A kind of fur dividing machine

A cutting machine, fur technology, applied in fur cutting, small raw hide/large raw hide/leather/fur mechanical processing, raw hide/leather/fur manufacturing equipment, etc., can solve the problem of edge thickness burn, waste of material, slow fur processing Pipeline efficiency and other issues, to achieve the effect of ensuring integrity, preventing scorch and curling, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

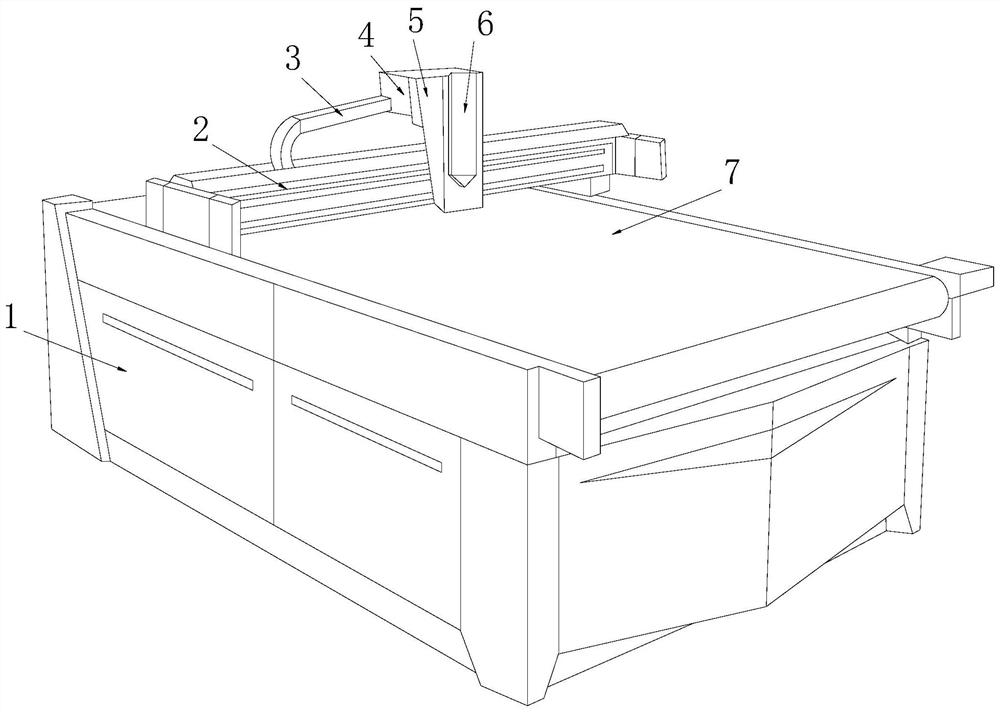

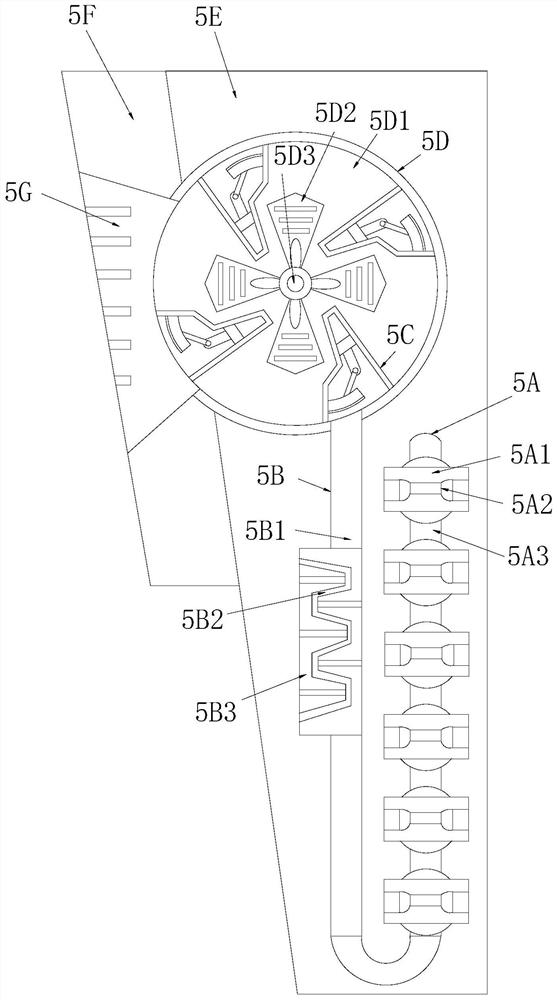

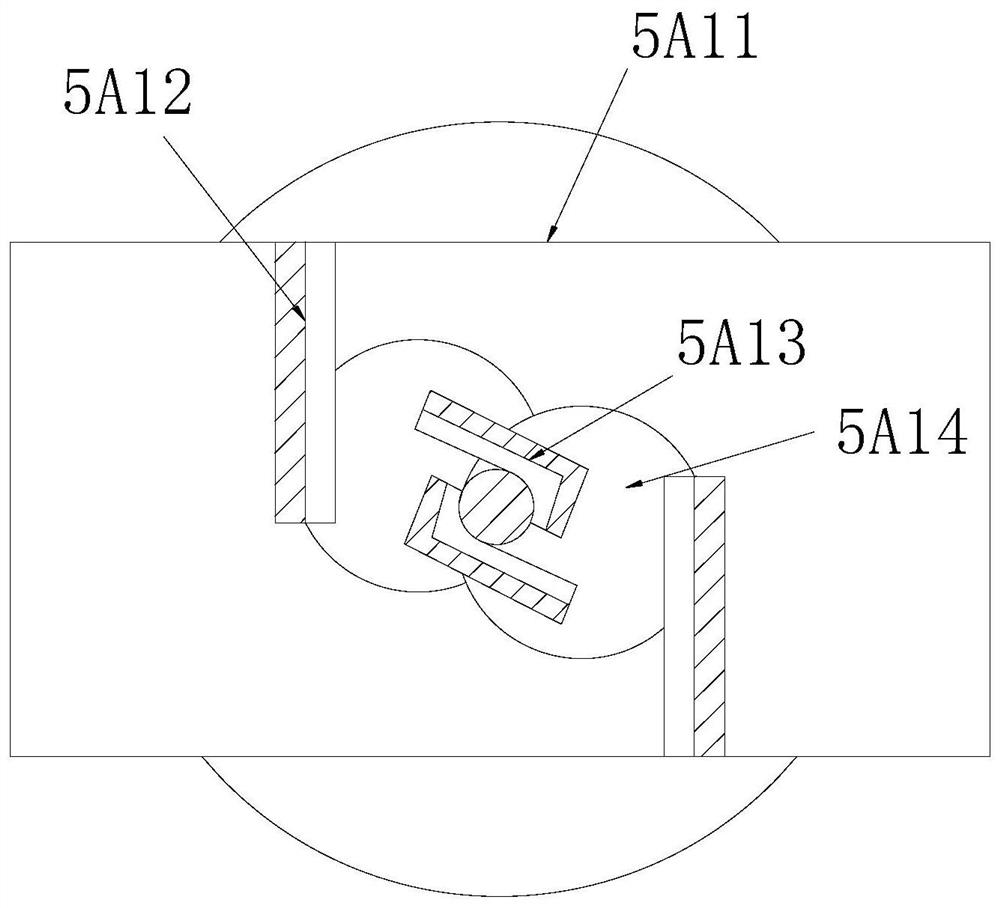

[0032] see Figure 1-Figure 6, the present invention provides a fur dividing machine, the structure of which includes: power distribution base box 1, truss track 2, transmission chain belt 3, relay slot seat 4, line distance pipe cylinder liner seat 5, laser light board 6, working The transmission table 7, the line distance pipe cylinder liner 5 is close to the rear side of the laser light board 6 and is on the same vertical plane, and the line distance pipe cylinder liner 5 is nested in the front of the relay slot seat 4 On the side, the relay slot seat 4 is mechanically connected with the truss track 2 through the transmission chain belt 3 and is on the same level. The truss track 2 is installed on the top of the working transmission platform 7 and is parallel to each other. Nested on the top of the power distribution base box 1, the power distribution base box 1 is electrically connected to the relay slot seat 4 through wires, the truss track 2 is movably connected to the w...

Embodiment 2

[0039] see Figure 1-Figure 6 , the present invention provides a kind of fur dividing machine, other respects are identical with embodiment 1, and difference is:

[0040] see figure 2 The tube extraction tube 5B is composed of a long-necked tube 5B1, a gradient push frame 5B2, and a lifting beam tube groove 5B3. The gradient pushing frame 5B2 is installed inside the lifting beam tube groove 5B3 and is on the same vertical plane. The lifting beam tube groove 5B3 and the long-necked through pipe 5B1 adopt an interference fit, and the gradient pushing frame 5B2 is elastically pressed in the lifting beam tube groove 5B3 to form a sliding force for pushing up and down, so as to ensure the efficient heating of the counterweight beam pressure.

[0041] see Figure 5 , the gradient pushing frame 5B2 is composed of a bow frame bar 5B21, a spacer bar 5B22, a spacer bar 5B23, and a nylon thin tube frame 5B24. Inside the 5B21, the spacer bar 5B23 is nested with the nylon thin tube fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com