Automatic oil edge machine and positioning device thereof

A positioning device and oil edge machine technology, which is applied in the direction of conveyor objects, transportation and packaging, small raw hide/large raw hide/leather/fur mechanical processing, etc., which can solve the problem of complex positioning mechanism settings, high user requirements, and inaccurate positioning and other issues to achieve the effect of saving working time, low manufacturing cost and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

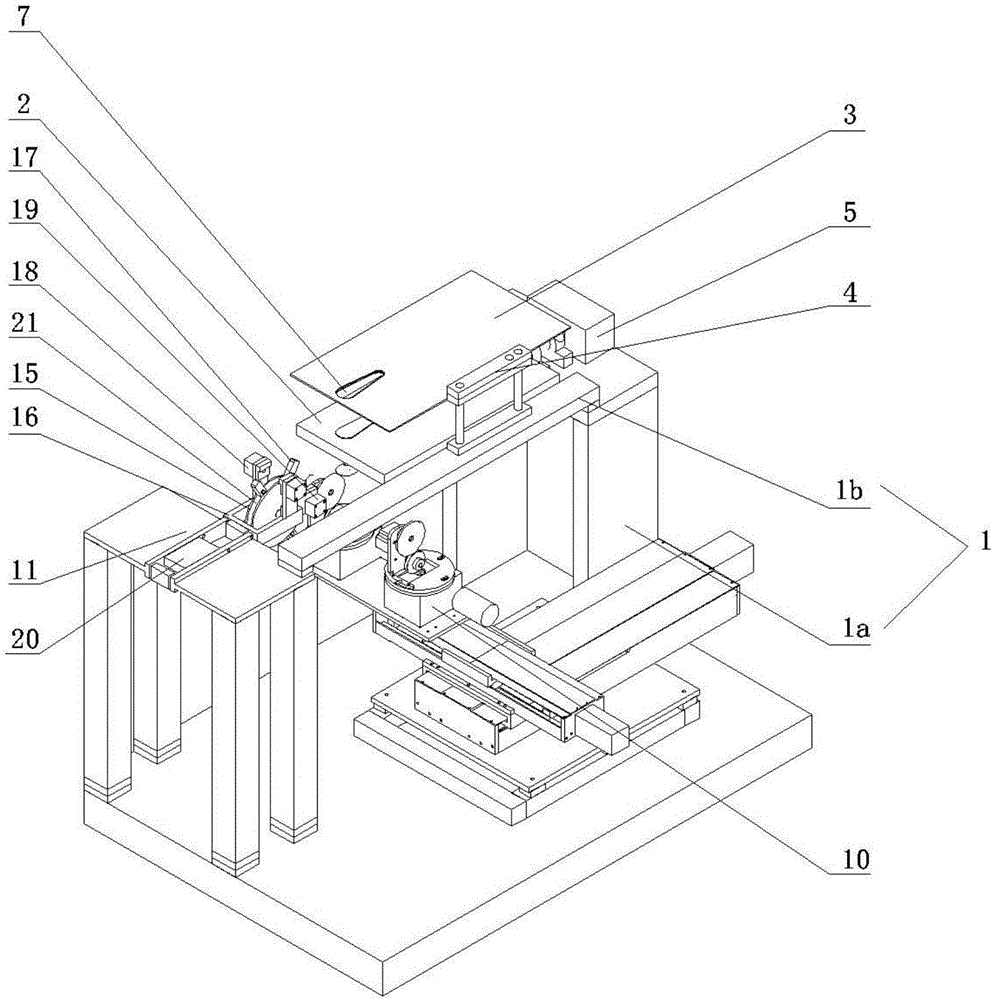

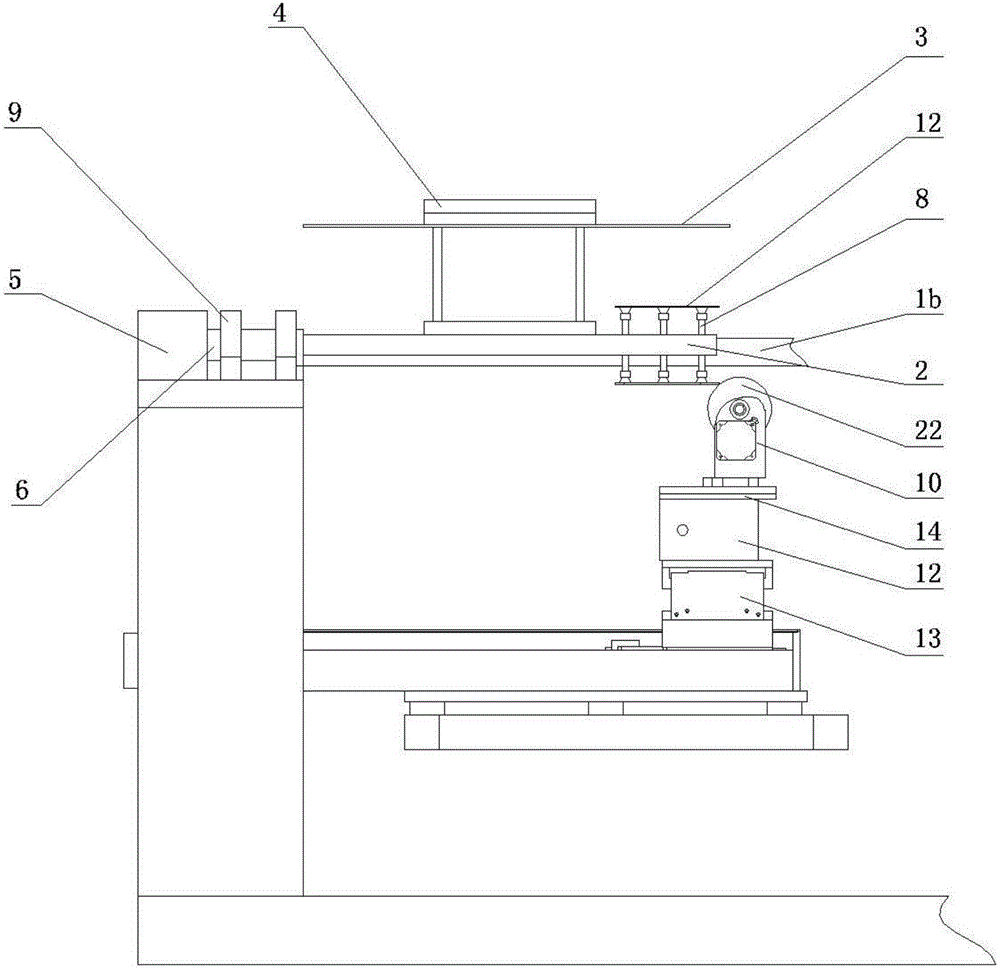

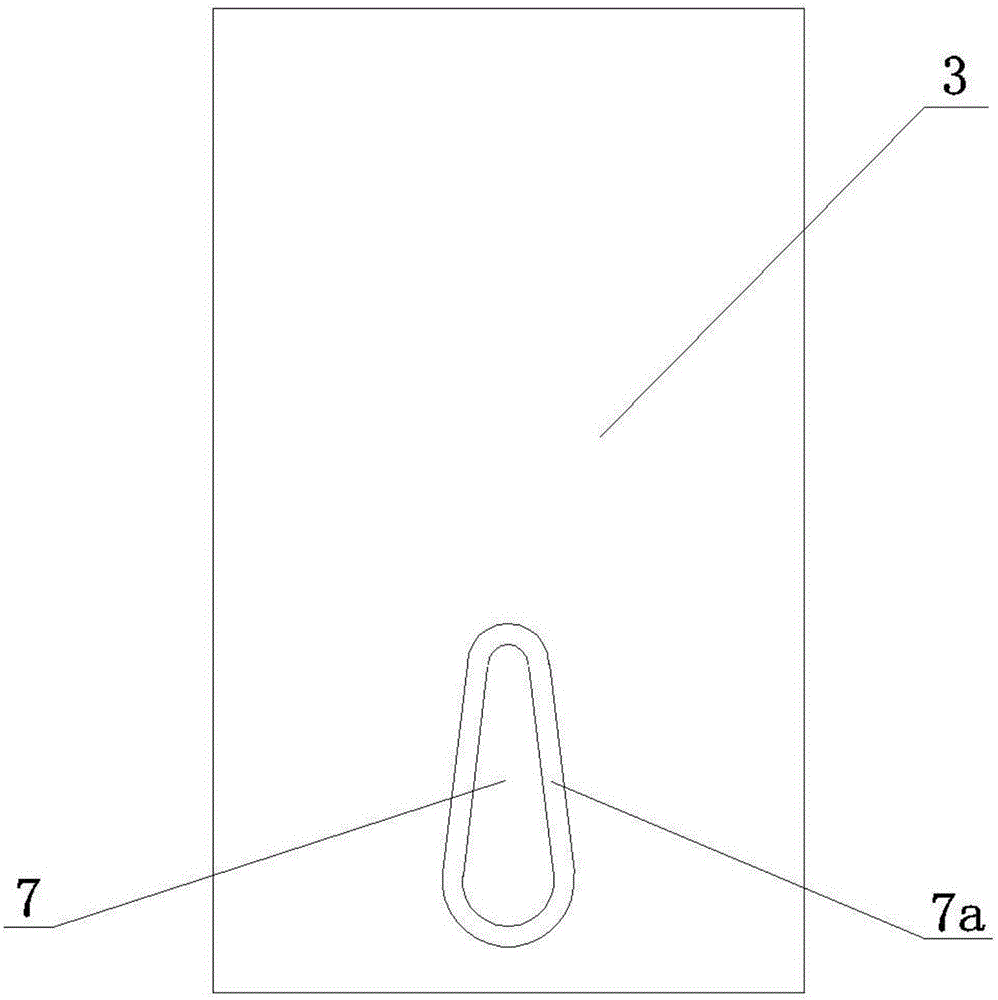

[0027] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1~3 :

[0028] like Figure 1~2 As shown, a positioning device for an automatic oil edge machine includes a frame 1, a positioning plate 2 and a template 3, the frame 1 includes a base 1a, and a support rod 1b is provided on the support rod, and the support rod A lifting cylinder 4 is fixedly installed on 1b; a mold hole 7 corresponding to the shape of the oil edge material is formed on the template 3; the template 3 is detachably connected to the lifting cylinder 4; A suction nozzle 8 capable of absorbing oil edge materials is provided; a steering cylinder 5 is provided on the frame 1 ; the positioning plate 2 is connected to the steering cylinder 5 through a main shaft 6 .

[0029] The upper and lower sides of the positioning plate 2 are provided with more than one suction nozzle 8, the position of the suction nozzle 8 corresponds to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com