Device for automatically cutting fur into strips

A technique of fur and strip cutting, applied in fur cutting and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

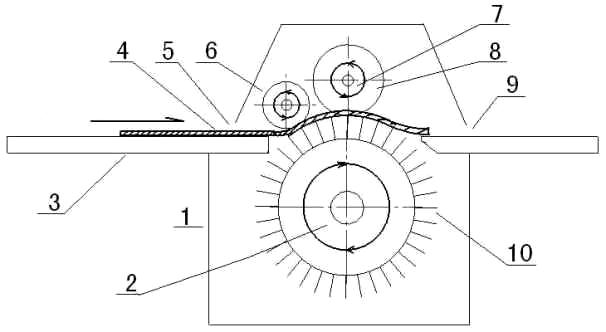

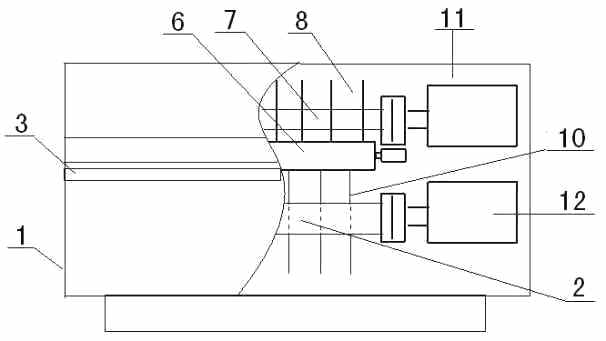

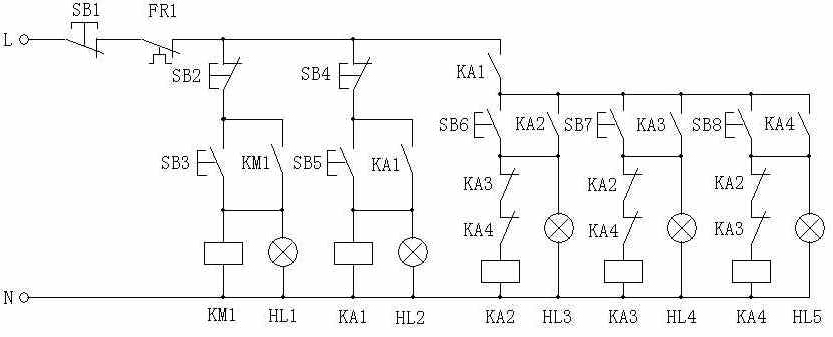

[0012] 1. The basic structure of the device

[0013] Such as figure 1 As shown, the automatic fur strip cutting device provided by the present invention comprises a machine casing 1, a needle shaft 2 and a needle shaft drive motor 12 are installed in the bottom of the machine casing, a workbench 3 is installed in the middle of the machine casing, and the two ends of the workbench extend to The outside of the front and rear sides of the machine shell, the middle part of the workbench to the outside of the circumference of the rubber shaft, the front end of the machine shell above the workbench is opened with a material inlet 5, and the rear end is opened with a material outlet 9, and the upper part of the machine shell is located above the workbench Cutter shaft 7 and cutter shaft driving motor 11 are installed, and a row of disc rotating knives 8 is installed on the knife shaft. The interval of disc rotating knives is the width of the fur to be cut. Correspondingly, the ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com