Carding operating platform for floating hair on surface of fur

An operation platform and floating hair technology, which is applied in the fur repairing and other directions, can solve the problems of pollution, inconvenient operation, and affecting the quality of the surface fluff of the fur, and achieve the effect of improving the operating environment and improving portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

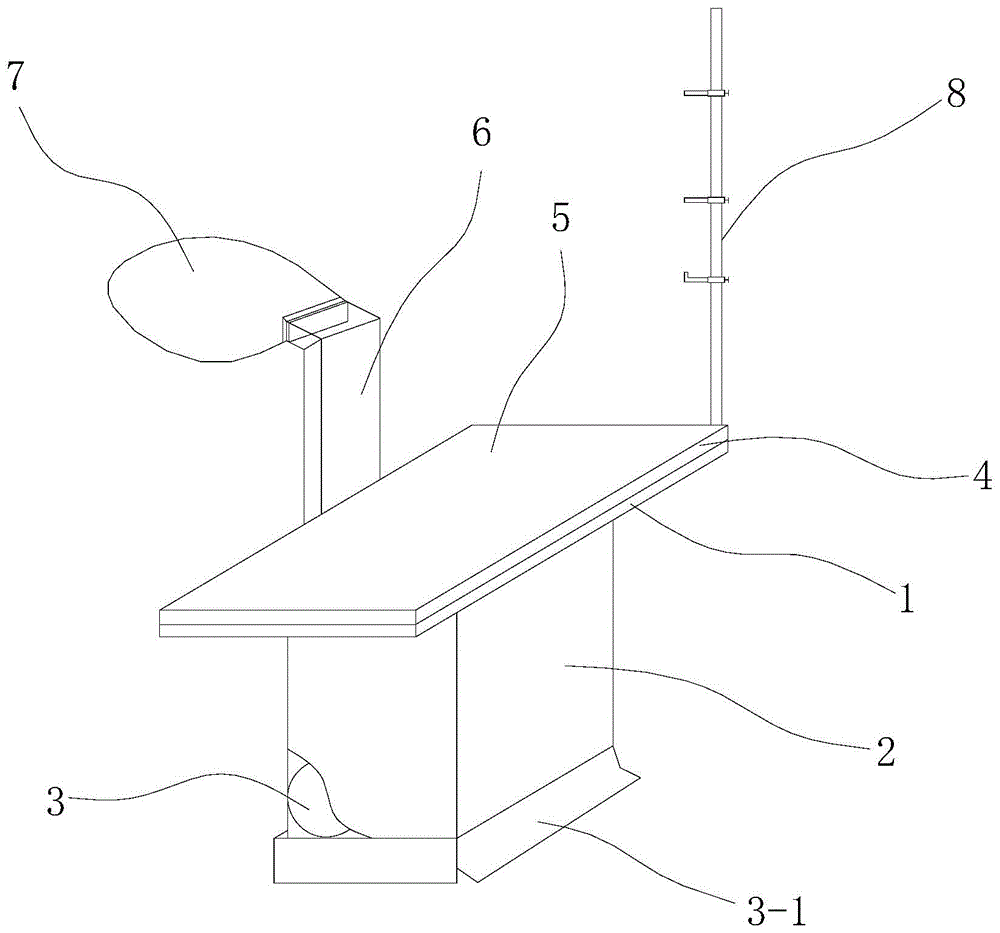

[0009] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0010] see figure 1 , an operating platform for combing floating hair on the fur surface, mainly comprising an operation panel 1 and a bellows 2, wherein the bellows is located below the operation panel, an induced draft fan 3 is fixedly installed in the bellows, and the operation panel 1 is provided with a The air inlet connected to the induced draft fan, the switch 3-1 of the induced draft fan is designed as a foot switch, and a breathable sponge pad 4 is placed on the upper surface of the operation panel 1; a breathable pad 5 is laid on the top of the breathable sponge pad, The surroundings of the pad cloth are wrapped on the sponge pad, the air outlet of the induced draft fan is connected with an exhaust duct 6, and the tail end of the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com