Patents

Literature

31results about "Fur finishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

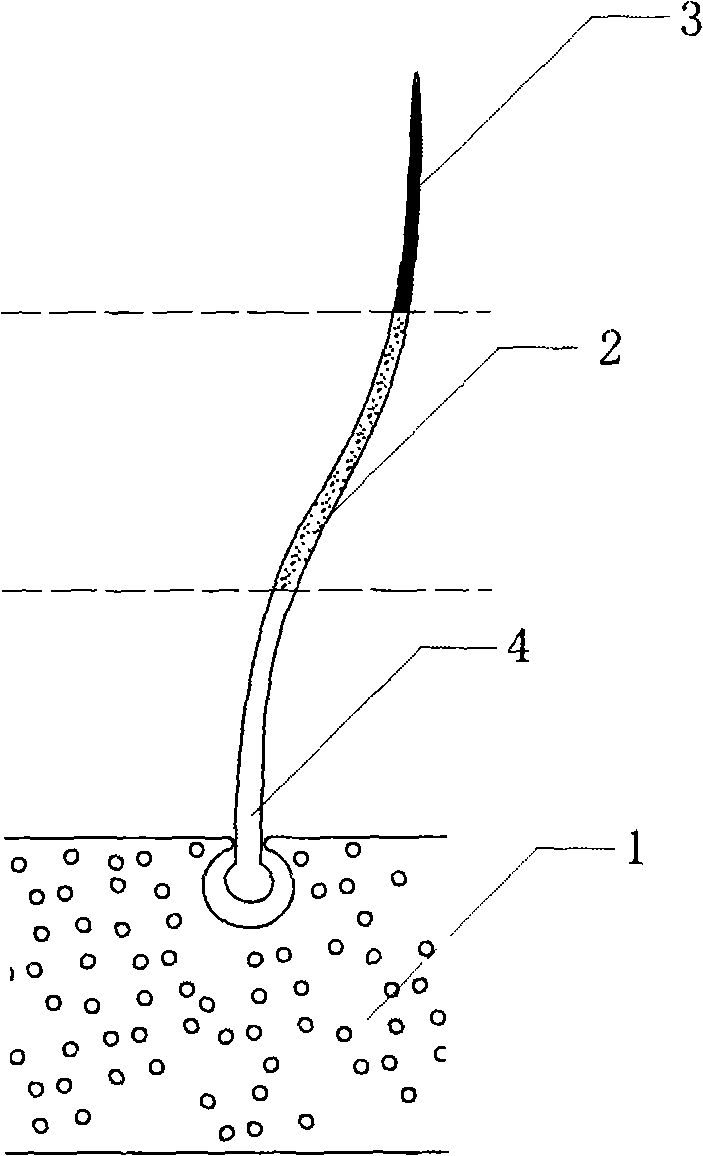

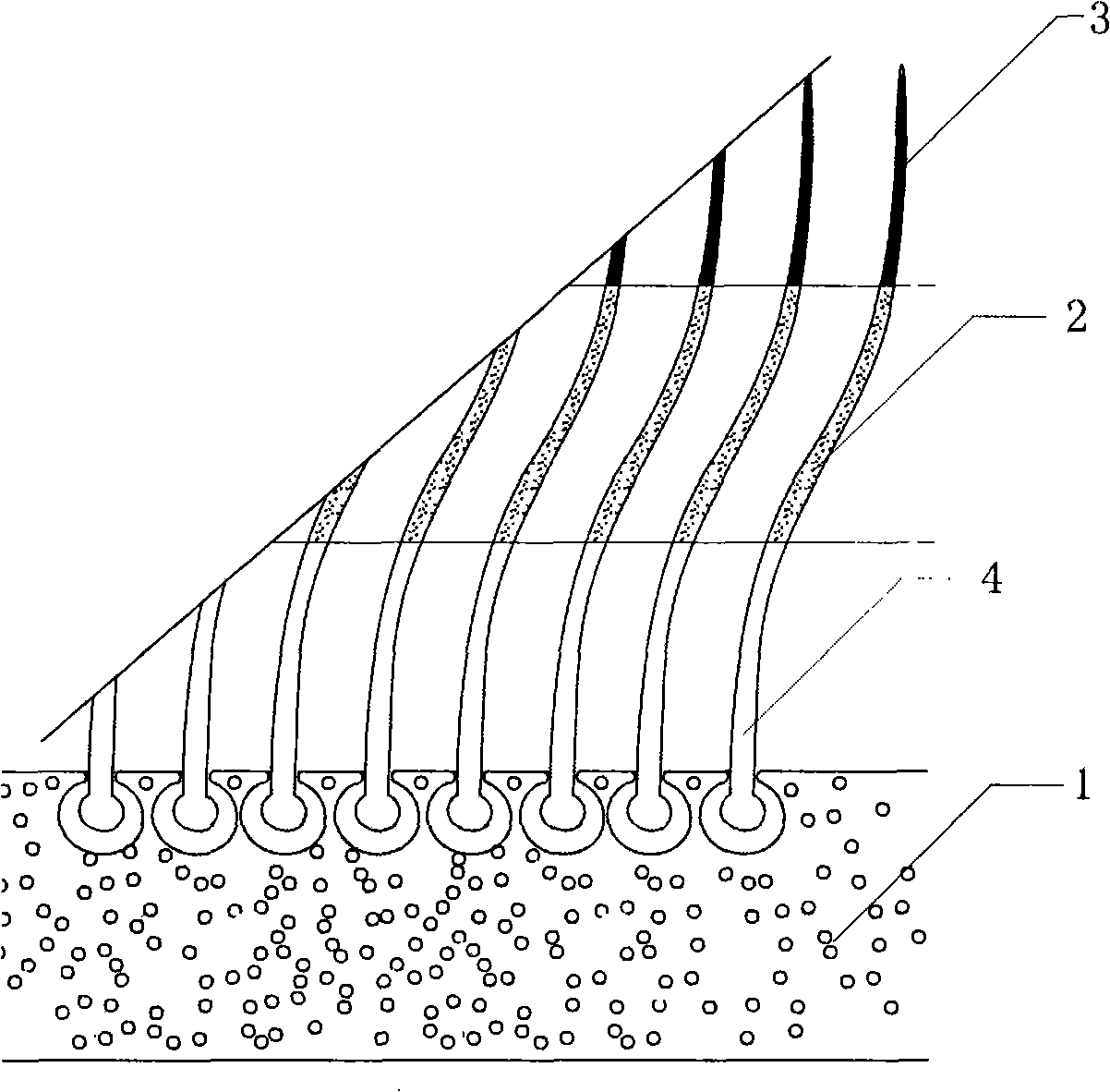

Technology for imitating mink fur by using rabbit fur

The invention discloses a technology for imitating mink fur by using rabbit fur and is characterized in that the technology comprises the following steps that: 1) the rabbit fur is tanned by using a routine technique; 2) hairs are sheared, ironed and combed, and treatment such as shaving, carving and the like is conducted; 3) surface finish treatment is conducted; 4) surface waterproof treatment is conducted; 5) leather sheet strength treatment is conducted; 6) mordant dyeing is conducted; 7) coloring treatment is conducted; and 8) imitated mink fur is formed. By using low-level fur such as rabbit fur, beaver rabbit fur and the like, through routine process treatment such as hair shearing, hair ironing, hair combing and the like, then through special process treatment such as hair surface finish treatment, hair surface waterproof performance treatment, leather sheet strength treatment and the like and finally through process treatment such as dyeing, color spraying, printing, carving and the like, the processed rabbit fur and beaver rabbit fur can reach the effect of mink velvet, thereby realizing the effect of turning low-level fur into high-level fur.

Owner:HUASI HLDG CO LTD

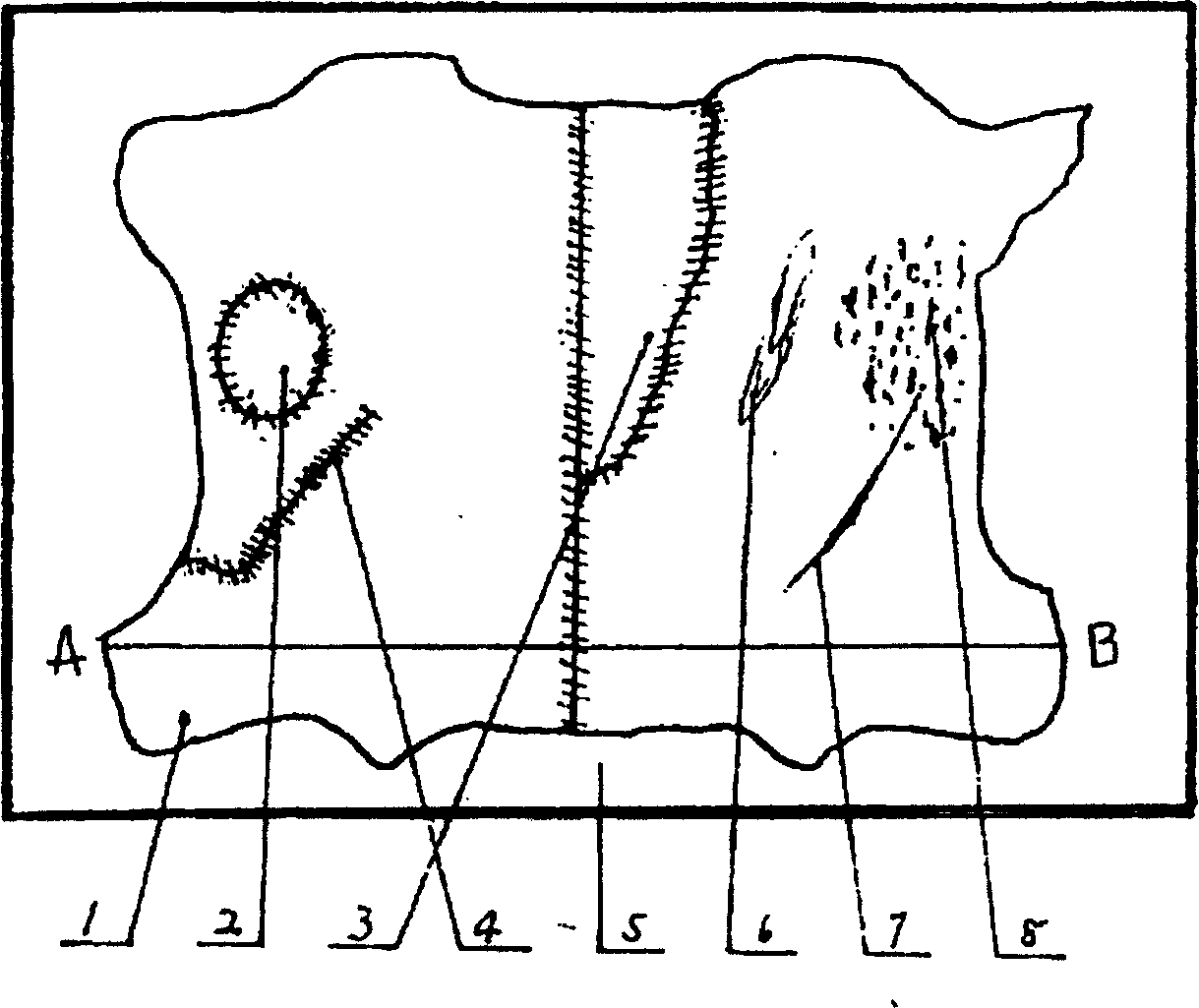

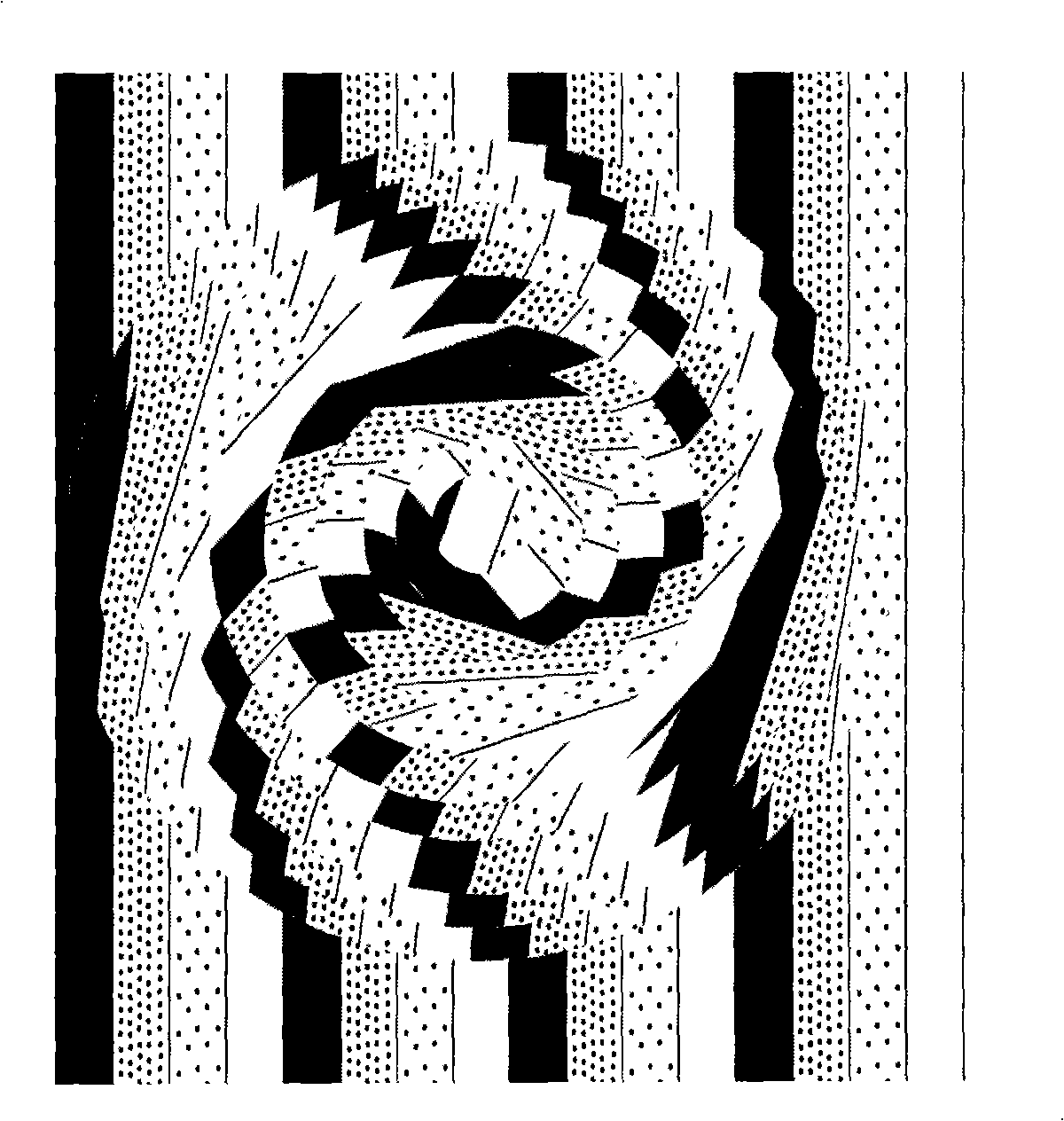

Method for processing fur facing material design and colour

The invention relates to a design and color processing method for the deep processing of fur shell fabrics and a product thereof, and is characterized in that thick and intermediate-thick animal furs with burly cutis plate and compact and plump wool type are chosen, and technical measurements of bleaching, dyeing, color spraying and fading are adopted for processing fluff color from a root part to a mucro part into different color laminations. Flower patterns are designed according to the situations of the number of the color laminations and color changes, a flower cutting device is used for optionally cutting fur surface into the patterns with different shapes and thicknesses, and different flower patterns are formed by the colors in different color laminations. The design and color processing method of the deep processing of fur shell fabrics combines the existing processing methods for use, has the advantages of novel method, unique effect and strong ornamental property, etc., and can particularly improve the level of concealing the flaws of original materials. The design and color processing method of the deep processing of fur shell fabrics can be implemented on a whole sheet or a part of the fur material, and can be popularized and implemented on the shell fabrics with superficial fluff such as dyed furs and artificial furs, etc.

Owner:潘春宇

Production of suede leather from low quality leathers

A method for processing suede clothing leather, suede shoes, caps and casing leather by substandard leather includes: sewing and pinning expanding for injury, erasing surface injury by bonder, permeating filling for internal chaff board and frid, coating bonder for mended dermatome and flocking, covering injury after drying and curing, and obtaining suede clothing leather, suede shoes, caps and casing leather.

Owner:陈财千

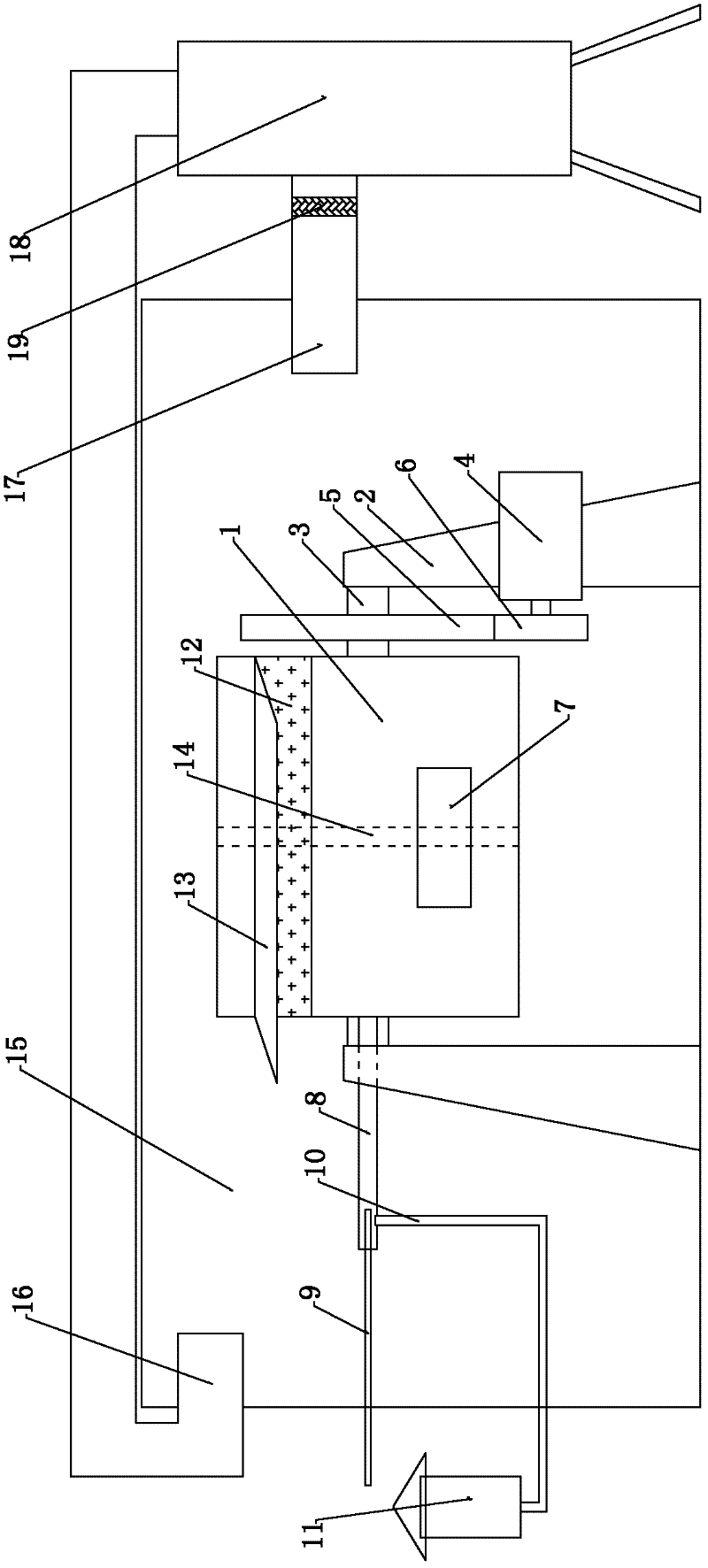

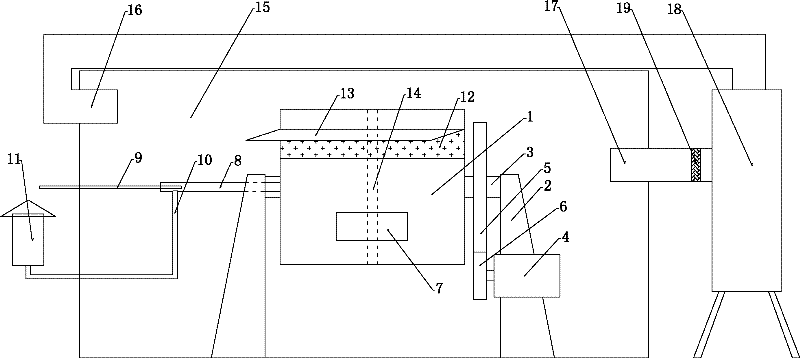

Method and device for printing Tibet lamp skins

InactiveCN102505052AGood adhesionRich and beautiful colorsLeather/skins/hides/pelt chemical treatment apparatusLeather softeningPulp and paper industrySpray drying

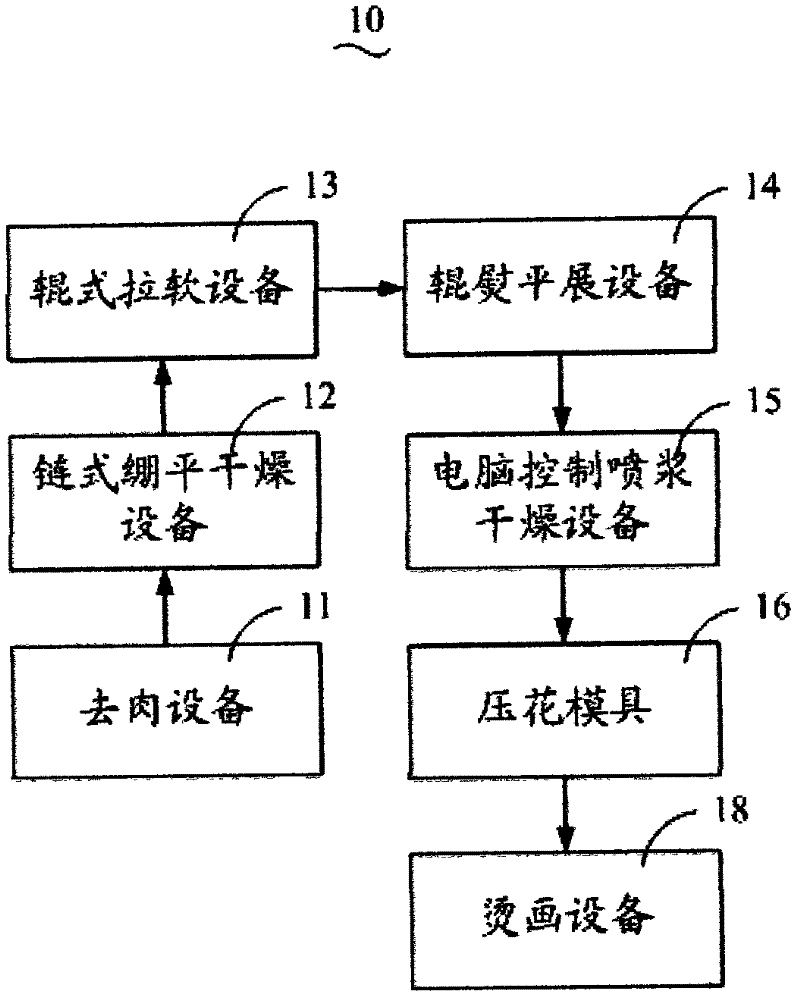

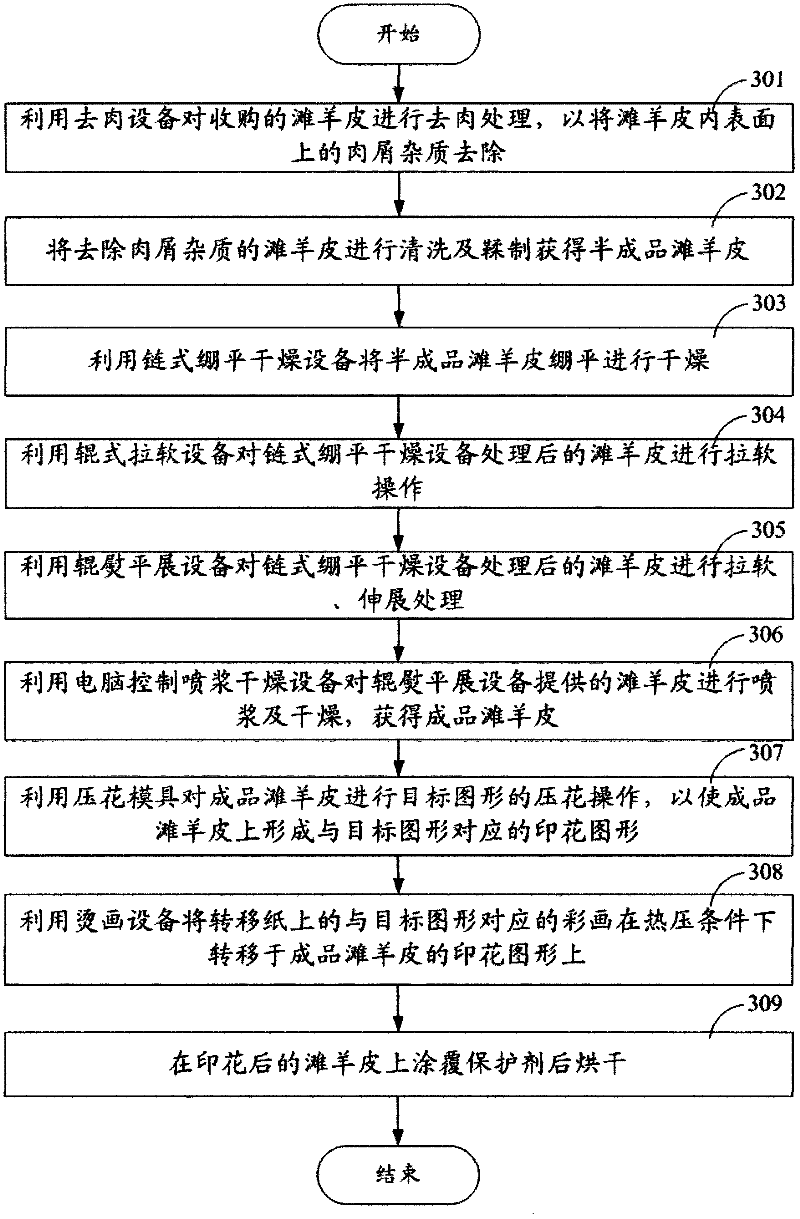

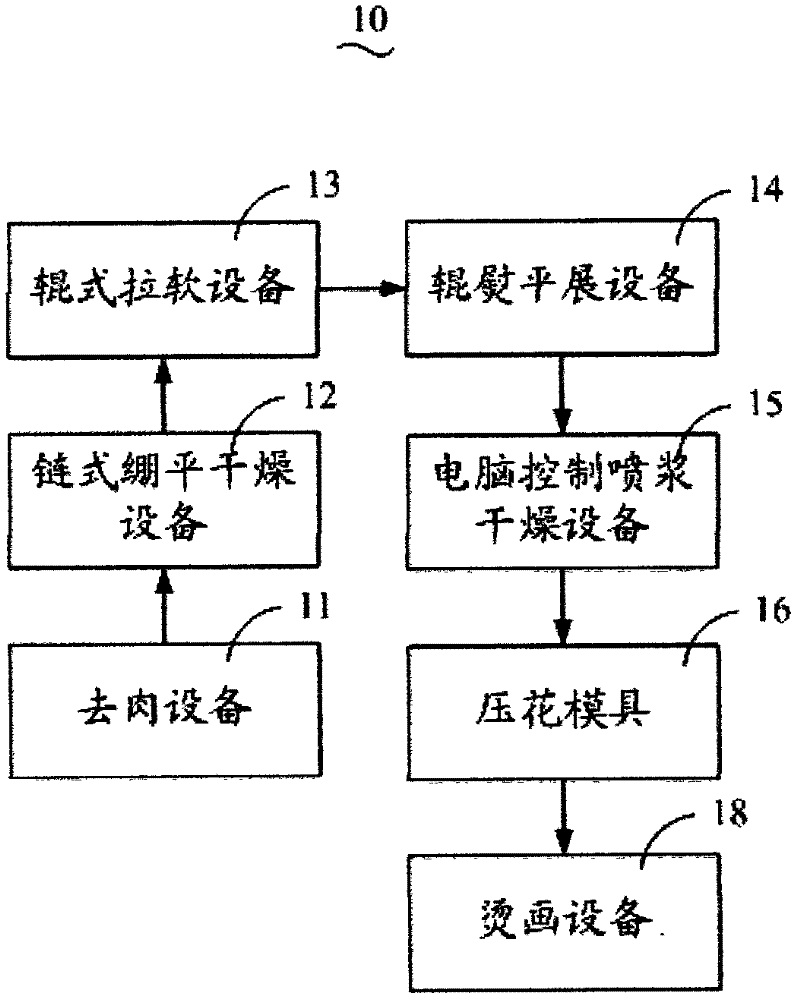

The invention provides a device for printing Tibet lamp skins. The device comprises fleshing equipment, chain toggling drying equipment, roller staking equipment, roller ironing equipment, computer controlled spray drying equipment, an embossing mold and heat press equipment, wherein the fleshing equipment is connected with the chain toggling drying equipment; the roller staking equipment is connected with the chain toggling drying equipment; the roller ironing equipment is connected with the roller staking equipment; the computer controlled spray drying equipment is connected with the roller ironing equipment; the embossing mold is connected with the computer controlled spray drying equipment; and the heat press equipment is connected with the embossing mold. The invention also provides a method for printing Tibet lamp skins.

Owner:宁夏西部皮草有限公司

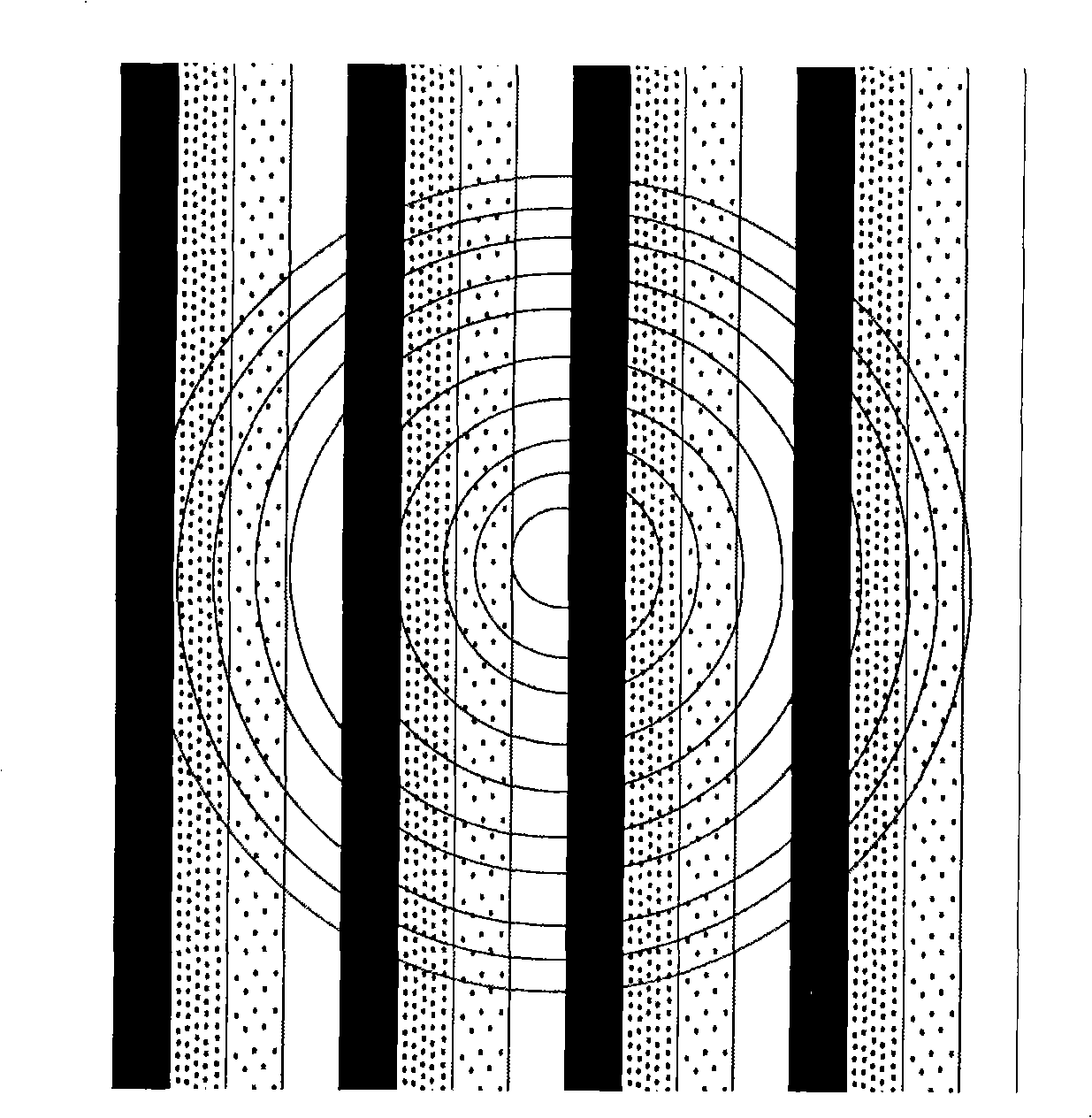

Method for processing color matching design of fur garment facing material

The invention relates to a machining method for a color matching pattern of fur fabric deep processing, and a product. The machining method is characterized in that small piece fur raw material is sorted and lengthways split-jointed to form strips, wherein, the fuzz length and the color of the small piece fur raw material are same to the greatest extent; the longitudinal strips are arrayed and split-jointed to form face-shaped fur material at intervals according to different colors. The fur material is cut according to the contour of patterns with symmetrical center, concentric amplification, and unlimited layer number; inner patterns and outer patterns are split-jointed after rotating an angle relatively to form new colors and patterns. The colors and the patterns created by using the machining method are natural and novel, and have the advantages that the fur material is fully utilized, the pollution is reduced, and the cost is lowered. The machining method can be implemented on full piece or part of the fur material, and also can be popularized and implemented to the fur fabric provided with surface fuzz such as dyeing fur, artificial imitation fur, etc.

Owner:梁惠娥

Production process for preparing leather by virtue of numerical control cutting machine

ActiveCN106591504AImprove stabilityHigh glossFur dressingSkins/hides/leather/fur manufacturing apparatusNumerical controlEconomic benefits

The invention relates to the technical field of leather processing, and specifically relates to a production process for preparing leather by virtue of a numerical control cutting machine. The production process comprises the following steps: (1) material selection: using sheepskin leather, pigskin leather or calfskin leather as a crust; (2) pattern drawing: drawing a pattern through a computer of the numerical control cutting machine, and outputting the pattern; and (3) numerical control cutting: cutting the lines of reptiles in the nature on the surface of the leather through the output pattern by the numerical control cutting machine, so as to prepare the leather. The production process disclosed by the invention has simple steps, and is convenient to operate and control, stable in quality and high in production efficiency; the raw materials are low in price and easily available; and the leather is high in utilization rate, low in production cost, and capable of realizing large-scale industrialized production. The quality of the prepared finished leather is similar to that of top-layer leather, the additional value of the finished leather is greatly increased, and the finished leather is wide in application range and high in economic benefit.

Owner:DONGGUAN TIANYI LEATHER TECH CO LTD

Process for making furred art blankets

The invention relates to a fur processing technique, providing a fur artistic blanket making technique, and solving the problems of roughly processing fur, simple making technique and only having a single cold-proof and warm-keeping function, etc. The making technique includes the following steps: design pattern, match colors, cut fur, process, integrate, rewetting, and trim. The made artistic blanket has exquisite design, and has both a cold-proof and warm-keeping function and an artistic appreciation value.

Owner:杨屏

Fur burning-out improving process

The invention discloses a fur burning-out improving process which is characterized by adopting the following steps: (1) selecting fur; (2) chrome tanning; (3) dyeing; (4) nailing on a board for drying, tumbling and finely cutting; and (5) burning out: printing a pattern onto the surface of hair by a printed screen board by using caustic soda of 400g / L, gelatin of 24g / L and HAC (glacial acetic acid) of 2ml / L then drying for 1 hour in a drying chamber at high temperature; and (6) finishing. According to the method for burning out with caustic soda disclosed by the invention, the pattern obtained by burning out is complete and beautiful without smell of scorching, and the color of the pattern obtained by burning out is the same as that of the ground color, thus being approved by customers.

Owner:HUASI HLDG CO LTD

Fur sawdust rolling process

InactiveCN102517406AGlossinessGood flexibilityFur finishingLeather surface finishingSawdustMaterials science

The invention discloses a fur sawdust rolling process, which comprises the following steps: 1, placing a fur in a roller; 2, casting sawdust on the fur according to the following proportion that: 1 stere of the sawdust is casted on 13-15 of the furs; 3, adding a brightener and a swelling agent; 4, rotating the roller to make the mixture comprising the fur, the sawdust, the brightener and the swelling agent completely rub, wherein the rotation speed range of the roller is 70-90 rotations per minute; 5, stopping the rotation of the roller, taking out of the fur, and placing the fur in another roller with holes on the outer wall; 6, rotating the roller, such that the sawdust on the fur is thrown out from the holes on the side wall of the roller, wherein the rotation speed range of the roller is 70-90 rotations per minute, and the lasting time is 50-70 minutes; 7, stopping the rotation of the roller, taking out of the fur, and completing the sawdust rolling. The process of the present invention has characteristics of good sawdust rolling effect, fur odor reducing, and simple operation.

Owner:TIANJIN YINGDAK

Preparation method for chenille oar leather product

ActiveCN107338338AImprove processing efficiencyImprove efficiencyFur shearingFur dressingWaxColor changes

The invention provides a preparation method for a chenille oar leather product. The preparation method comprises the following steps that (1) chenille fur after retanning and dyeing is neatened for the first time; (2) the fur after processing in the first step is subjected to staking and leather buffing and then is neatened for the second time; (3) a top side of the fur after processing in the second step is subjected to bottom oar spraying, color paste spraying and top oar spraying in sequence; (4) after the fur after processing in the third step is milled, wax change effect leather is obtained. A wax color change effect glaze can be obtained from a chenille flesh side. The product has good color fastness to light, dry and wet rubbing color fastness and PVC transfer resistance.

Owner:HENAN PROSPER SKINS & LEATHER ENTERPRISE

Fur fulling and shaping rotary pan

InactiveCN102312022AFeel goodReduce usageSkins/hides/leather/fur manufacturing apparatusFur finishingEngineeringAtmospheric pressure

The invention designs a fur fulling and shaping rotary pan, which mainly comprises a rotary pan, a rotary shaft, a support and an electromotor. The pot also includes a vent pipe with one end connected to the rotary pan by traversing the rotary shaft and the other end inserted with a certain length of a steam jet pipe, and meanwhile, the vent pipe end and the outer wall of the steam jet pipe are sealed, and a liquid medicine inlet pipe is arranged between the sealed end of the vent pipe and the vent pipe end within the vent pipe. The fur fulling and shaping rotary pan of the invention makes use of the steam jet pipe to blow out steam, so that the air pressure of the space between the sealed end of the vent pipe and the steam jet pipe end can be reduced. Meanwhile, air pressure at the end of the liquid medicine inlet pipe is lower than external atmospheric pressure which presses the liquid medicine into the vent pipe, then the liquid medicine mixes with the steam and enters the rotary pan. Thus, usage of a compressor pump can be reduced, and energy consumption can also be reduced. Besides, filter screen belts are arranged on the surface of the rotary pan, so that saw dust can be filtered out during rotation, and the process of artificial removal of the saw dust can be reduced, thus reducing manpower input and production cost.

Owner:TONGXIANG NEW ERA FUR

Fox-fur-imitating production technology

InactiveCN105803132AImprove aestheticsTanning treatmentPre-tanning chemical treatmentEngineeringScalding

The invention relates to a fox-fur-imitating production technology. By means of the fox-fur-imitating production technology, through the technological steps such as water soaking, degreasing, re-soaking, flesh removing, secondary greasing, pickling softening, tanning, neutralizing, drying, separating, treatment before scalding, hair scalding and cage rotating and design of corresponding additives, goat fur obtained after processing has the property characteristics of fox fur, and the attractive degree is improved.

Owner:宁夏成丰农业科技开发股份有限公司

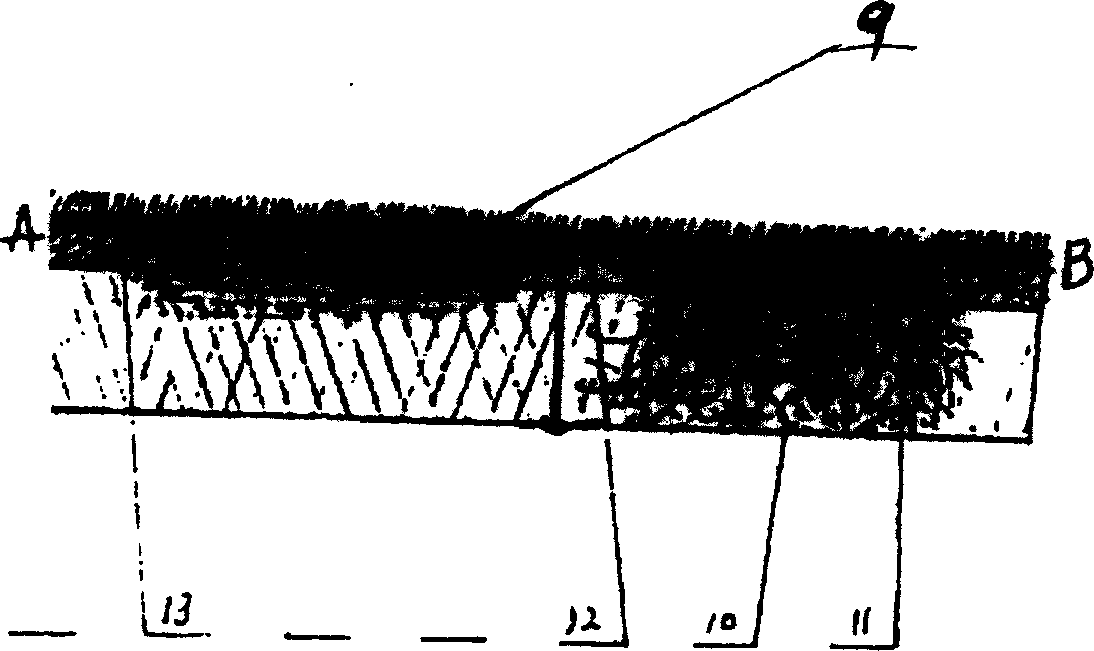

Setting and finishing process for indumentum on fur

The invention relates to a setting and finishing process for indumentum on fur, and belongs to the technical field of fur afterfinish. The setting process for the indumentum on the fur includes the following steps that 1, fell of the fur is wrapped by a polyethylene film, and O2 or N2 or other mixed plasmas are used for performing plasma processing in a vacuum chamber; 2, setting and finishing liquid is sprayed on a fur surface of the fur processed in the step 1, and the setting and finishing liquid is prepared from sodium dodecyl sulfate, monoethanolamine or a monoethanolamine sodium hydrogen sulfite solution or sodium hydrogen sulfite and resin; the fur processed in the step 2 is finished through a vacuum embosser and fast cooled after being rolled by the embosser.

Owner:JIAXING UNIV

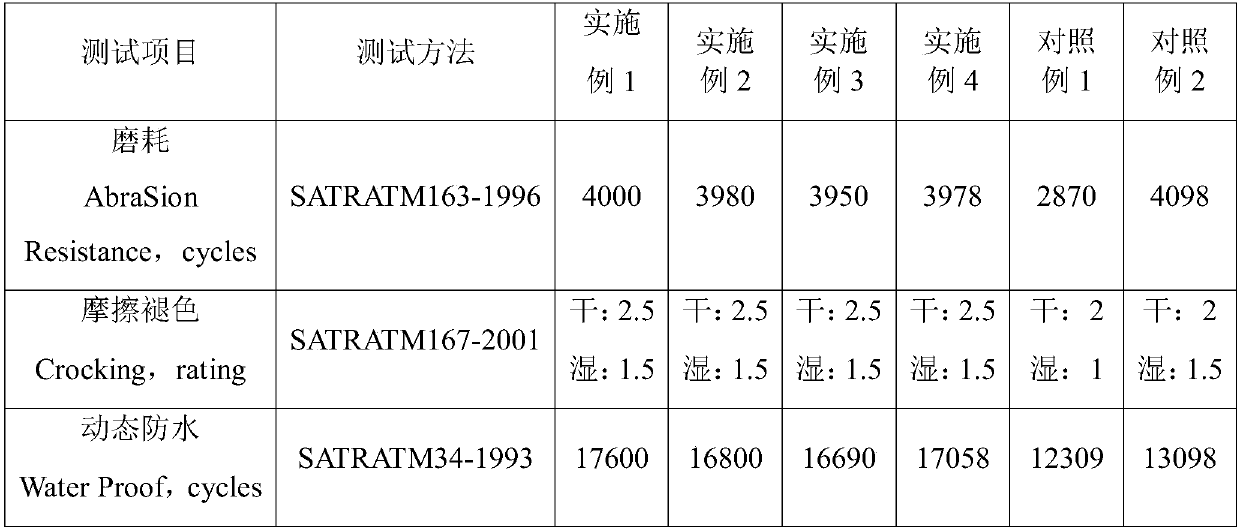

Manufacturing method for double-color printing oily leather

ActiveCN109628658ARich varietyImprove waterproof performanceFur finishingLeather surface mechanical treatmentAcetic acidWater based

The invention relates to a manufacturing method for double-color printing oily leather, and belongs to the technical field of leather manufacturing. The manufacturing method of the double-color printing oily leather comprises the following steps that a dry cow split leather blank is taken and sequentially subjected to leather fluffing, primary milling, oil roll painting, standing, printing, dryingand secondary milling, and the double-color printing oily leather is obtained; in the step of oil roll painting, oil is roll-painted on the surface of the leather blank obtained after primary milling, and the roll painting amount is 10-15 g per square foot; and in the step of printing, a printing material is roll-painted on the surface of the leather, a mixture of water-based acetic acid cotton gloss oil, 2-ethoxyethanol and dye water is taken as the printing material, the mass ratio of the water-based acetic acid cotton gloss oil to the 2-ethoxyethanol is 8:1, and the dye water is added according to the color needs. According to the manufacturing method for the double-color printing oily leather, the oily leather varieties are enriched, the application range of the oily leather is widened, and the manufactured double-color printing oily leather has the good water resistance and wear resistance.

Owner:漳州香洲皮革有限公司

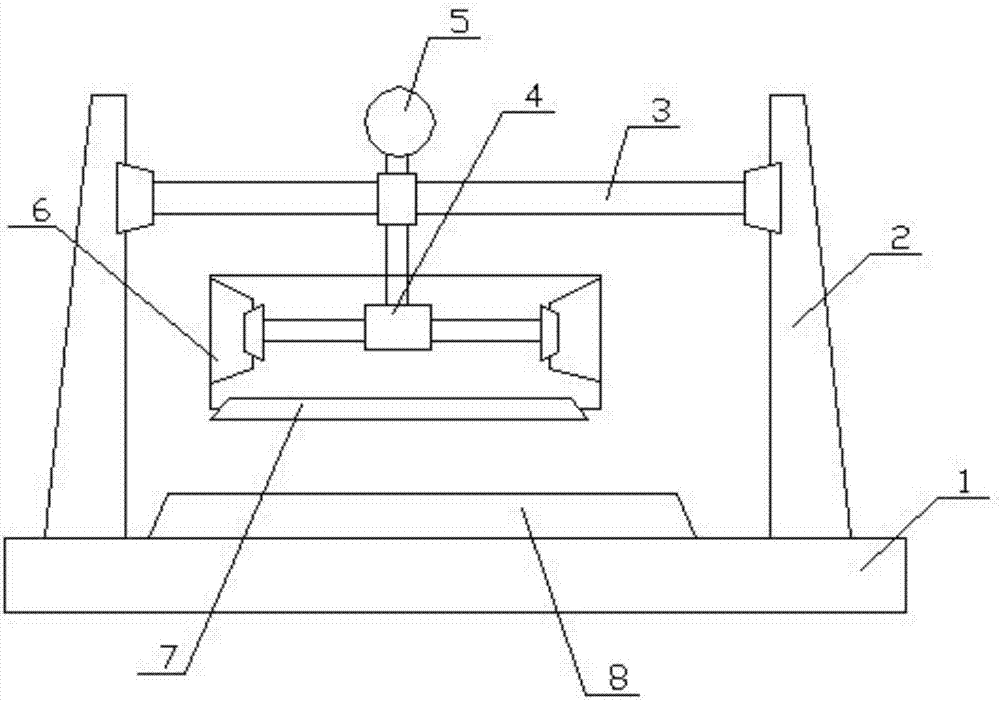

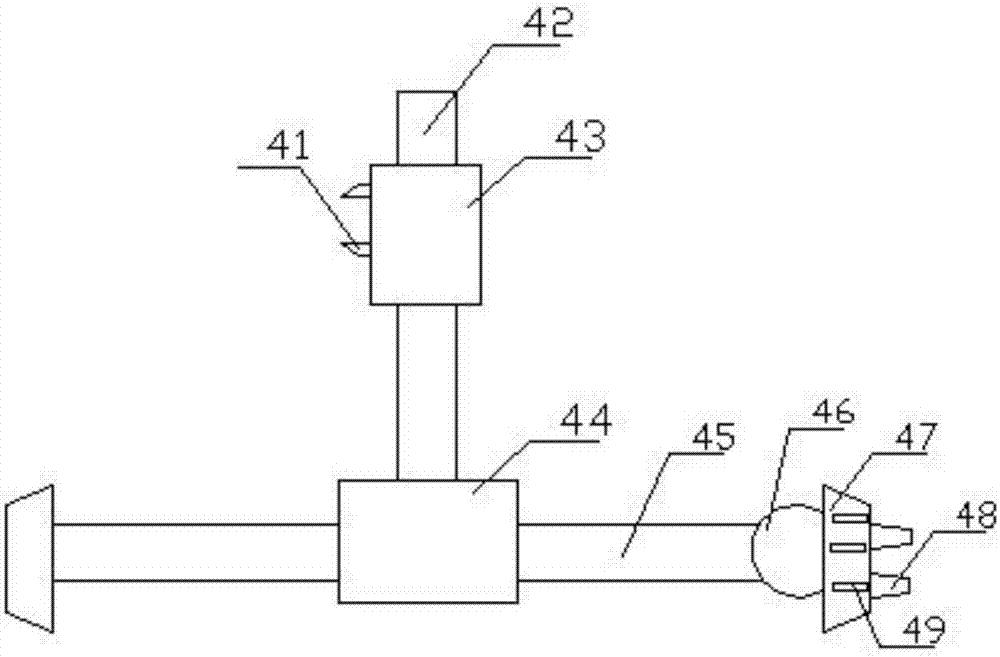

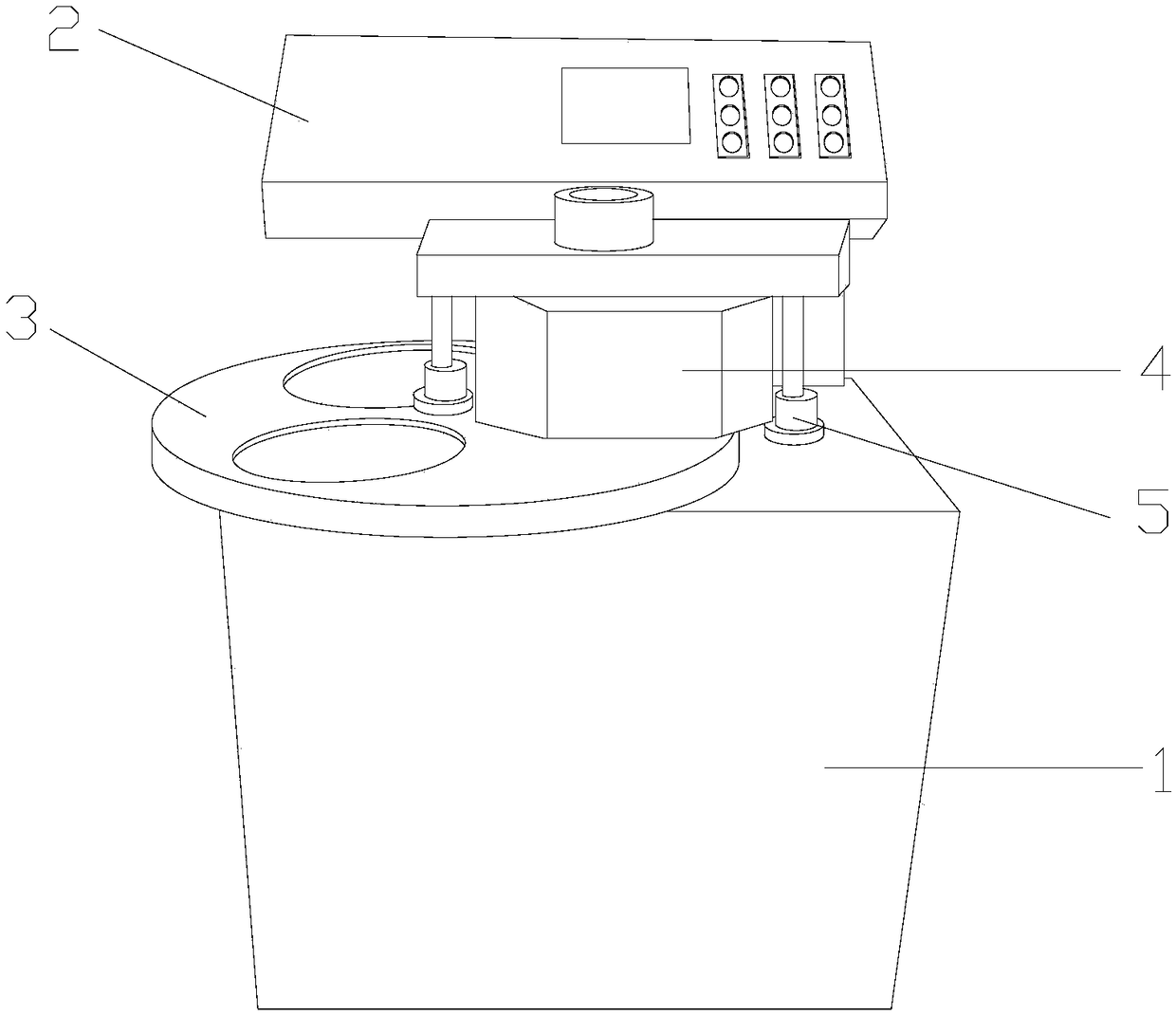

Leather embossing device for fur production

The invention relates to the technical field of leather embossing, in particular to a leather embossing device for fur production. The leather embossing device for fur production comprises a base and further comprises a supporting frame arranged on the edge of the upper end of the base, a cross beam arranged on the upper portion of the supporting frame, an operating platform arranged on the base, a transmission component arranged on the lower side of the cross beam, a motor rotationally arranged at the upper end of the transmission component, an installation cylinder arranged on the outer side of the transmission component and an embossing plate arranged on the outer side of the installation cylinder.

Owner:JIASHAN SHENGLAISI CASHMERE

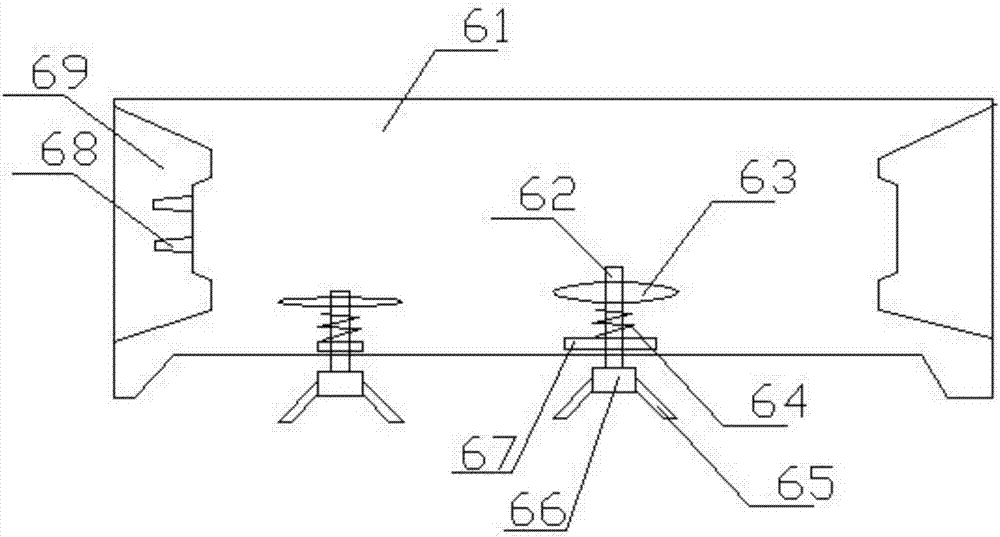

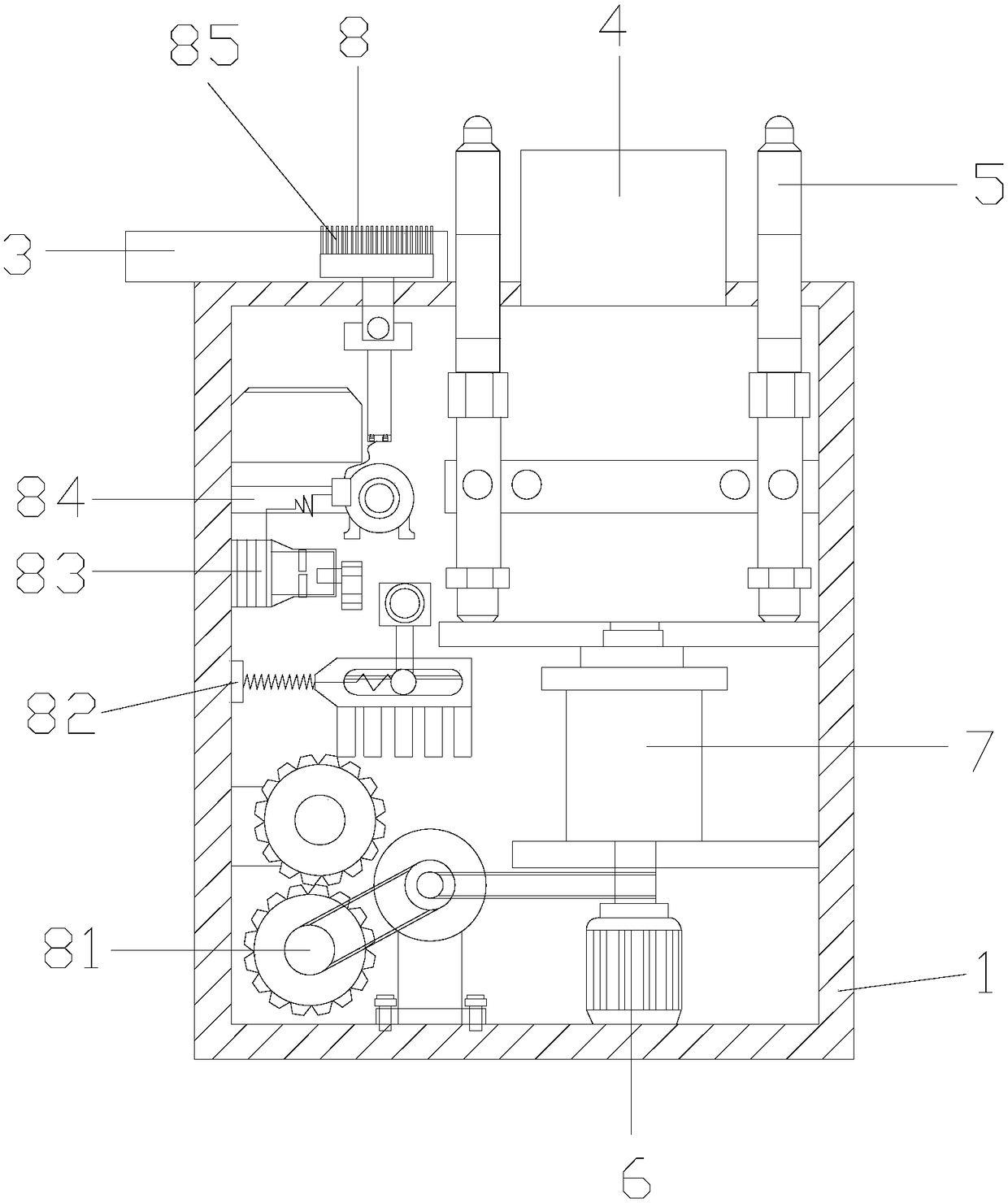

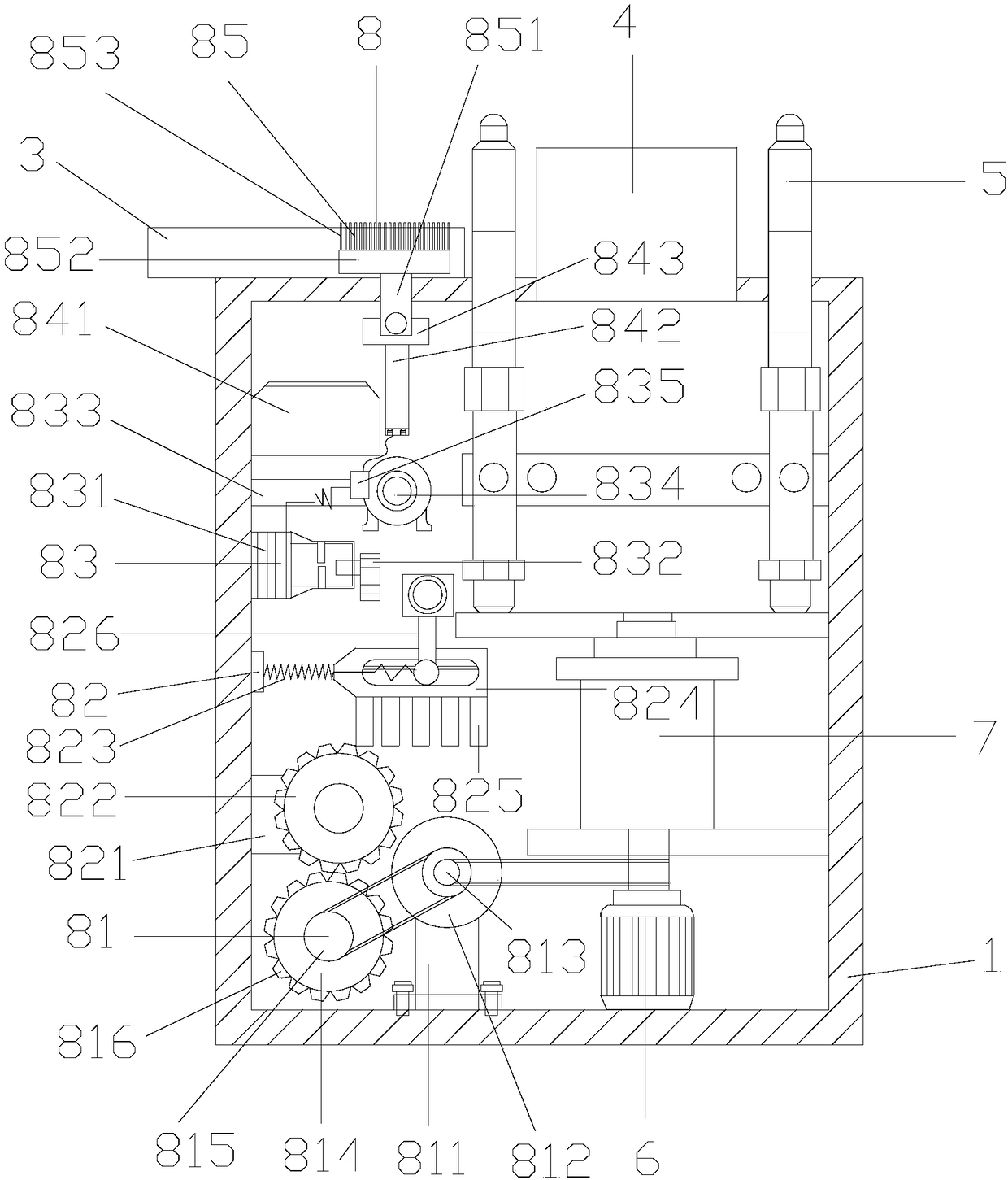

Pressing die device of leather product

InactiveCN108330221AGuaranteed accuracyGuaranteed aestheticsSkins/hides/leather/fur manufacturing apparatusFur finishingEngineeringCam

The invention discloses a pressing die device of a leather product. The pressing die device of the leather product structurally comprises a device body, a control device, a pressing die cam, an installation center pillar, positioning center pillars, a motor, a drive guide rod and an automatic leather product leftover material collection device. The pressing die cam is movably connected to the leftof the upper end surface of the device body. The positioning center pillars are distributed at the left position and the right position of the installation center pillar in parallel and penetrate theinterior of the device body. The drive guide rod is mechanically connected to the upper end surface of the motor and mechanically connected with the positioning center pillar. The automatic leather product leftover material collection device is movably connected with the left of an inner cavity of the device body. According to the pressing die device of the leather product, certain automatic cleaning and collecting treatment can be carried out on waste leather product leftover materials of the pressing die cam component of the equipment in the die pressing operation treatment process, the situation that due to the fact that the waste leftover materials cannot be collected, the normal work of related components in the device is affected is avoided, the precision and the attractiveness of the pressing die work are guaranteed, and the reliability performance of the equipment is effectively improved.

Owner:南安泊阅工业设计有限公司

A production process for preparing leather by using a numerical control cutting machine

ActiveCN106591504BImprove stabilityHigh glossFur dressingSkins/hides/leather/fur manufacturing apparatusNumerical controlEconomic benefits

The invention relates to the technical field of leather processing, and specifically relates to a production process for preparing leather by virtue of a numerical control cutting machine. The production process comprises the following steps: (1) material selection: using sheepskin leather, pigskin leather or calfskin leather as a crust; (2) pattern drawing: drawing a pattern through a computer of the numerical control cutting machine, and outputting the pattern; and (3) numerical control cutting: cutting the lines of reptiles in the nature on the surface of the leather through the output pattern by the numerical control cutting machine, so as to prepare the leather. The production process disclosed by the invention has simple steps, and is convenient to operate and control, stable in quality and high in production efficiency; the raw materials are low in price and easily available; and the leather is high in utilization rate, low in production cost, and capable of realizing large-scale industrialized production. The quality of the prepared finished leather is similar to that of top-layer leather, the additional value of the finished leather is greatly increased, and the finished leather is wide in application range and high in economic benefit.

Owner:DONGGUAN TIANYI LEATHER TECH CO LTD

Vegetable leather embossing process

ActiveCN109182617AEasy to operateEasy to implementLeather clicking/perforating/clickingLeather stretching/tensioningManufacturing engineering

The invention provides a vegetable leather embossing process. The self plasticity of materials is combined with bas-relief and leather molding processes to manufacture embossing models with delicate shapes, vivid forms and high third dimensions. Compared with the prior art, the vegetable leather embossing process has the advantages of simple operation and easy realization.

Owner:GUANGZHOU PANYU POLYTECHNIC

Finishing process of quilt on fur

The invention relates to a setting and finishing process for indumentum on fur, and belongs to the technical field of fur afterfinish. The setting process for the indumentum on the fur includes the following steps that 1, fell of the fur is wrapped by a polyethylene film, and O2 or N2 or other mixed plasmas are used for performing plasma processing in a vacuum chamber; 2, setting and finishing liquid is sprayed on a fur surface of the fur processed in the step 1, and the setting and finishing liquid is prepared from sodium dodecyl sulfate, monoethanolamine or a monoethanolamine sodium hydrogen sulfite solution or sodium hydrogen sulfite and resin; the fur processed in the step 2 is finished through a vacuum embosser and fast cooled after being rolled by the embosser.

Owner:JIAXING UNIV

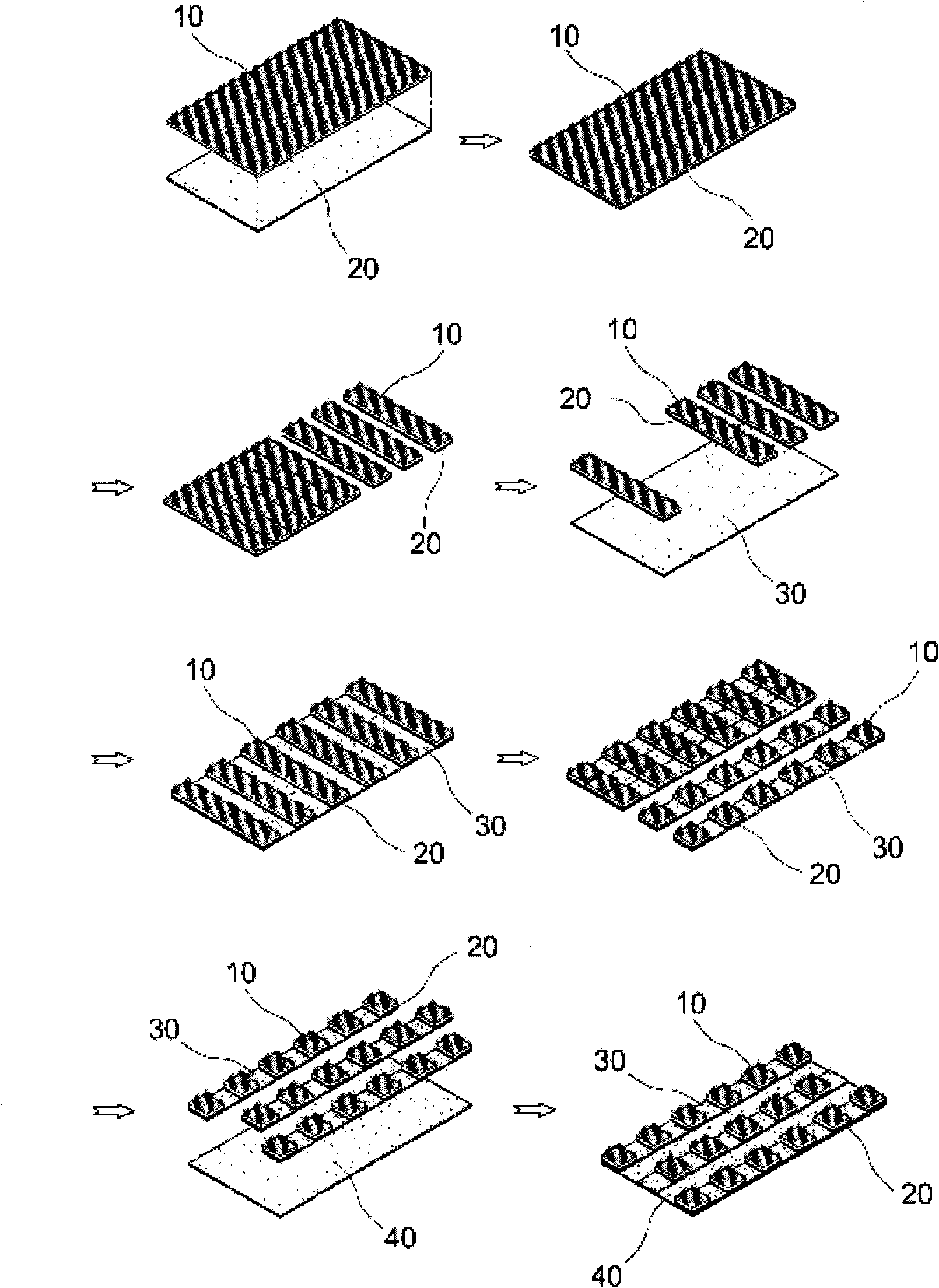

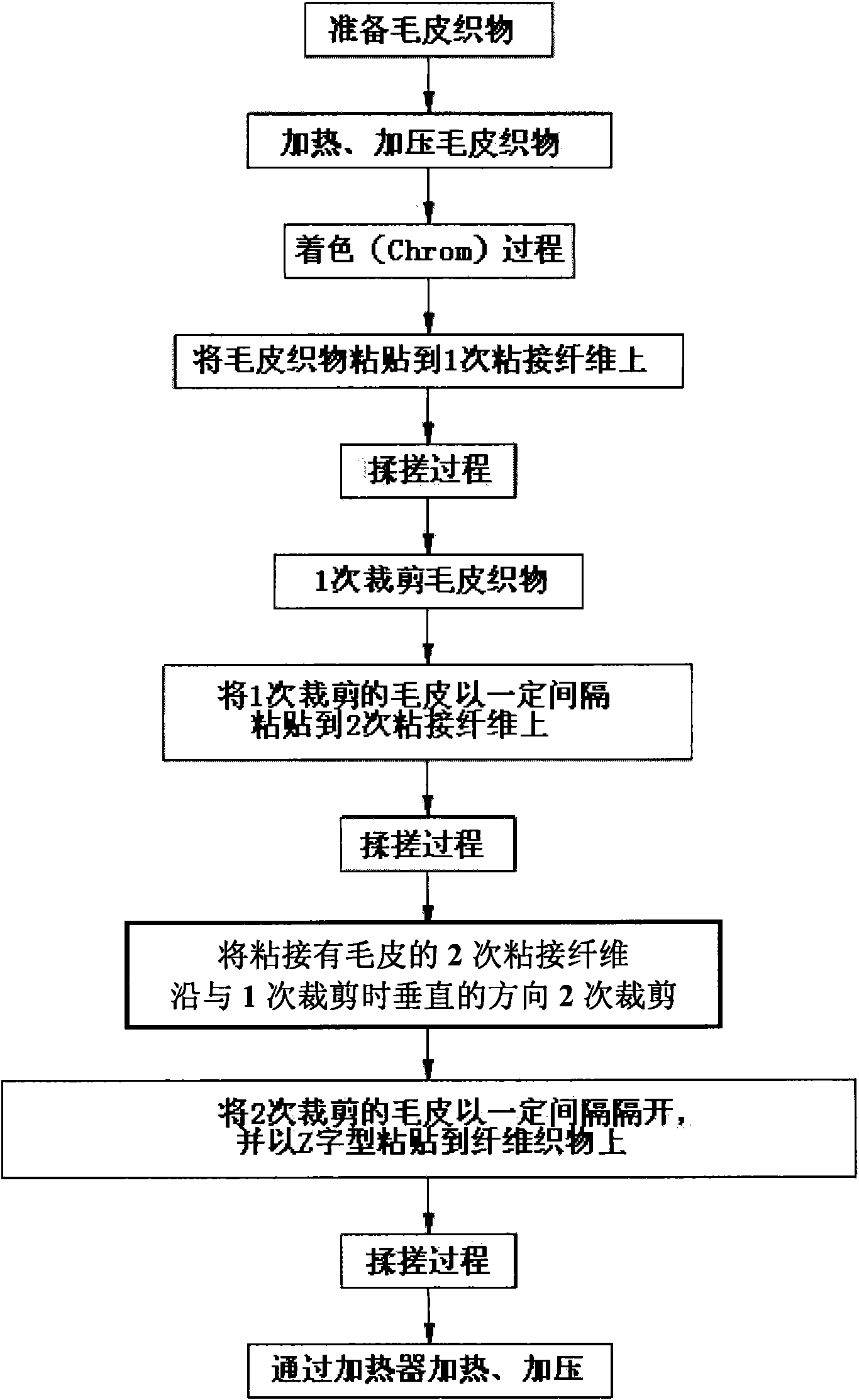

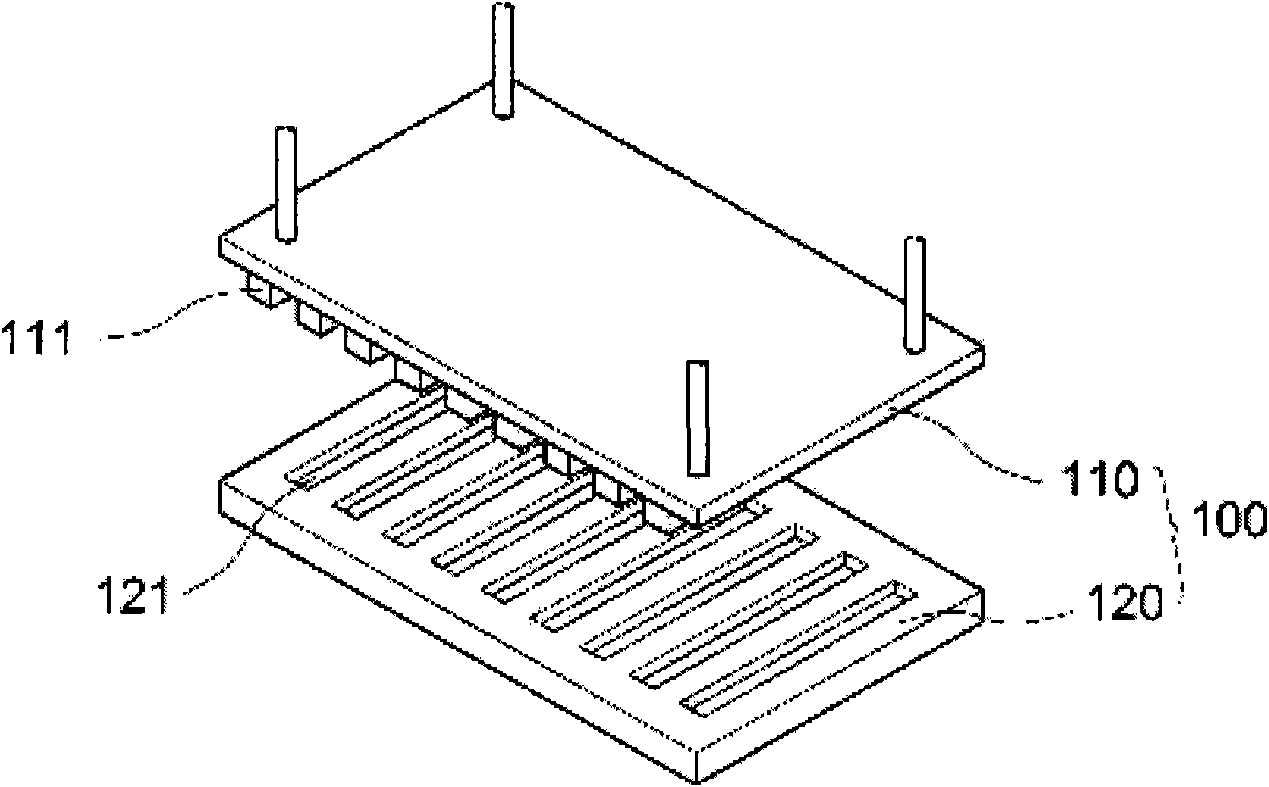

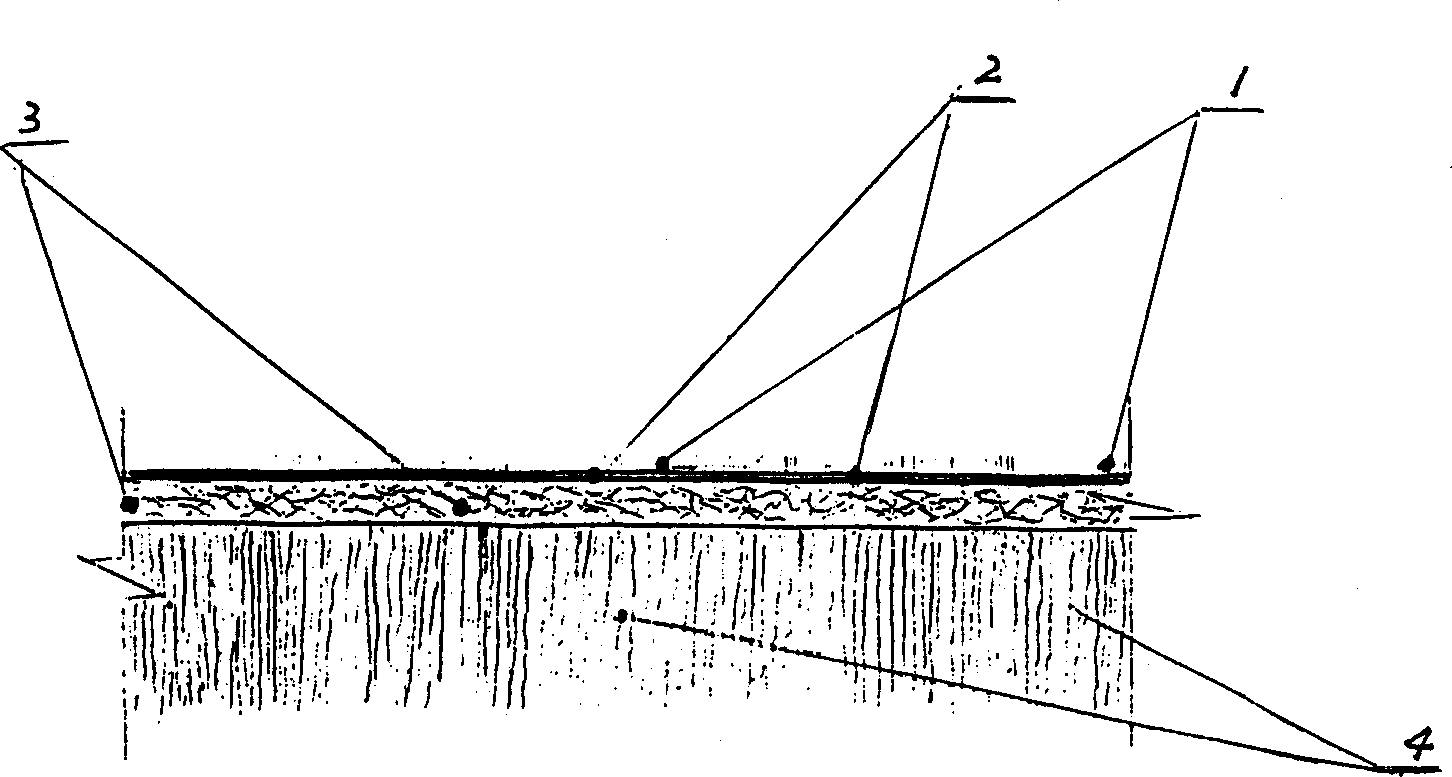

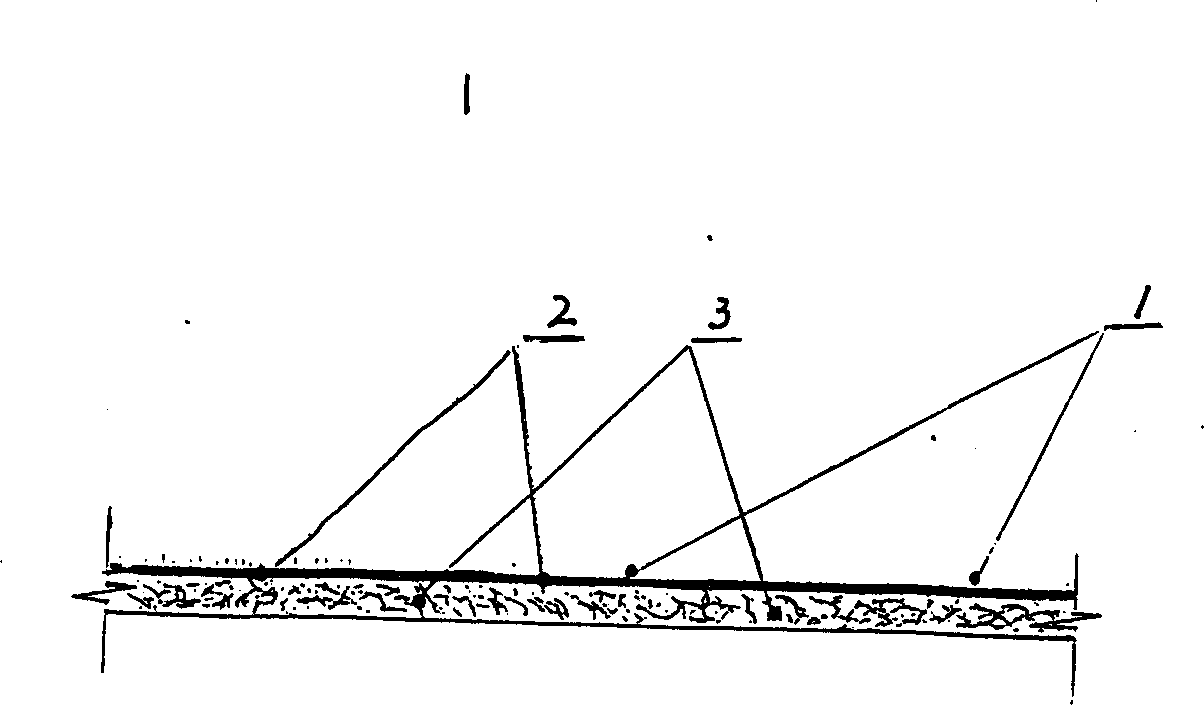

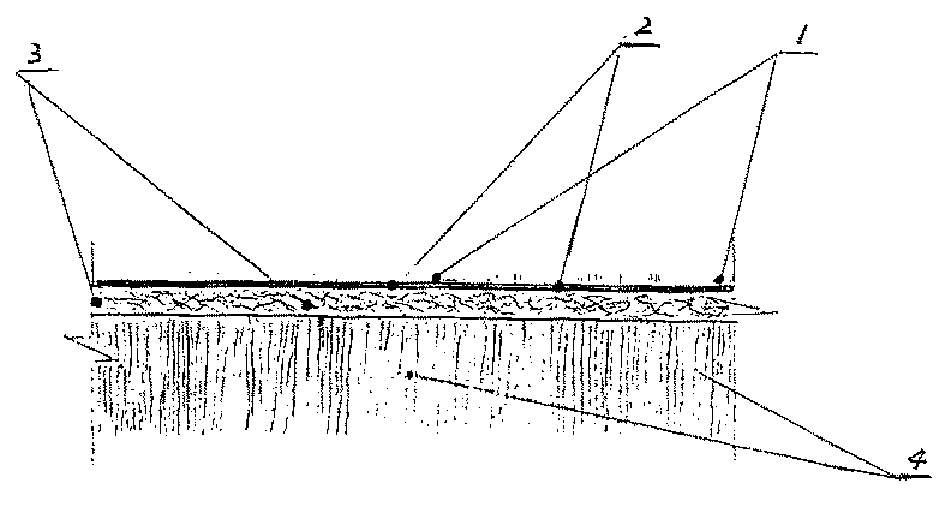

Method for attaching a minute fur to a textile and clothes using the same

The invention relates to a splicing method capable of firmly splicing fine or a plurality of furs that are unable to be spliced on fiber raw materials by needlework, comprising the steps of: splicing the fur raw materials to a piece of primary splicing paper; at certain interval, performing a primary cutting to the fur raw materials spliced to the piece of primary splicing paper; separating the fur raw materials at certain interval that are primarily cut and splicing the materials to a piece of secondary splicing paper; at certain interval, performing a secondary cutting to the piece of secondary splicing paper spliced with the furs in a direction vertical to the primary cutting; separating the furs at certain interval that are secondarily cut and arraying the furs zigzag to splice to thefiber raw materials.

Owner:金龙九

A kind of preparation method of grain effect leather product

ActiveCN109182623BControl Penetration DepthReduce the differenceFur finishingLeather surface finishingProcess engineeringDyeing

Owner:隆丰革乐美时尚有限公司

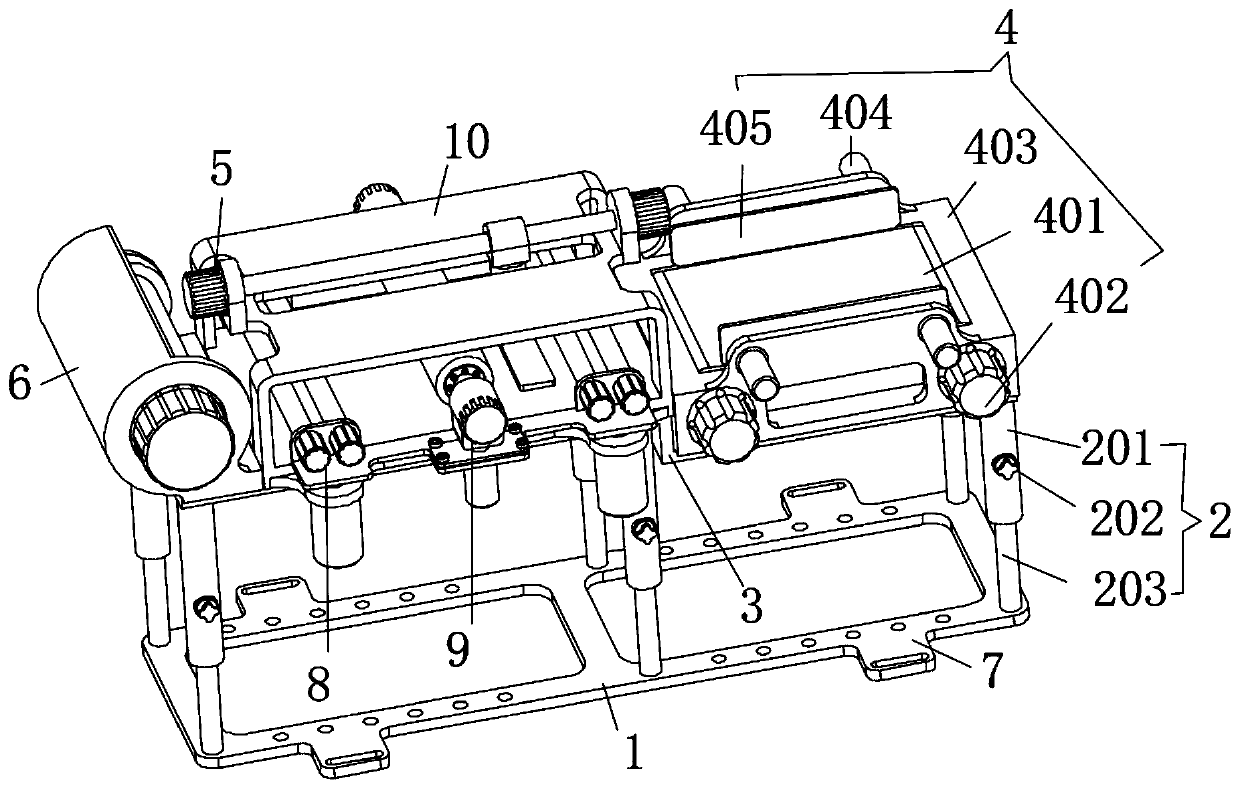

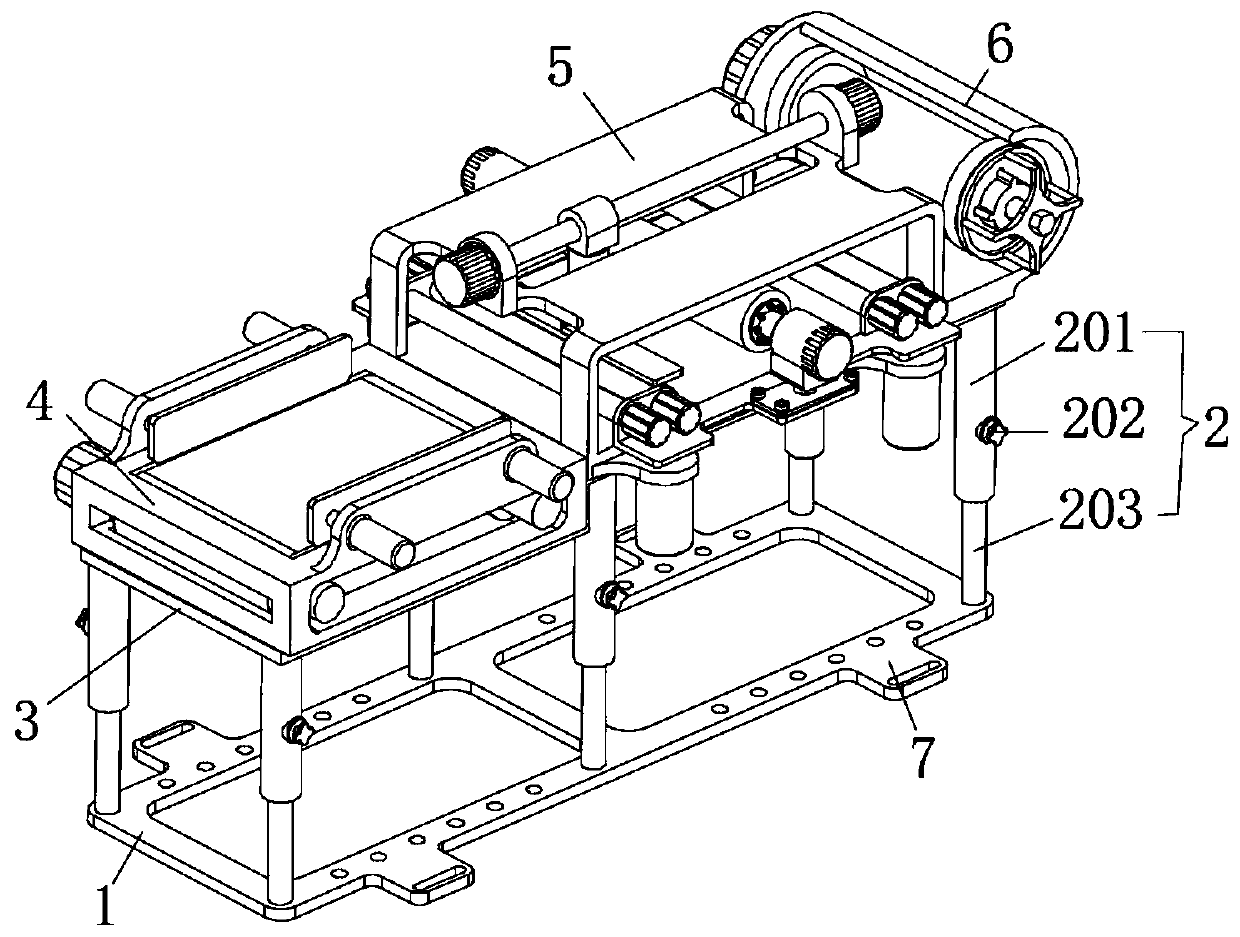

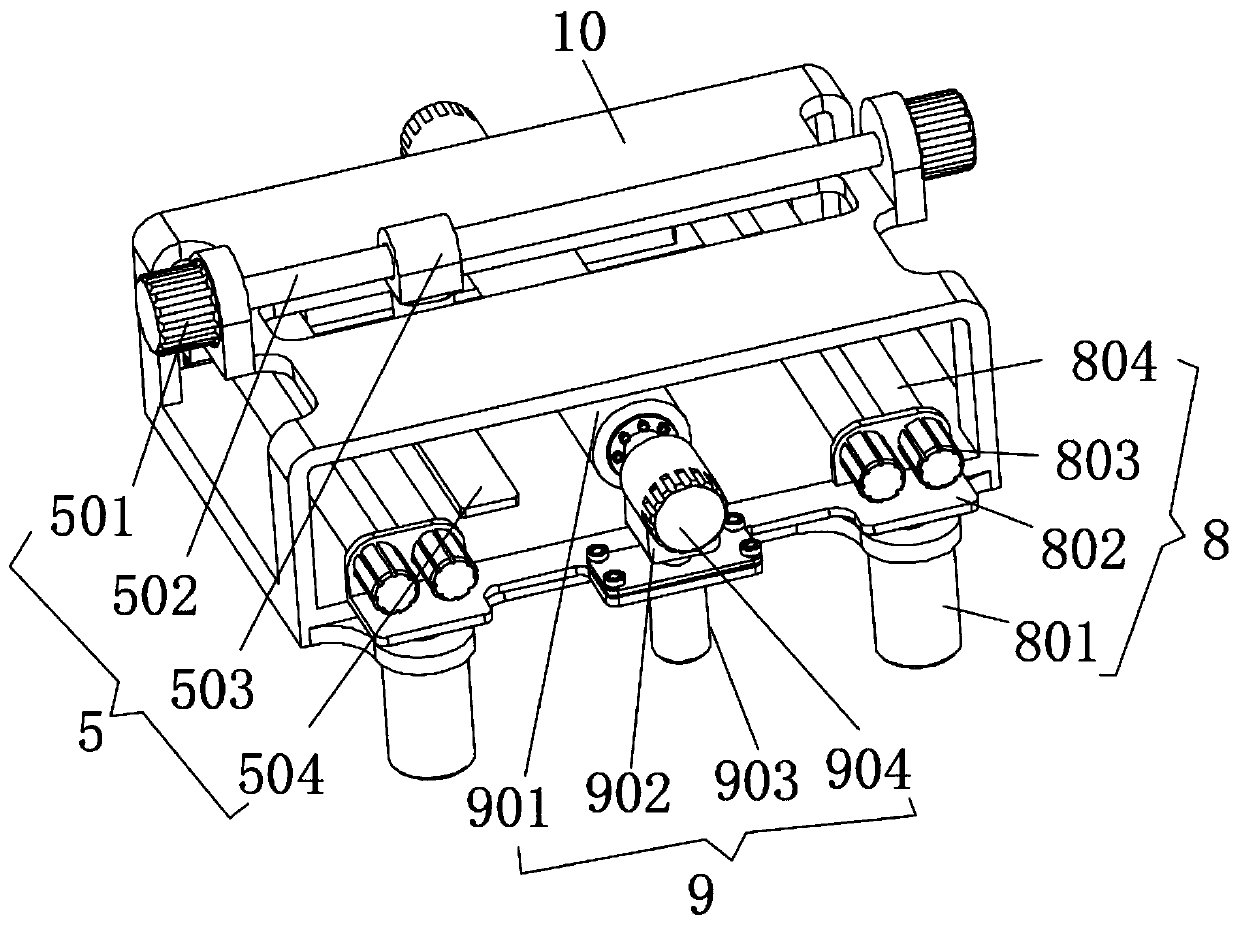

Printing device for fur production

InactiveCN109868333AAvoid multiple printing operationsHighly integratedSkins/hides/leather/fur manufacturing apparatusFur finishingDrive motorIndustrial engineering

The invention relates to the technical field of fur processing, and relates to a printing device for fur production. The printing device for the fur production comprises a base, wherein a lifting frame is fixedly installed at the upper part of the base, a supporting frame is fixedly installed at the upper part of the lifting frame; an installing frame is fixedly installed at the upper part of thesupporting frame by a bolt; a first printing mechanism is fixedly installed at the upper part of the installing frame; the first printing mechanism comprises a screw drive motor installed above the installing frame, and the output end of the screw drive motor drives a screw. The printing device for the fur production provided by the invention has the following beneficial effects: the fur printingdevice designed by the invention integrates feeding, printing and winding equipment on the same equipment, and can adopt at least two printing forms according to different printing parts, so that printing with different depths and positions can be embossed for the same fur; a plurality of printing operations can be avoided; and with high integration and simple operation, the printing device can reduce production difficulty and improve production efficiency effectively, and has high practical value.

Owner:南昌汇达知识产权有限公司

Preparing method for buffing effect leather product

ActiveCN109182623AControl Penetration DepthReduce the differenceFur finishingLeather surface finishingEngineeringPenetration depth

The invention discloses a preparing method for buffing effect leather products. The preparing method includes a primary spray dyeing step, a leather buffing step, a secondary spray dyeing step and anafter-treatment step of a leather blank; permeability detection is conducted on the leather blank before the first spray dyeing step, and a permeability detection value of the leather blank is obtained; and the total dosage of a penetrating agent in the primary spray dyeing step and the secondary spray dyeing step is determined according to the permeability detection value. By means of the preparing method, the penetrating agent dosage is controlled according to the permeability detection value of the leather blank, the penetration depth of dye water on a leather blank layer during spray dyeing can be controlled, the buffing effect degree obtained after leather buffing is controlled, the buffing effect is natural, the difference between leather skins of prepared buffing effect leather is low, and the appearance quality is stable.

Owner:HENAN PROSPER SKINS & LEATHER ENTERPRISE

A kind of preparation method of sheep shearing pulp leather product

ActiveCN107338338BImprove processing efficiencyImprove efficiencyFur shearingFur dressingWaxPulp and paper industry

The invention provides a preparation method for a chenille oar leather product. The preparation method comprises the following steps that (1) chenille fur after retanning and dyeing is neatened for the first time; (2) the fur after processing in the first step is subjected to staking and leather buffing and then is neatened for the second time; (3) a top side of the fur after processing in the second step is subjected to bottom oar spraying, color paste spraying and top oar spraying in sequence; (4) after the fur after processing in the third step is milled, wax change effect leather is obtained. A wax color change effect glaze can be obtained from a chenille flesh side. The product has good color fastness to light, dry and wet rubbing color fastness and PVC transfer resistance.

Owner:隆丰革乐美时尚有限公司

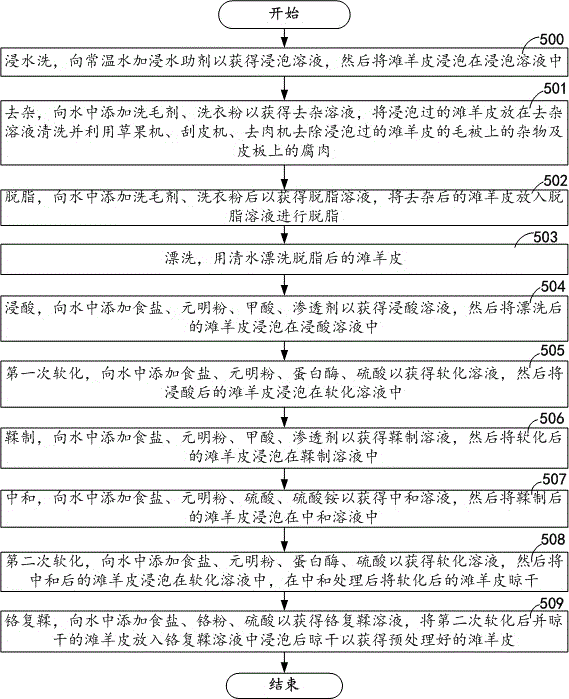

Production and processing technology of high-density sheared sheepskin

PendingCN114277202AHigh densityImprove drying efficiencyTanning treatmentPre-tanning chemical treatmentFiberSheep skin

The invention discloses a production and processing technology of high-density sheared sheepskin, and relates to the field of production and processing of sheared sheepskin, and the production and processing technology comprises the steps of raw skin obtaining, soaking, dehydration, primary fleshing, degreasing and dehydration, re-soaking, secondary fleshing, (softening, pickling and tanning), high-temperature shrinkage, dry cleaning, rewetting, high-temperature degreasing, primary ironing and shearing, dyeing and secondary ironing and shearing. According to the method, the traditional skinned skin concept is broken through, softening, pickling and tanning are completed in one bath, the density of fibers on a skin plate is controllable, and high-density sheared sheep velvet is formed; a new process system for synthesizing a tanning agent by using a BASF environment-friendly new auxiliary agent is established, and the traditional skinned leather concept is changed, so that the three working procedures of softening, pickling and tanning are condensed into one working procedure and one bath for tanning; according to the innovation point, the use number of equipment is reduced, the production time is shortened, the water and electricity use amount is saved, and the productivity is improved; meanwhile, a traditional natural airing method is abandoned, the drying room is invented, sheepskin is shrunk at high temperature, and a new drying process system is formed.

Owner:宁夏西部皮草有限公司

Method for manufacturing colour suede for product

InactiveCN1086423CAvoid Bubbling DefectsOvercome the technical difficulties of shrinkage degeneration in large areasSpecial leathers manufactureFur finishingEngineeringField intensity

The preparation method of furcoat product with colour pile face includes the following steps: selecting more than one kind of pile dyed with basic colour, mixing coloured piles according to a certain proportion to make colour of pile face uniform, and obtaining pre-designed colour. In order to make pile face colour uniform, flying up and screening every monochromatic pile under the condition of same field intensity to make flying-up capability and flying-up rate of all coloured piles uniform when leather surface is flocked, and making the piles flocked on the leather product keep relative verticality, this can be implemented by regulating field intensity, so that it can obtain furcoat product and leather product with predesigned colour.

Owner:陈文典

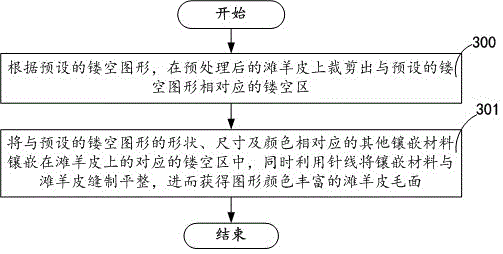

Method for increasing figure colors of tan sheep skin hair side

InactiveCN105039605ARich in colorTanning treatmentPre-tanning chemical treatmentSheep skinPre treatment

Disclosed is a method for increasing figure colors of a tan sheep skin hair side. The method comprises the following steps that according to preset hollowed-out figures, hollowed-out areas corresponding to the preset hollowed-out figures are cut out in a preprocessed tan sheep skin; other inlay materials corresponding to the preset hollowed-out figures in shape, size and color are inlaid in the corresponding hollowed-out areas on the tan sheep skin; and at the same time, the inlay materials and the tan sheep skin are sewn smoothly by using a needle and threads, then the tan sheep skin hair side with abundant figure colors is obtained, the stitches are even and dense, and depths of stitches are uniform.

Owner:NINGXIA WUZHONG JINGYI FUR PROD

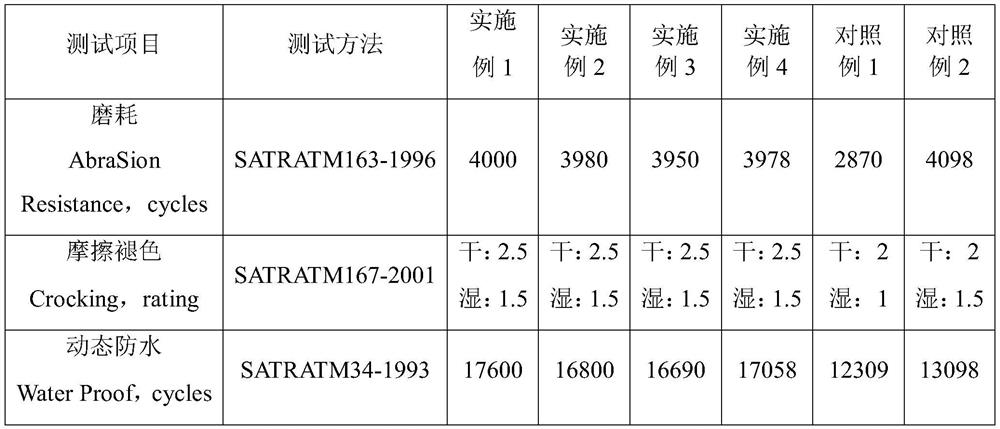

The production method of two-color printing oil leather

ActiveCN109628658BPromote absorptionFeel comfortableFur finishingLeather surface mechanical treatmentTextile printerAcetic acid

The invention relates to a method for making two-color printed oil leather, which belongs to the technical field of leather production. The production method of the two-color printing oil leather comprises the following steps: take the dried cow split leather and successively grind the leather → first softening → roller coating with grease → standing → printing → drying → secondary crushing to obtain a two-color printing Oil leather; the roller coating grease is specifically: roller coating grease on the surface of the leather embryo that has been softened once, and the roller coating amount is 10-15g / square foot; the printing is specifically: rolling the printing chemical material to the leather surface , the printing chemical is a mixture of water-based cotton varnish acetate, 2-ethoxyethanol and dye water, the mass ratio of the water-based cotton varnish acetate and 2-ethoxyethanol is 8:1, and the dye water is according to Color needs to be added. The invention enriches the types of oily skins and widens the application range of the oily skins; the prepared two-color printing oily skins also have good water resistance and abrasion resistance.

Owner:漳州香洲皮革有限公司

Production technique of domestic raccoon fur imitating American raccoon fur

InactiveCN105695643AShiny brightIncrease added valueTanning treatmentFur finishingHair dyesBiomedical engineering

The invention discloses a production technique of domestic raccoon fur imitating American raccoon fur. The production technique comprises the steps of pre-trimming, retanning, slight bleaching and dyeing, drying, needle hair brush-dyeing, steam cluster needling, post-trimming and finished product obtaining. Slight bleaching and dyeing are conducted on retanned fur; the original grayish raccoon fur is faded with oxidation dye, needle hair dyeing is conducted on the pretreated raccoon fur by means of a needle hair dyeing agent, and the light-golden bottom of needle hair is made to be golden; under hair dyeing is conducted on the raccoon fur subjected to needle hair dyeing by means of an under hair dyeing agent, so that under hair is dyed to be golden yellow; a tip hair dyeing agent is sprayed onto tip hair of the raccoon fur subjected to under hair dyeing for tip hair dyeing, so that the tip hair is modified to be black; the fur subjected to slight bleaching and dyeing is dried; and needle clusters are formed on the raccoon fur through the mechanical streaming action. According to the domestic raccoon fur produced through the technique, the lower portion of the needle hair is golden, the upper portion of the needle hair is modified to be black, and the under hair part is golden yellow; and the domestic raccoon fur is as lustrous and bright as the American raccoon fur, and the added value can be increased by 50%.

Owner:ZHEJIANG ZHONGHUI FUR & LEATHER

A plant tanned leather embossing process

ActiveCN109182617BEasy to operateEasy to implementLeather clicking/perforating/clickingLeather stretching/tensioningMechanical engineeringIndustrial engineering

The invention provides a vegetable leather embossing process. The self plasticity of materials is combined with bas-relief and leather molding processes to manufacture embossing models with delicate shapes, vivid forms and high third dimensions. Compared with the prior art, the vegetable leather embossing process has the advantages of simple operation and easy realization.

Owner:GUANGZHOU PANYU POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com