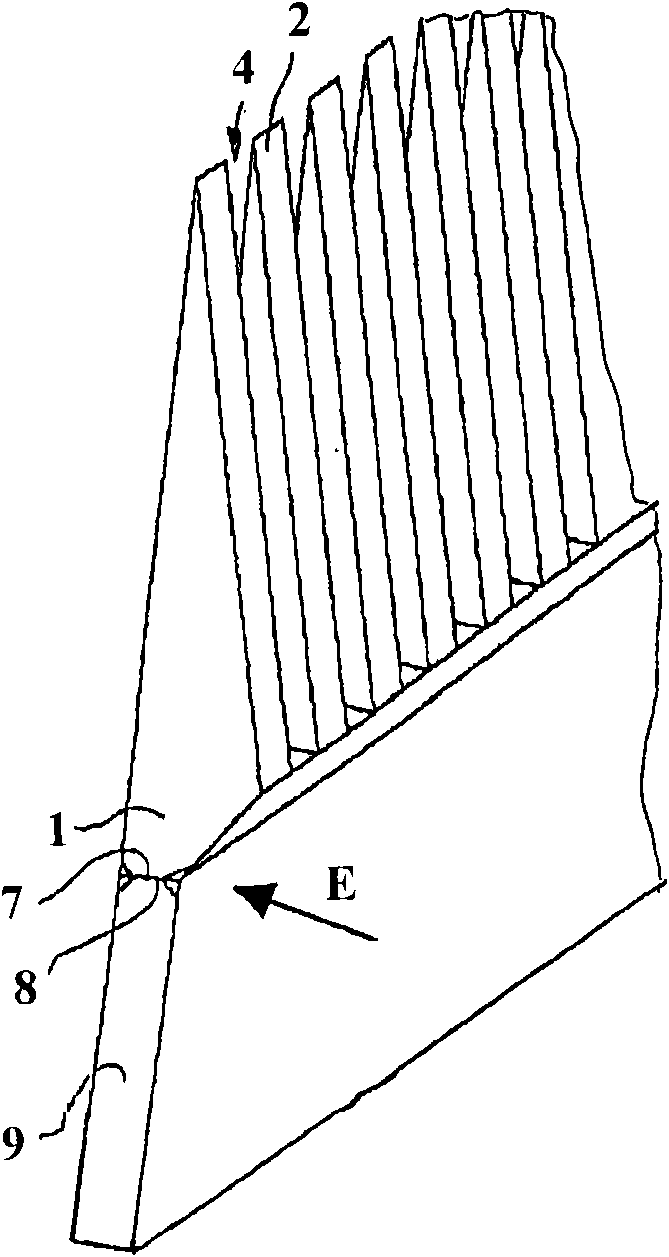

[0019] in figure 1 Shown therein is a toothed card clothing 1 according to the invention for the top comb of a carding machine. The working mode of the top comb in a carding machine is known per se and is described, for example, in the document DE 102006030763A1. The toothed card clothing 1 includes a large number of teeth 2 arranged side by side, which constitute a tooth row 3. The working direction of card clothing 1 is figure 1 It is represented by arrow A. The tooth row 3 is oriented perpendicular to the working direction. Between two adjacent teeth 2 there is a tooth gap 4 extending in the working direction.

[0020] Viewed transversely to the working direction A, the tooth 2 has a width F and the tooth gap 4 has a width B. The widths F and B are each measured parallel to the extension of the tooth row 3 (Erstreckung). in figure 1 In the figure, the width B and width F from the tip of the tooth to the root (Zahnfuss) are constant. This is only an advantageous design sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com