Patents

Literature

50results about "Fur cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

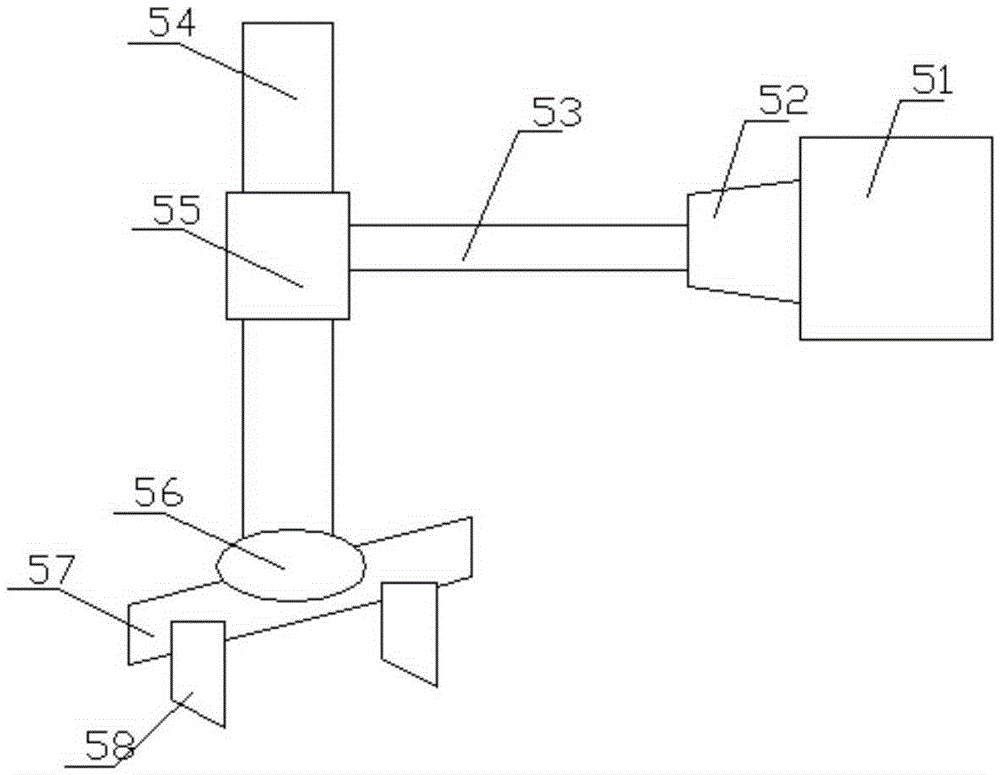

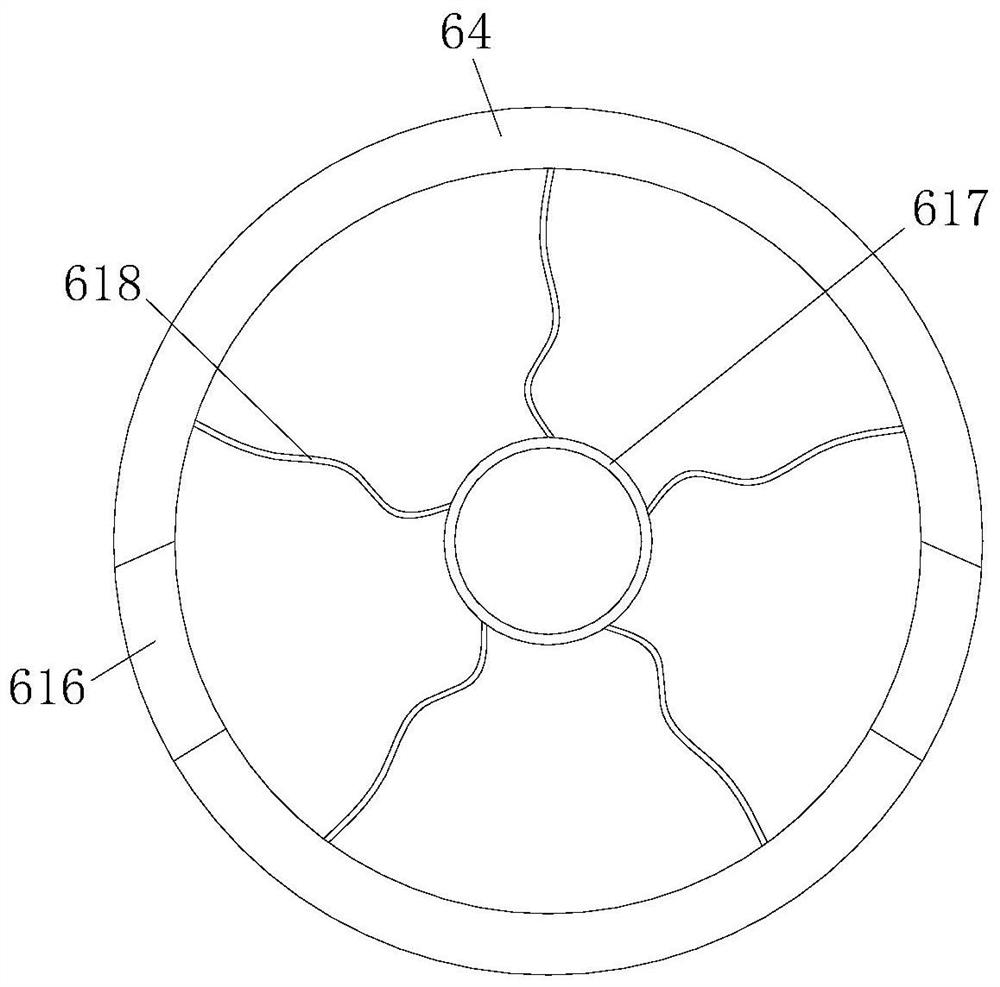

Rotary platform cow leather cutting machine

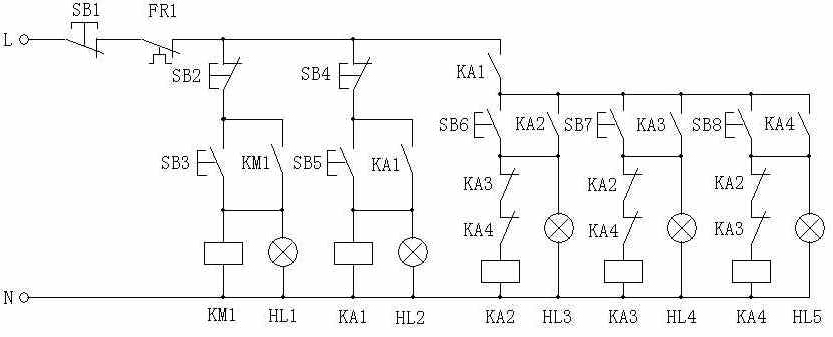

InactiveCN106881738APrevent movementDimensionally stableFur cuttingMetal working apparatusEngineeringMechanical engineering

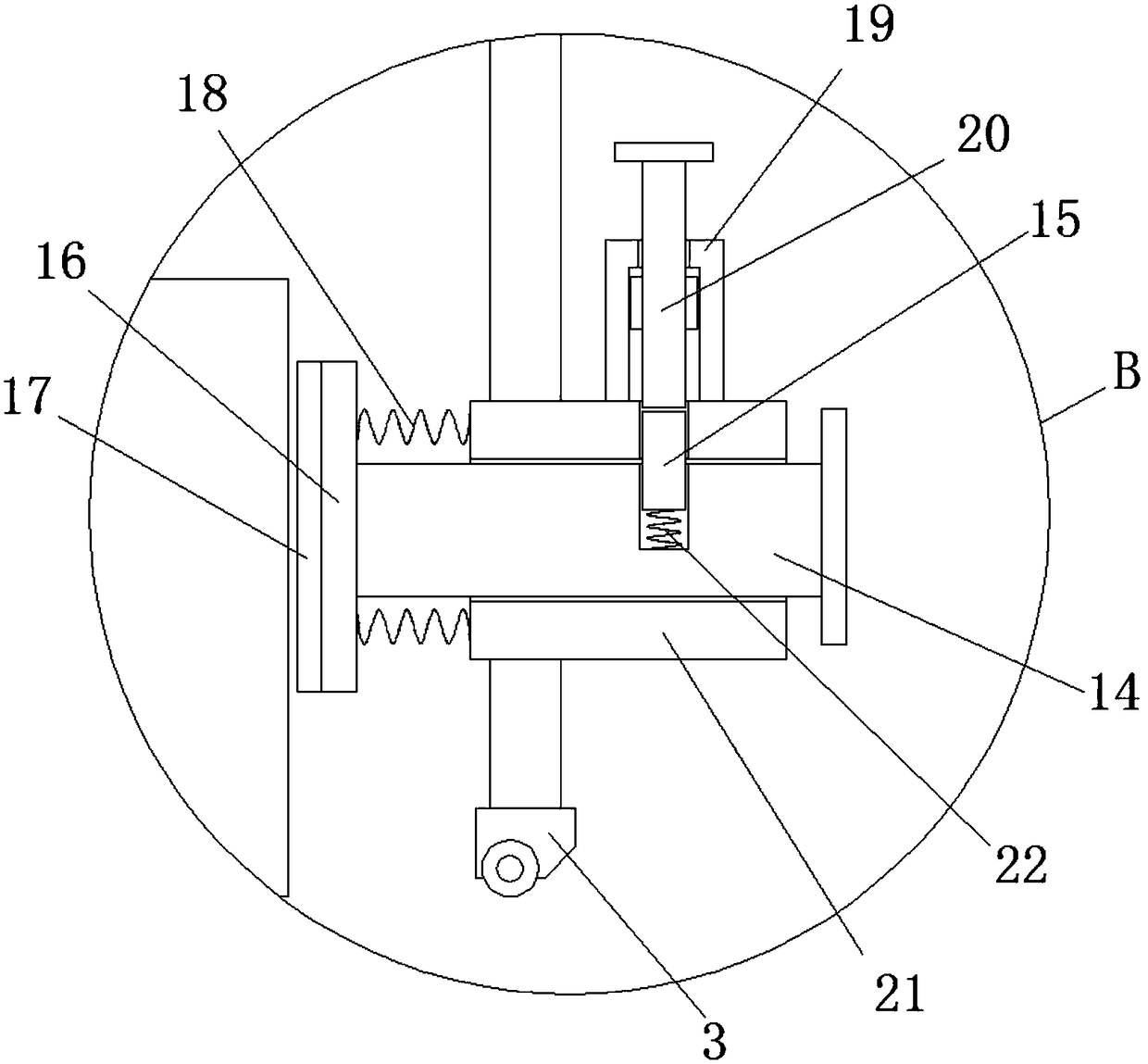

The invention discloses a rotary platform cow leather cutting machine, and belongs to the technical field of cow leather cutting equipment. The rotary platform cow leather cutting machine is characterized by comprising a cutting platform, a pressing mechanism and a cutting mechanism; the pressing mechanism is arranged above the cutting platform and cooperates with the cutting platform to press to-be-cut cow leather, and the cutting mechanism and the pressing mechanism cooperate to cut the cow leather; and a rotating mechanism driving the cutting platform to rotate is connected to the lower portion of the cutting platform, so that the cow leather is cut into blocks by the cutting mechanism. According to the rotary platform cow leather cutting machine, the rotating mechanism driving the cutting platform to rotate is connected to the cutting platform, the rotating mechanism drives the cutting platform together with the cow leather on the cutting platform to rotate, accordingly, the cow leather can be cut in different directions through only one cutting mechanism and is cut into blocks; and the pressing mechanism and the cutting platform are matched to clamp the to-be-cut cow leather, so that the cutting precision of a longitudinal cutting mechanism and the cutting precision of a transverse cutting mechanism are greatly improved, and the stability of the size of the cut cow leather is ensured.

Owner:SHANDONG UNIV OF TECH

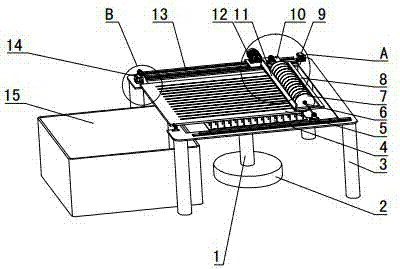

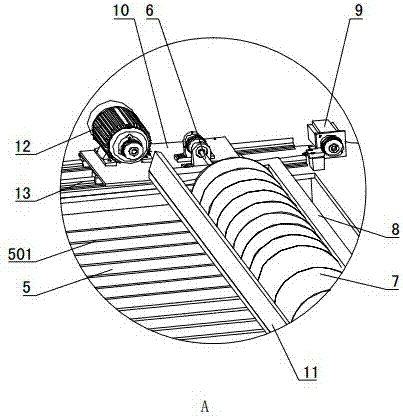

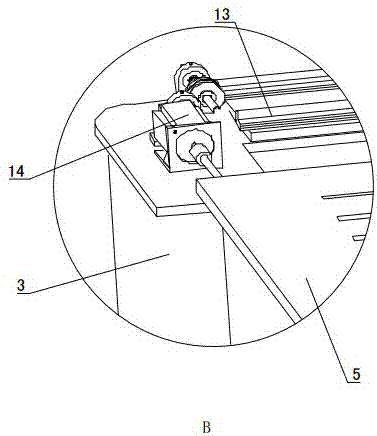

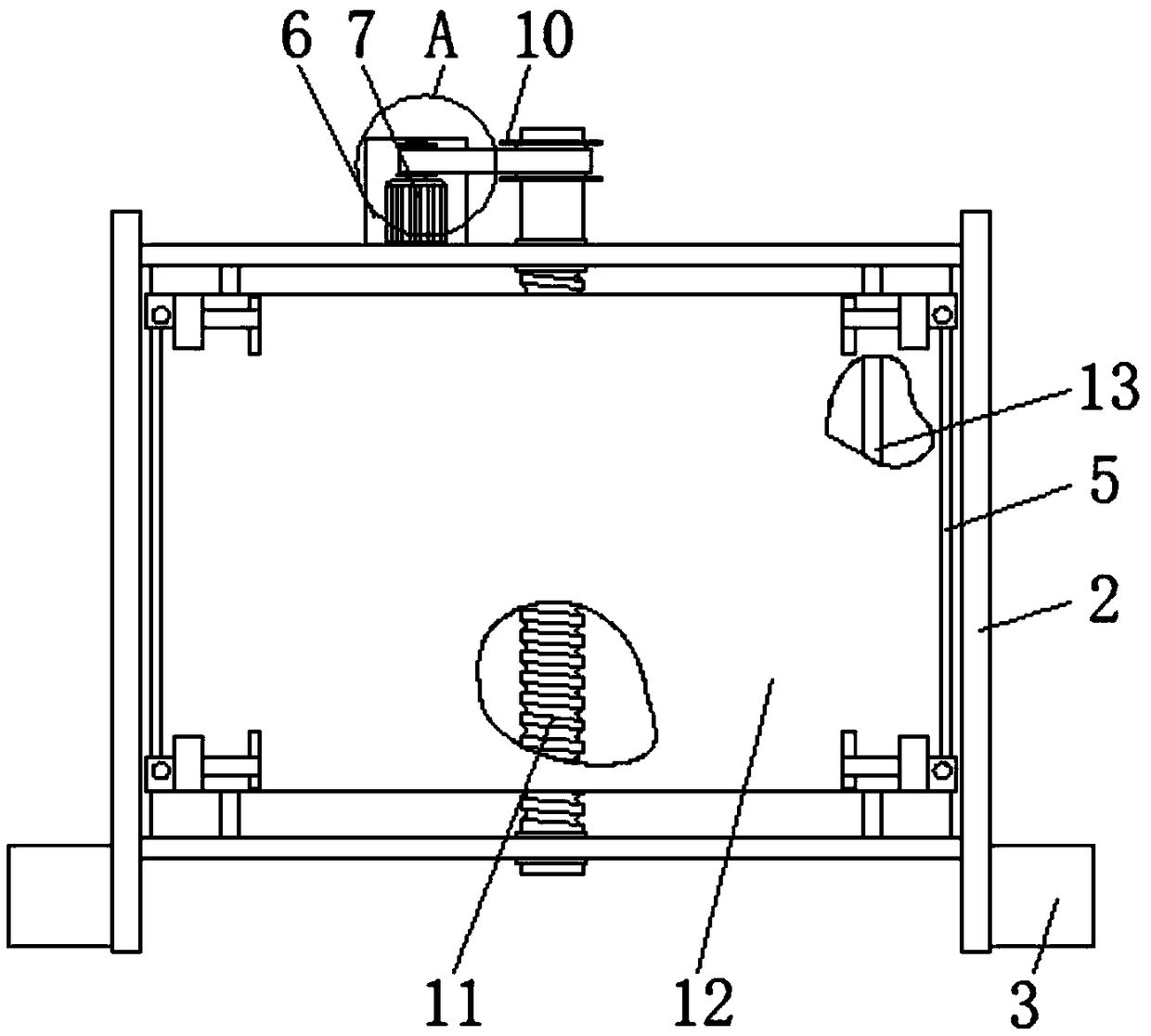

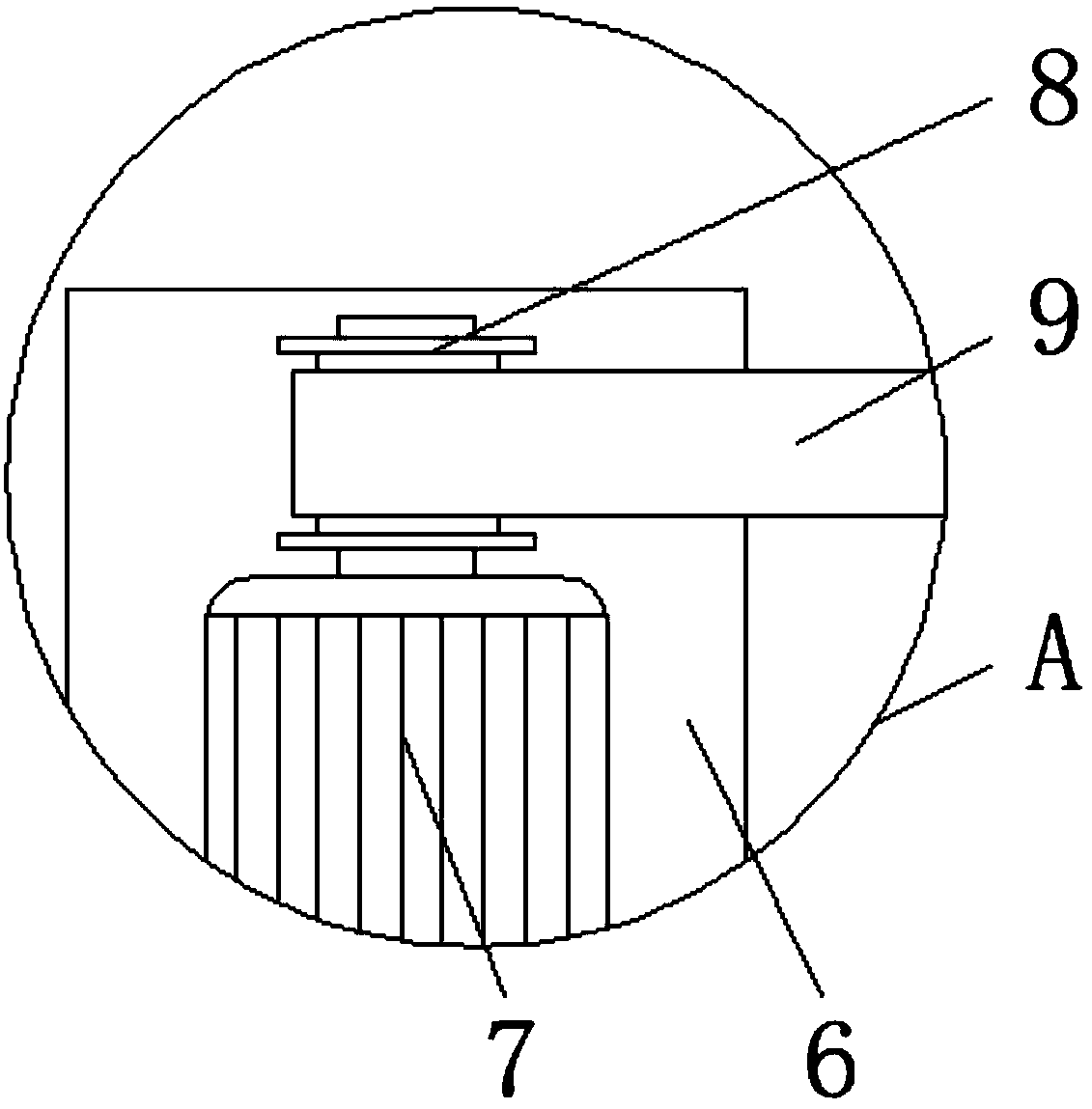

Vertical pressing plate type cow leather cutting machine

InactiveCN106881737APrevent movementDimensionally stableFur cuttingMetal working apparatusEngineeringMechanical engineering

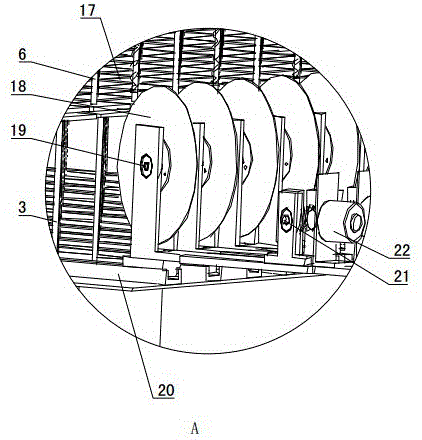

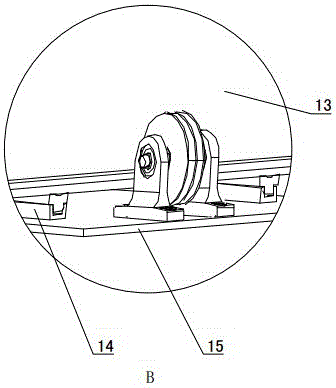

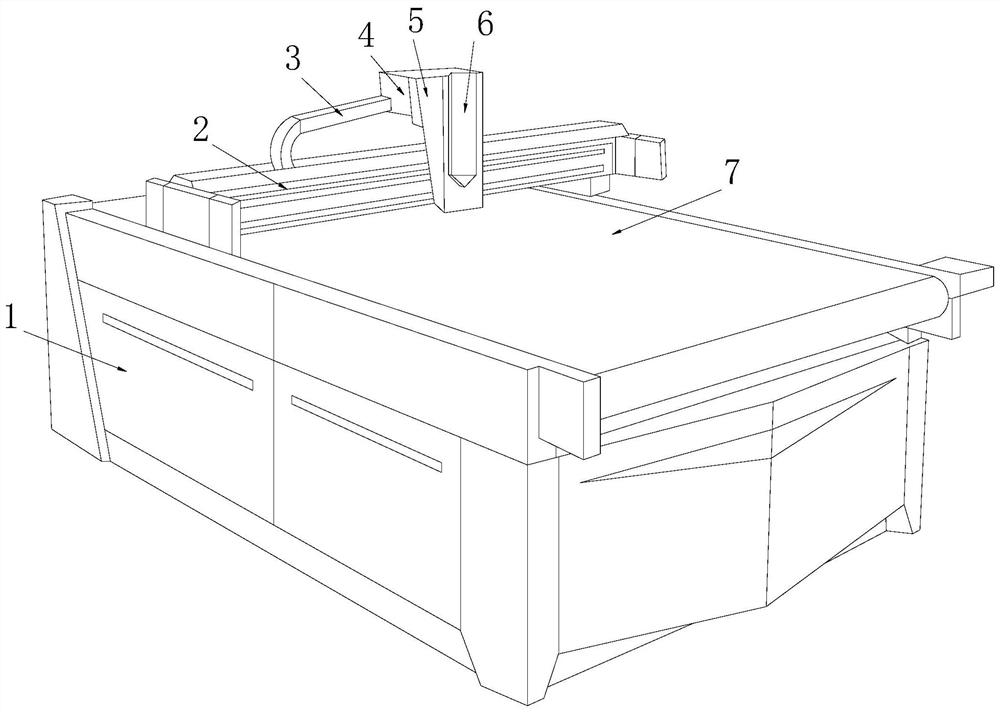

The invention discloses a vertical pressing plate type cow leather cutting machine and belongs to the technical field of cow leather cutting equipment. The vertical pressing plate type cow leather cutting machine is characterized by comprising a cutting platform (7), a transverse cutting mechanism and a longitudinal cutting mechanism; a longitudinal pressing mechanism and a transverse pressing mechanism are arranged on the cutting platform (7) and alternately matched with the cutting platform (7) to tightly press to-be-cut cow leather; and the transverse pressing mechanism and the transverse cutting mechanism cooperate to cut the cow leather, and the longitudinal pressing mechanism and the longitudinal cutting mechanism cooperate to cut the cow leather, so that the cow leather is cut into blocks. According to the vertical pressing plate type cow leather cutting machine, the longitudinal pressing mechanism and the transverse pressing mechanism can be matched with the cutting platform to tightly press the cow leather, the situation that the cow leather moves in the cutting process is avoided, accordingly, the cutting precision of the longitudinal cutting mechanism and the cutting precision of the transverse cutting mechanism are greatly improved, and the stability of the size of the cut cow leather is ensured; and thus, the follow-up machining technology is simplified, and the product quality is improved.

Owner:SHANDONG UNIV OF TECH

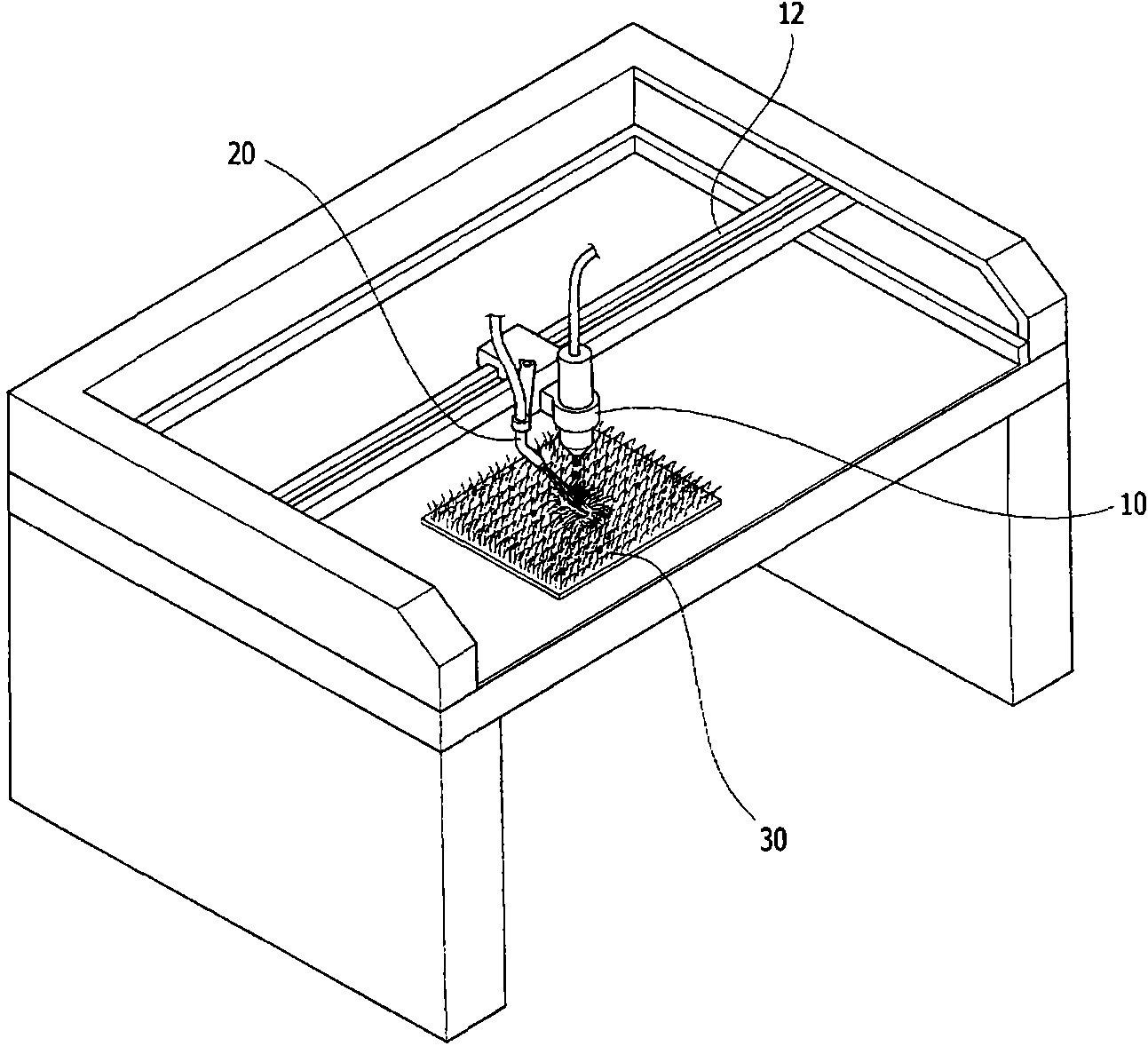

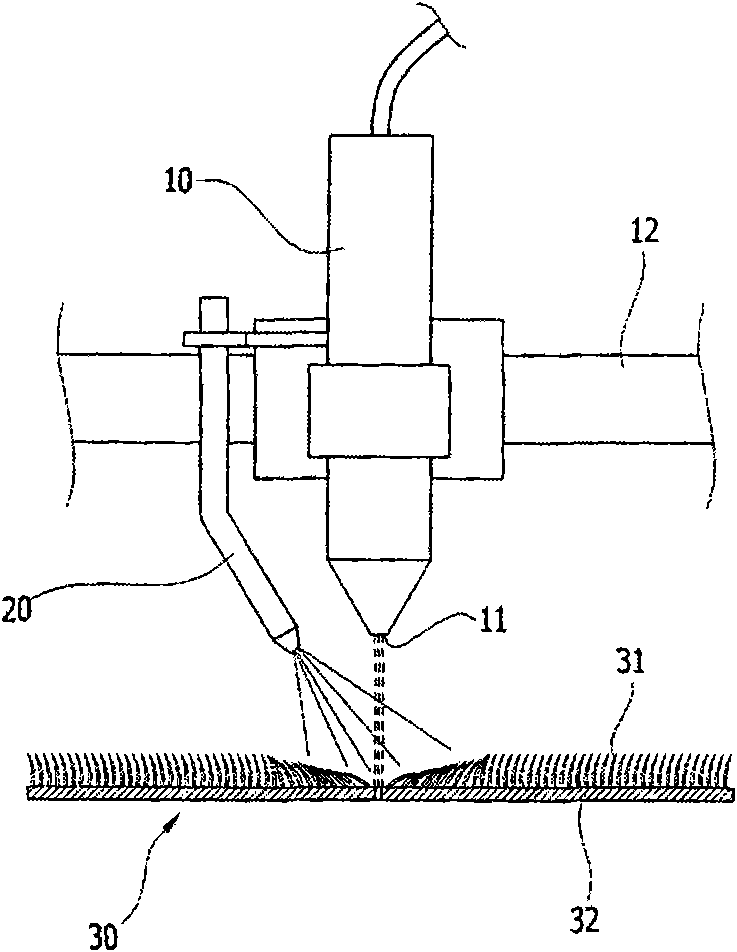

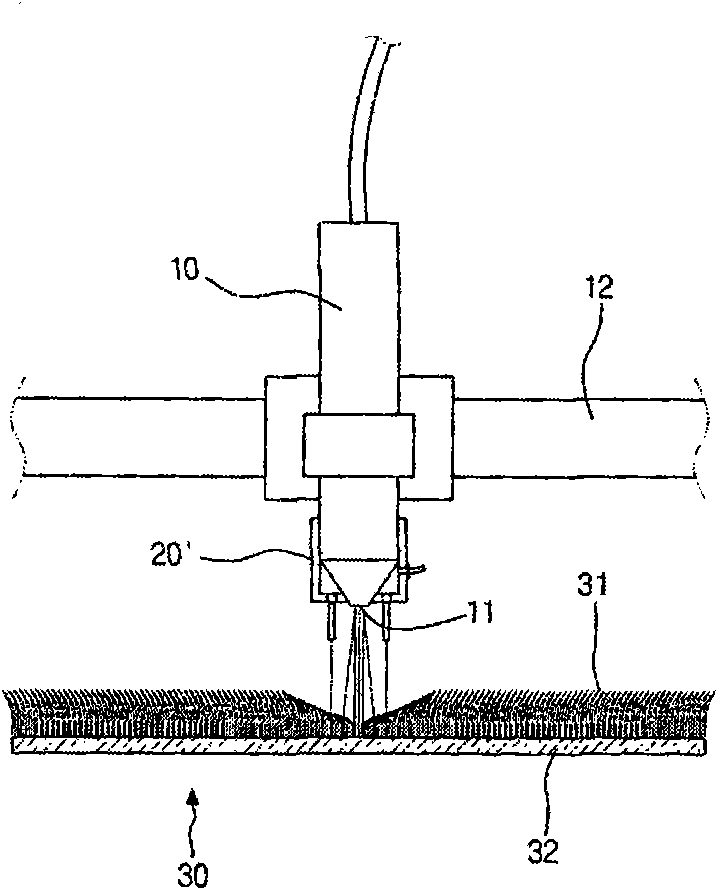

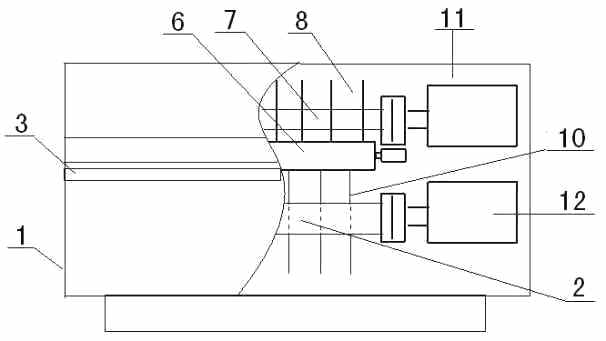

Laser device for cutting fur and fur cutting method using laser device

InactiveCN101792824AReduce laborLow costSkins/hides/leather/fur manufacturing apparatusFur cuttingPeripheralEngineering

The invention relates to a laser device for cutting fur and fur cutting method using the laser device. The invention regards to a fur cutting method and a laser device for cutting fur which uses a laser device to irradiate laser on the fur, can both form various shapes of cutting surfaces and can minimize the fur loss. The invention irradiate laser from one side of the fur during fur cutting to cut one part or integral of the fur, which is characterized in that high pressure air is injected to the peripheral of the fur for receiving the laser irradiation. The invention uses laser to cut the fur, therefore the labor force and fees of the handwork can be largely reduce, the fur damnification is minimum in despite of laser irradiation, and the invention is a very useful invention that can provide quality product.

Owner:金龙九

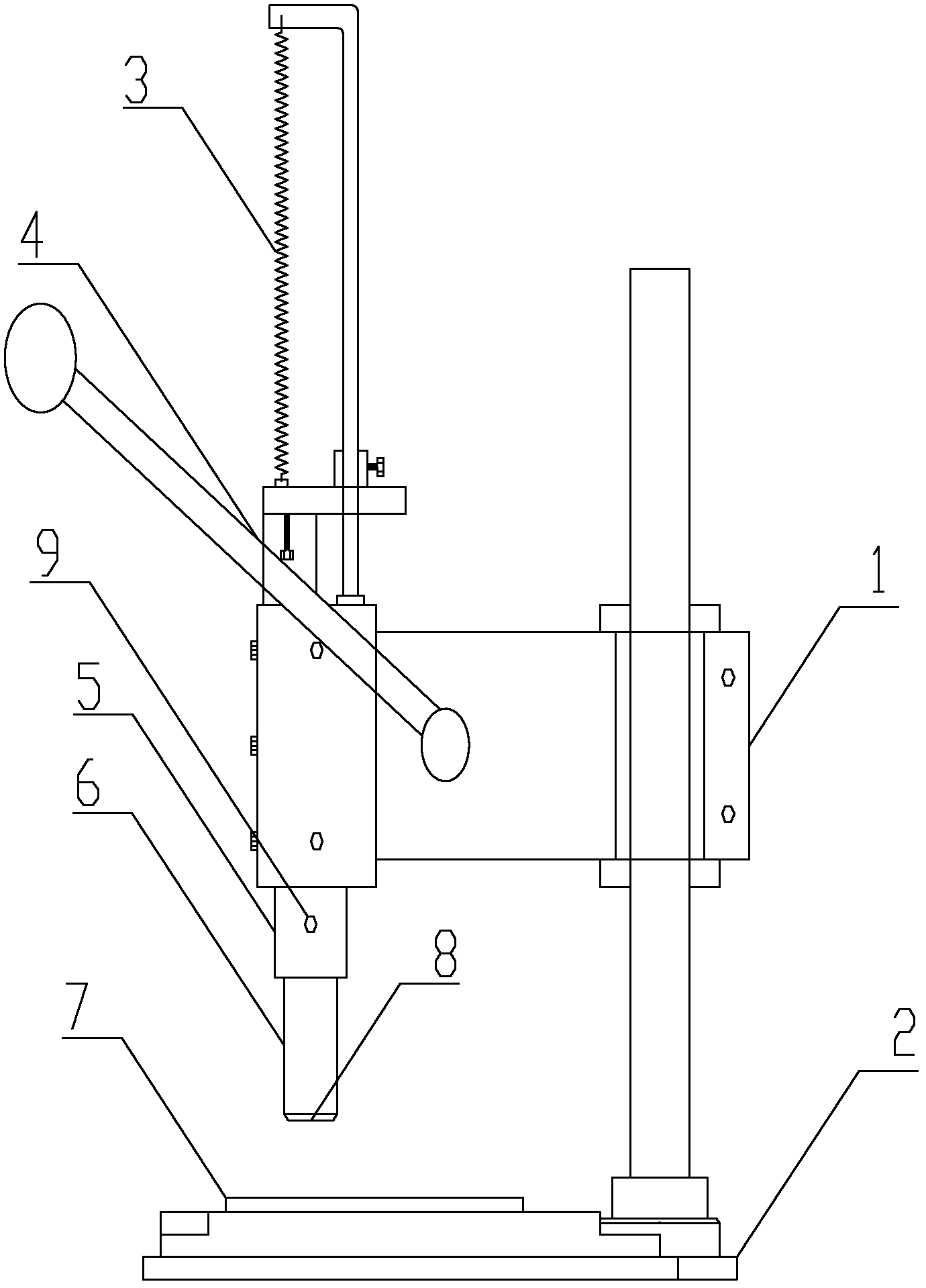

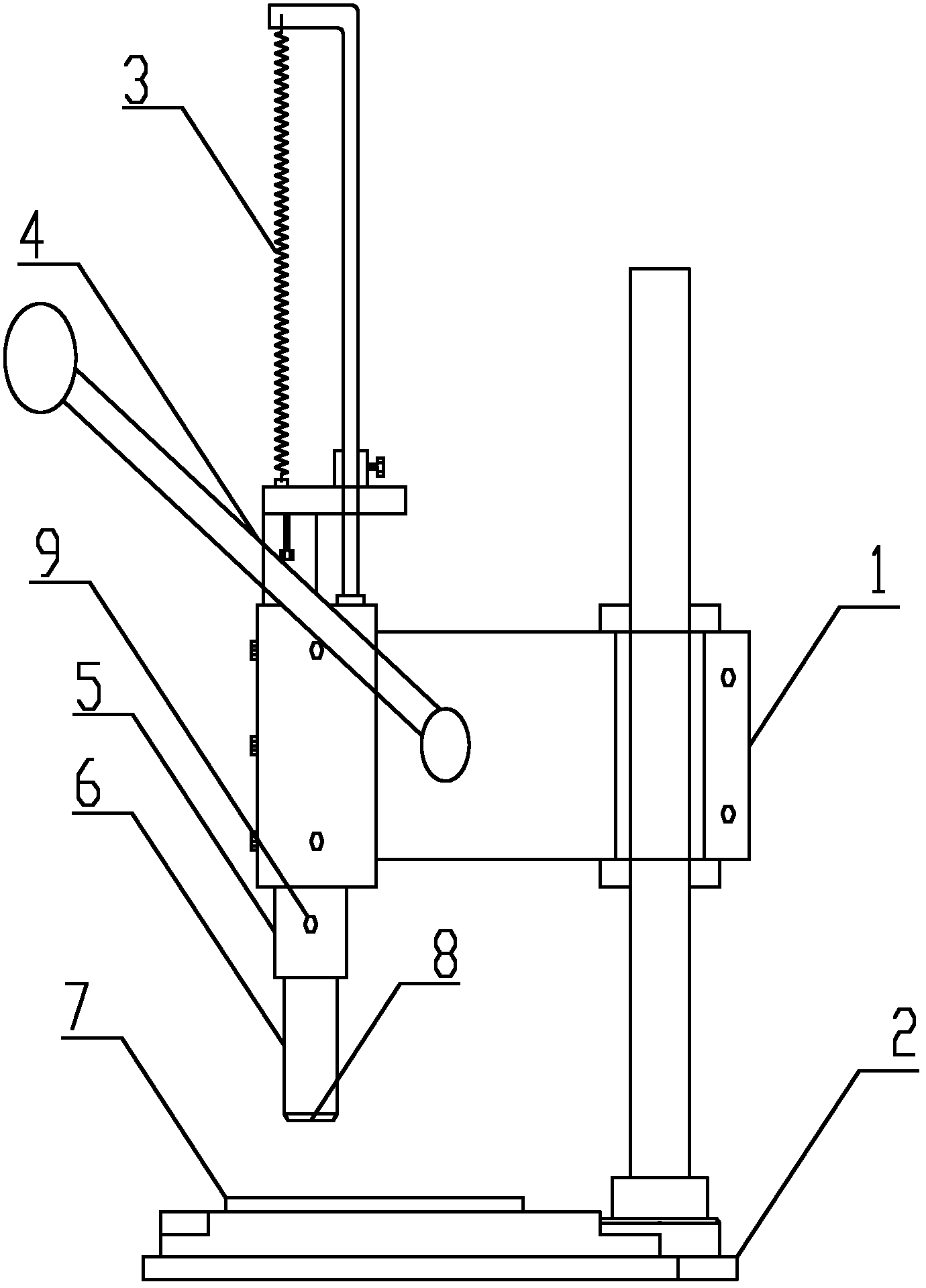

Manual punching shear type slicing device

InactiveCN102492787ACut less tedious operationImprove peeling efficiencyFur cuttingEngineeringMechanical engineering

The invention relates to a manual punching shear type slicing device, which comprises a manual press and a punching shear mould. The manual press comprises a base, a framework, a reset spring and a rocker, the framework is fixed on the base, and the reset spring and the rocker are arranged on the framework. The punching shear mould comprises a mould groove, a punching shear head and a base platform, the mould groove is arranged on the framework, the punching shear head is arranged in the mould groove and connected with the reset spring and the rocker, and the base platform is arranged on the base and below the punching shear head. The rocker drives the punching shear head to press a to-be-sheared object on the base platform, and the punching shear head is reset through the reset spring after shearing. Compared with the prior art, the manual punching shear type slicing device has the advantages of high efficiency and low labor intensity and the like.

Owner:SHANGHAI RES INST OF CHEM IND

Materials and products using strip of real or artificial

Owner:NABRO CORP

Production process for preparing leather by virtue of numerical control cutting machine

ActiveCN106591504AImprove stabilityHigh glossFur dressingSkins/hides/leather/fur manufacturing apparatusNumerical controlEconomic benefits

The invention relates to the technical field of leather processing, and specifically relates to a production process for preparing leather by virtue of a numerical control cutting machine. The production process comprises the following steps: (1) material selection: using sheepskin leather, pigskin leather or calfskin leather as a crust; (2) pattern drawing: drawing a pattern through a computer of the numerical control cutting machine, and outputting the pattern; and (3) numerical control cutting: cutting the lines of reptiles in the nature on the surface of the leather through the output pattern by the numerical control cutting machine, so as to prepare the leather. The production process disclosed by the invention has simple steps, and is convenient to operate and control, stable in quality and high in production efficiency; the raw materials are low in price and easily available; and the leather is high in utilization rate, low in production cost, and capable of realizing large-scale industrialized production. The quality of the prepared finished leather is similar to that of top-layer leather, the additional value of the finished leather is greatly increased, and the finished leather is wide in application range and high in economic benefit.

Owner:DONGGUAN TIANYI LEATHER TECH CO LTD

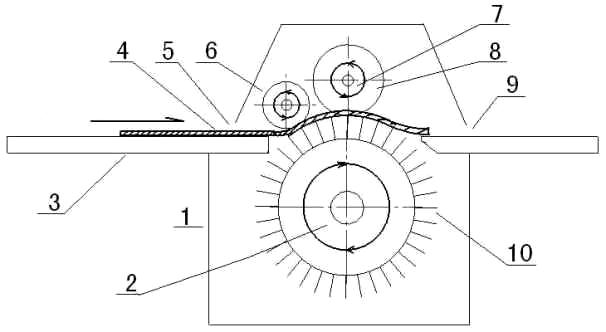

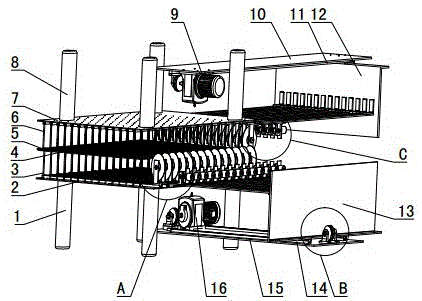

Device for automatically cutting fur into strips

The invention discloses a device for automatically cutting a fur into strips, comprising a machine casing, wherein a pin shaft and a pin shaft driving motor are installed at the lower part of the interior of the machine casing; operating platforms are installed in the front and at the back of the middle part of the machine casing; the front end of the machine casing arranged above the operating platforms is provided with a feeding hole, and the rear end of the machine casing is provided with a discharging hole; a cuter shaft and a cutter shaft driving motor are installed above the operating platforms at the upper part of the interior of the machine casing; the cutter shaft is provided with a row of disc rotary cutters which are spaced at an interval equal to the width of a fur to be cut; the pin shaft arranged below the cutter shaft is provided with a rubber shaft corresponding to the disc rotary cutters; and the rubber shaft is in contact with the pinpoint of the pin shaft and is driven by the pinpoint on the pin shaft. A driving motor is installed on the pin shaft, pins are embedded in the pin shaft, and each circle of pins are staggered with the disc rotary cutters. Based on the market demand, the invention develops the device for automatically cutting the fur into strips, wherein the device meets the market demand. Proven by tests, the device is stable and reliable, has nodamage to the fur, can be well received by testers and is brought into use.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

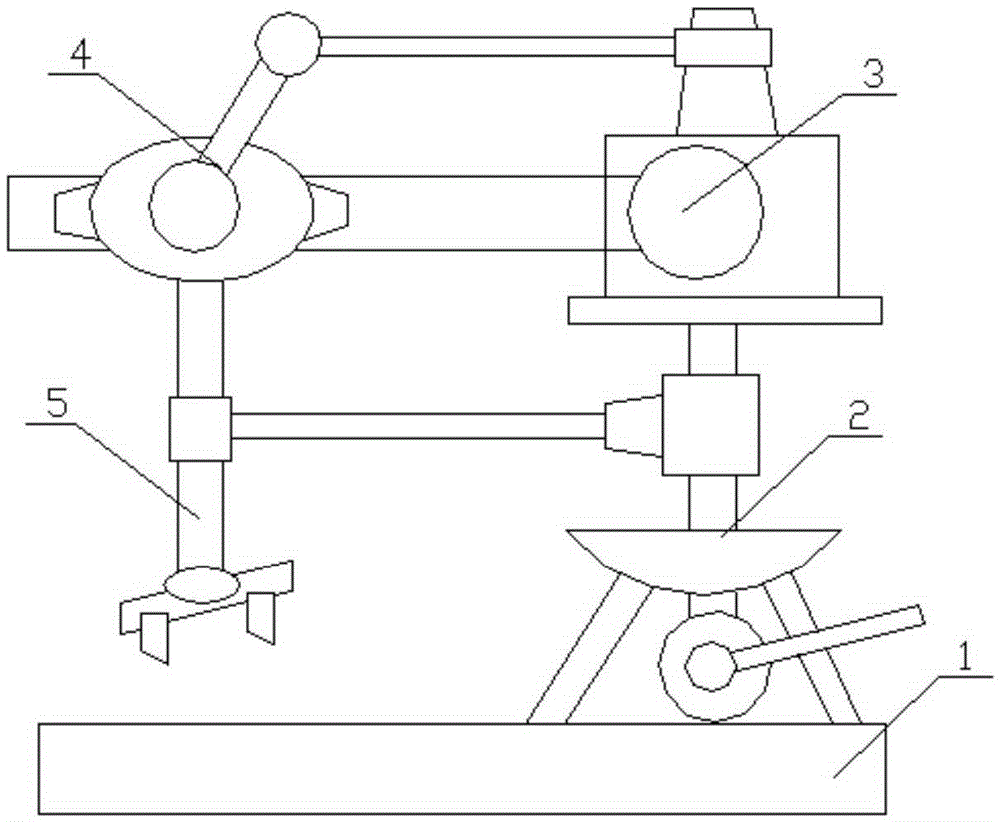

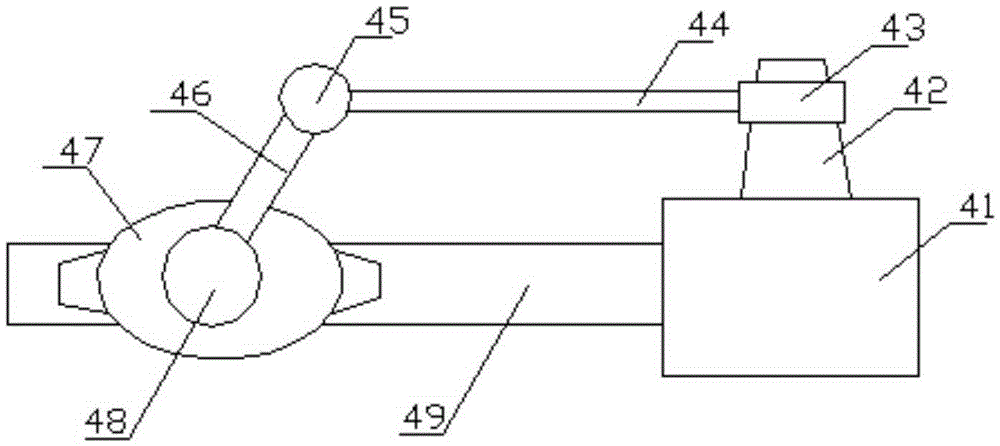

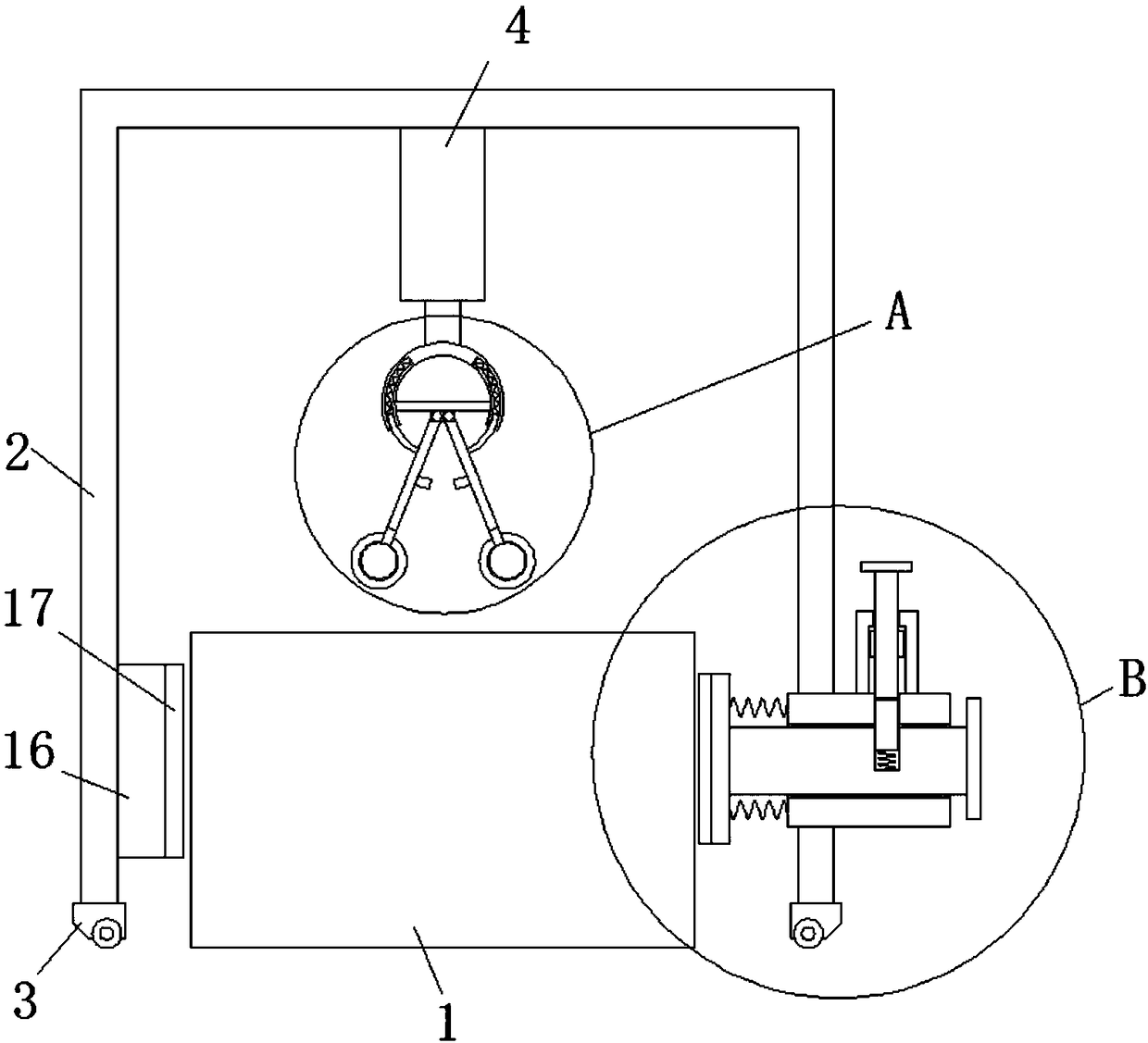

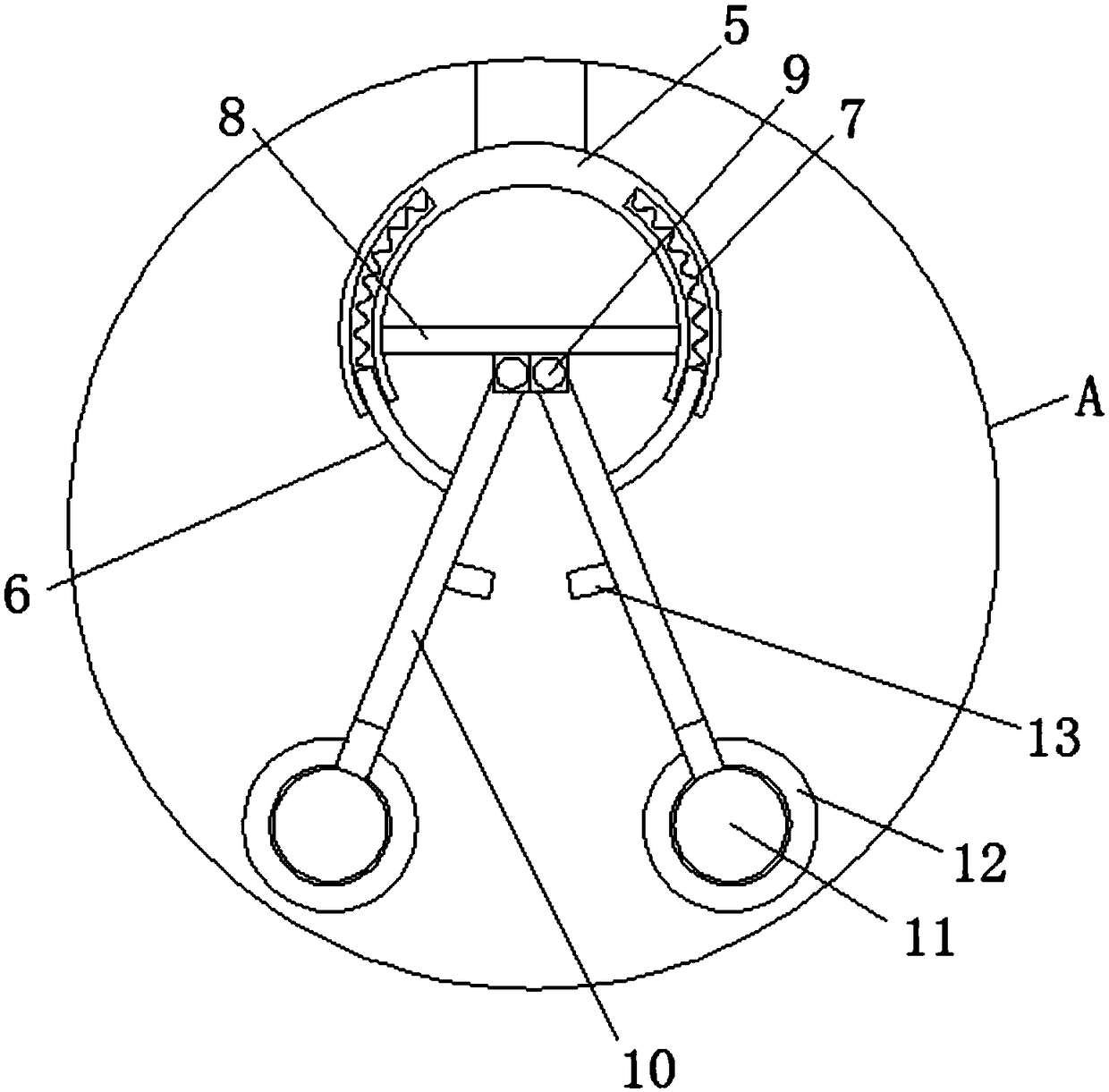

Fur cutter

InactiveCN105274265AEasy to operateEasy to adjustSkins/hides/leather/fur manufacturing apparatusFur cuttingMechanical equipmentFur cutter

The invention relates to the technical field of mechanical equipment, in particular to a fur cutter. The fur cutter comprises a base, and further comprises a regulating part, a motor, a transmission part and a cutting part which are arranged at one side of the upper end of the base, wherein the transmission part comprises a main case, a regulating positioning part, a rotary ring, a drawbar, a hinged part, an output shaft, an integrated part, an inner connector and a driven rod; the upper part of the main case is provided with a first fixed slot in a concave manner; the side wall of the rotary ring is provided with a second fixed slot in the concave manner; a first guide hole is formed in the side wall of the main case in a penetration mode; the integrated part is ellipsoidal, and is internally provided with a main spinning hole in the penetration mode in a radial direction of the integrated part; and in a radial direction of the inner connector, the inner connector is internally provided with a first connecting hole in the penetration mode. The fur cutter is convenient in operation, convenient in regulation, high in cutting efficiency and good in cutting quality.

Owner:JIASHAN LONGXIANG ARTIFICIAL FUR

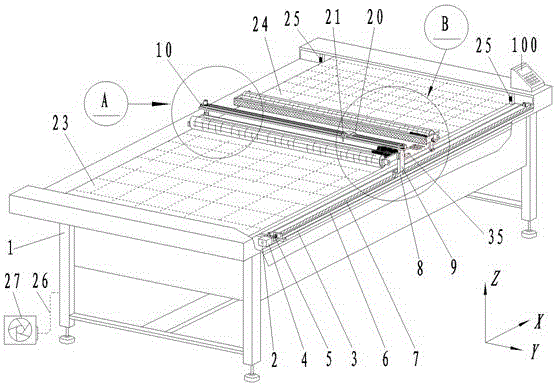

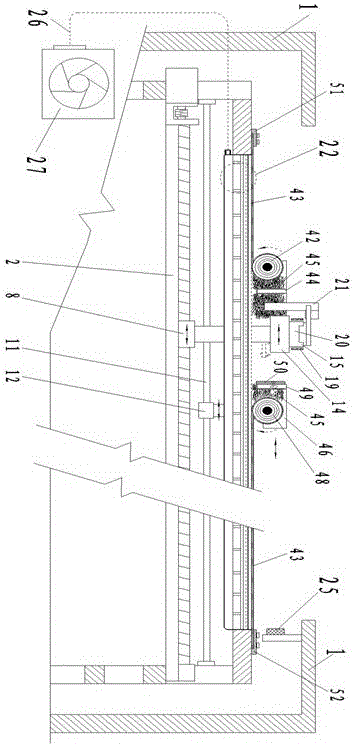

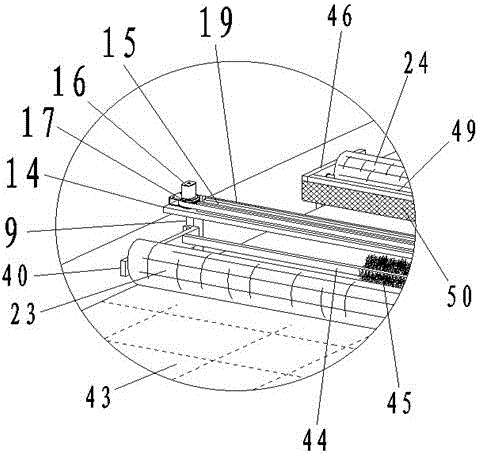

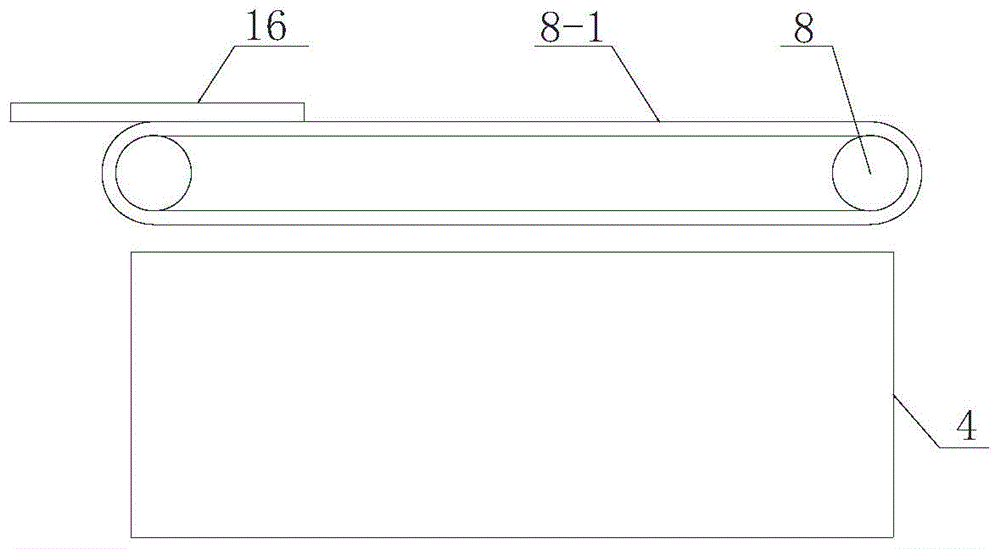

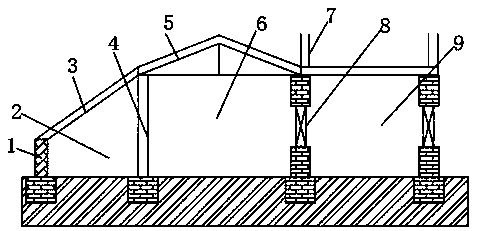

Cutting machine with hoisting curtains

ActiveCN105751284ASimplify the substructureReduce air leakageSkins/hides/leather/fur manufacturing apparatusFur cuttingEngineeringAdsorption effect

The invention discloses a cutting machine with hoisting curtains. The cutting machine comprises a machine frame, a bearing platform, a vacuum device, a cutting tool bit, the left hoisting curtain, the right hoisting curtain and a locking device. The bearing platform is arranged on the machine frame, the vacuum device is arranged below the bearing platform, and the cutting tool bit can be freely arranged above the bearing platform in a sliding mode. The left hoisting curtain comprises a hoisting curtain belt, a left curtain hoisting motor and a left curtain hoisting roller. The right hoisting curtain comprises a hoisting curtain belt, a right curtain hoisting motor and a right curtain hoisting roller. One end of the hoisting curtain belt of the left hoisting curtain and one end of the hoisting curtain belt of the right hoisting curtain are fixed to the left end and the right end of the machine frame respectively, and the other end of the hoisting curtain belt of the left hoisting curtain and the other end of the hoisting curtain belt of the right hoisting curtain are wound on and fixed to the left curtain hoisting roller and the right curtain hoisting roller respectively. An output shaft of the left curtain hoisting motor and an output shaft of the right curtain hoisting motor are in transmission connection with the left curtain hoisting roller and the right curtain hoisting roller respectively. The right end of the hoisting curtain belt of the left hoisting curtain and left end of the hoisting curtain belt of the right hoisting curtain are both provided with a sealing device. The cutting machine is good in vacuum adsorption effect, low in production operation energy consumption, low in noise, simple in structure and low in cost.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

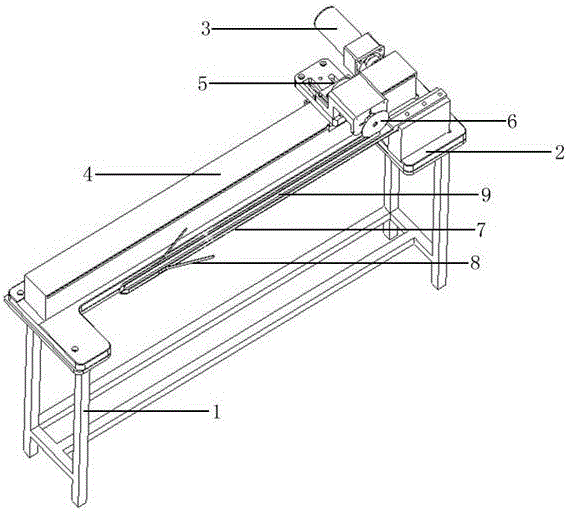

Novel mink ripping device

The invention relates to a novel mink ripping device which mainly comprises a rack. A worktable is installed on the rack. A stroke motor is installed at one end of the worktable, and the worktable and the stroke motor are connected with a movement guide rail. The movement guide rail is fixedly provided with a cutting motor. The cutting motor is connected and provided with a blade. A positioning clamp is installed at one end of the worktable, and a stroke guide rail is arranged on the positioning clamp. An opening is formed in the stroke guide rail, and at least one supporting piece is installed at one end of the positioning clamp. The movement guide rail and the positioning clamp are installed in parallel. The blade runs in the stroke guide rail, a belt wheel is arranged in the movement guide rail, and a power source is installed on the worktable. The novel mink ripping device has the beneficial effects that firstly, the structure is reasonable, and use is convenient; secondly, cutting is accurate, and the effect obtained after cutting is particularly good; and thirdly, the cutting speed is high, and the production efficiency is greatly improved.

Owner:黄子滔

Cutting device for production of leather products

InactiveCN108504789AImprove cutting efficiencyEasy to moveSkins/hides/leather/fur manufacturing apparatusFur cuttingWrinkle skinEngineering

The invention discloses a cutting device for production of leather products. The cutting device comprises a cutting machine body, wherein a movable bracket is sheathed at the outer side of the cuttingmachine body; an air cylinder is fixedly arranged at the inner wall of the top part of the movable bracket; an output shaft of the air cylinder is fixedly connected with a fixed bent plate; the fixedbent plate is an arc-shaped plate and is provided with a downward opening; both sides of the fixed bent plate are provided with arc-shaped slide grooves; the interior of each arc-shaped slide grooveis slidably connected with a slide arc-shaped plate; each slide arc-shaped plate and a bracket at the inner wall of each arc-shaped slide groove are fixedly connected with a spring group I; one side,away from the spring group I, of each slide arc-shaped plate extends to the outer side of the corresponding fixed bent plate, and is respectively fixedly connected with a rotary plate. The cutting device has the advantages that when the leather with larger size or the leather with more wrinkles is cut by a worker, the leather can be mechanically paved without artificial operation, so as to greatlyimprove the cutting efficiency of the cutting machine; a paving mechanism can be more conveniently and rapidly moved and fixed, the operation is convenient, and the use requirement of people in production and life can be met.

Owner:海宁德里法新材料有限公司

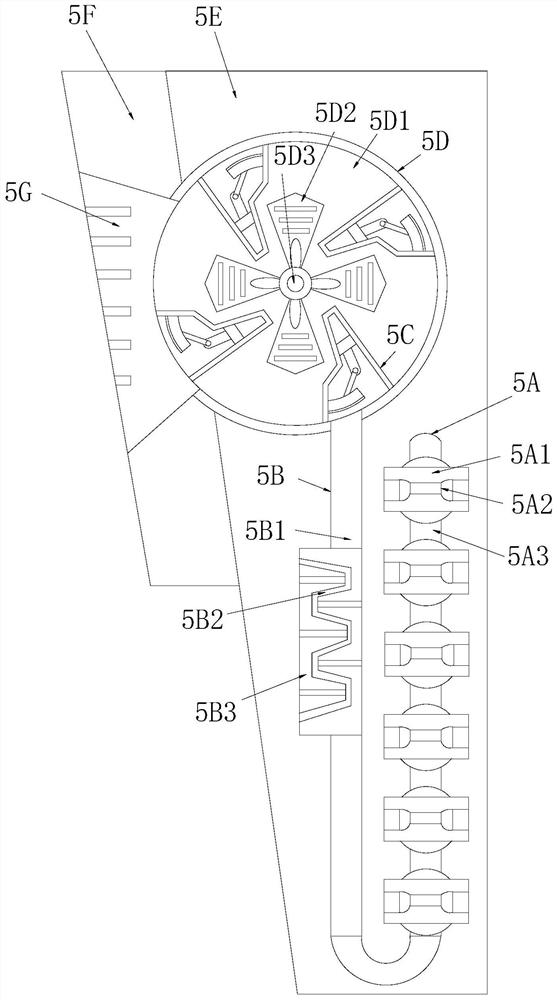

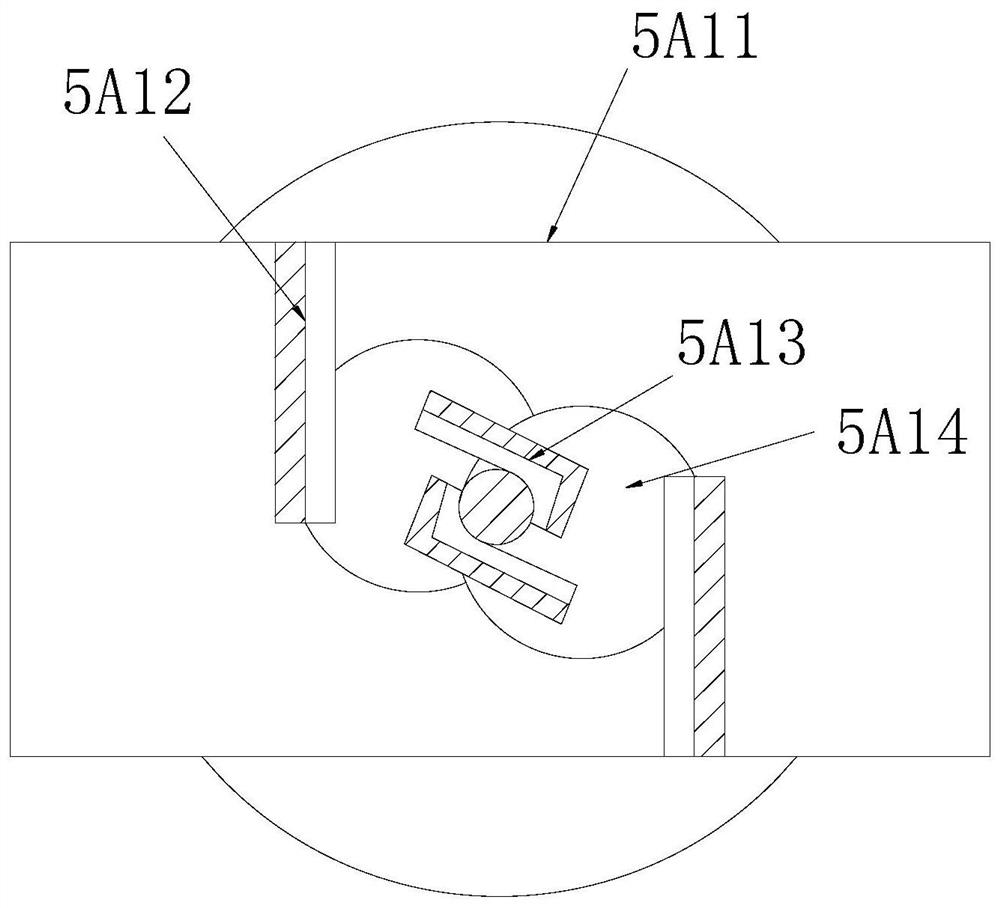

Cutting machine head and cutting machine

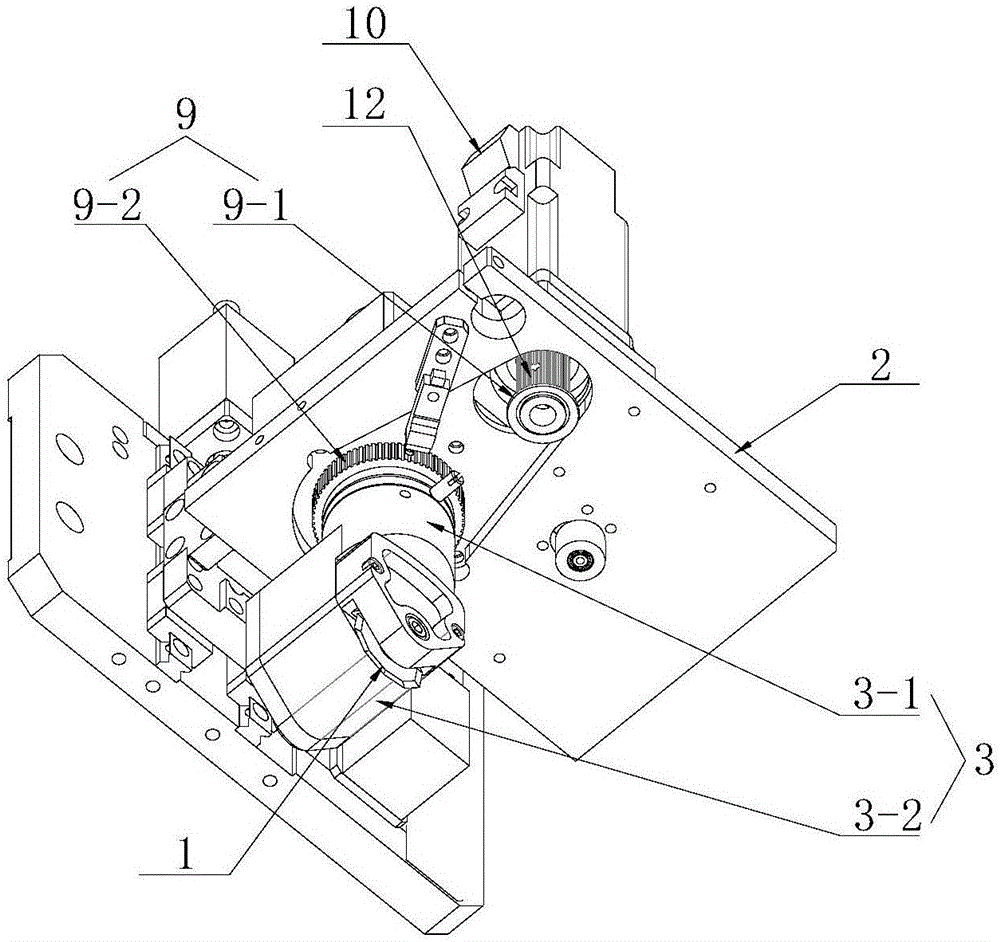

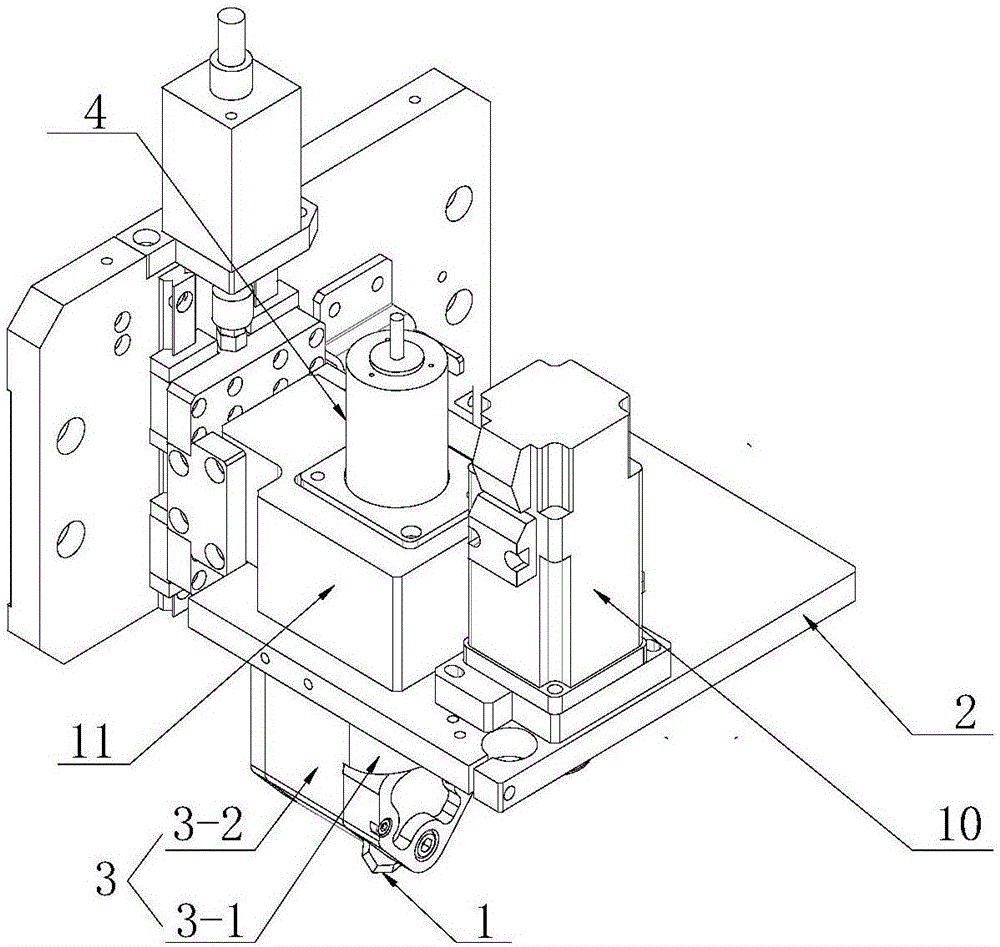

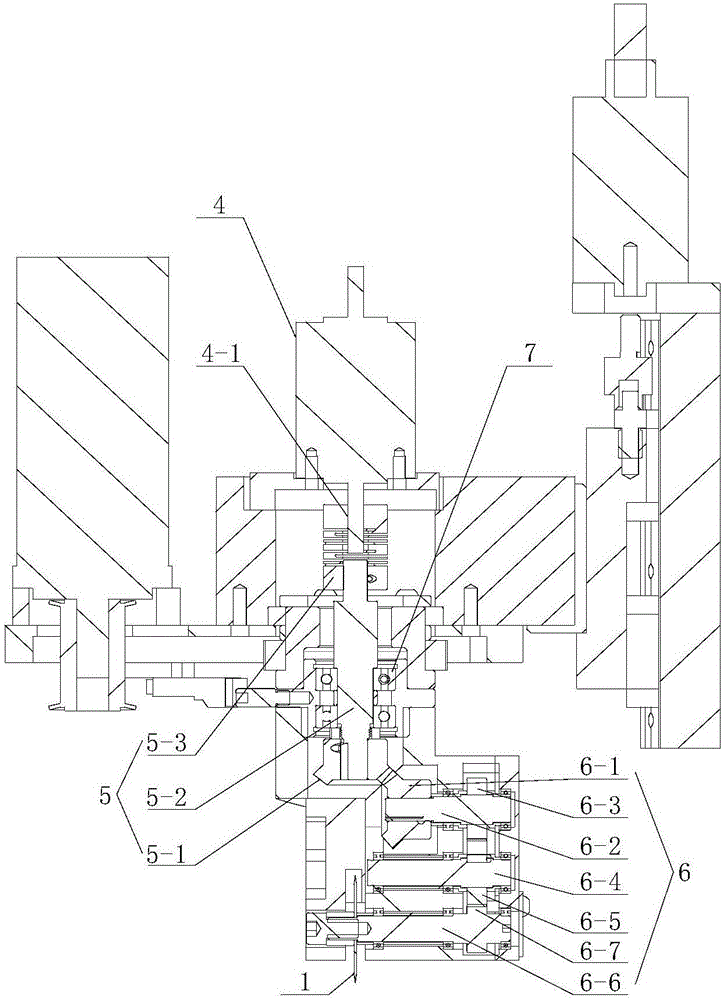

InactiveCN106702041AImprove cutting efficiencyReduce sharpnessMarking textilesSevering textilesMechanical engineeringEngineering

The invention relates to a cutting machine head which is installed on a walking rack of a cutting machine. The cutting machine head comprises a cutter mechanism, a machine head installing plate used for installing the cutter mechanism and a lifting mechanism used for driving the machine head installing plate to conduct vertical movement in a manner of being perpendicular to a tabletop of the cutting machine; the cutter mechanism comprises a circular cutter and a cutter handle which is rotatably arranged on the machine head installing plate, and the cutter handle is used for being connected with the circular cutter; and the cutter mechanism further comprises a first driving device used for driving the circular cutter to rotate and a second driving device used for driving the cutter handle to rotate. Compared with the prior art, when the cutter mechanism is used for cutting leather materials, the circular cutter can be driven by the driving device to rotate, and therefore cutting of the leather materials is achieved; the second driving device controls the cutter handle to rotate and controls cutting angles of the circular cutter to the leather materials, therefore, the circular cutter can cut the leather materials in an active rotary manner, it is guaranteed that the leather materials can be completely cut in the cutting process, and the cutting efficiency of the cutting machine to the leather materials can be greatly improved.

Owner:长园和鹰科技(河南)有限公司

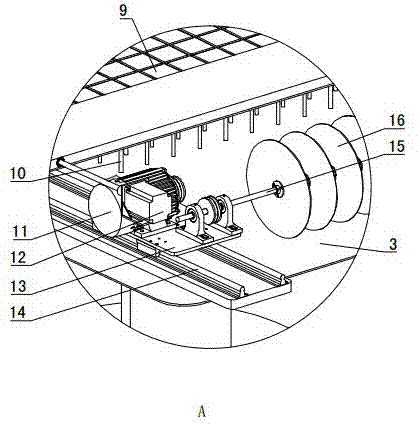

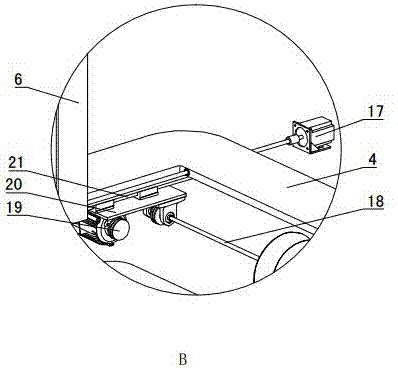

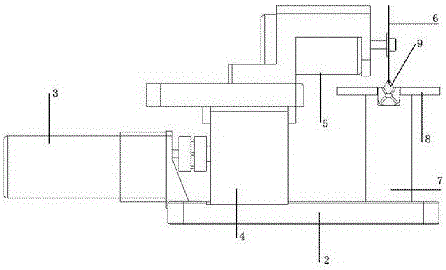

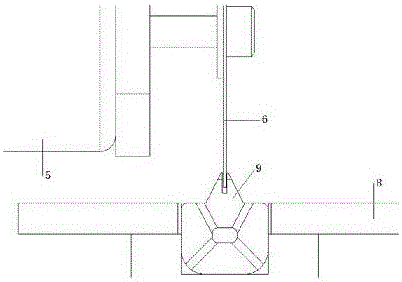

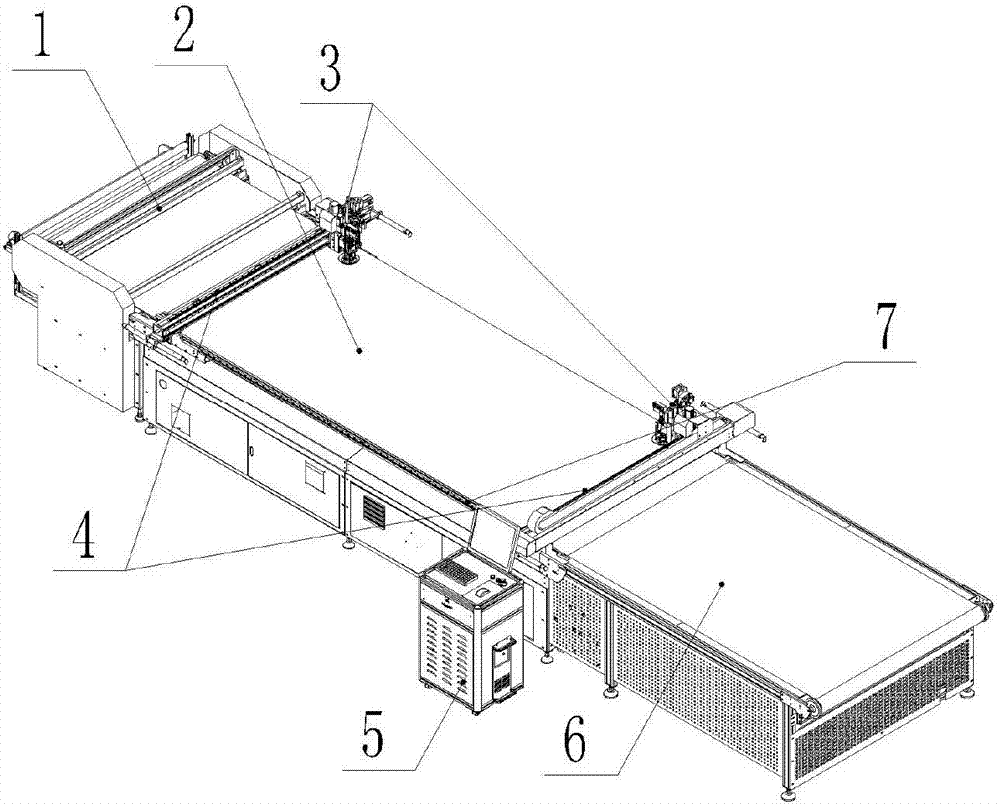

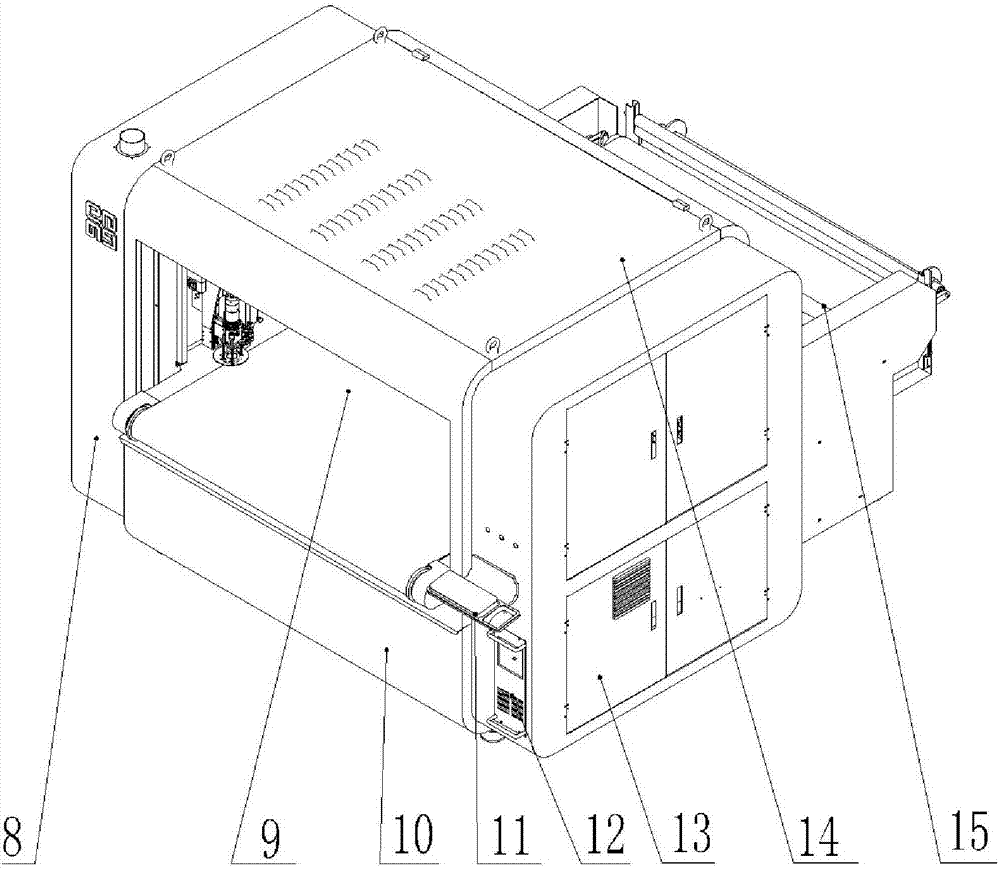

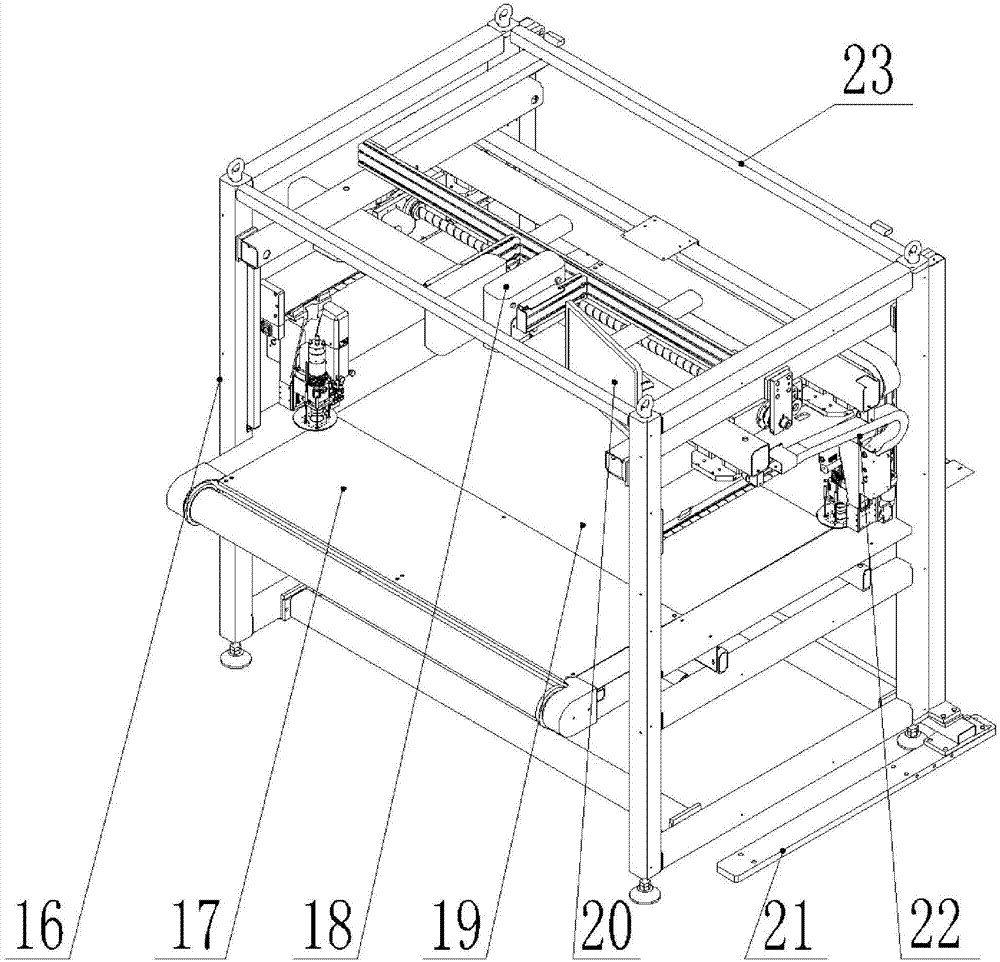

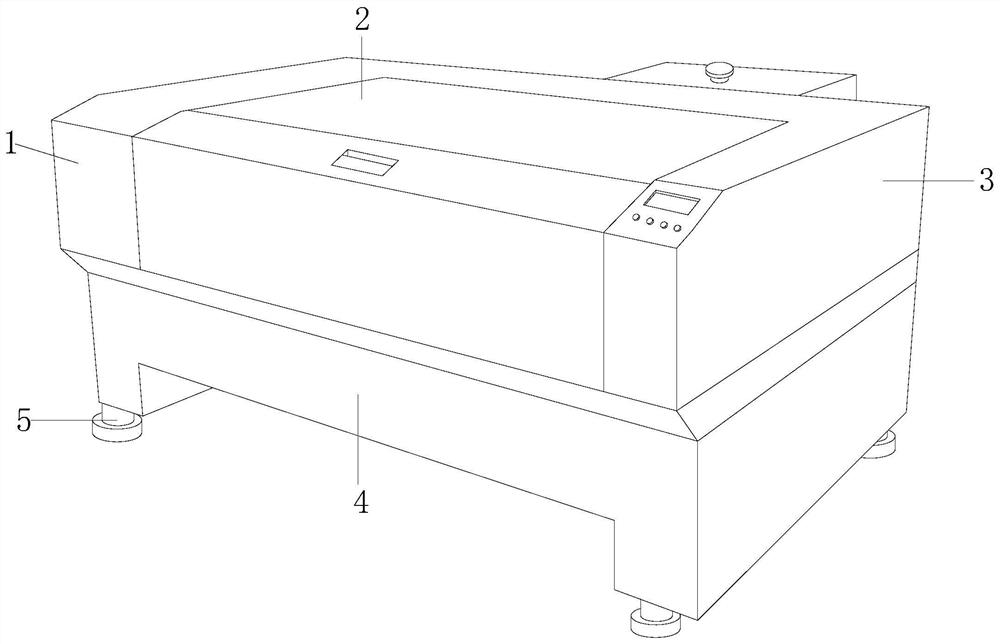

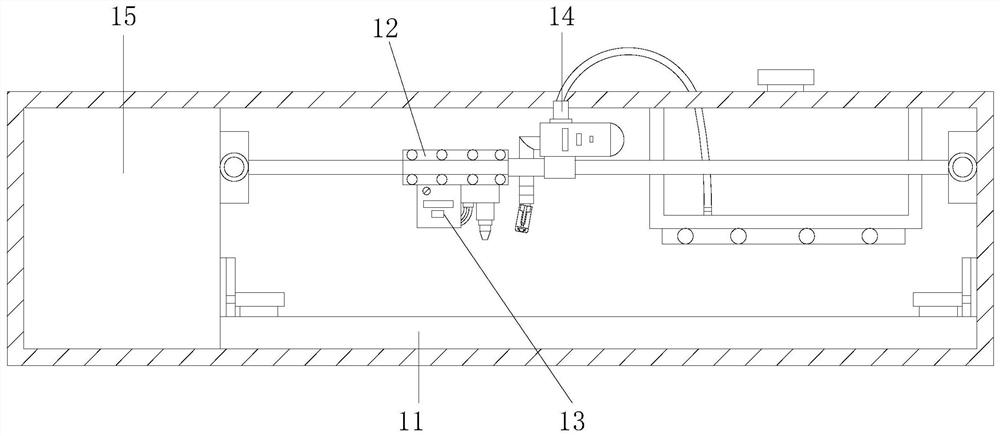

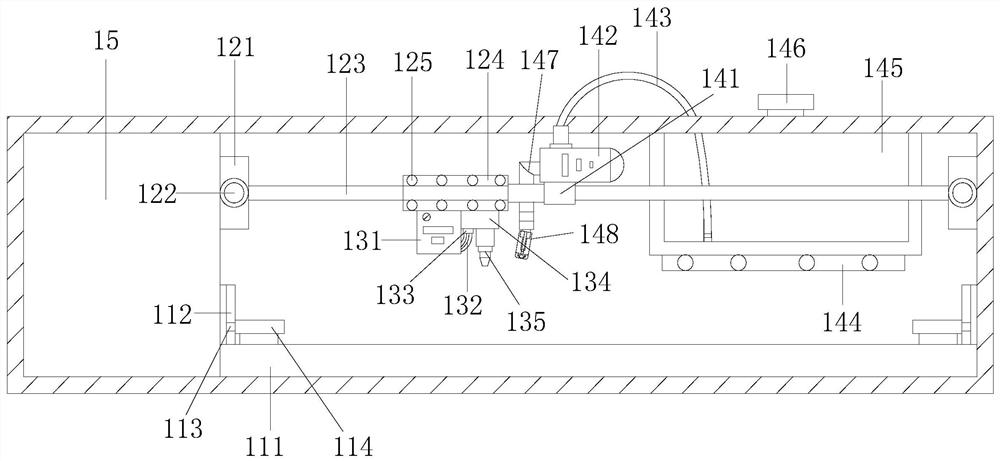

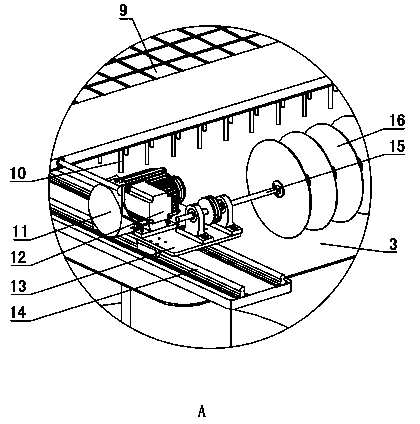

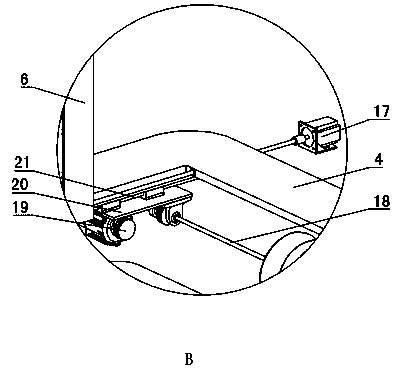

Screw rod transmission cutting machine

InactiveCN107090526ACompact structureSmall footprintLeather clicking/perforating/clickingFur cuttingEngineeringChassis

The invention relates to a screw rod transmission cutting machine. The screw rod transmission cutting machine comprises a machine frame; the machine frame comprises a bottom frame and an upper bracket; the bottom frame is provided with an attraction platform and a material collecting platform, and the rear side of the attraction platform is provided with a feeder; a transverse transmission device comprises a transverse transmission screw rod fixed to the upper bracket, the outer sides of transverse transmission nuts are rotationally sleeved with transverse transmission nut installation plates, and nut driving devices are connected to the transverse transmission nuts; longitudinal transmission frames are connected to the transverse transmission nut installation plates, and a transverse transmission guiding device is arranged between the longitudinal transmission frames and the upper bracket; the longitudinal transmission frames are provided with longitudinal transmission screw rods rotationally and longitudinal driving motors; cutter bits are fixed to longitudinal transmission nuts, and longitudinal transmission guiding devices are arranged between the cutter bits and the longitudinal transmission frames; and an operation apparatus of a control device is adjacent to the material collecting platform. Power is transmitted through the screw rod nuts, and the transmission precision and cutting precision are high; and an operation platform is arranged at the position of the material collecting platform, operation and material collecting positions are the same, and operation is convenient.

Owner:DONGGUAN EMMA CNC TECH CO LTD

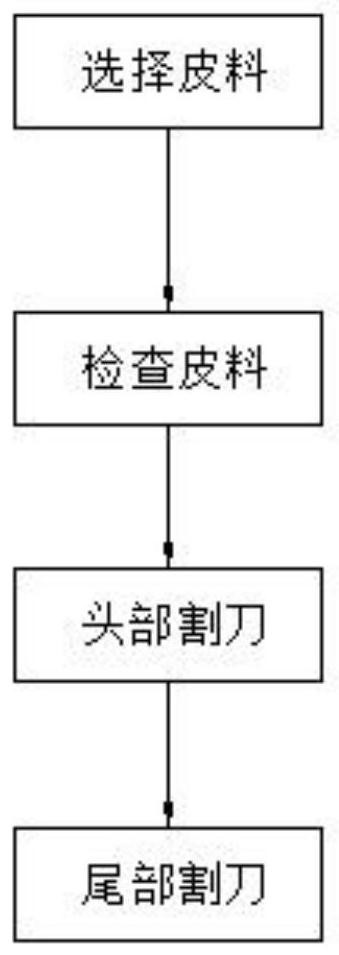

A method for high-end quality mink clothing without cutting marks on the hair surface

ActiveCN112195294BFull sense of luxurySkins/hides/leather/fur manufacturing apparatusFur cuttingRough surfaceEngineering

The present invention belongs to the technical field of mink cutting knife, and is specifically a method of high-end quality mink clothing without cutting knife traces on the hair surface. Currently, the mink clothing on the market has very obvious cutting knife traces on the wool surface of the clothes during workmanship, which affects Clothes are beautiful. With the improvement of people's living standards, they are no longer suitable for the needs of consumers. The characteristic of mink fur is that the underpile density of the head part is thin, and the underpile density of the buttocks is high. The present invention adopts different methods according to this characteristic. For cutting and sewing, since the hair on the back legs of the mink is thinner than the hair on the body, after the cutting knife is cut at a width of 0.2 inches, the sewing interval is sewed at a distance of 0.1-0.2 inches, otherwise there will be traces of the knife on the fur surface. There are no knife marks on the outside of the clothes sewn by this method, and the hair surface is very smooth. The hair surface of the mink clothing made by this method has no obvious knife marks. Feel full.

Owner:故城县民夕毛皮制品有限公司

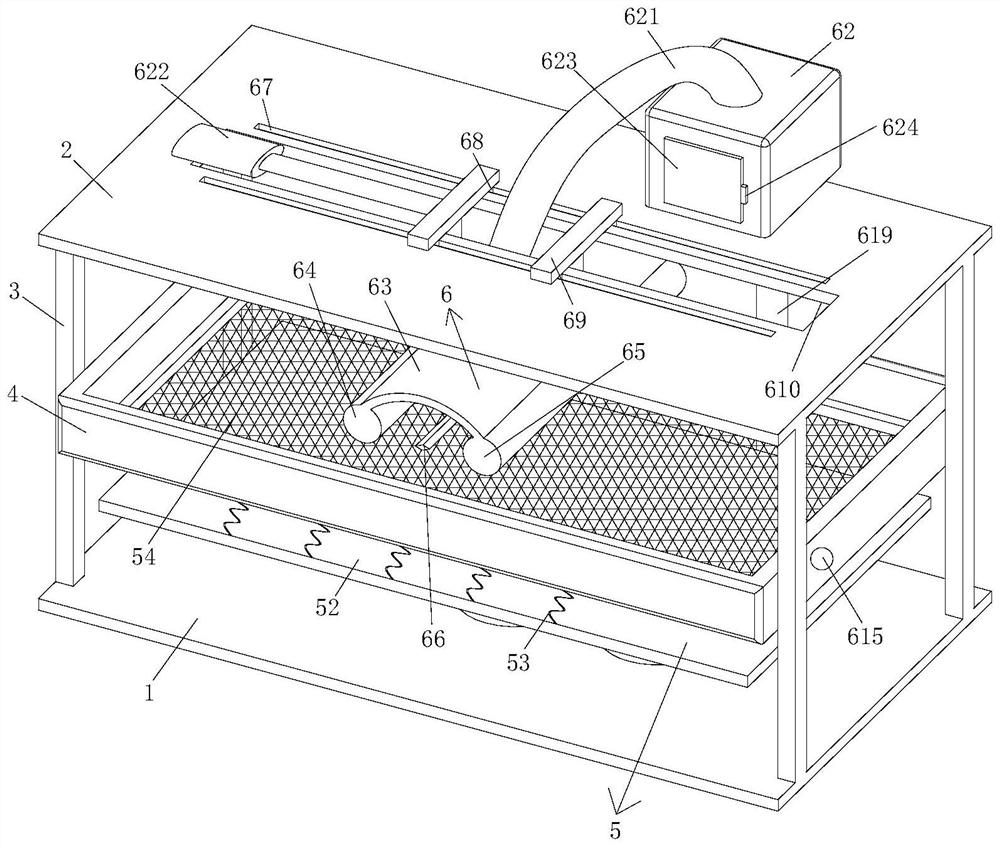

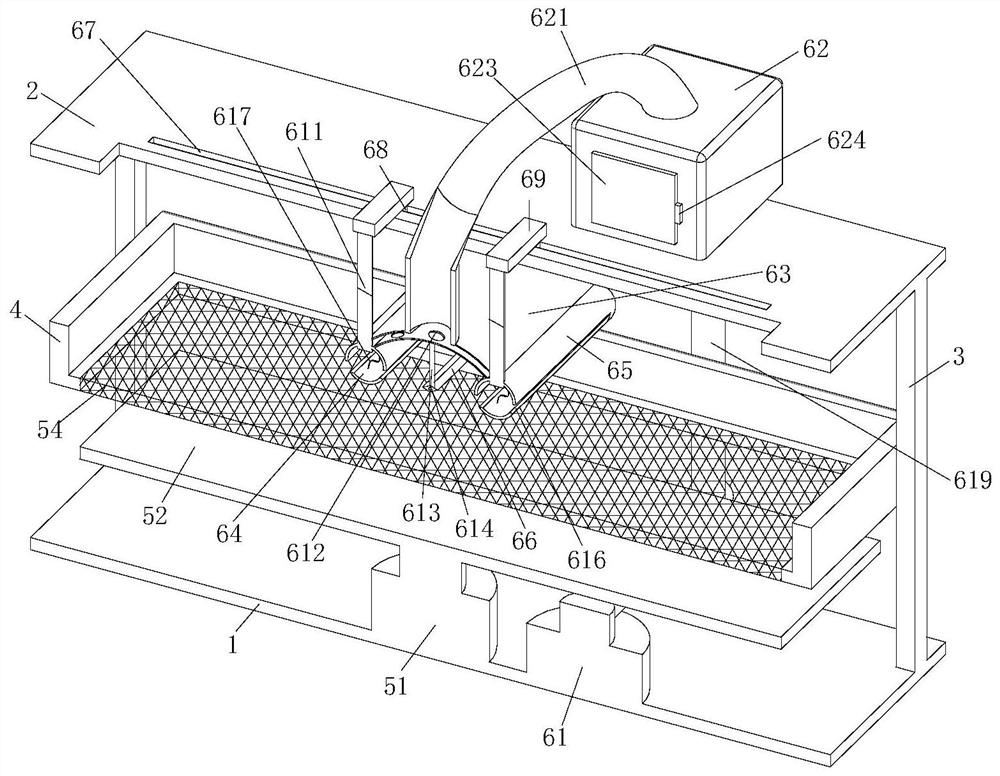

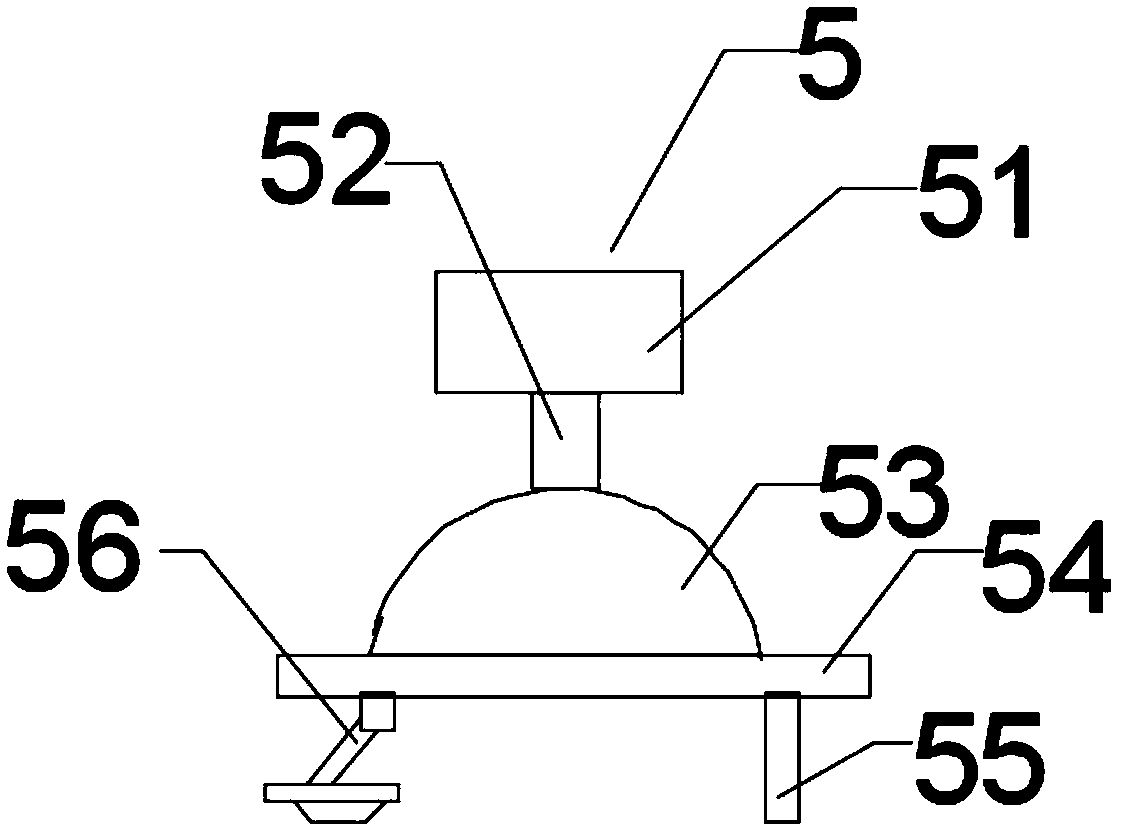

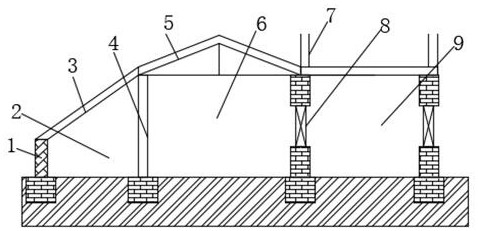

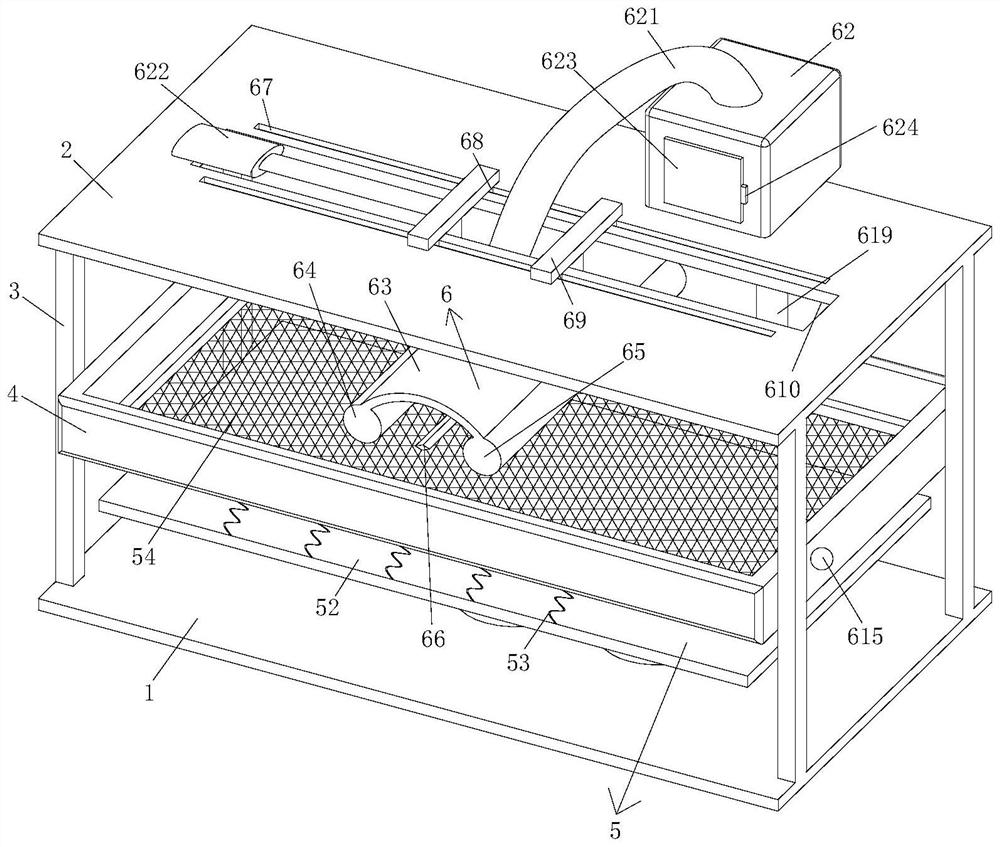

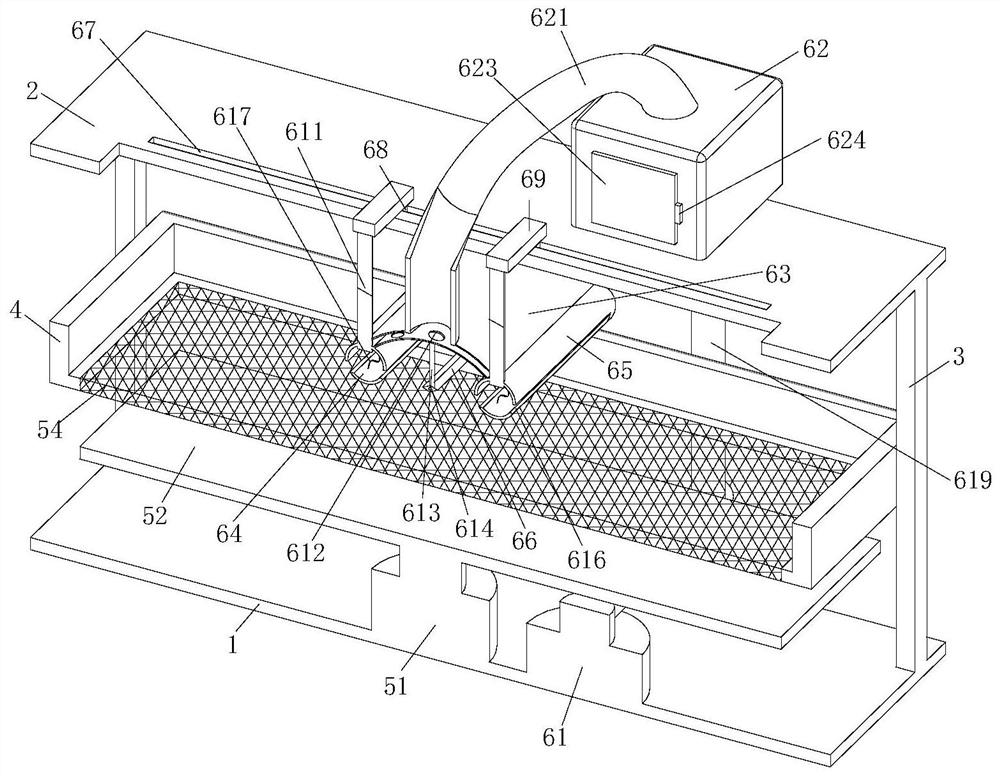

Long fur trimming device based on negative pressure traction

ActiveCN111961767AAvoid wrinklesAvoid untidy pruningSkins/hides/leather/fur manufacturing apparatusFur cuttingEngineeringStructural engineering

The invention provides a long fur trimming device based on negative pressure traction. The long fur trimming device comprises a support bottom plate, a support top plate, a plurality of support columns, a support frame body, an extension adjusting mechanism for extending and adjusting fur and a negative adsorption traction trimming mechanism for trimming the fur, wherein a plurality of support columns are fixedly connected to the surface of the support bottom plate; the ends, far away from the support bottom plate, of the support columns are fixedly connected with the support top plate; and the surfaces of the support columns are fixedly connected with the support frame body. The invention relates to the field of fur processing. Through adoption of the long fur trimming device based on thenegative pressure traction, a special specific structure is designed specific to the problem of irregular wrinkles and falling existing in the fur processing process, and the fur can be trimmed regularly at one time, so that the problem of influence on the product quality after the fur is processed due to a plurality of factors such as non-uniform fur length, wrinkles and falling of the fur, anddifficulty in regularly trimming the fur on leather is solved effectively.

Owner:李德清

Processing technology of belt

InactiveCN106388098AExtended service lifeHigh strengthLeather clicking/perforating/clickingFur cuttingZinc alloysEngineering

The invention discloses a processing technology of a belt, and relates to the field of leather processing. The processing technology comprises the following steps: (1) selecting and cutting leather; (2) disinfecting the leather; (3) sealing the leather; (4) drilling holes in the leather; (5) trimming edges of the leather; (6) making a belt head; and (7) mounting the belt head. The belt is made by dehydrating and sterilizing first-class pigskin, so that bacterium growth of the belt is effectively prevented and the service life of the belt is prolonged; a polyamide thread is seamed on the outer edge of the belt by a circle, so that the strength of the belt is improved and the belt is protected from becoming broken when the edge part of the belt gets worn; by covering the belt with PVC leather, the service life of the belt is prolonged, and in addition, an aesthetic effect is achieved; and by plating a layer of zinc alloy outside the belt head, cost is saved, and meanwhile, the belt head is protected from getting rusted.

Owner:ANHUI CHUANGRONG CLOTHING ACCESSORIES

Mechanical type splitting machine used for leather

InactiveCN108728590AEasy to cutGuaranteed accuracySkins/hides/leather/fur manufacturing apparatusFur cuttingElectric machinePulp and paper industry

The invention relates to the technical field of leather processing equipment, and discloses a mechanical type splitting machine used for leather. The mechanical type splitting machine comprises a base, wherein the two ends of the base are fixedly connected with two groups of supporting frames separately; sides of the two groups of supporting frames are fixedly connected with stable blocks separately; the top end of the base is fixedly connected with the bottom ends of supporting columns; the top ends of the supporting columns are fixedly connected with the bottom end of a mounting table; the top end of the mounting table is fixedly equipped with a mounting plate; the top end of the mounting plate is fixedly equipped with a motor; and a sleeve I fixedly sleeves the outer wall of the outputshaft of the motor. According to the mechanical type splitting machine used for the leather disclosed by the invention, the supporting frames, the mounting table, the mounting plate, the motor, the sleeve I, a belt, a sleeve II, a threaded rod, a workbench, a limiting rod, a slide rod and a slide slot are arranged, so that the workbench can slide on the top of the mounting table; and the threadedrod can be arranged to control movement speed, so that cutting precision can be guaranteed while cutting is conveniently performed.

Owner:徐佳东

Cutting component for fur production

InactiveCN108977592AImprove cutting efficiencyEasy to adjustSkins/hides/leather/fur manufacturing apparatusFur cuttingSlide platePulp and paper industry

The invention relates to the technical field of fur production and provides a cutting component for the fur production. The cutting component comprises a sliding seat, a sliding rod welded at the lower end of the sliding seat, a reinforcing part screwed at the bottom of the sliding rod through threads, a sliding plate screwed at the lower end of the reinforcing part through threads, a pressing part fastened at the lower end of the right side of the sliding plate as well as a cutting part welded at the lower end of the left side of the sliding plate. According to the cutting component disclosedby the invention, a pressing block can be fixed with fur by adjusting the pressing part and then the cutting part is adjusted for cutting; the sliding seat can be arranged on a cross beam and furthercan be manually pushed to move toward the right side; cutting is performed while the pressing part is fixed, so that high cutting efficiency and high adjustability are realized and the production efficiency is favorably improved.

Owner:JIASHAN SHENGLAISI CASHMERE

Soft leather processing process

InactiveCN105936948AEnough softnessLeather manufacturingTanning treatmentPulp and paper industryRaw material

The invention provides a soft leather processing process. The soft leather processing process comprises the following steps: raw material preparing, washing, neutralizing, retanning, dyeing and fat-liquoring, and post-processing. By adopting the processing method provided by the invention, the leather obtains enough softness; and surface fat-liquoring is carried out by use of an unstable fat-liquoring agent, heating, pressurizing, pressing and ironing are carried out after drying, so that the leather is softer.

Owner:ANHUI CHUANGRONG CLOTHING ACCESSORIES

Method for making high-end-quality mink garment with rough surface free of cutter marks

ActiveCN112195294AFull sense of luxurySkins/hides/leather/fur manufacturing apparatusFur cuttingRough surfaceEngineering

The invention belongs to the technical field of mink cutters, and particularly relates to a method for making a high-end-quality mink garment with the rough surface free of cutter marks. The method aims to solve the problem that the cutter marks are commonly quite obvious in mink garment of the existing market when the appearance of the garment rough surface is processed, so that the attractiveness of the garment is influenced, and with the improvement of the living standard of people, the garment is not suitable for meeting the requirements of consumers. The mink skin has the characteristicsthat the density of bottom hair at the head part is small, and the density of bottom hair at the butt part is large, different methods are adopted for cutting and sewing according to the characteristics, and because the density of back leg hair of the mink is smaller than that of body hair of the mink, after a cutter completes cutting according to the width of 0.2 inch, the sewing spacing distanceis 0.1-0.2 inch, or else, the rough surface has the cutter marks. The outer surface of the mink garment sewn by the method are free of the cutter marks, the hair surface is very smooth, the hair surface of the mink garment manufactured by the method has no obvious cutter marks, and the hair surface has no cutter marks like a whole piece of leather and is very smooth and very high in senior sense.

Owner:故城县民夕毛皮制品有限公司

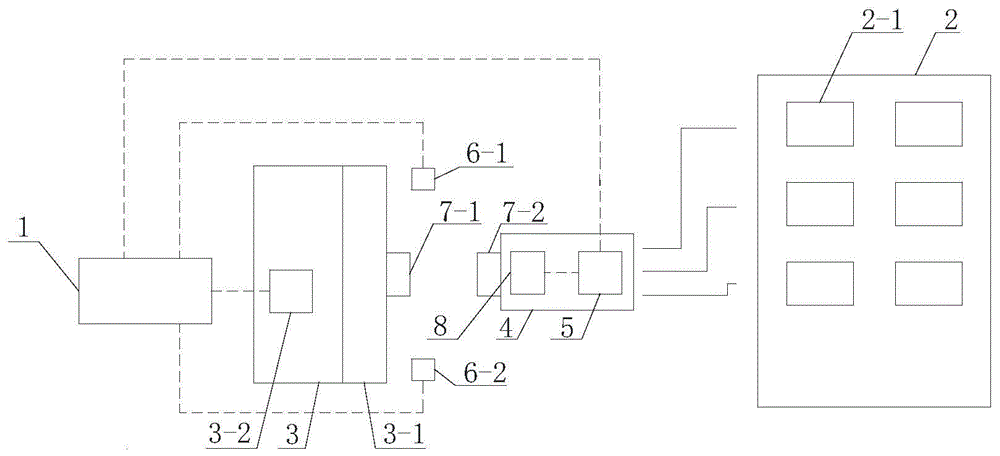

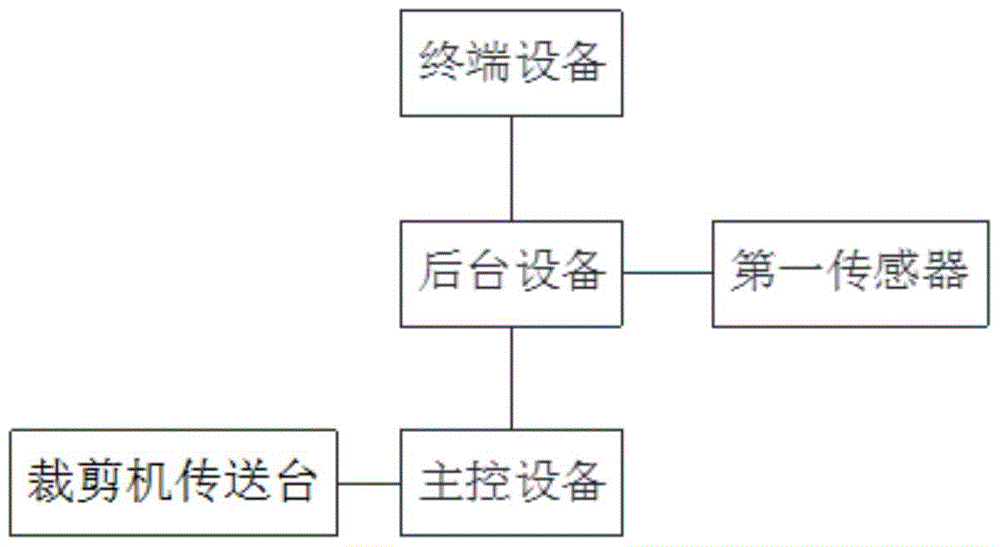

Automatic leather discharging system of leather processing center

InactiveCN105671218AEasy to cutRealize automatic outboundFur cuttingInternal memoryTerminal equipment

The invention relates to an automatic leather discharging system of a leather processing center. The automatic leather discharging system of the leather processing center comprises a background device, a bin, leather hoisting devices, a skip car and a terminal device, wherein the bin is provided with a plurality of positions; the leather hoisting devices are arranged in the positions; the skip car moves back and forth between the bin and a cutting machine; position numbers of the positions are pre-stored in the background device; and the terminal device is arranged on the skip car and controls the skip car. Compared with the prior art, the automatic leather discharging system of the leather processing center has the features that after leather on the leather hoisting device of the corresponding position is conveyed to the skip car, the background device acquires the position number of the position of the current leather from an internal memory, and transmits the position number to the terminal device, and the terminal device acquires a running path, which corresponds to the position number, of the skip car from the internal memory according to the received position number, and controls the skip car to run from a discharging side of the leather hoisting device of the corresponding position to a feeding side of a conveying table of the cutting machine according to the running path, so that the leather is discharged automatically.

Owner:长园和鹰科技(河南)有限公司

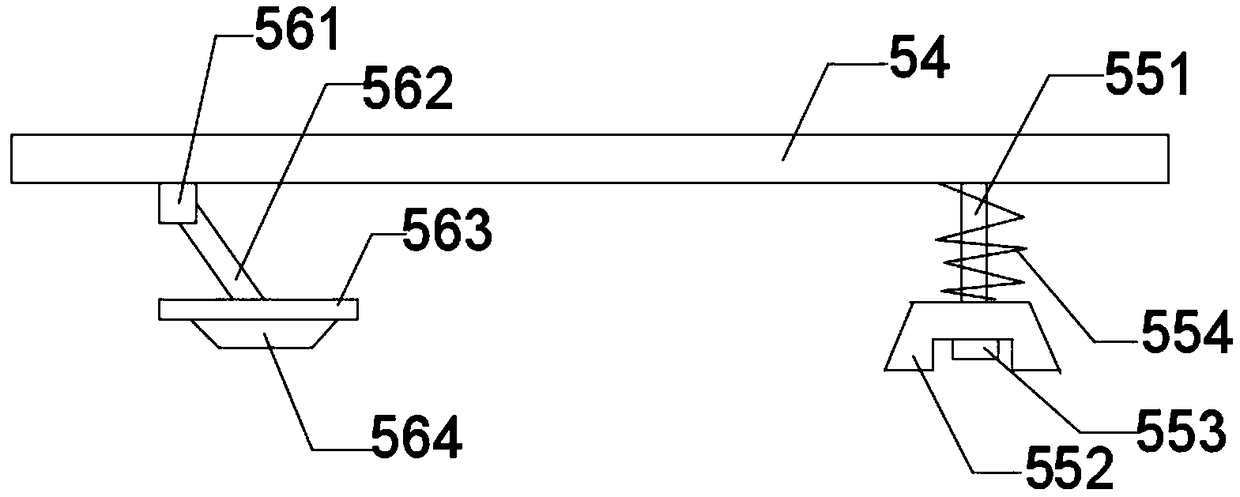

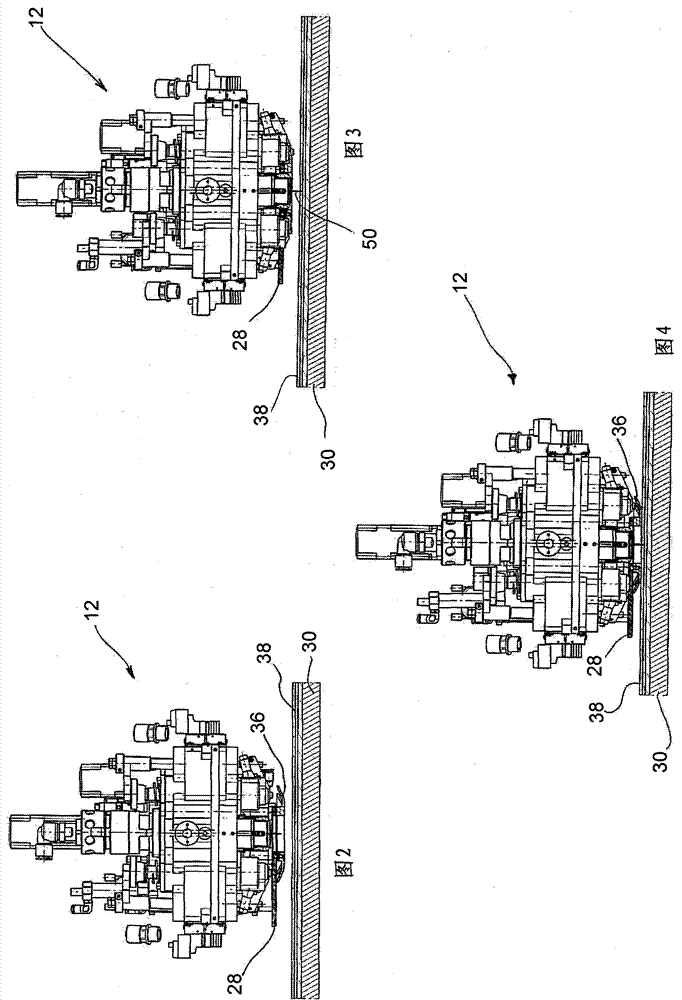

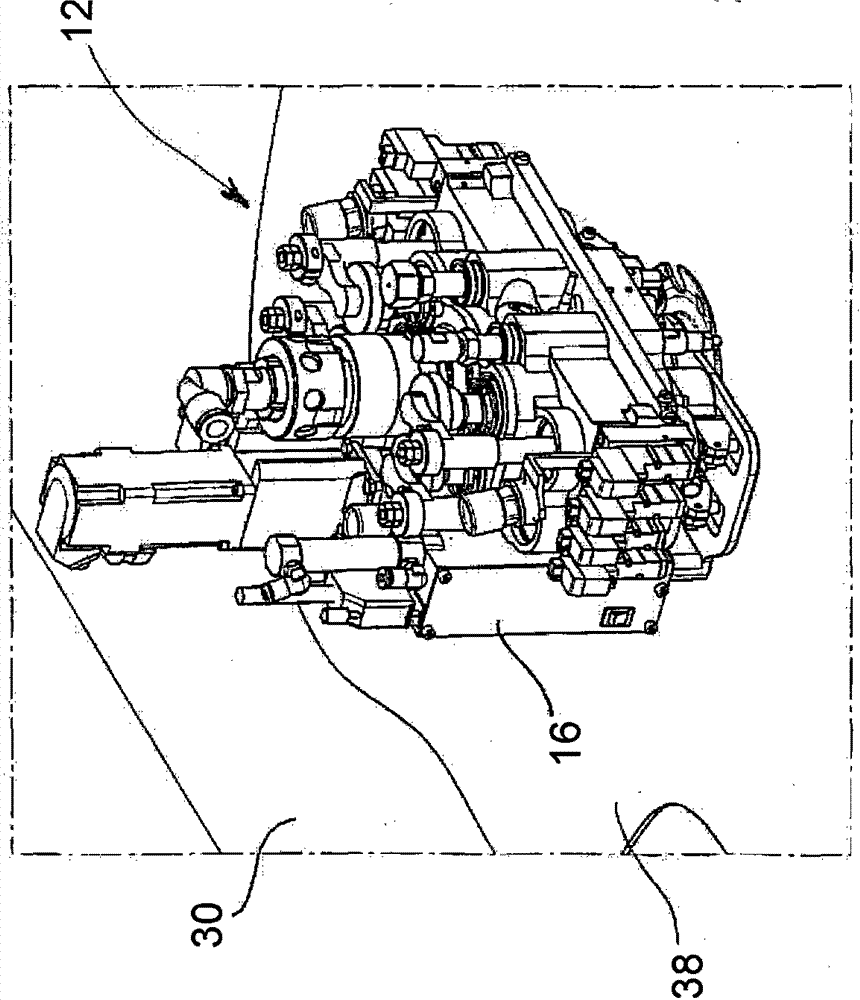

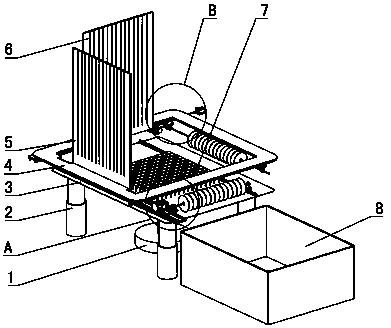

Adjustable device for temporarily stabilizing the material to be cut on the cutting table

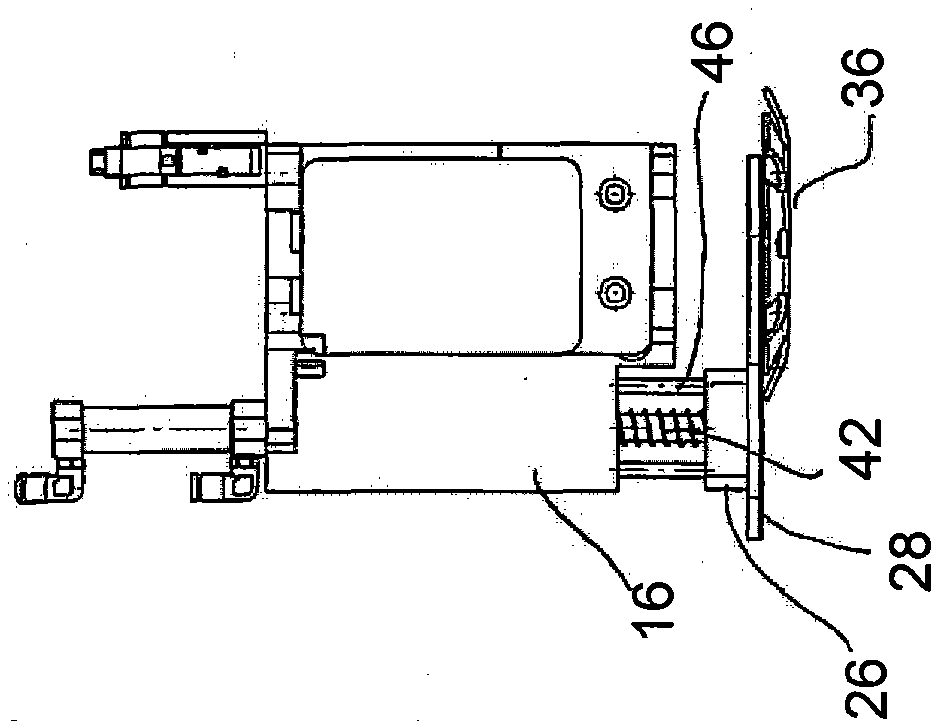

An adjustable device (10) for temporarily stabilizing the material (38) to be cut on the working surface of the cutting table, combined with a unit (12) of the table, the adjustable device comprising a A forming plate (36) moves vertically in the direction of the working surface (30) to abut the material (38). The device includes a frame (14) carrying pneumatic means for moving the shaft incorporating a coil spring (42).

Owner:原子股份公司

Anti-fake cutting system and method

ActiveCN113151617AAvoid it happening againTo avoidDispersed particle filtrationSkins/hides/leather/fur manufacturing apparatusElectric machineStructural engineering

The invention discloses an anti-fake cutting system and method. The anti-fake cutting system structurally comprises an atomization particle-preventing smoke-sucking filtering device, a device sealing cover, a device operation table, a device base and supporting legs, the device sealing cover is embedded in the surface of the atomization particle-preventing smoke-sucking filtering device, and the device operation table is arranged on the right side of the device sealing cover. The device operation table is electrically connected with the atomization particle-preventing smoke-sucking filtering device through a wire, and the bottom of the device operation table is connected with the top of the device base. During cutting, a driving motor can be started to drive suction fan blades to rotate slowly so as to suck generated smoke into a pipeline, and the smoke enters a pushing and accumulating box filled with carbon powder. Filtered gas is lighter than air in mass and can be exhausted through an exhaust pipe, it is avoided that the smoke is accumulated in the anti-fake cutting system in the mode that more smoke is converged, in the cutting process, water can be pumped through a water suction pump and then is atomized, waste heat on leather products is reduced, and black particles are prevented from being generated on the edges of the leather products.

Owner:KUNMING TONGKE DIGITAL PRINTING CO LTD

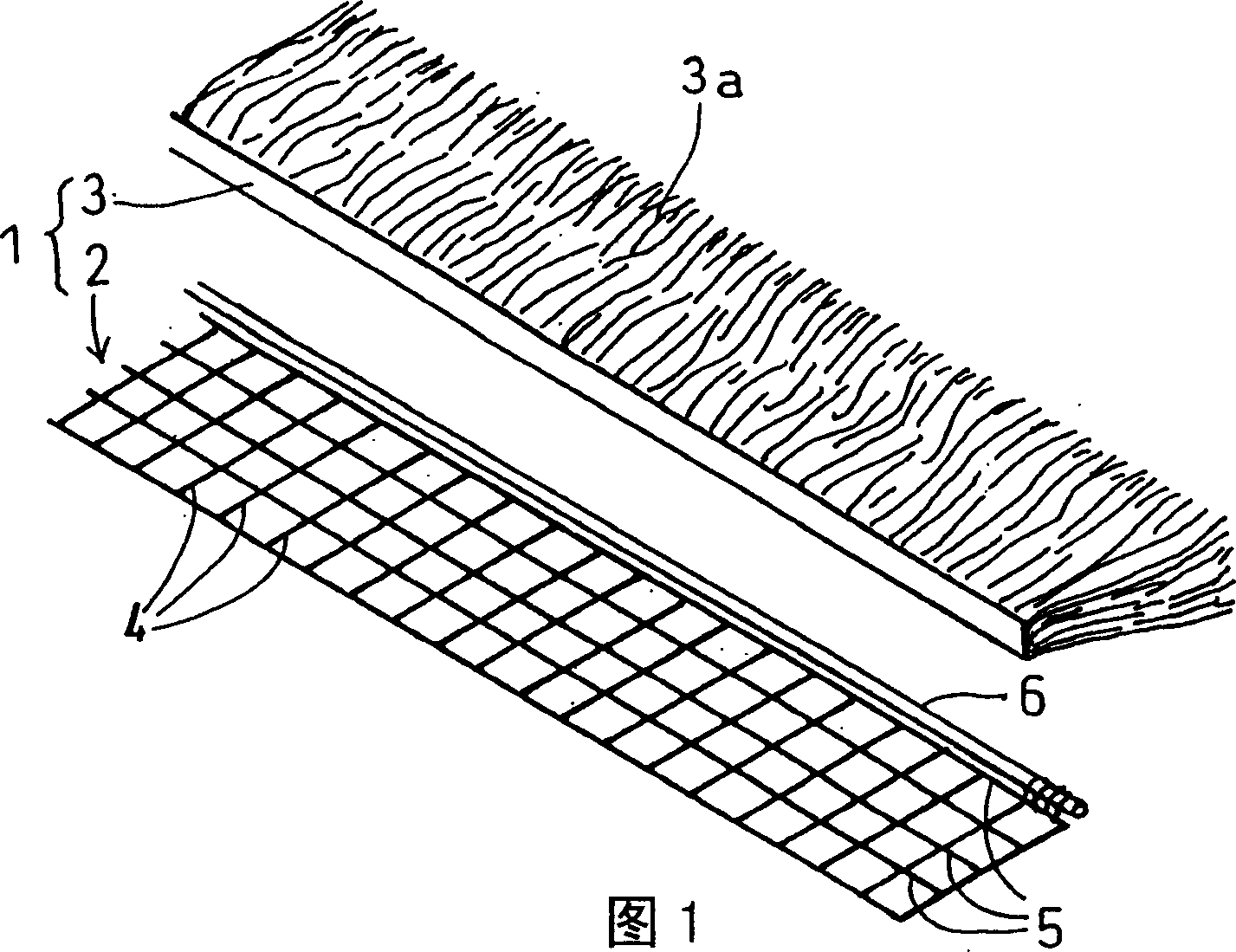

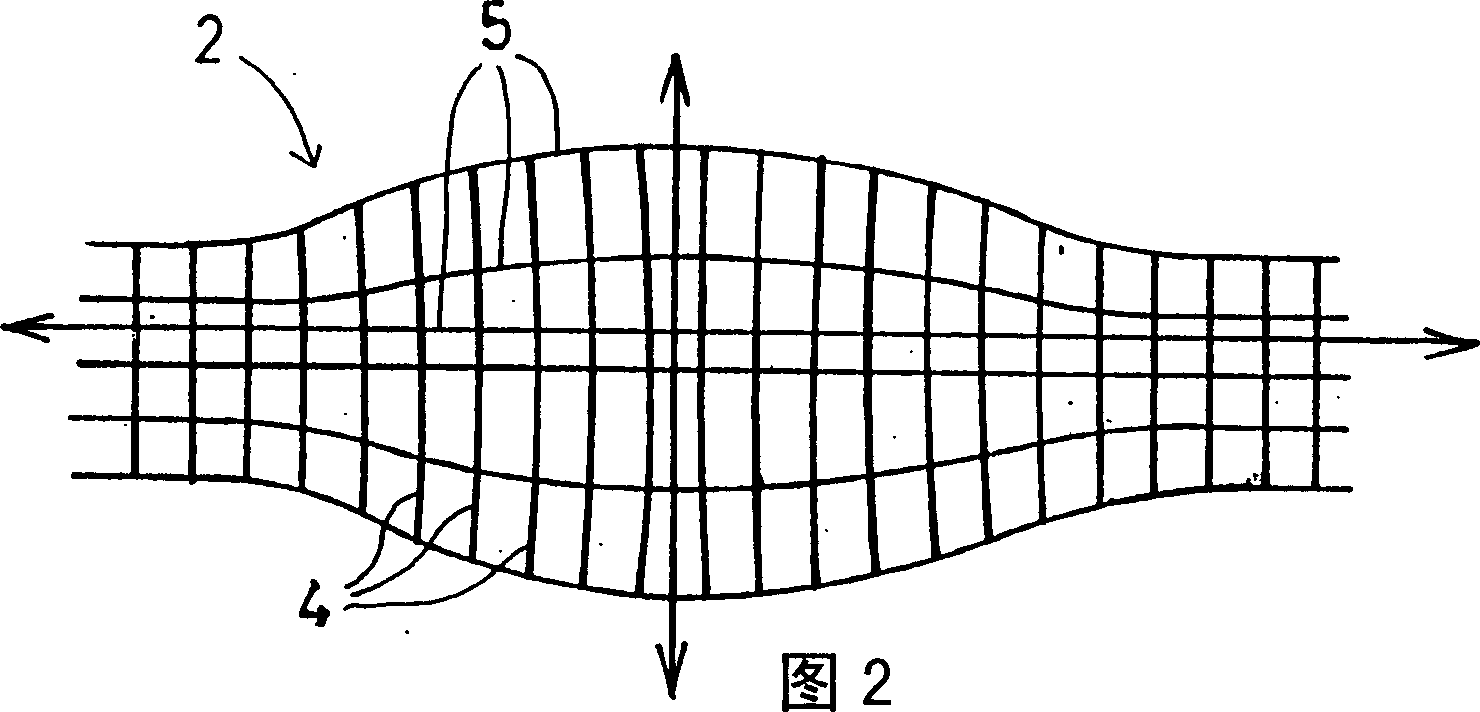

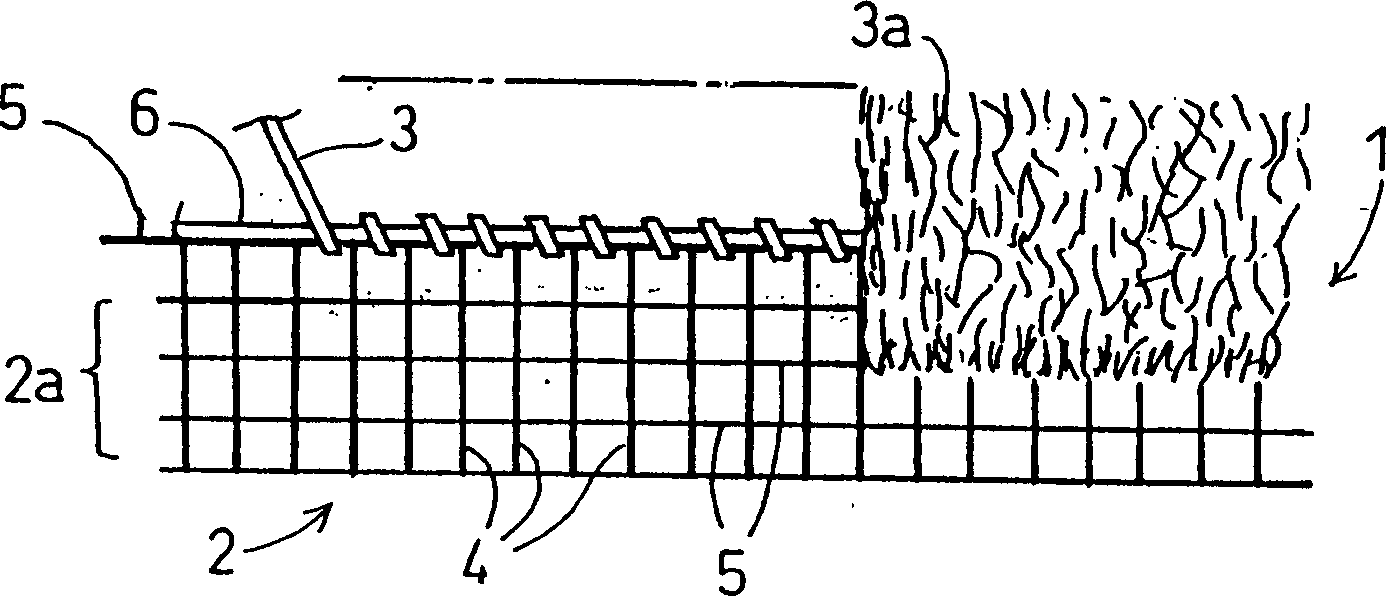

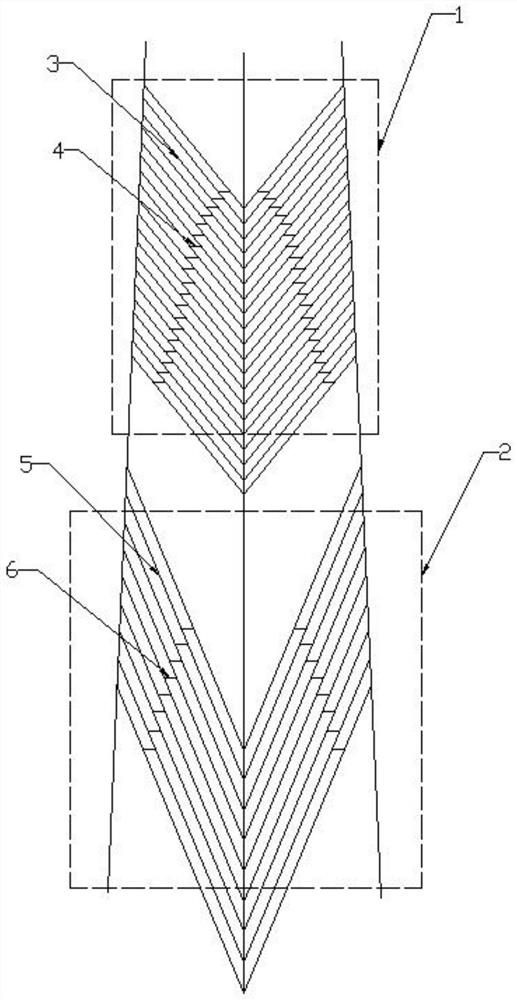

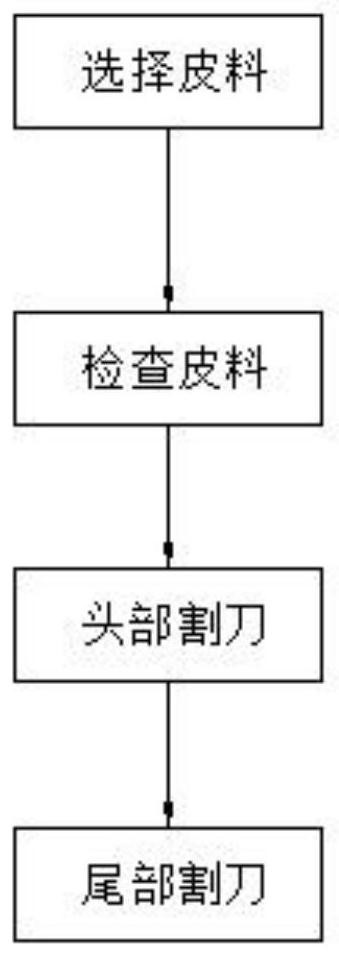

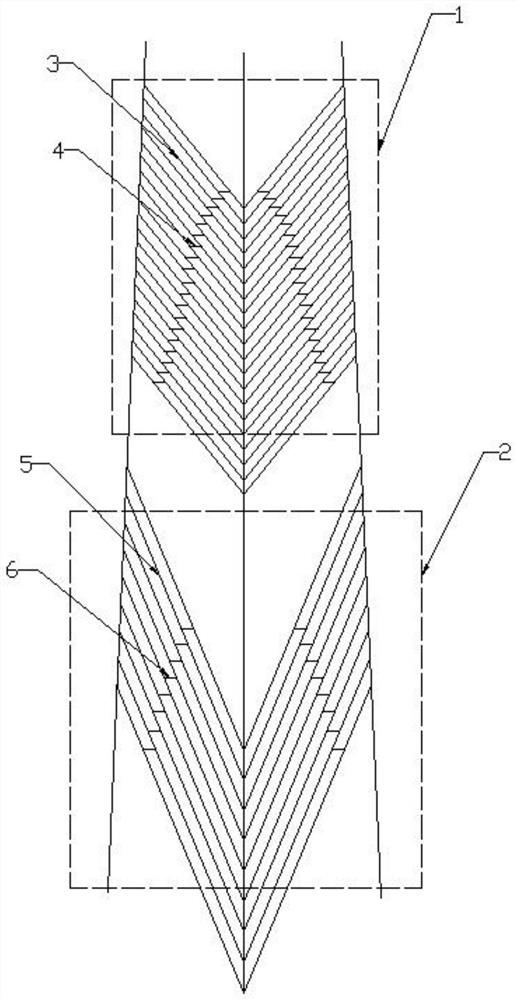

Aone inspector broach inner container process flow

The invention discloses an aone inspector broach inner container process flow. The aone inspector is also named desman, originates in the North America and widely spreads. The fur of the desman is excellent raw material for manufacturing high-grade fur clothes and has a full, thick, fine and soft fuzz, good elasticity, rich hand feeling and good luster; and the heat retention and the draining performance are only second to the skin of an otter. The invention is characterized in that a special sample sheet is needed in the fur preparing process, and fur materials needed by each inner containerare arranged. The broaching process comprises the steps as follows: firstly, cutting out two corners at two sides of a fur material with the shape approximating to a square so that the fur material issimilar to a triangle; and then cutting out two sides of the fur material to form small strips spaced at a certain distance, wherein the length of broaching is calculated according to the length of the sample sheet. The fur turning process comprises the steps as follows: firstly, placing the two cut corners of the fur material at two sides, and then splicing the cut small strips of the fur material with the two corners together so that the fur material is changed into a strip shape, wherein the seam turned every time needs to have consistent depth and be smooth, thus the fur material with theshape approximating to a square becomes strip-shaped after being processed, thereby facilitating matching color and splicing, obtaining better vision effect and being beneficial to beauty and sale.

Owner:TIANJIN BAERDI GARMENT

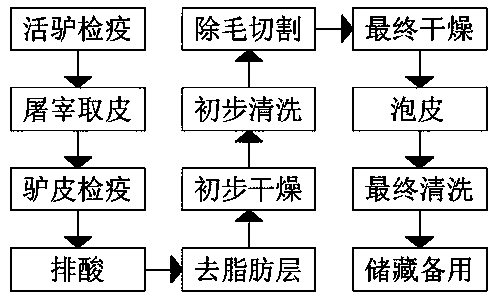

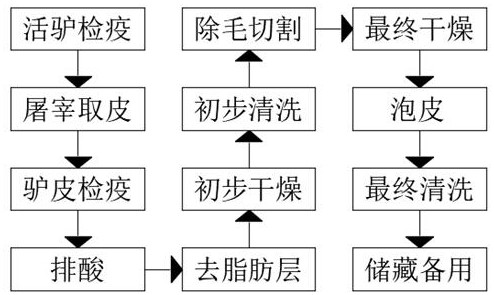

Donkey hide treatment method before donkey-hide gelatin decoction and process flow

ActiveCN109055626AGuaranteed freshnessReduce retentionFur shearingFur cuttingIndustrial waste waterMedicine

The invention discloses a donkey hide treatment method before donkey-hide gelatin decoction and a process flow, and belongs to the field of donkey hide treatment. Donkey hide non-salt treatment is adopted for reducing generation of dust and industrial waste water in the donkey hide machining process, in the treatment process, the acid discharge process after the donkey hide is stripped from a living body is added, retaining of bad blood in a blood vessel in the donkey hide after slaughter can be reduced, foam extraction is facilitated in donkey-hide gelatin decoction, after the donkey hide iscleaned, the donkey hide is saved, contact with the nature pollution sources can be reduced, meanwhile, the pollution, caused by donkey hide outdoor airing, to the atmospheric environment is reduced,the cold storage technology is adopted in final storage, freshness of donkey hide is ensured, the donkey hide is kept in the fresh donkey hide state all the time, and the fresh collagen source is ensured.

Owner:哈哈驴(天津)国际贸易有限公司

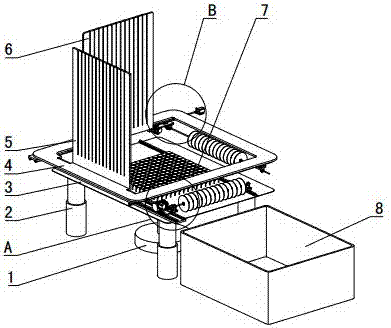

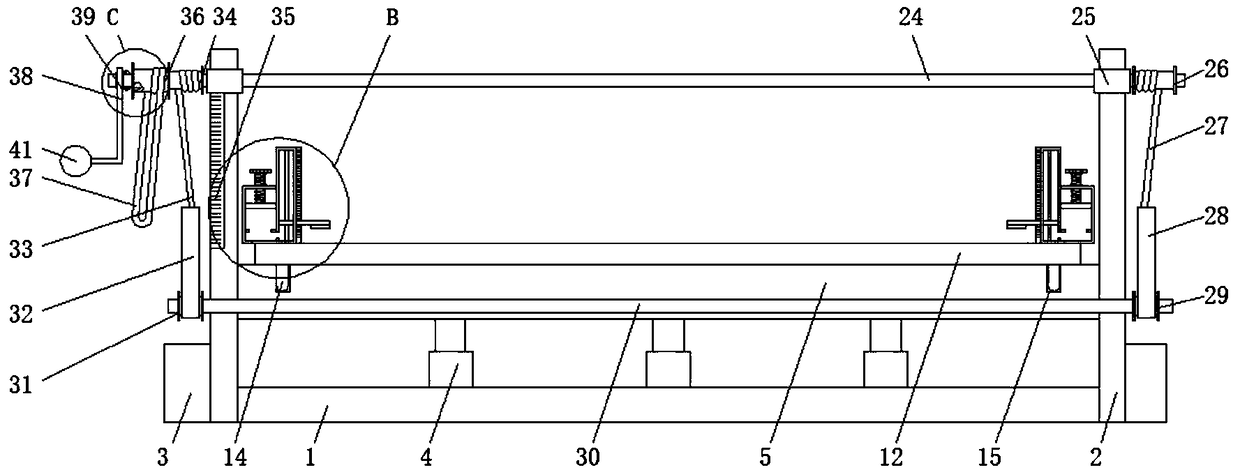

Transverse-longitudinal multi-layer cattle hide cutting machine

InactiveCN106801112APrevent movementDimensionally stableFur cuttingEngineeringMechanical engineering

The invention discloses a transverse-longitudinal multi-layer cattle hide cutting machine, and belongs to the technical field of cattle hide cutting equipment. The transverse-longitudinal multi-layer cattle hide cutting machine is characterized by comprising a cutting platform (4), a transverse cutting mechanism and a longitudinal cutting mechanism, wherein a pressing mechanism is arranged above the cutting platform (4); the pressing mechanism is matched with the cutting platform (4) to tightly press cattle hide to be cut; the transverse cutting mechanism and the longitudinal cutting mechanism are used for cutting the cattle hide respectively, so that the cattle hide can be cut into pieces. Due to the cooperation of the pressing mechanism and the cutting platform of the transverse-longitudinal multi-layer cattle hide cutting machine, a plurality pieces of cattle hide can be clamped simultaneously, the cattle hide is cut into pieces from two directions by the transverse cutting mechanism and the longitudinal cutting mechanism respectively, and the cattle hide is prevented from being moved when being cut, so that the cutting precision of the transverse cutting mechanism and the longitudinal cutting mechanism can be greatly improved, the size stability of the cut cattle hide can be ensured, later processing processes are simplified, and the product quality can be improved.

Owner:SHANDONG UNIV OF TECH

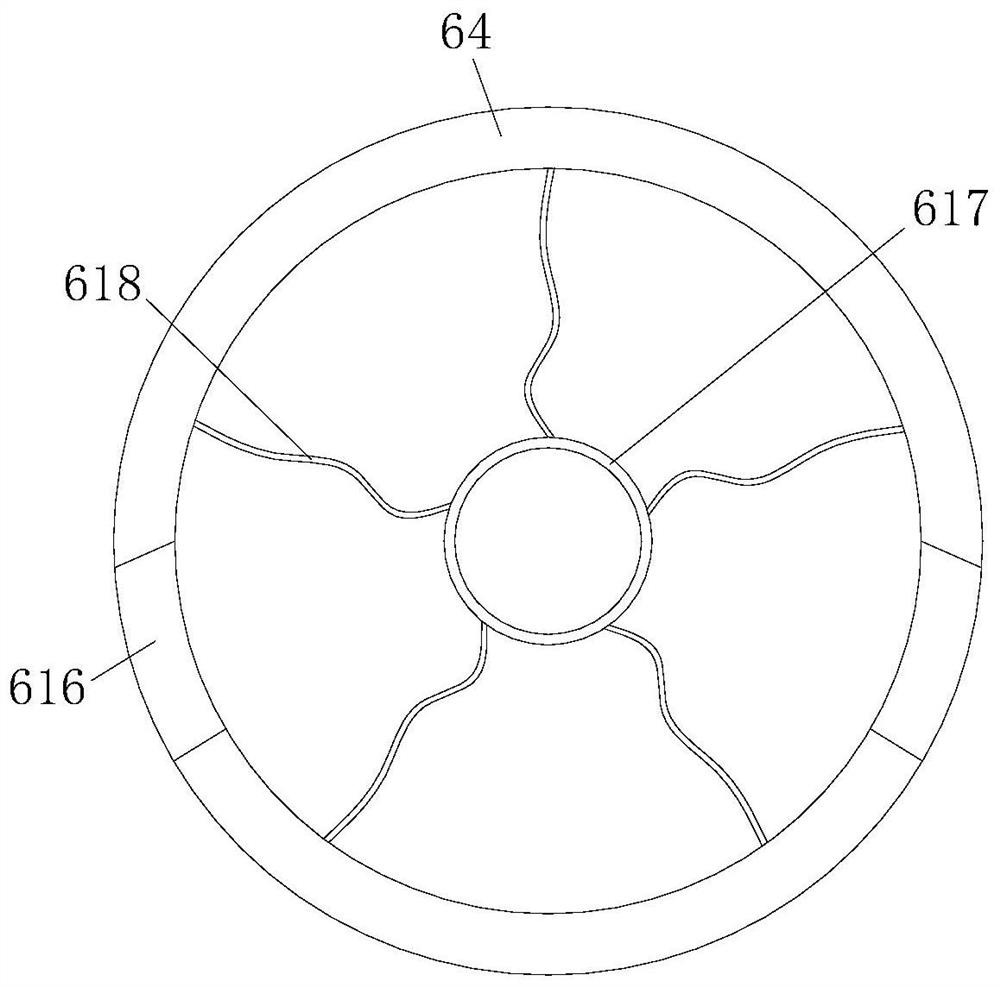

A kind of fur dividing machine

ActiveCN111411180BLower the heatGuaranteed slewing balanceSkins/hides/leather/fur manufacturing apparatusFur cuttingBeam tubeLight beam

The invention discloses a fur dividing machine, the structure of which comprises: a power distribution base box, a truss track, a transmission chain belt, a relay slot seat, a line distance pipe cylinder lining seat, a laser light board, and a working transmission platform. In order to use the line distance tube cylinder liner to cooperate with the laser light board, the heat suction tube frame and the beam tube extraction tube can realize the anti-thermal power suction effect at the laser output end, and when the laser vertically divides the fur, the heat can ensure the constant temperature of the atmosphere , to avoid scalding materials after cutting, and the buoy angle distance plate of the turret ball cylinder cooperates with the advancement of the vertical beam line speed to form a gradient measurement of angular velocity, which ensures the accuracy of coordinate advancement accuracy and improves the overall fur division edge alignment wheel The positioning efficiency of scanning is convenient to ensure the laser segmentation distance and fur heat detection. If the calorific value is too high, the laser head can be automatically fed back with an electrical signal, and the anti-thermal power suction backflow cylinder pressure can form a benign through horizontal exhaust and longitudinal suction. Heat insulation split processing effect.

Owner:陈亚楠

A kind of donkey hide treatment method and technological process before boiling donkey-hide gelatin

ActiveCN109055626BGuaranteed freshnessReduce retentionFur shearingFur cuttingIndustrial waste waterBlood vessel

The invention discloses a donkey hide treatment method before donkey-hide gelatin decoction and a process flow, and belongs to the field of donkey hide treatment. Donkey hide non-salt treatment is adopted for reducing generation of dust and industrial waste water in the donkey hide machining process, in the treatment process, the acid discharge process after the donkey hide is stripped from a living body is added, retaining of bad blood in a blood vessel in the donkey hide after slaughter can be reduced, foam extraction is facilitated in donkey-hide gelatin decoction, after the donkey hide iscleaned, the donkey hide is saved, contact with the nature pollution sources can be reduced, meanwhile, the pollution, caused by donkey hide outdoor airing, to the atmospheric environment is reduced,the cold storage technology is adopted in final storage, freshness of donkey hide is ensured, the donkey hide is kept in the fresh donkey hide state all the time, and the fresh collagen source is ensured.

Owner:哈哈驴(天津)国际贸易有限公司

A vertical platen cowhide cutting machine

InactiveCN106881737BPrevent movementDimensionally stableFur cuttingMetal working apparatusEngineeringMechanical engineering

The utility model relates to a vertical platen type cowhide cutting machine, which belongs to the technical field of cowhide cutting equipment. It is characterized in that: it includes a cutting platform (7), a transverse cutting mechanism and a longitudinal cutting mechanism, a longitudinal pressing mechanism and a transverse pressing mechanism are arranged above the cutting platform (7), and the transverse pressing mechanism and the longitudinal pressing mechanism alternate with the cutting The platform (7) cooperates to compress the cowhide to be cut, the horizontal pressing mechanism cooperates with the horizontal cutting mechanism to cut the cowhide, and the longitudinal pressing mechanism cooperates with the longitudinal cutting mechanism to cut the cowhide, thereby cutting the cowhide into blocks. The longitudinal pressing mechanism and the horizontal pressing mechanism of the vertical platen cowhide cutting machine can respectively cooperate with the cutting platform to press the cowhide tightly, avoiding the movement of the cowhide during cutting, so that the cutting accuracy of the longitudinal cutting mechanism and the horizontal cutting mechanism is greatly improved. , to ensure the dimensional stability of the cut cowhide, thereby simplifying the subsequent processing technology and improving the quality of the product.

Owner:SHANDONG UNIV OF TECH

A long fur trimming device based on negative pressure traction

ActiveCN111961767BAvoid wrinklesAvoid untidy pruningSkins/hides/leather/fur manufacturing apparatusFur cuttingStructural engineeringMechanical engineering

The invention provides a long fur trimming device based on negative pressure traction, which includes a supporting bottom plate and a supporting top plate. A number of support columns, a support frame, an extension adjustment mechanism for stretching and adjusting the fur, and a negative suction traction trimming mechanism for trimming the fur, the surface of the support base plate is fixedly connected with several support columns, and the support columns are far away from the support One end of the bottom plate is fixedly connected with a support top plate, and the surface of the support column is fixedly connected with a support frame, which relates to the field of fur processing. According to the problems of irregular folds and lodging that are easy to appear in the fur processing process, the device for trimming long fur materials based on negative pressure traction has designed a special targeted structure, which can trim the fur neatly at one time, thus effectively solving the problem of general The length of the fur is different, affected by various factors such as folds and fur lodging, it is difficult to trim the fur on the leather material uniformly, and it is easy to affect the quality of the processed fur products.

Owner:李德清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com