Manual punching shear type slicing device

A slicing device, punching and shearing technology, applied in fur cutting and other directions, can solve problems such as time-consuming and long, achieve the effect of reducing cumbersome operations and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

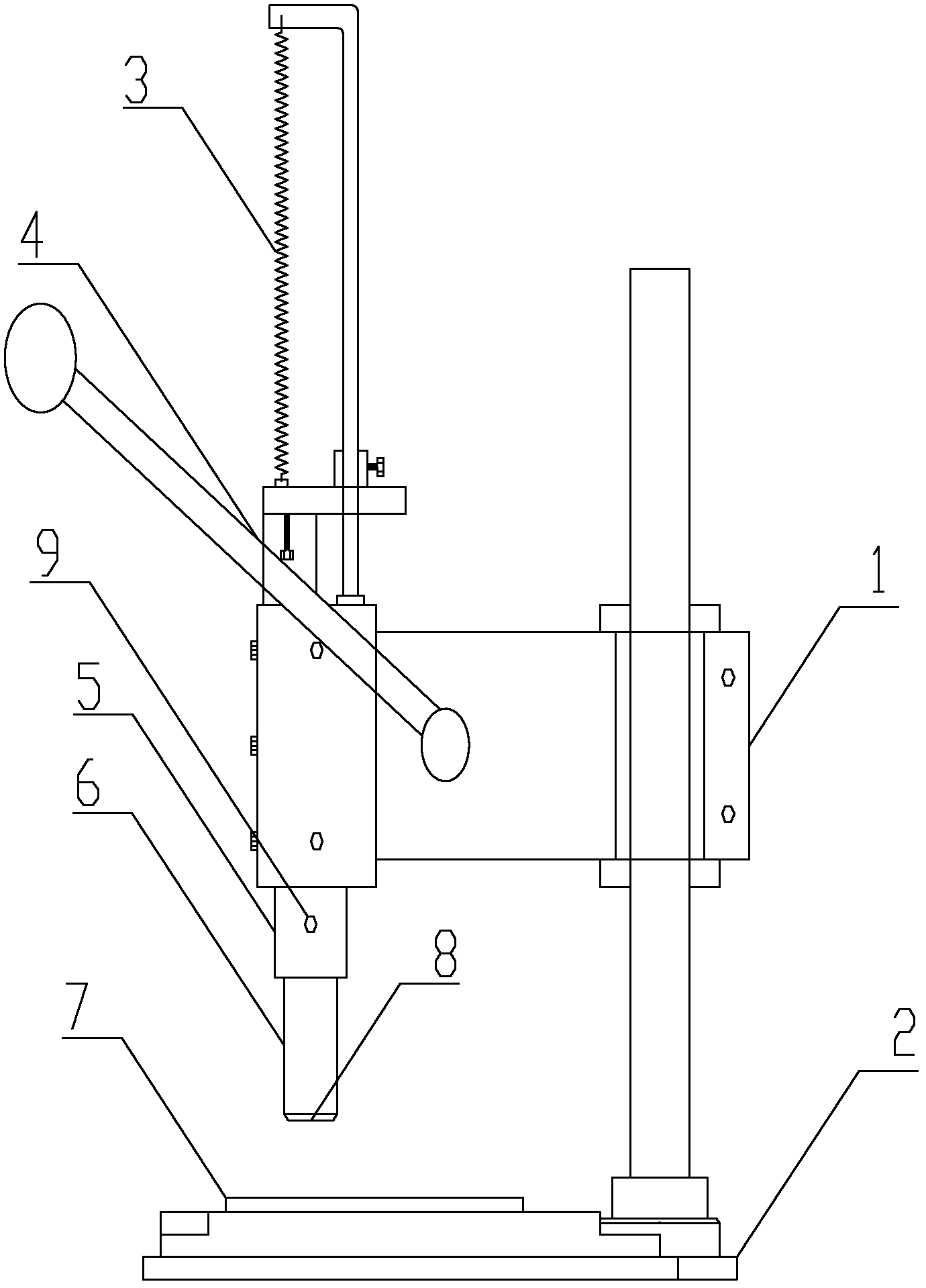

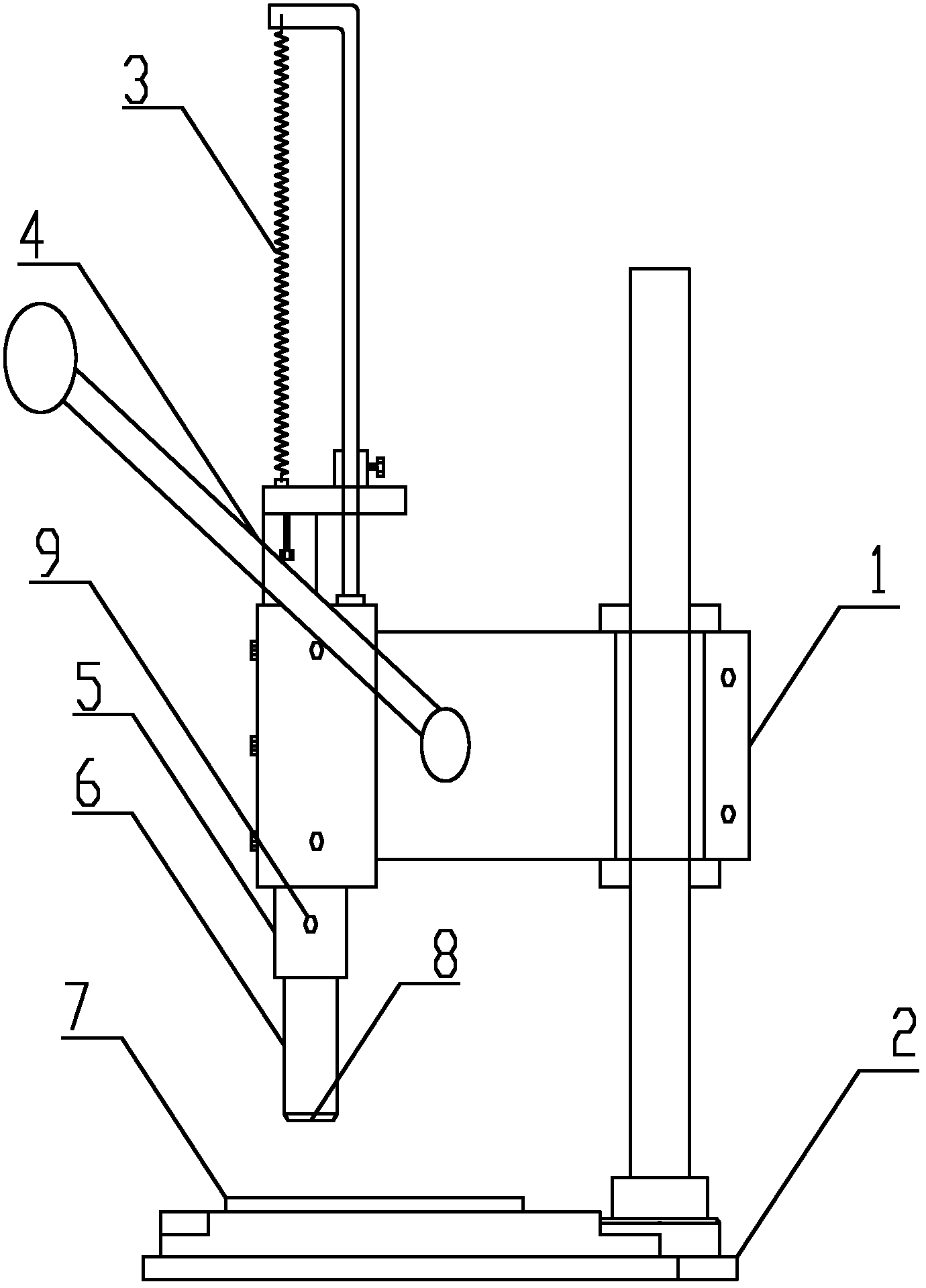

[0013] Such as figure 1 As shown, a manual punching and shearing type slicing device includes a manual press and a punching die, and the manual press includes a machine base 2, a frame 1, a return spring 3, and a rocker 4. The described The frame 1 is fixed on the frame 2, the return spring 3 and the rocking bar 4 are arranged on the frame 1, the punching die includes a die groove 5, a punching head 6 and a base platform 7, the The mold groove 5 is set on the frame 1, the punching head 6 is set in the mold groove 5, fixed by the fixing bolt 9, one end of the punching head 6 is connected to the return spring 3 and the rocker 4, and the other end is provided with Get leather mouth 8, described base platform 7 is arranged on the machine base 2, and is positioned at the below of the leather mouth 8 of punching and shearing head; The combination of rack and pinion drives the punching and shearing head to move, and presses down on the object to be cut on the cutting base platform. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com