Method for making high-end-quality mink garment with rough surface free of cutter marks

A high-quality mink technology, applied in the field of high-end mink clothing with no knife marks on the hair surface, can solve the problems that affect the appearance of the clothes and do not meet the needs of consumers, and achieve a high-end effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

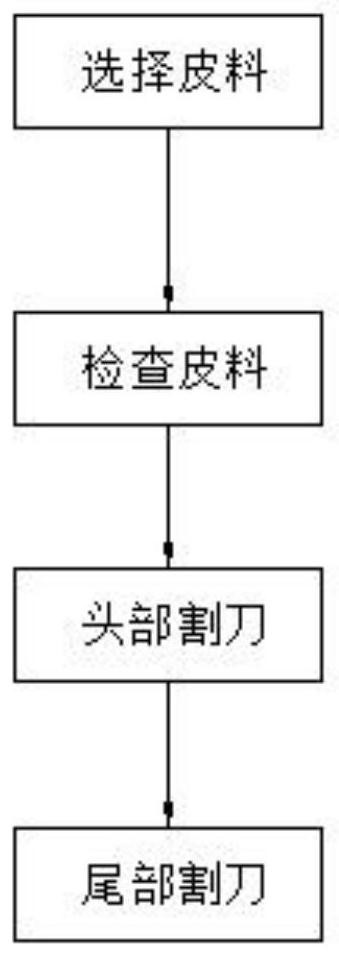

[0026] A method for making the hair surface of high-end mink clothing free of knife marks, including leather materials and knives, includes the following steps:

[0027] Step 1: According to different clothing styles, choose different leather materials to prepare for the next step of cutting;

[0028] Step 2: Place the selected leather on the workbench, and the processing personnel check the surface of the leather to see if there is any damage;

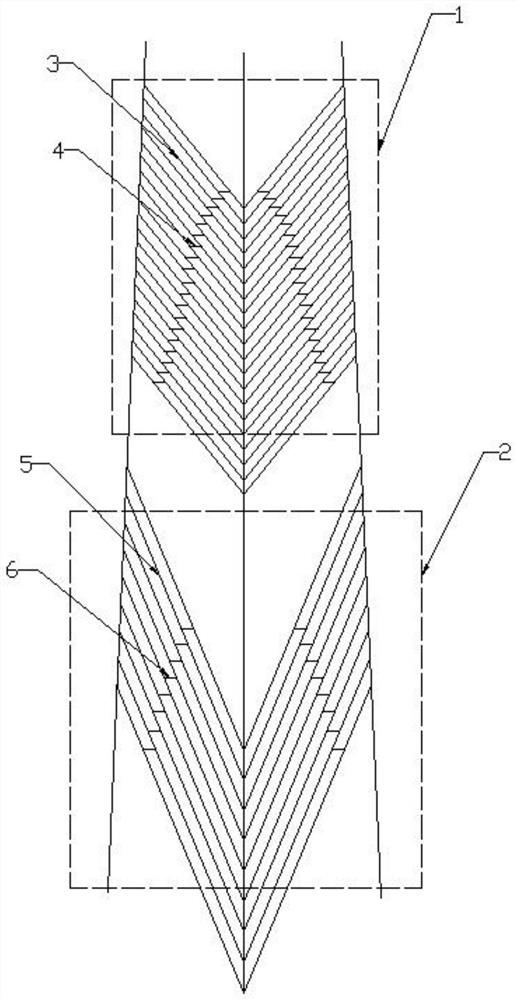

[0029] Step 3: Start to cut the knife according to the clothes pattern, and cut the head of the clothes with a knife. According to the clothes pattern, cut each strip with a width of 0.2 inches, cut the required number of strips according to the shape, and then Cut the clothes and sew them, and sew them at intervals of 0.1 inches, such as figure 2 Shown, among the figure 1 is the clothes head, among the figure 3 is the cutter line of the clothes head, among the figure 4 is the head sewing line;

[0030] Step 4: Use a knife to cut t...

Embodiment 2

[0039] A method for making the hair surface of high-end mink clothing free of knife marks, including leather materials and knives, includes the following steps:

[0040] Step 1: According to different clothing styles, choose different leather materials to prepare for the next step of cutting;

[0041] Step 2: Place the selected leather on the workbench, and the processing personnel check the surface of the leather to see if there is any damage;

[0042] Step 3: Start to cut the knife according to the clothes pattern, and cut the head of the clothes with a knife. According to the clothes pattern, cut each strip with a width of 0.2 inches, cut the required number of strips according to the shape, and then Cut the clothes to sew, and sew them at intervals of 0.2 inches, such as figure 2 Shown, among the figure 1 is the clothes head, among the figure 3 is the cutter line of the clothes head, among the figure 4 is the head sewing line;

[0043] Step 4: Use a knife to cut the but...

Embodiment 3

[0052] A method for making the hair surface of high-end mink clothing free of knife marks, including leather materials and knives, includes the following steps:

[0053] Step 1: According to different clothing styles, choose different leather materials to prepare for the next step of cutting;

[0054] Step 2: Place the selected leather on the workbench, and the processing personnel check the surface of the leather to see if there is any damage;

[0055] Step 3: Start to cut the knife according to the clothes pattern, and cut the head of the clothes with a knife. According to the clothes pattern, cut each strip with a width of 0.2 inches, cut the required number of strips according to the shape, and then Cut the clothes to sew, and sew them at intervals of 0.3 inches, such as figure 2 Shown, among the figure 1 is the clothes head, among the figure 3 is the cutter line of the clothes head, among the figure 4 is the head sewing line;

[0056] Step 4: Use a knife to cut the butto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com