Parachute cord combing clamp with self-locking function

A self-locking, paracord technology, applied in thin material handling, conveying filamentous materials, transportation and packaging, etc., can solve the problems of low carding process efficiency and mutual misalignment of paracords, so as to improve efficiency and prevent damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] The fixture of the present invention is used to check whether the assembly relationship between the umbrella rope and the canopy is wrong. If a problem is found, the umbrella rope and the canopy can be reassembled, so that the inspection time of the whole process is greatly shortened. The specific structure is as follows:

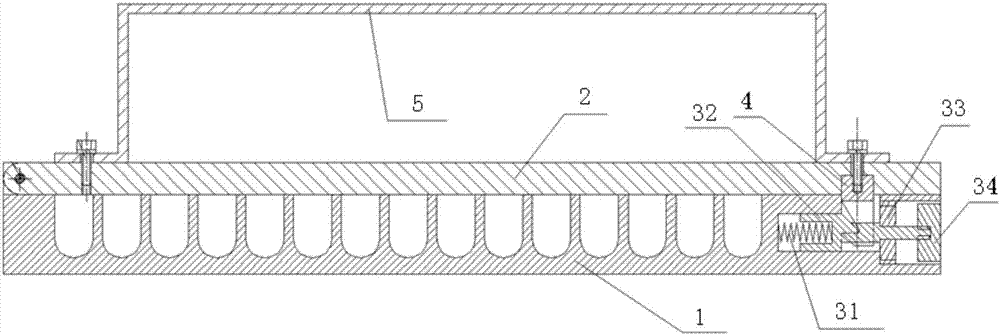

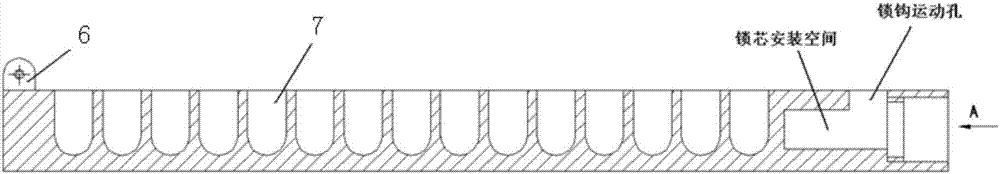

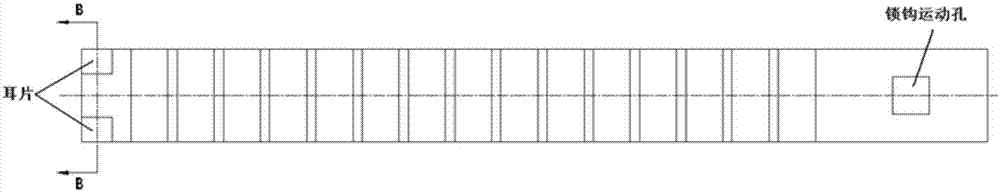

[0031] A parachute carding fixture with self-locking function, such as figure 1 , image 3 and Figure 4 As shown, it includes a comb groove 1, a pressing plate 2 and a locking structure. The comb groove 1 is provided with a number of grooves matching the number of paracords for passing through the umbrella ropes; the pressing plate 2 is connected to the comb groove 1, and can be just cover groove 7, such as figure 2 As shown; the locking structure is located inside the carding fixture, and is used to realize the locking and unlocking b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com