Screw rod transmission cutting machine

A technology of screw drive and cutting machine, which is applied in fur cutting, leather punching/punching/cutting, small raw hide/big raw hide/leather/fur mechanical treatment, etc. Inconsistent operation and receiving positions, unsatisfactory cutting efficiency, etc., to achieve the effect of small footprint, improved production efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

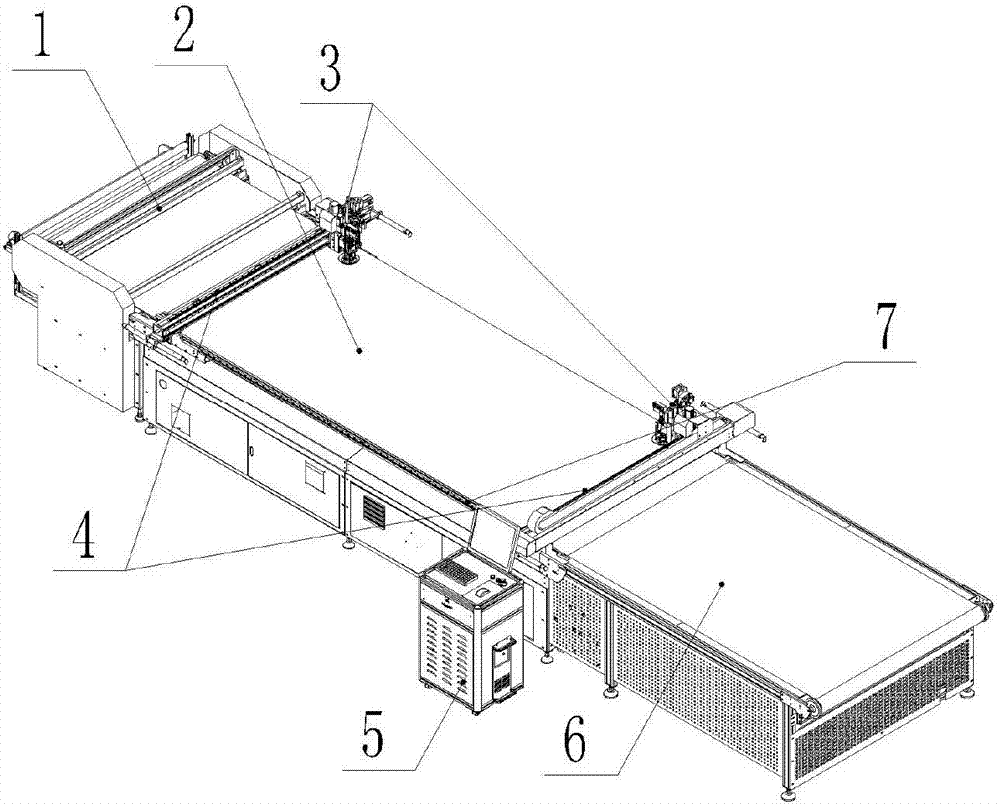

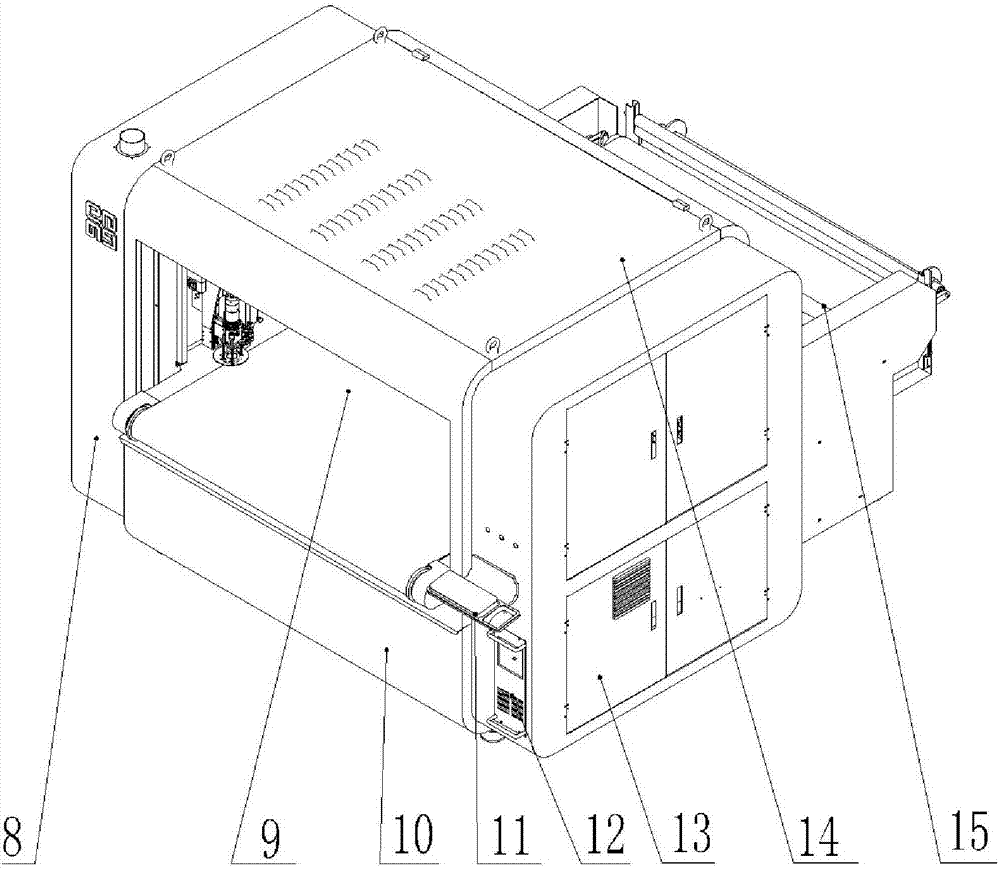

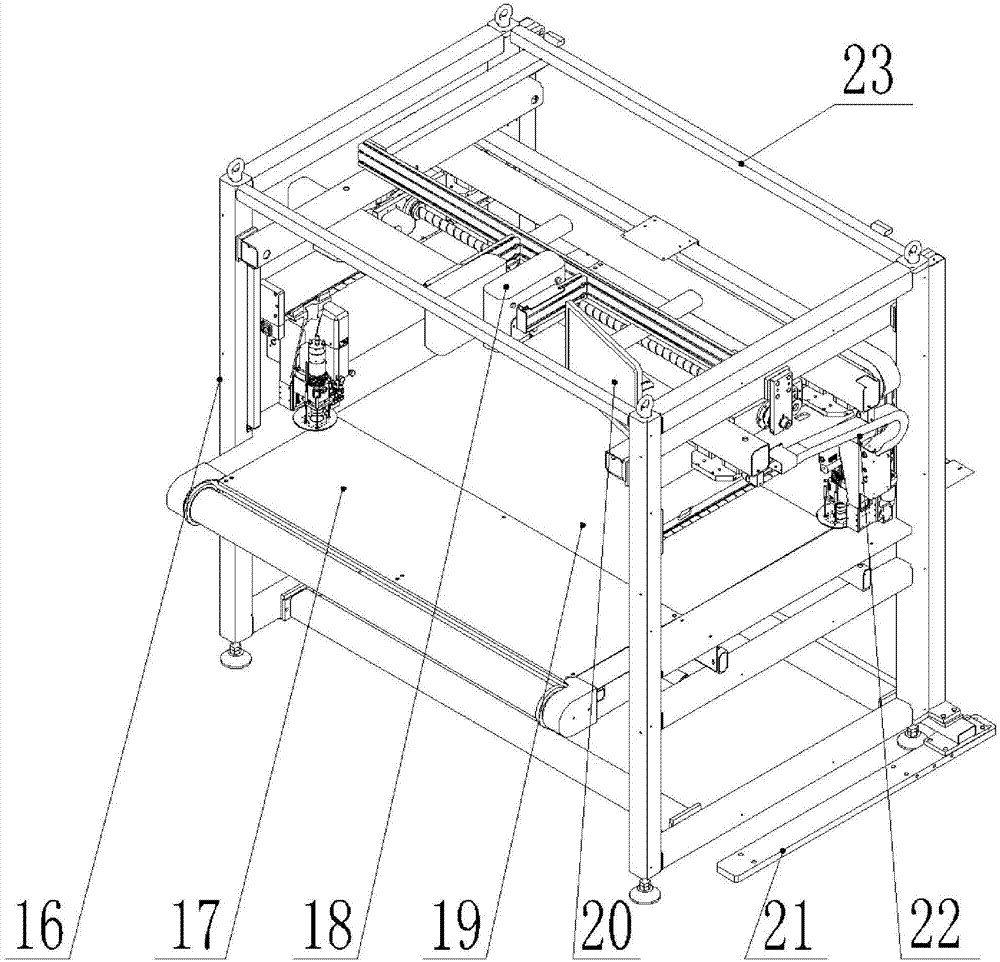

[0026] Such as figure 1 and figure 2 As shown, the screw drive cutting machine includes a frame, and the frame includes an underframe 16, and the underframe 16 is provided with an adsorption platform 19, and the front side of the adsorption platform 19 is provided with a receiving platform 17, and the adsorption The upper side of the platform 19 and the receiving table 17 is provided with a cutting mat 9 , and the front side of the receiving table 17 is provided with a receiving hopper 10 . The rear side of the adsorption platform 19 is provided with a feeder 15 for feeding the cutting platform. An upper bracket 23 is arranged above the underframe 16, and the upper bracket 23 is welded by square tubes. The outer side of the upper bracket 23 is provided with a casing 14, and the casing 14 is provided with ventilation holes. Four corners of the upper end of the housing 14 are provided with lifting lugs. The right side of the frame is provided with a projection stand 21 . A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com