Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about "Special leathers manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

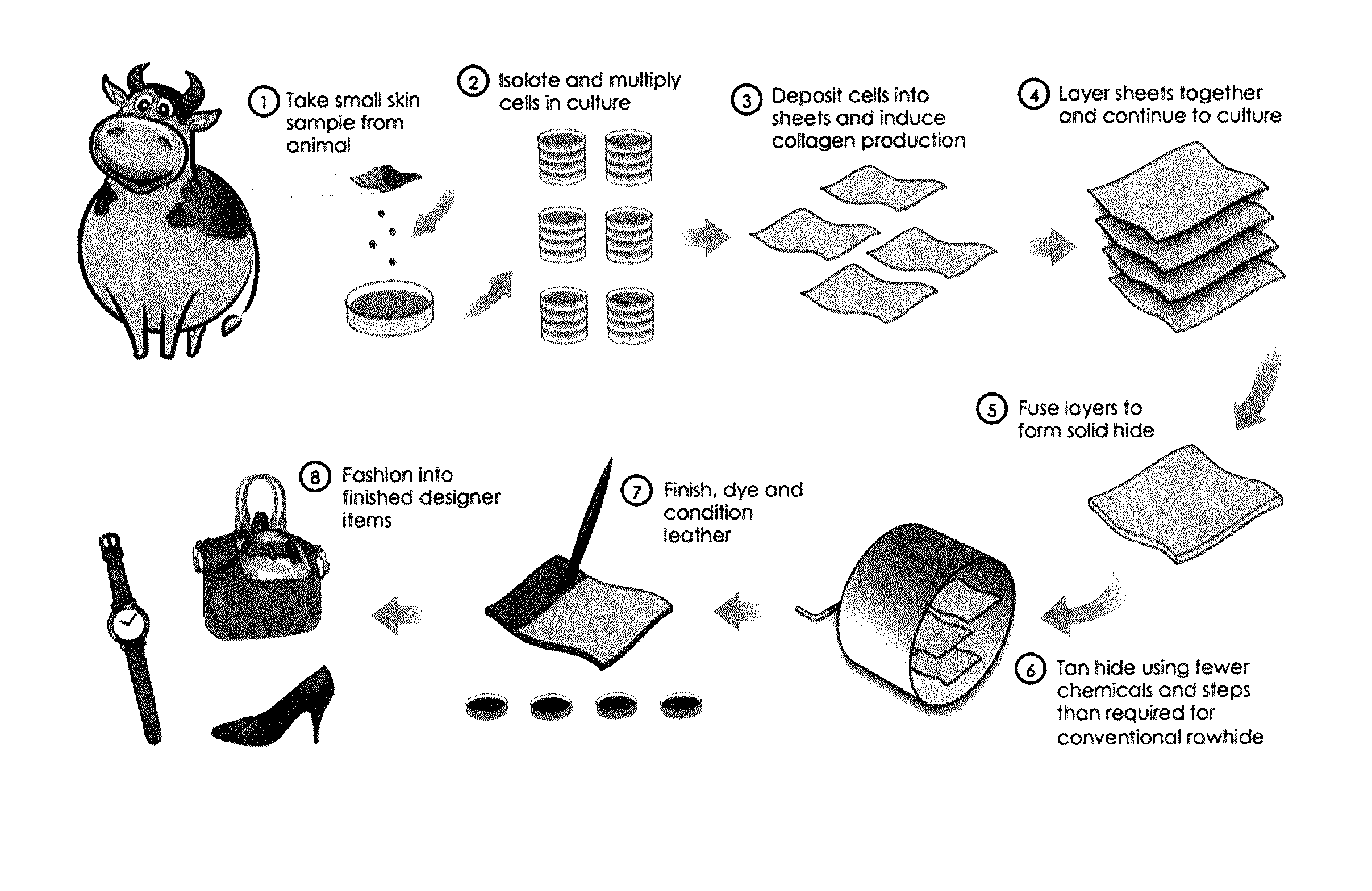

Engineered leather and methods of manufacture thereof

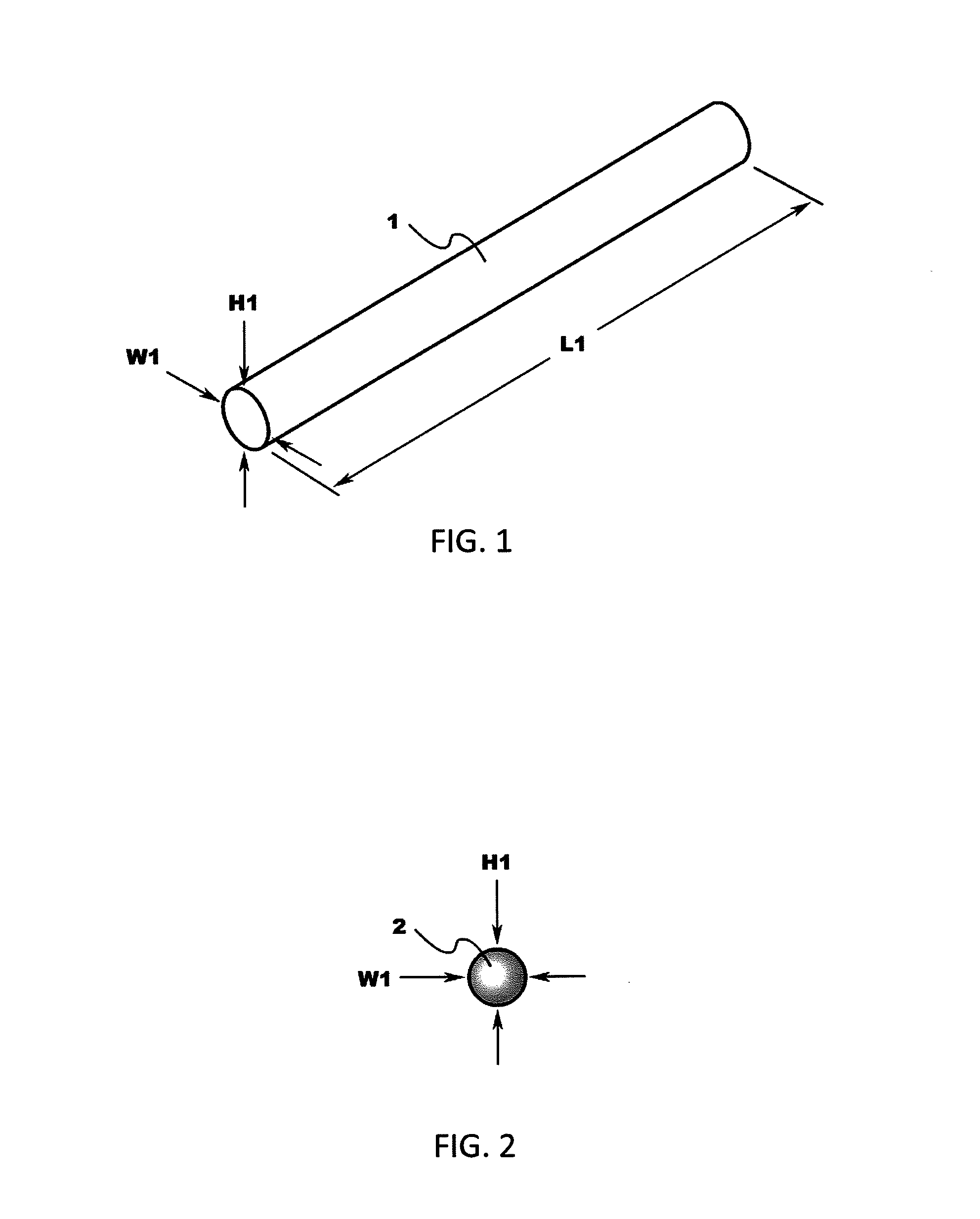

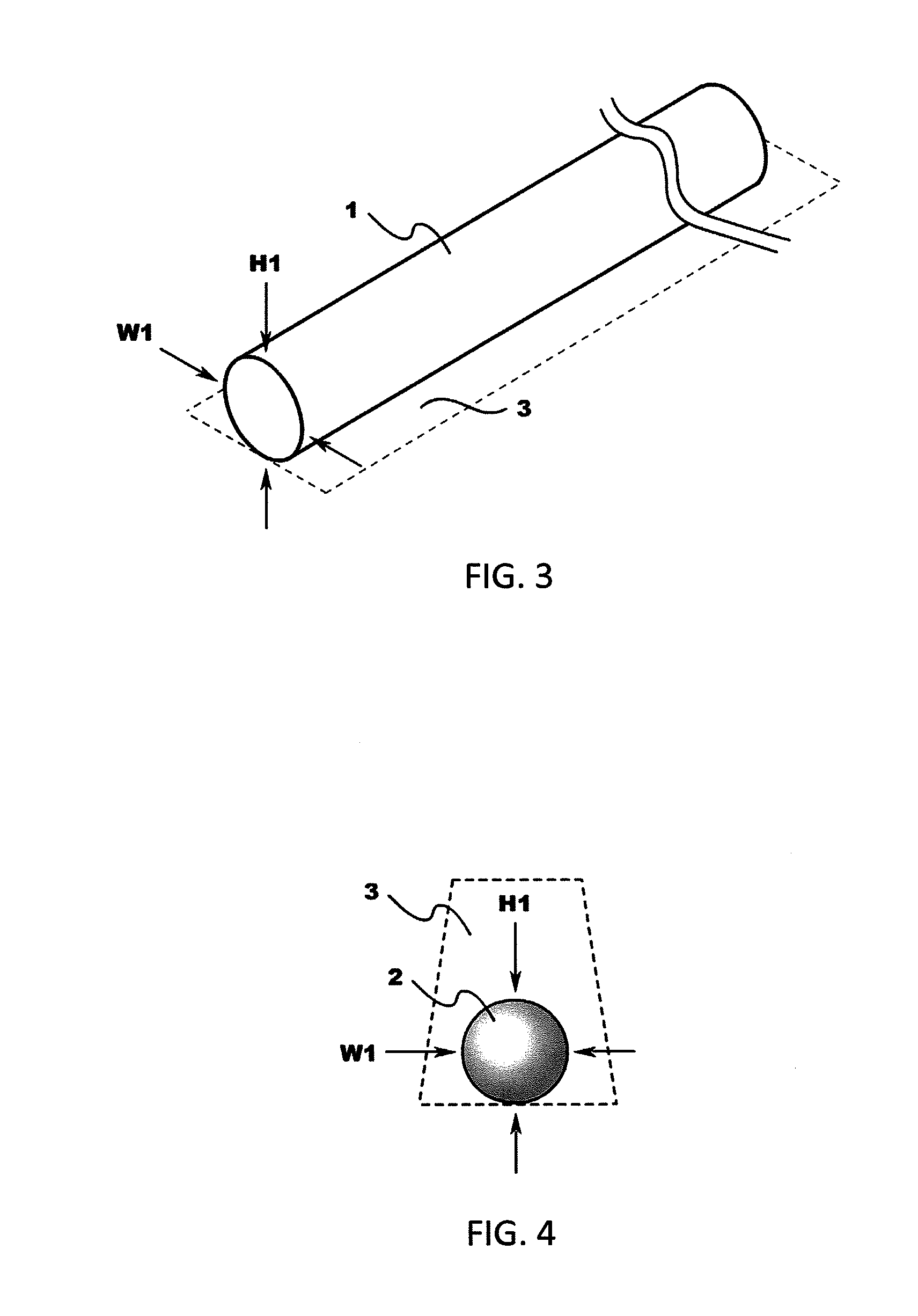

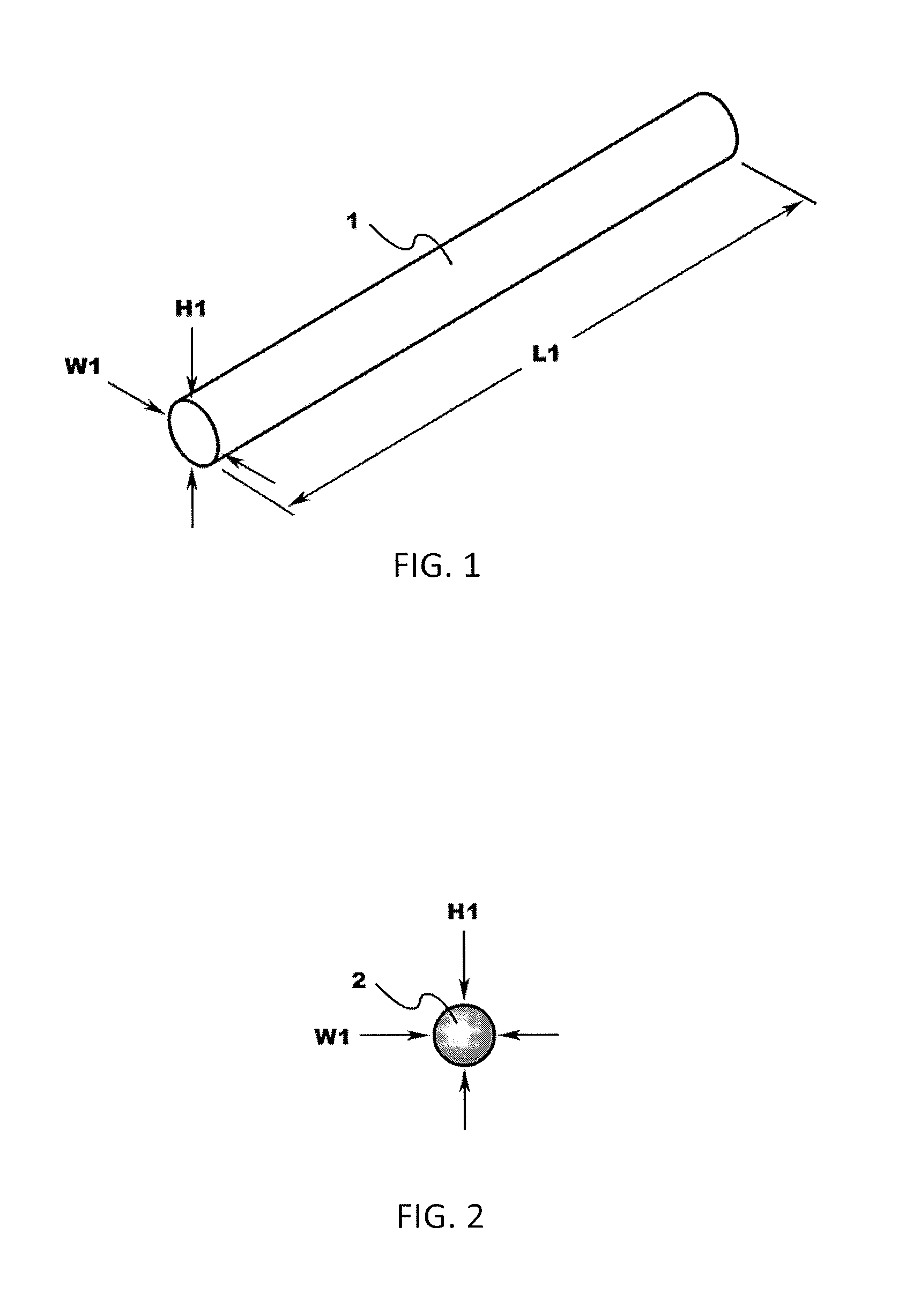

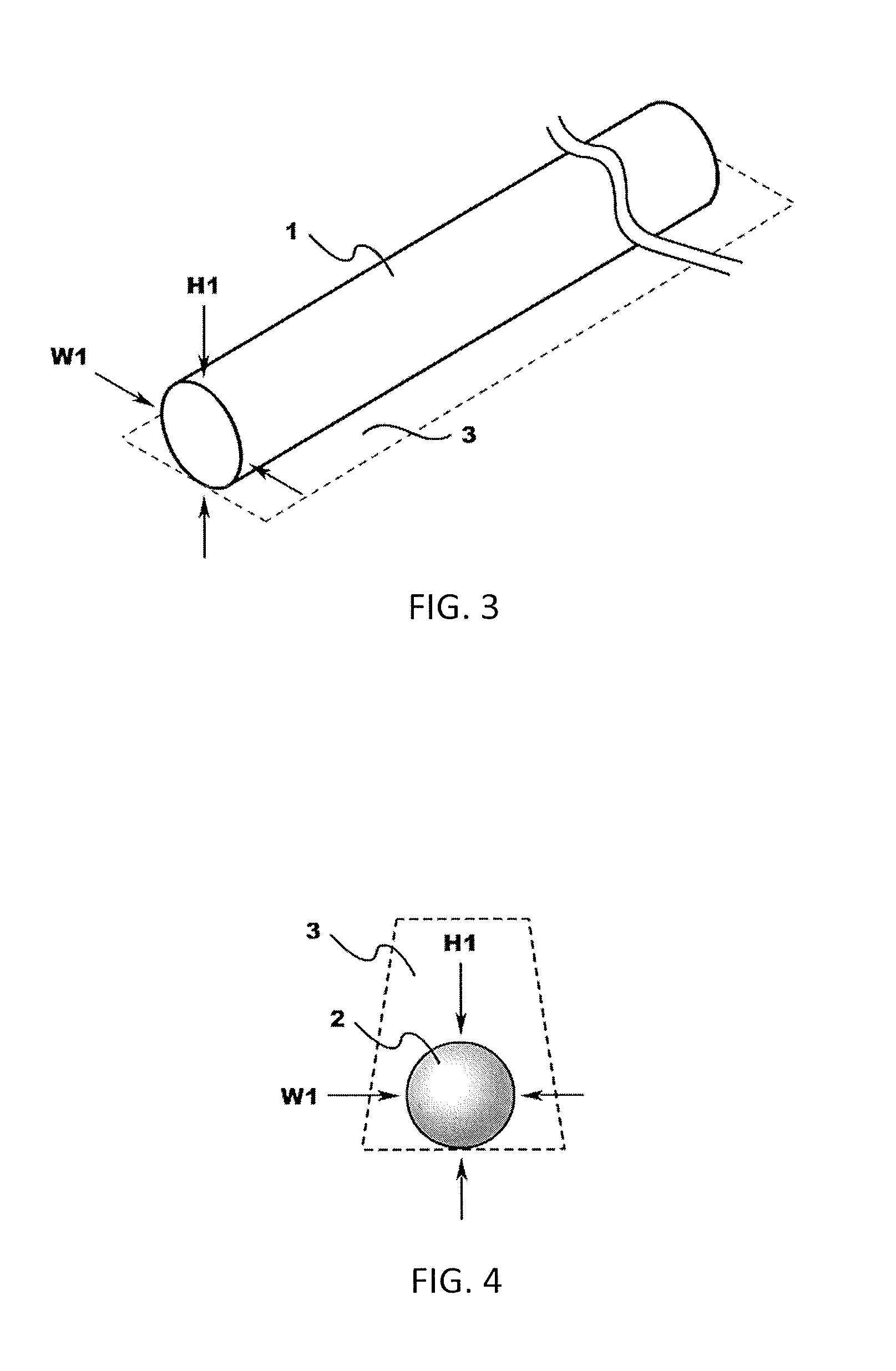

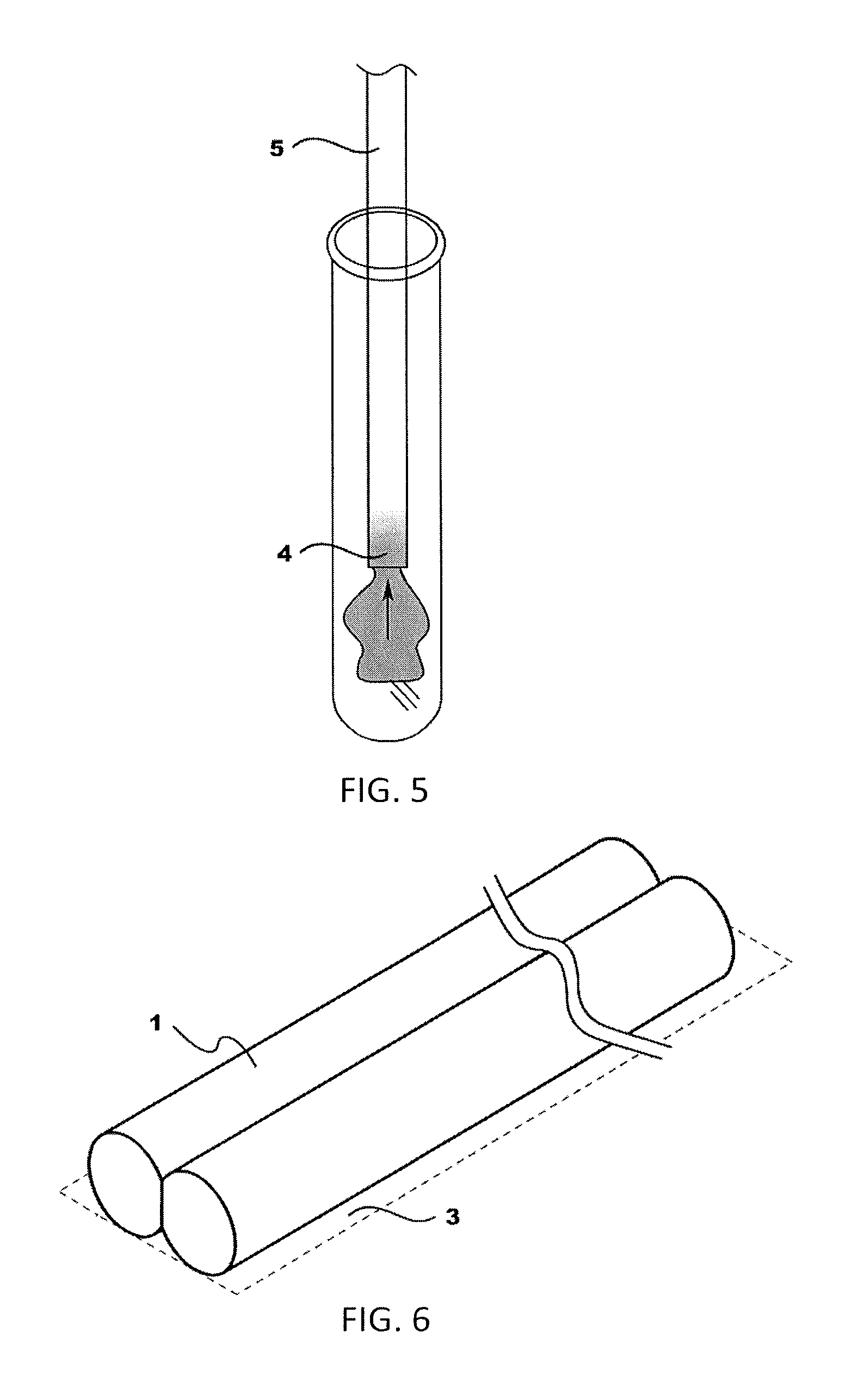

Engineered animal skin, hide, and leather comprising a plurality of layers of collagen formed by cultured animal collagen-producing (e.g., skin) cells. Layers may be formed by elongate multicellular bodies comprising a plurality of cultured animal cells that are adhered and / or cohered to one another; wherein the elongate multicellular bodies are arranged to form a substantially planar layer for use in formation of engineered animal skin, hide, and leather. Further described herein are methods of forming engineered animal skin, hide, and leather utilizing said layers of animal collagen-producing cells.

Owner:MODERN MEADOW INC

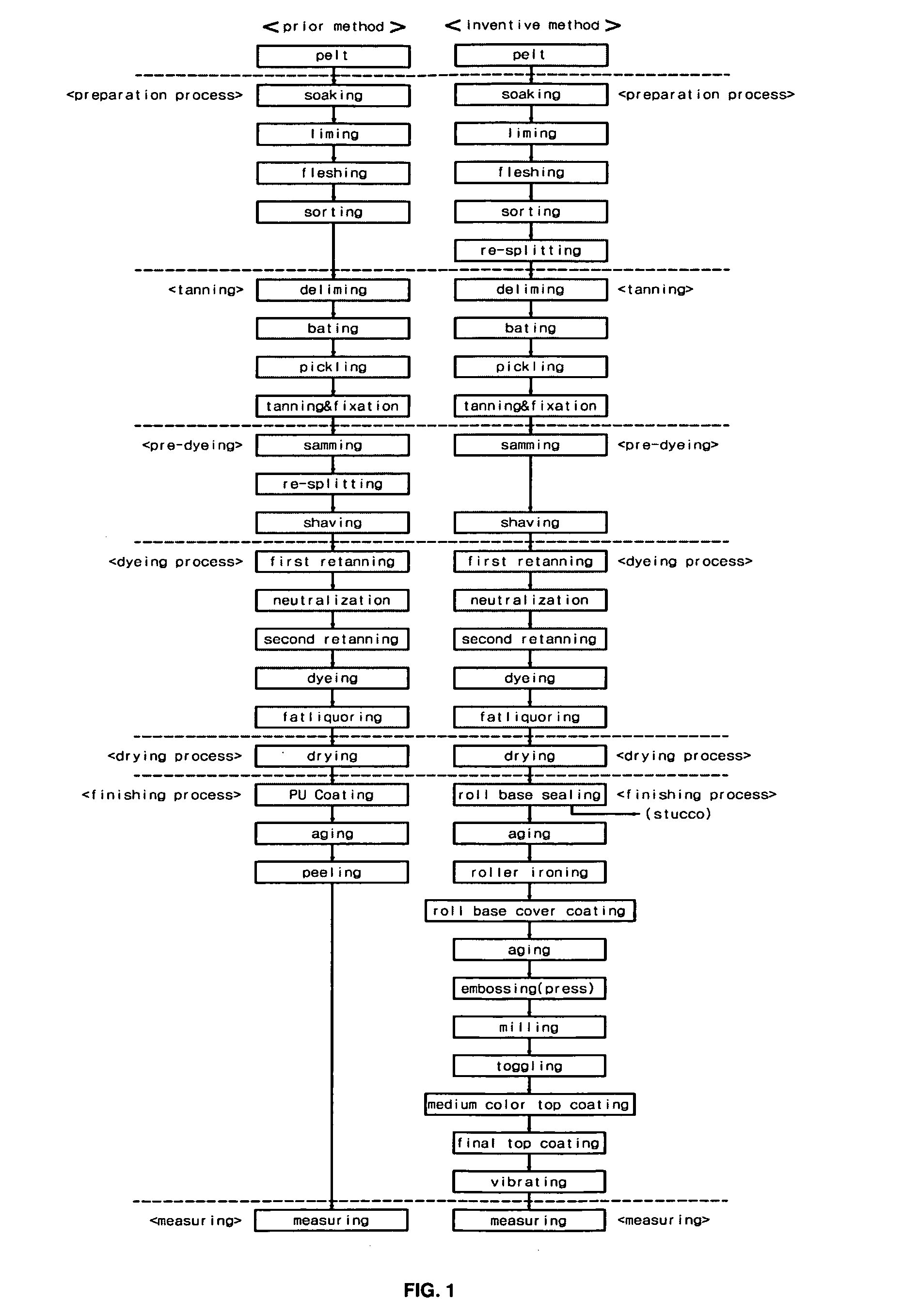

Split Leather for Car Seats and Manufacturing Method Thereof

InactiveUS20080299406A1Maximally maintain propertyCost advantageVehicle seatsTanning treatmentCar seatEngineering

Disclosed herein are split leather for car seats and a manufacturing method thereof. The method comprises a preparation process, a tanning process, a pre-dyeing process, a dyeing process, a drying process and a finishing process, wherein the method comprises, after the preparation process, but before the tanning process, a re-splitting process of splitting pelt into an upper grain layer and a split layer, having a thickness of 2.5-4 mm, and re-splitting the split layer to have a thickness of 1.8-2.5 mm starting from the upper side thereof, thus obtaining split leather, and the finishing process comprises sequentially forming a roll base sealing layer, a roll base cover layer, a medium color top coating layer and a final top coating layer on the split leather, thus treating the surface of the split leather. The split leather for car seats has a luxuriousness close to that of full-grain leather and a soft touch and feel, and can give customers a cost advantage. Also, the range of selection of raw material for manufacturing car seat leather can be widened, and waste can be recycled to thus reduce the generation of waste, thus being helpful to the environment. In addition, leather seats can be diversified and a new product group can be created.

Owner:NAM CHUNG

Engineered leather and methods of manufacture thereof

Engineered animal skin, hide, and leather comprising a plurality of layers of collagen formed by cultured animal collagen-producing (e.g., skin) cells. Layers may be formed by elongate multicellular bodies comprising a plurality of cultured animal cells that are adhered and / or cohered to one another; wherein the elongate multicellular bodies are arranged to form a substantially planar layer for use in formation of engineered animal skin, hide, and leather. Further described herein are methods of forming engineered animal skin, hide, and leather utilizing said layers of animal collagen-producing cells.

Owner:MODERN MEADOW INC

Engineered leather and methods of manufacture thereof

Owner:MODERN MEADOW INC

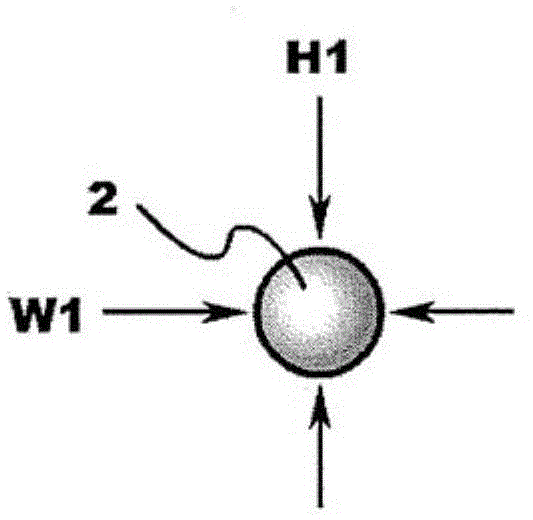

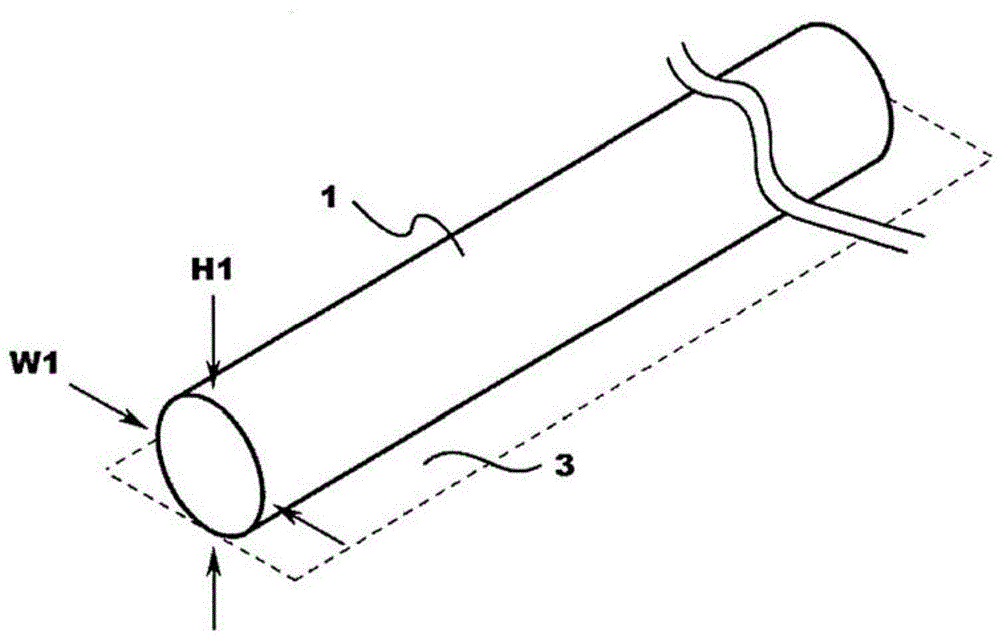

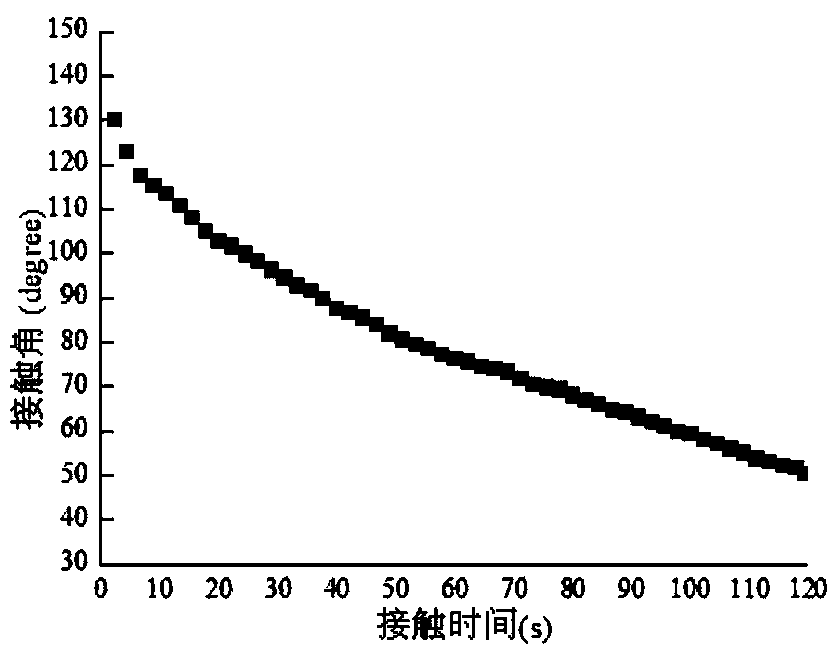

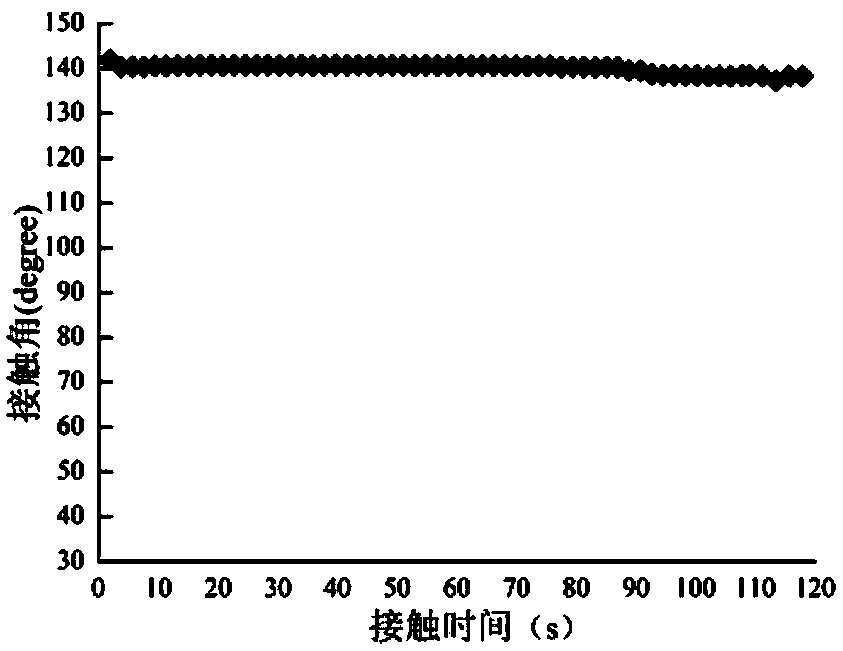

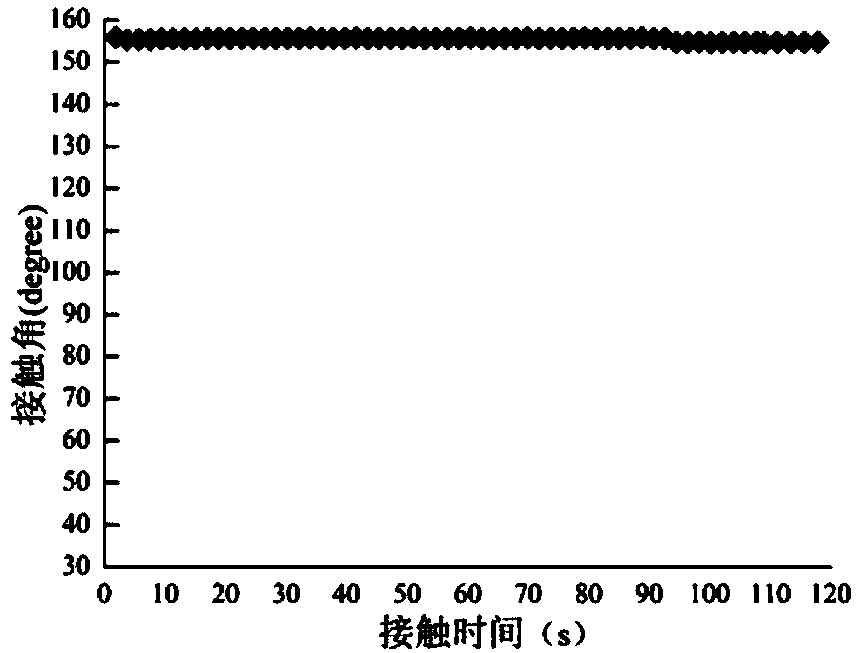

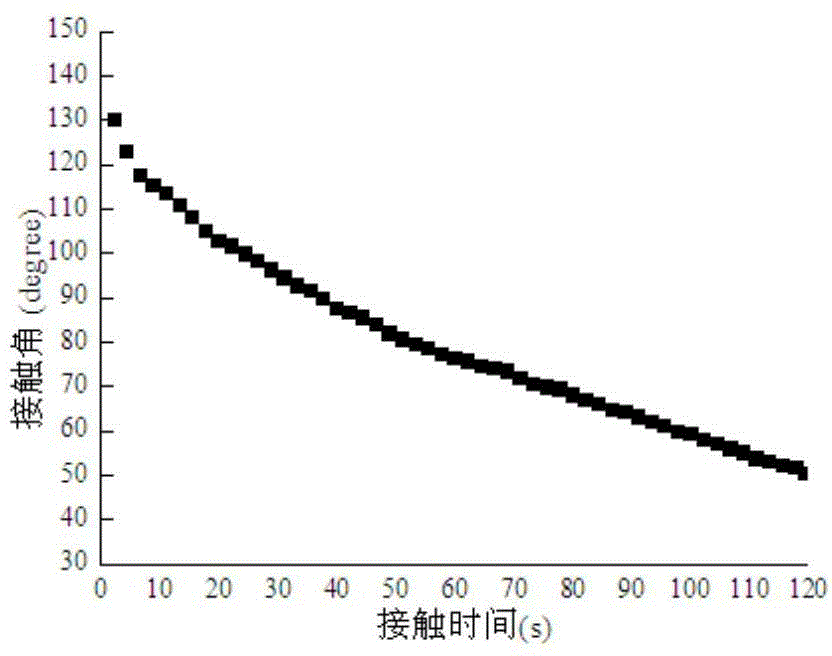

Waterproof leather prepared via polymerization deposition of low-temperature plasmas and preparation method of waterproof leather

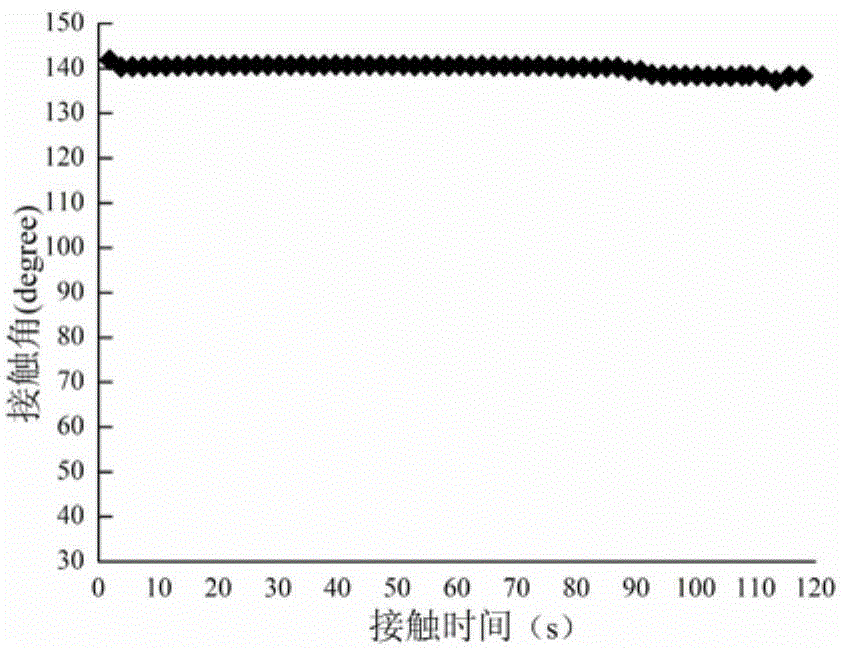

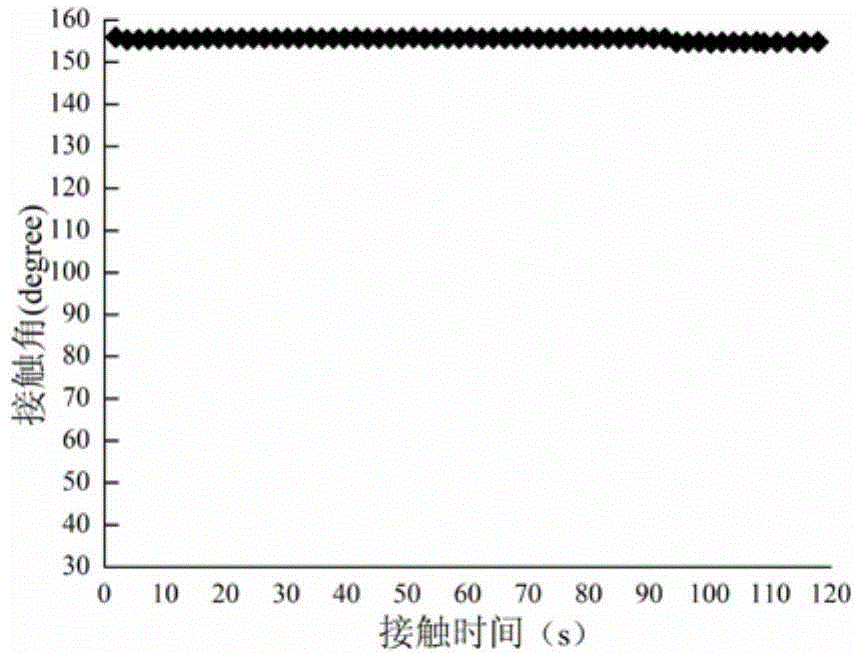

InactiveCN103468835AKeep leatherGuaranteed hygienic performanceSpecial leathers manufactureFiberPolymer science

The invention discloses waterproof leather prepared via polymerization deposition of low-temperature plasmas and a preparation method of the waterproof leather. The method comprises the following steps: vaporizing siloxane monomers or crylic acid monomers or acrylate monomers or fluorinated acrylate monomers or fluorosilane monomers under the vacuum degree of 25Pa to 45Pa at the temperature of 25 DEG C to 50 DEG C; then adding the vaporized monomers into plasma reaction equipment according to a certain flow and reacting for 1 to 25 minutes under the discharge power within 0.15W / cm<2> to 1.5W / cm<2>; and depositing the monomers on the leather in the plasma reaction equipment, wherein the thickness of a waterproof membrane deposited on the surface of the leather in a polymerization manner is in a micron level or below the micron level, the static contact angle of the waterproof membrane is within 136 DEG to 155 DEG and the rolling angle of the waterproof membrane is within 7 DEG to 22 DEG, and stagger collagen fibers can be seen clearly by observing through a scanning electron microscope. The method is simple in treatment process, short in time, high in efficiency and low in energy consumption. The obtained waterproof membrane is thin, and not only can maintain the real leather feeling of the surfaces of stone washed leathers, suede leathers, double-purpose leathers and the like but also can maintain the sanitation performance of nature leathers.

Owner:SICHUAN UNIV

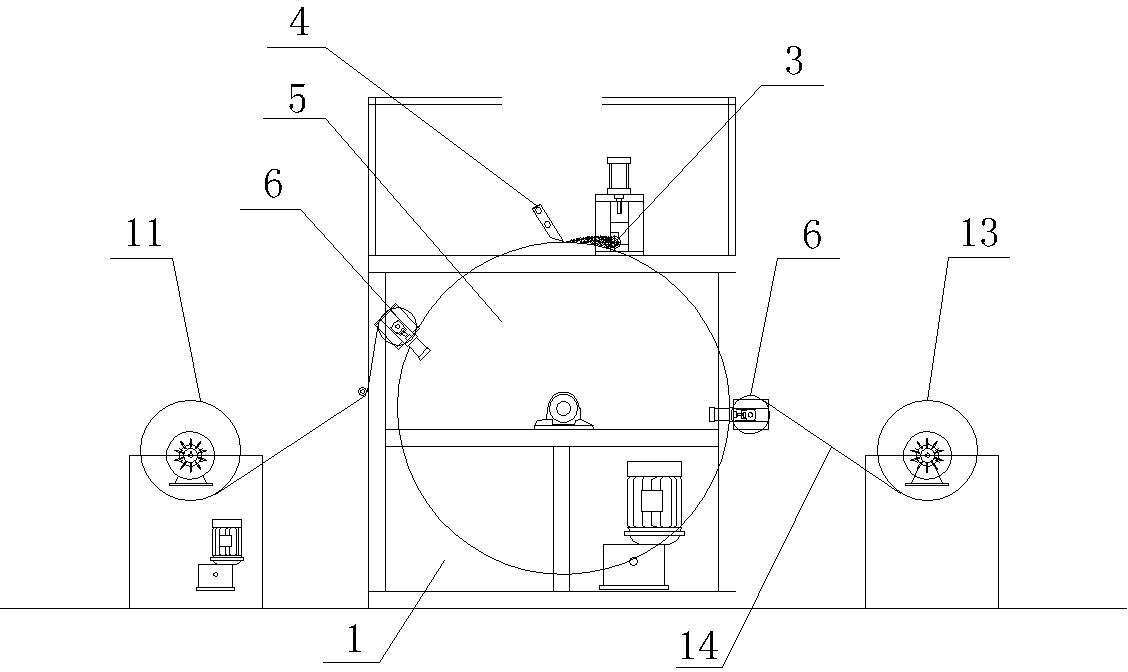

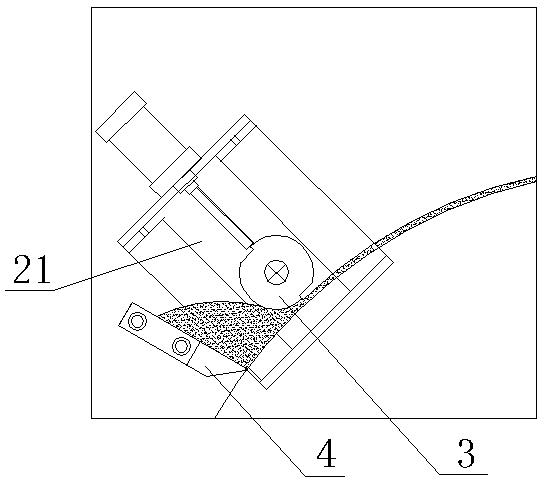

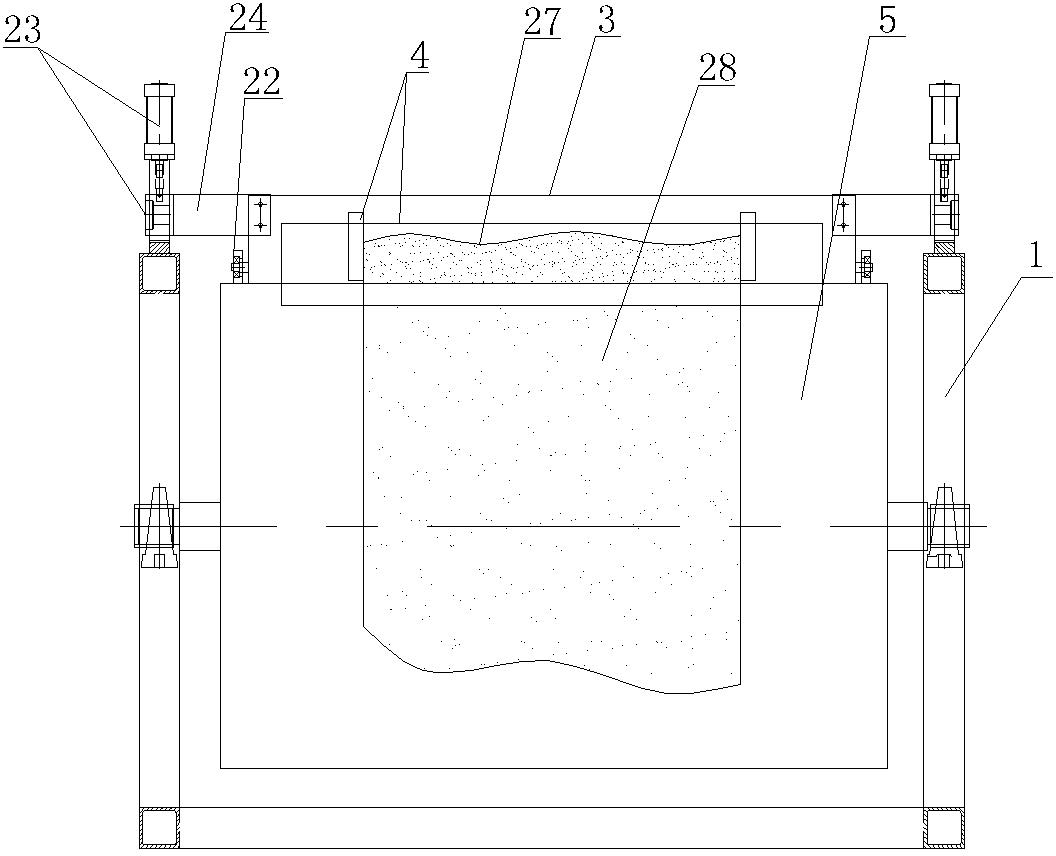

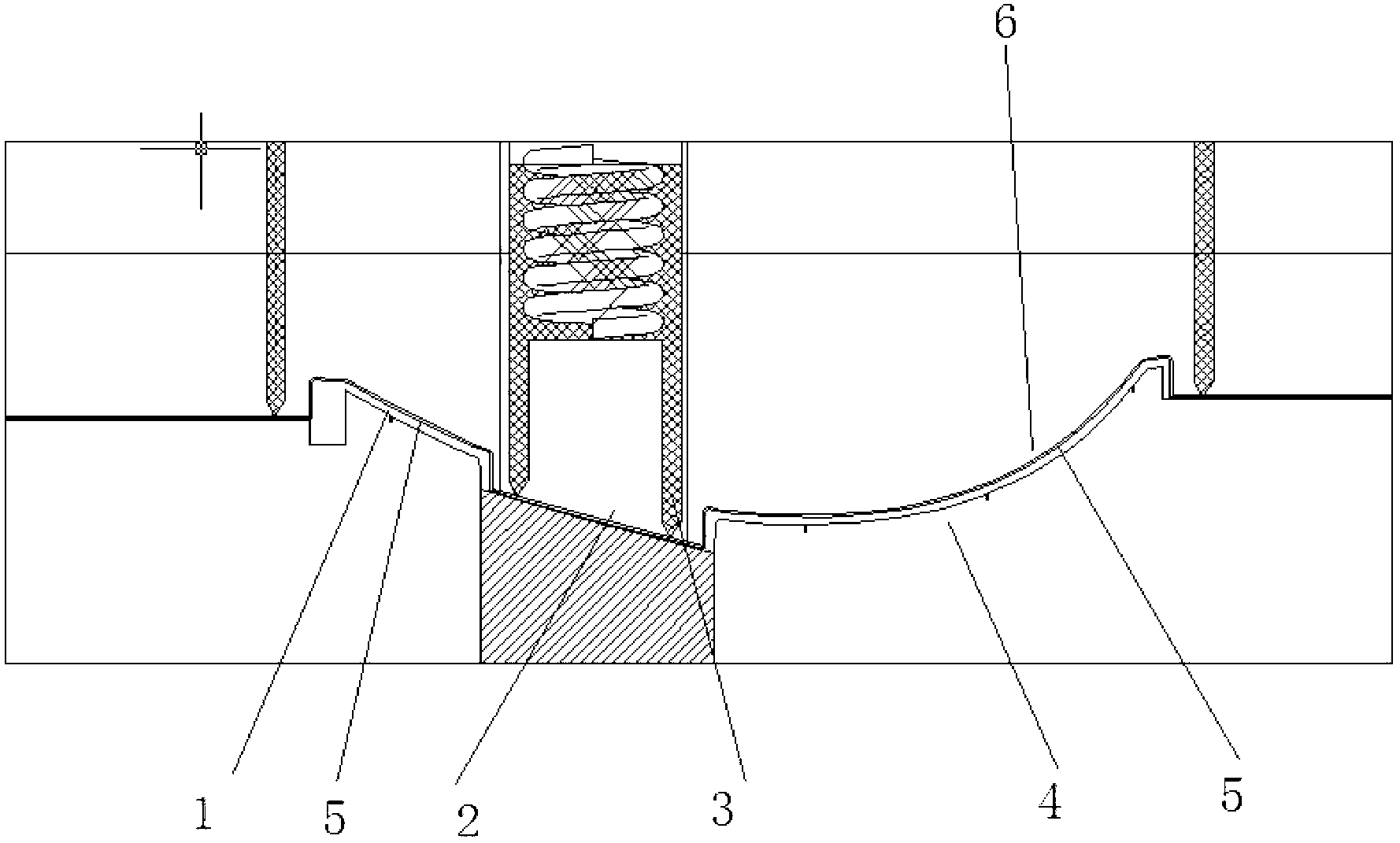

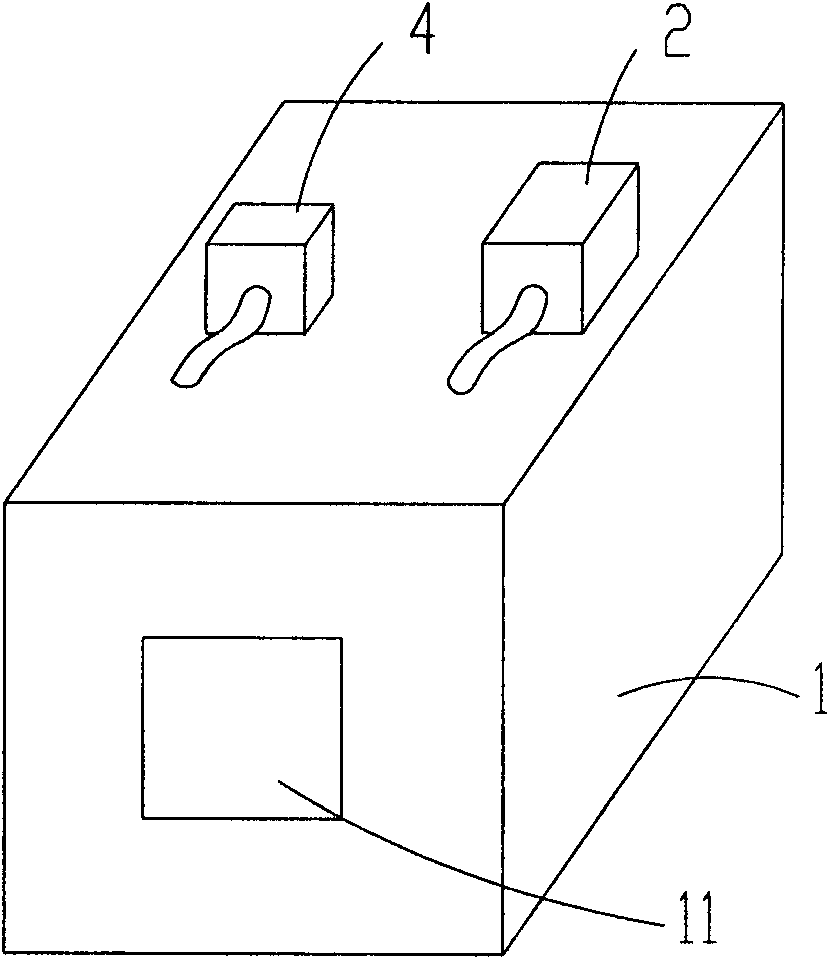

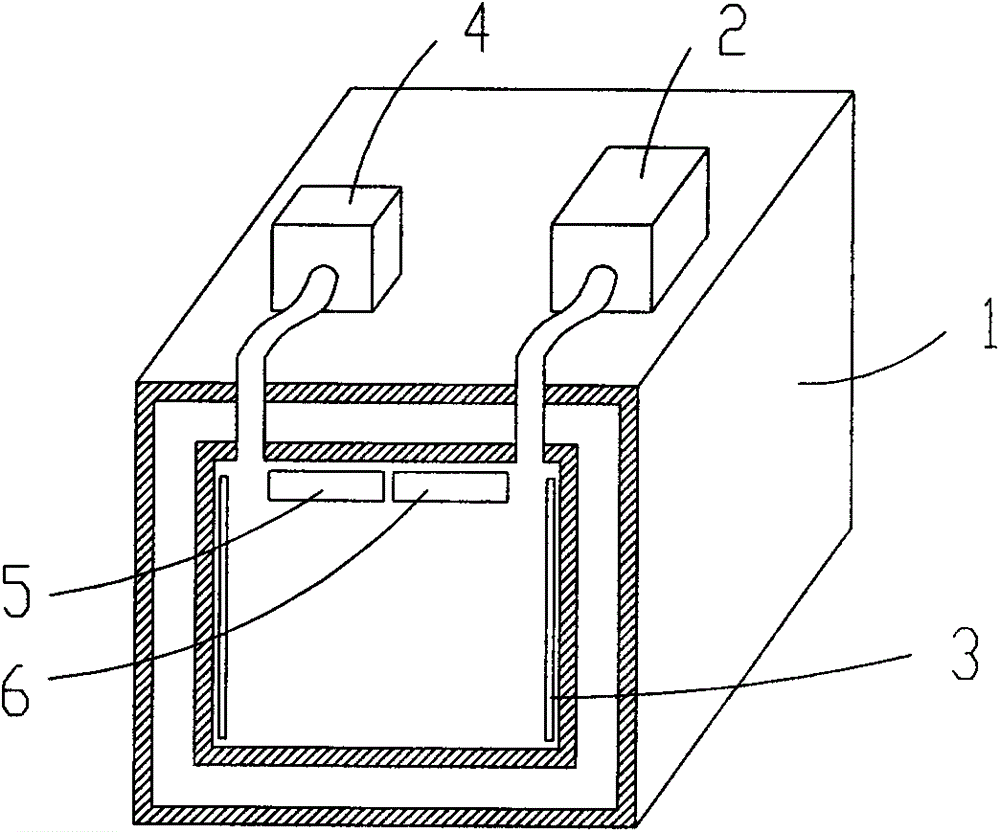

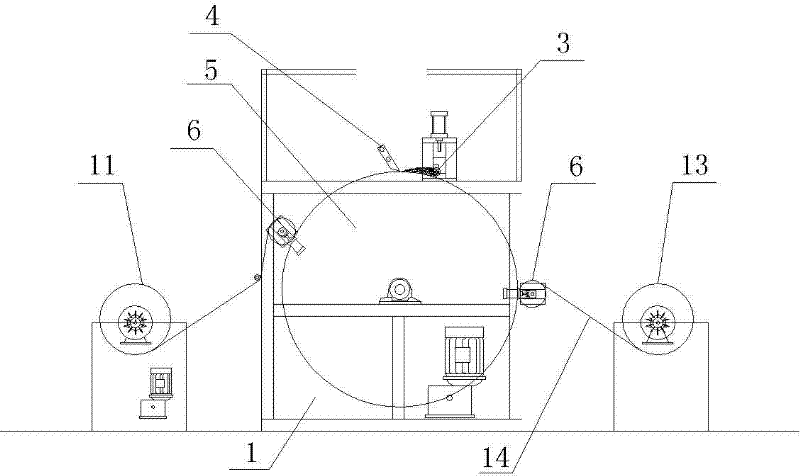

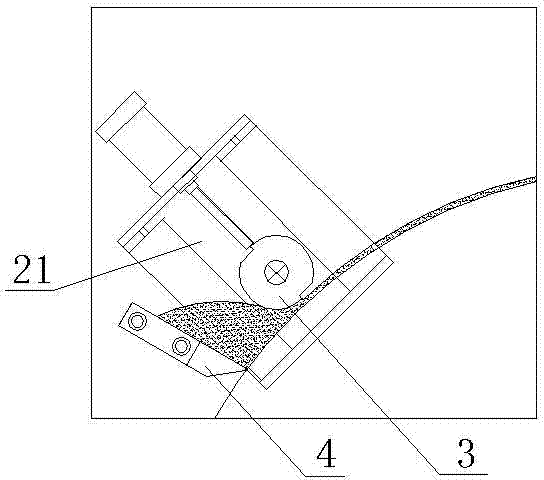

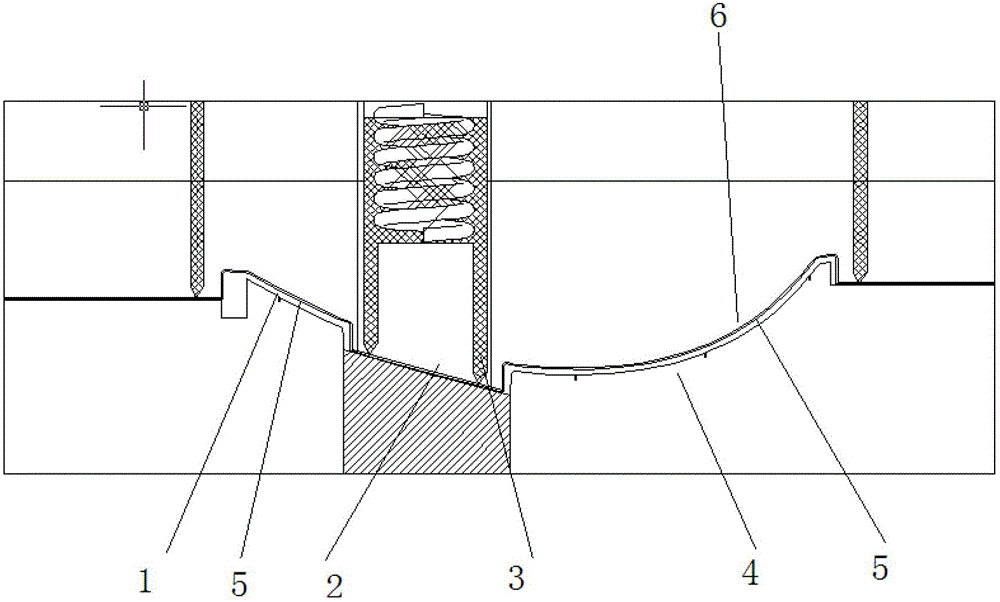

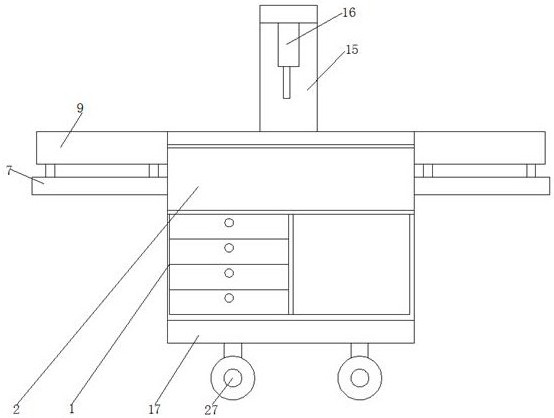

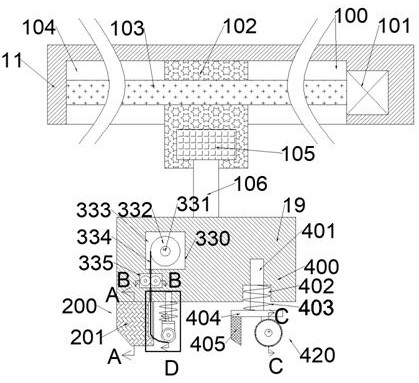

Dry artificial leather making machine

ActiveCN102011323ALong-term useSave costsLiquid surface applicatorsLamination ancillary operationsEngineeringTransmission equipment

The invention provides a dry artificial leather making machine. The machine comprises a frame and a heat wheel mechanism arranged on the frame, wherein the heat wheel mechanism comprises a scraper mechanism, a heat wheel capable of rotating and an abutted wheel; the heat wheel is provided with a heat supply device; the outer circumferential surface of the heat wheel is a flat working surface; the working surface of the scraper mechanism corresponding to the heat wheel is arranged above the heat wheel; and the working surface of the abutted wheel corresponding to the heat wheel is arranged at the lateral side of the heat wheel, and is arranged in front of the scraper mechanism on the rotating direction of the heat wheel. In the invention, scraper equipment, heat equipment, transmission equipment, joint equipment and molding equipment in the traditional process are ingeniously combined to the heat wheel mechanism, the heat wheel is shared in scraping, heating, transmitting, jointing and molding processes, so that scraping, heating, transmitting, jointing and molding steps on paint and a matrix belt can be completed when the paint and the matrix belt pass through the heat wheel mechanism. The dry artificial leather making machine has short production line, and does not require release paper consumption in the producing process.

Owner:东莞市金银丰机械实业有限公司

Aqueous multi-stage copolymer compositions for use in leather topcoats

ActiveUS10100377B2Keep the lookMaintain softnessSpecial leathers manufacturePolyurea/polyurethane coatingsPolymer scienceTotal solid content

The present invention provides aqueous composition comprising a multi-stage acrylic emulsion polymer having a first stage polymer of from 0.5 to 4 wt. %, based on the total weight of monomers used to make the first stage polymer, of a copolymerized carboxylic acid or salt group containing monomer, and having 10 to 30 wt. %, on total solids of the multi-stage acrylic emulsion polymer, of a second stage polymer of from 3 to 15 wt. % of a copolymerized hydroxyl group containing monomer, the first stage polymer having a glass transition temperature (Tg) by dynamic mechanical analysis (DMA) of less than −10° C. and the second stage polymer having a Tg (DMA) of greater than 80° C.; and (ii) from 25 to 75 wt. %, based on the total solids weight of the multi-stage acrylic polymer, of a polyurethane.

Owner:ROHM & HAAS CO

Leather capable of releasing negative oxygen ions

InactiveCN109735667AGood filling effectImprove the bactericidal effectSpecial leathers manufactureLeather surface finishingOxygen ionsSulfite

The invention provides leather capable of releasing negative oxygen ions. The leather capable of releasing negative oxygen ions comprises leather body and a coating attached to the surface of the leather body, and the coating is composed of the following raw materials of sodium chloride, tourmaline, sulfite, sodium fluosilicate, and triethanolamine. Compared with the prior art, the leather capableof releasing negative oxygen ions has the following beneficial effects that the filling effect and the sterilization and deodorization effects of the leather are improved, the leather has antibacterial and sterilization effects, the leather can clean air, and compared with a traditional leather product the leather is easy to clean, can be scrubbed, is resistant to friction and is not prone to damage.

Owner:智贝(上海)实业有限公司

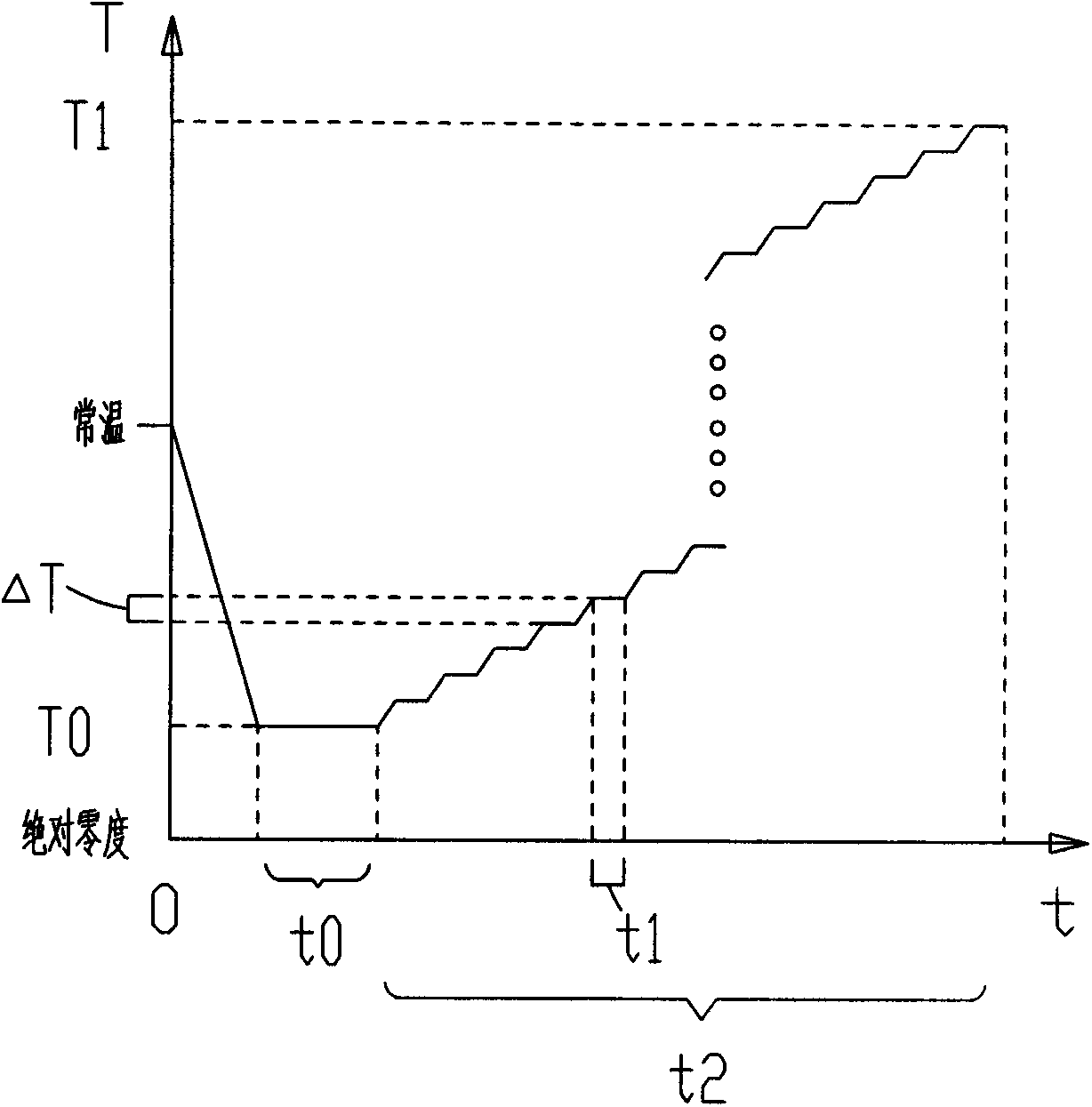

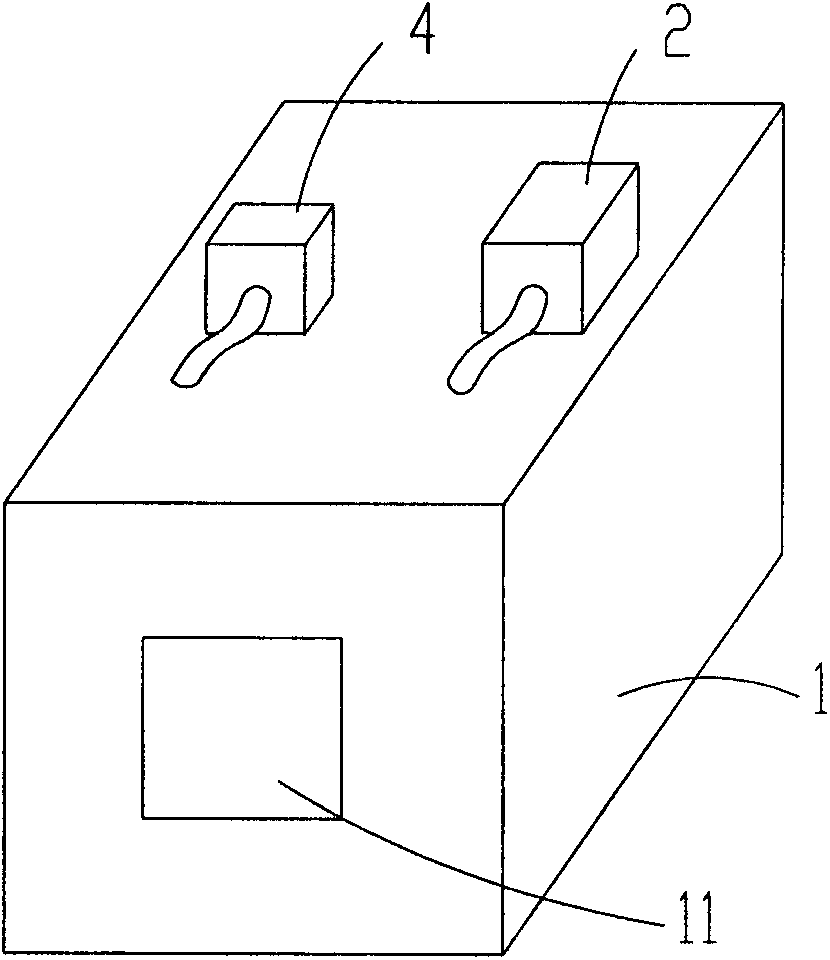

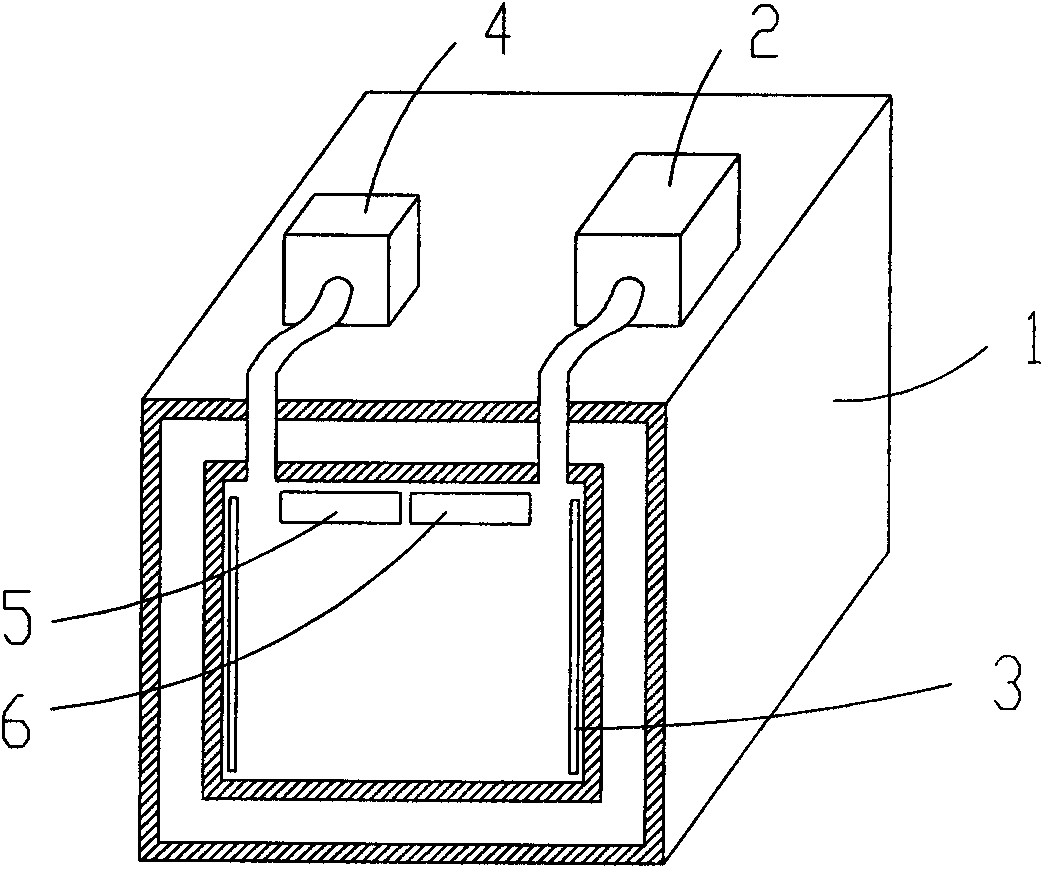

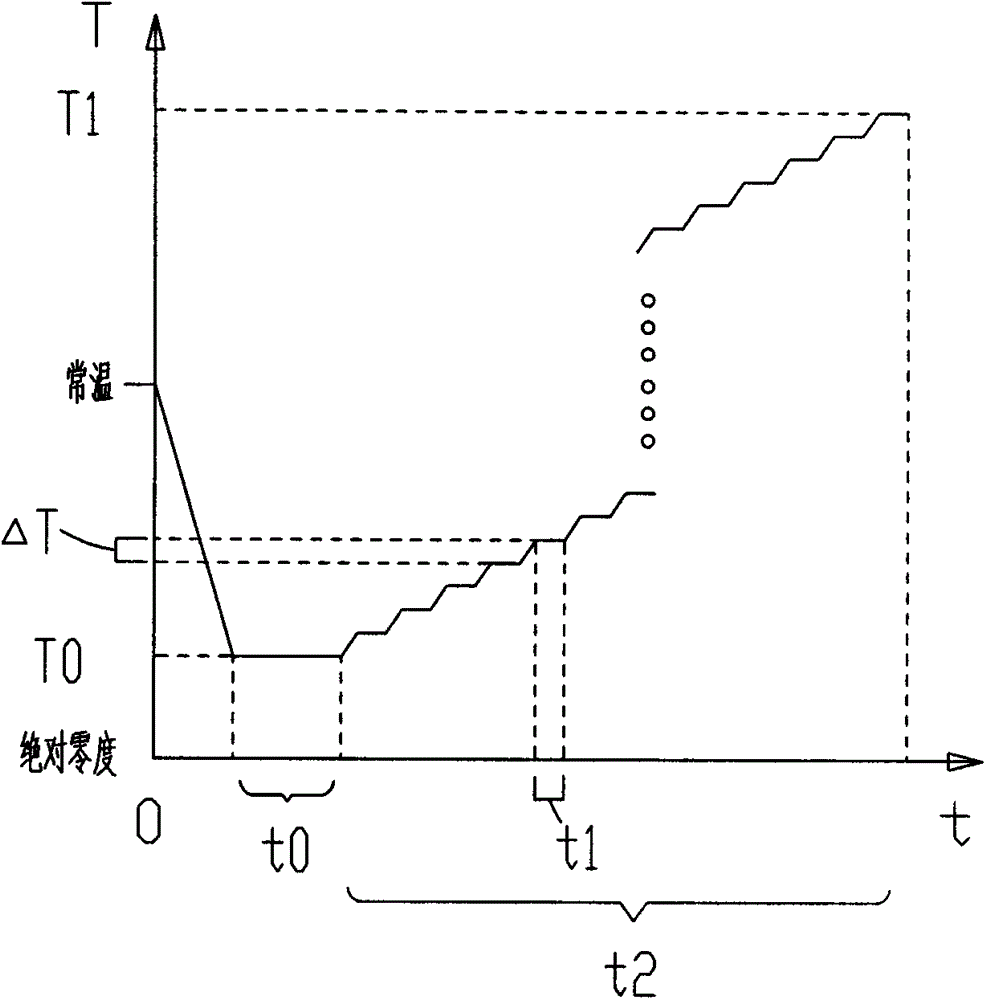

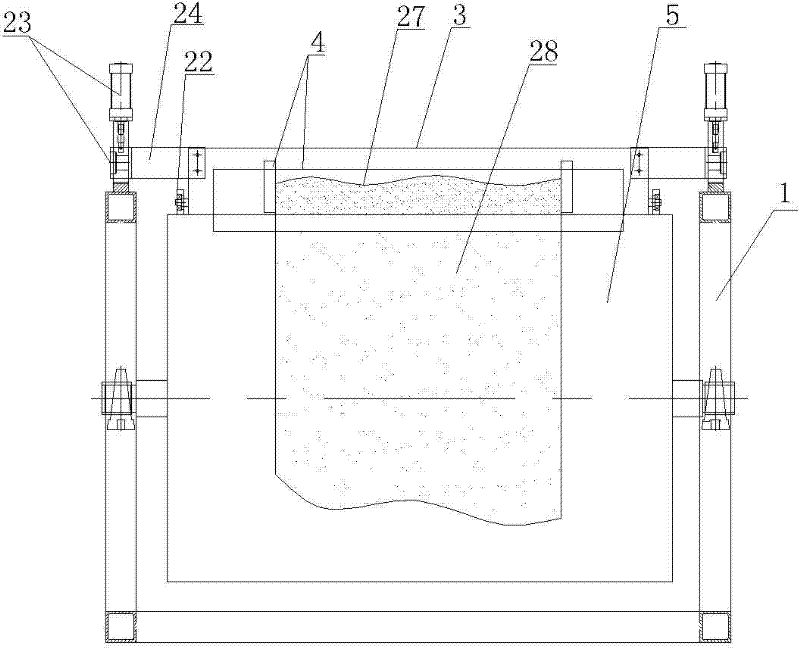

Preparation method for far-infrared material and device

InactiveCN103463739AEnhanced far-infrared functionWith far infrared health care functionCosmetic preparationsToilet preparationsEmissivityPhysical chemistry

The invention relates to the technical field of material manufacturing and particularly relates to a preparation method for a far-infrared material and a device. The preparation method includes steps of: S1: carrying out cooling and refrigeration treatment on a base material and keeping for a period of time t0 after a lowest temperature T0 is achieved; carrying out temperature-rising treatment on the refrigerated base material and carrying out polarization treatment in a temperature-rising period; S3: stopping the temperature-rising treatment and the polarization treatment, and naturally cooling the material to a normal temperature. The method is capable of greatly improving normal emittance of far-infrared rays, with a wavelength of 4 mum-16 mum, released by a common material, so that the normal emittance is approximate to or equal to a standard for the far-infrared material.

Owner:李旺菊 +1

Producing method for stretch-proof leather

ActiveCN103498014AImprove tensile propertiesAvoid deformationSpecial leathers manufactureWaxAcrylic resin

The invention relates to the technical field of leather production, in particular to a producing method for stretch-proof leather. The producing method comprises the sequential steps of taking soft leather materials, firstly coating the soft leather materials, drying the soft leather materials in a suspension mode, polishing the soft leather materials, lustering the soft leather materials and spraying color on the soft leather materials. Thus, the stretch-proof leather can be manufactured. In the first coat step, burned black wax and soft casein acrylic resin are dissolved into water to carry out roller coating treatment. In the polishing step, a polishing machine is used for polishing the soft leather materials. In the lustering step, a tumbling mill is used for lustering the soft leather materials. The stretch-proof leather obtained in the producing method is strong in stretch resistance and not prone to deforming in a using process.

Owner:漳州香洲皮革有限公司

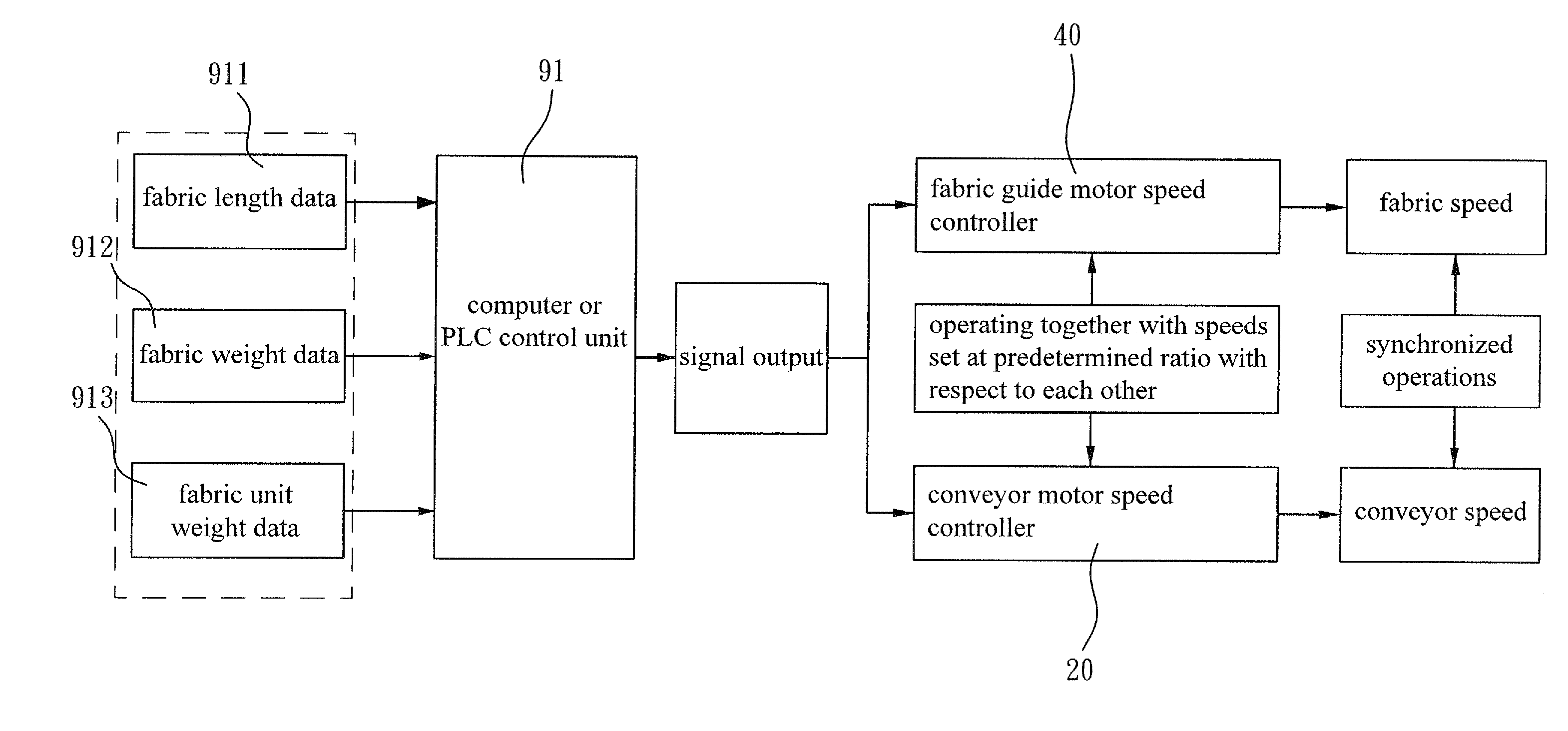

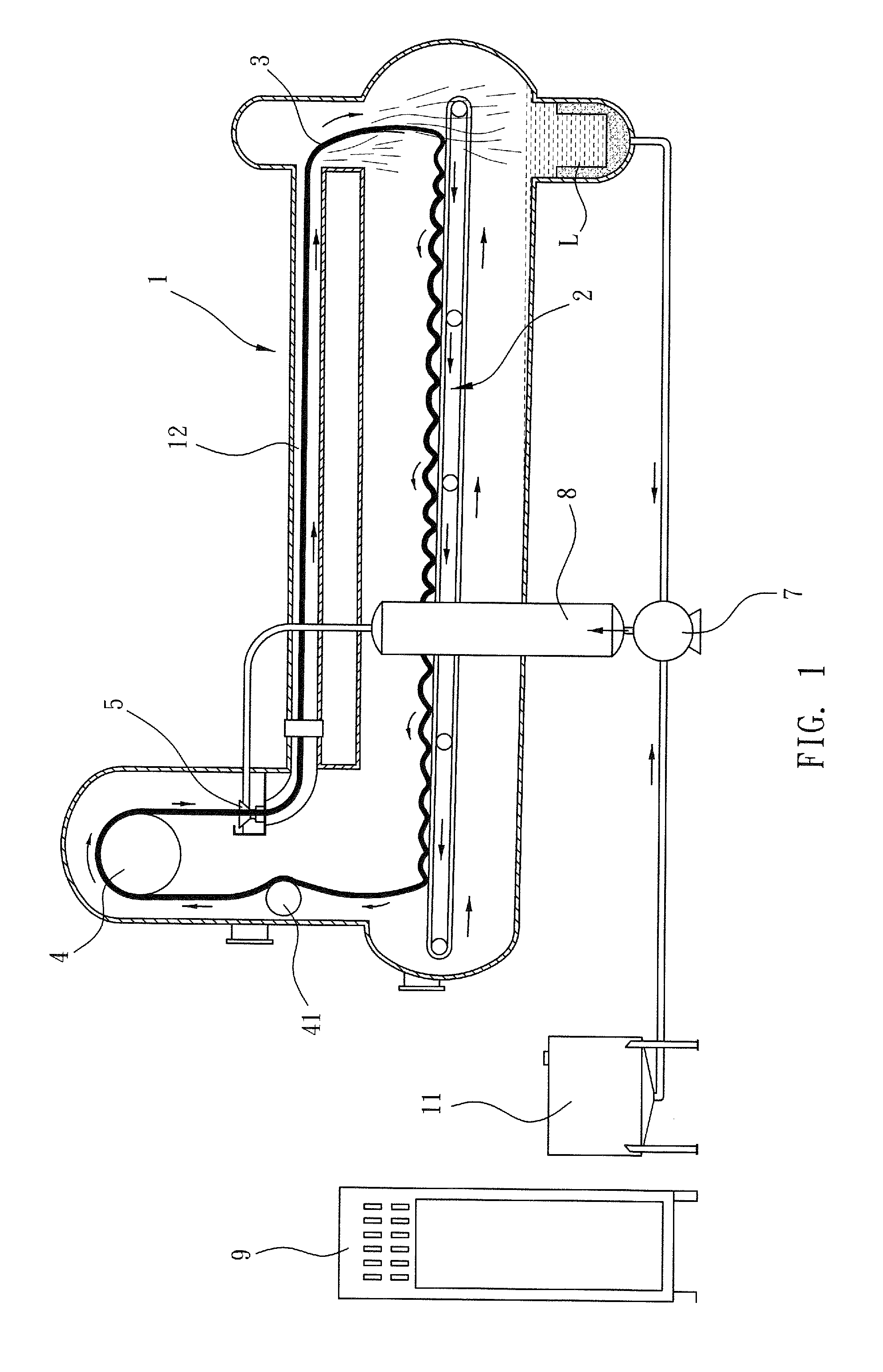

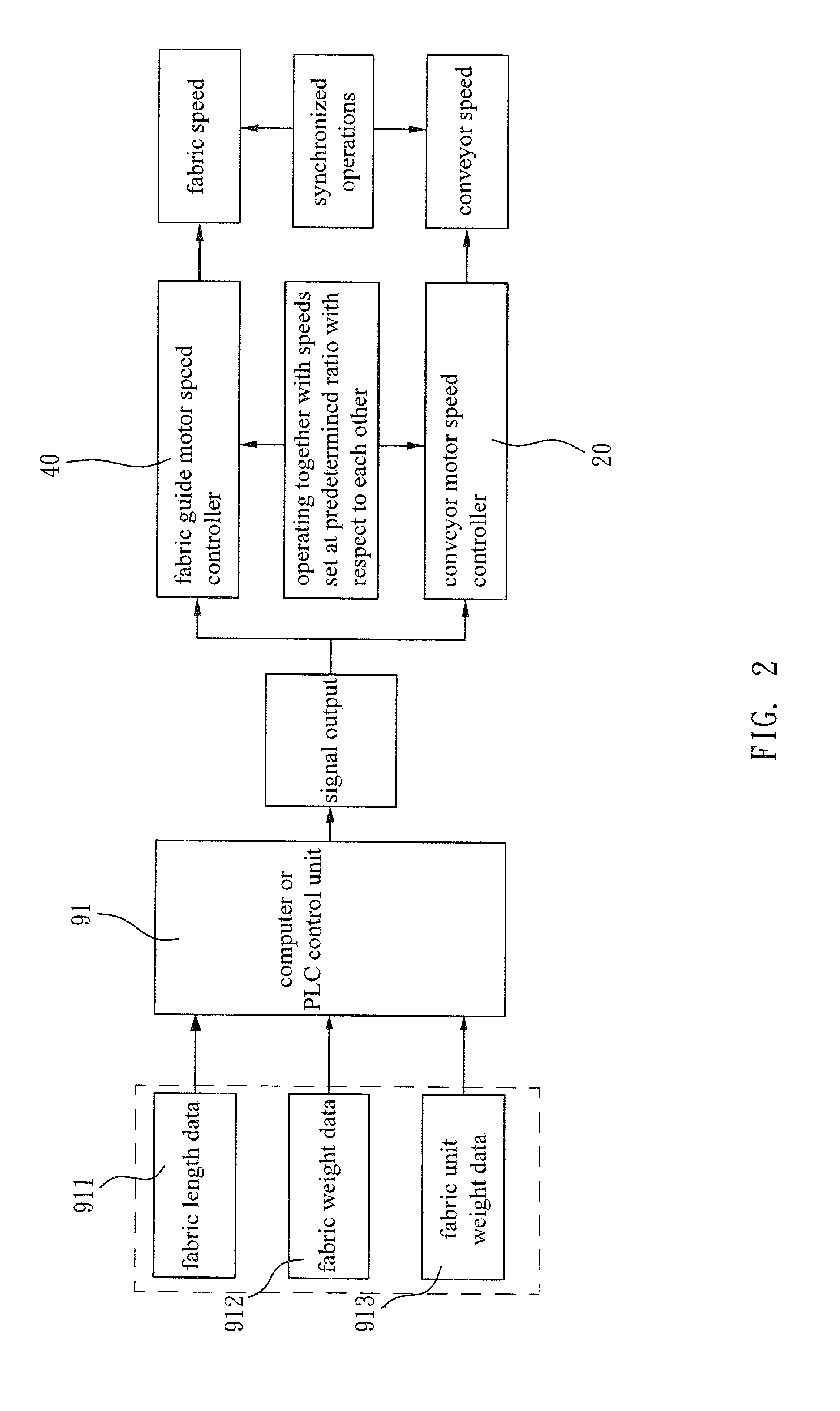

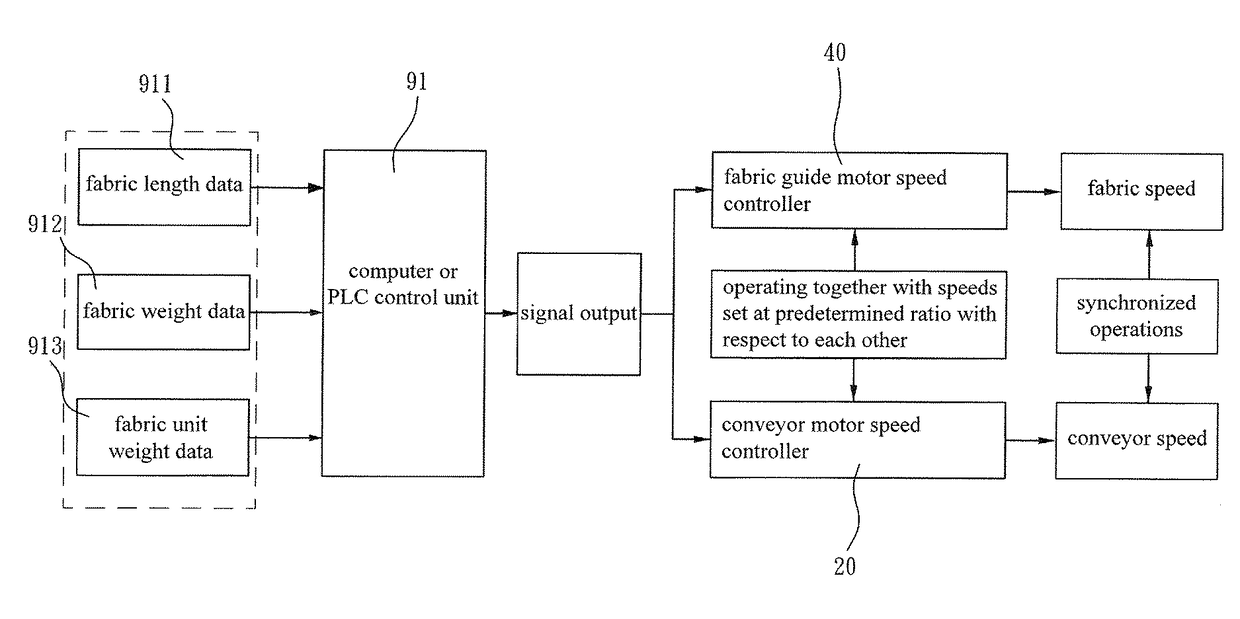

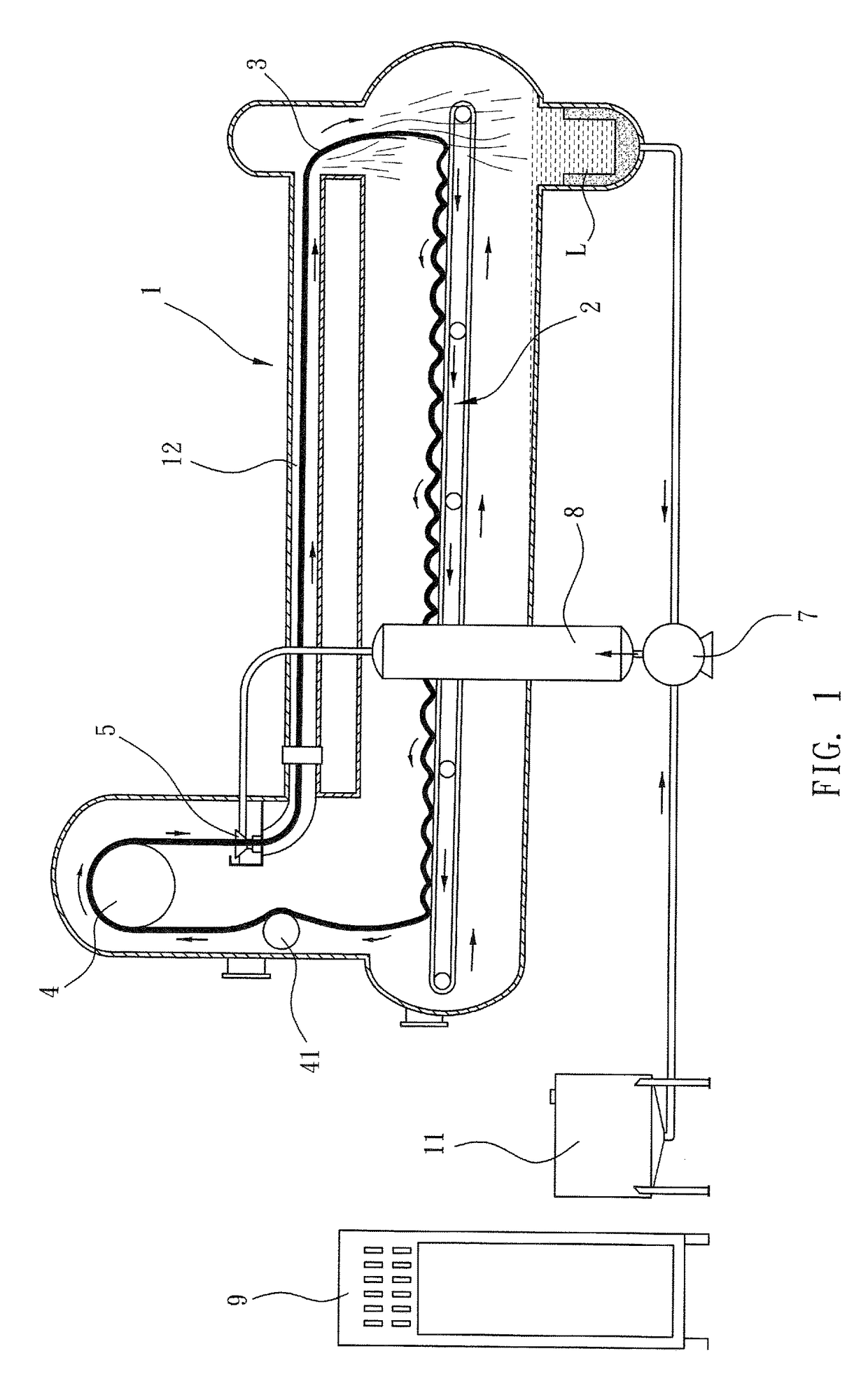

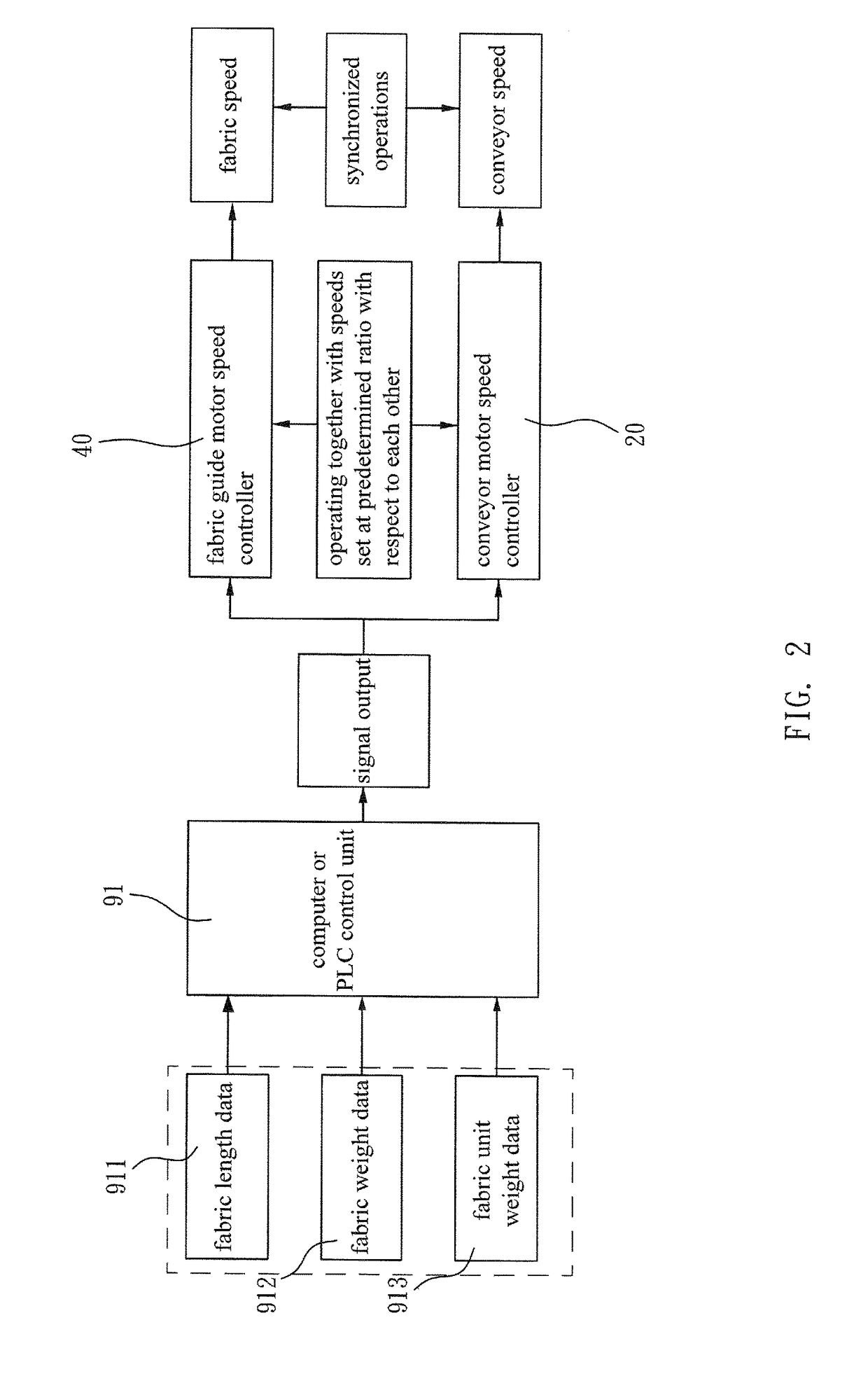

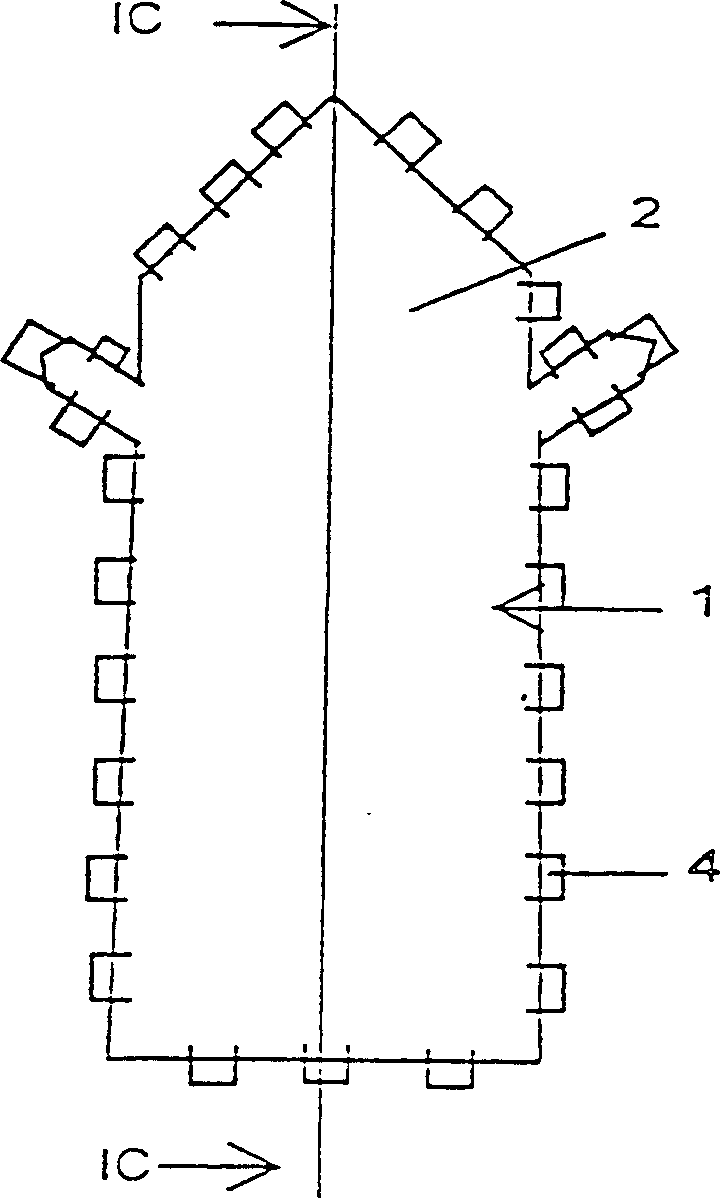

Control Method For Synchronized Fabric Circulation In Conveyor Drive Fabric Dyeing Machine

ActiveUS20160153130A1Smooth circulationEasy to operate the machineLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor treatment of propelled fabricsEngineeringVelocity controller

Disclosed is a control method for synchronized fabric circulation in a conveyer drive fabric dyeing machine. During a dyeing process of fabric, the fabric is driven by a fabric guide to move in a circulating manner and the time period for a cycle of circulation is set in consistency with the time period that a conveyor moving from a rear end to a front end so as to achieve synchronization that makes the circulation smooth. The control method is performed with a computer or a PLC control unit that is supplied with fabric length data or fabric weight data and fabric unit weight data and, based on such data, performs an automatic operation of computation and supply of a signal to speed controllers of the fabric guide motor and the conveyor motor to set the speeds thereof at a predetermined ratio with respect to each other for synchronized operations.

Owner:CHANG

Method for compositing leather on surface of bonder used by car door interior parts and containing modified diatomite

ActiveCN103171232AImprove efficiencyHigh bonding strengthMineral oil hydrocarbon copolymer adhesivesLamination ancillary operationsEpoxyMicrocrystalline wax

The invention provides a method for compositing leather on the surface of a bonder used by car door interior parts and containing modified diatomite. The method is characterized by spraying the bonder on the interior part surface needing leather compositing and then composting leather, wherein the bonder is prepared from the following raw materials in parts by weight: 57-62 parts of EVA (ethylene-vinyl acetate copolymer), 8-12 parts of epoxy resin, 12-16 parts of C5 petroleum resin, 3-5 parts of microcrystalline wax, 0.5-1 part of WPP type polypropylene wax, 1-2 parts of dimethyl carbonate, 2-4 parts of nanometer celestite powder, 7-10 parts of modified diatomite, 2-3 parts of modified rice hull ash, 1.3-1.6 parts of a silane coupling agent KH560, 0.2-0.4 part of ferrocene, 0.3-0.6 part of n-butyl methacrylate, 0.4-0.6 part of epoxidized soybean oil, 0.4-0.6 part of an antioxidant 264, 0.2-0.4 part of an antioxidant 616 and 0.2-0.4 part of an antioxidant 333. The method has the beneficial effects that the method adopts a molding process, achieves automatic trimming and is high in efficiency; and meanwhile, the specific bonder is adopted, has high bonding strength, is flat and can not bubble after being used for a long time.

Owner:TAIZHOU JINSONG

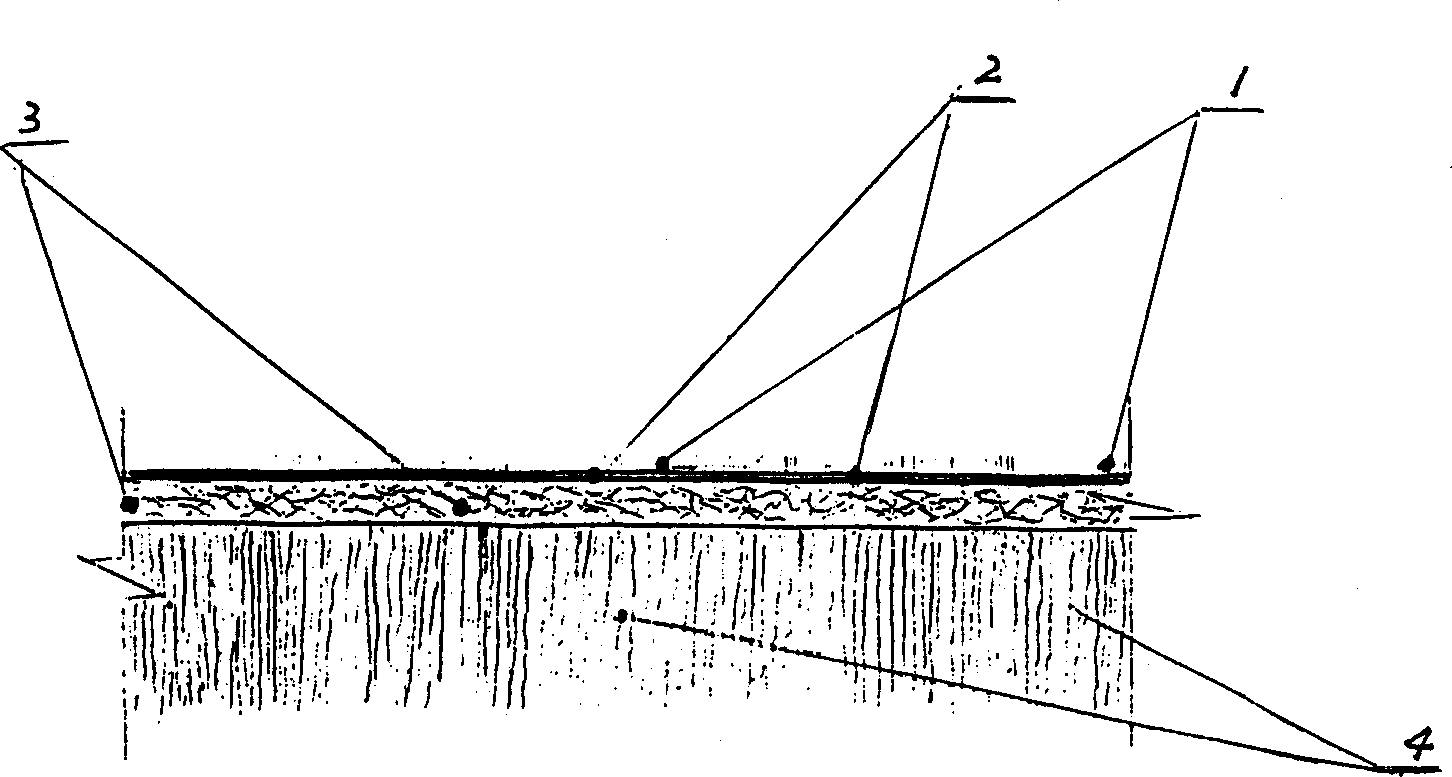

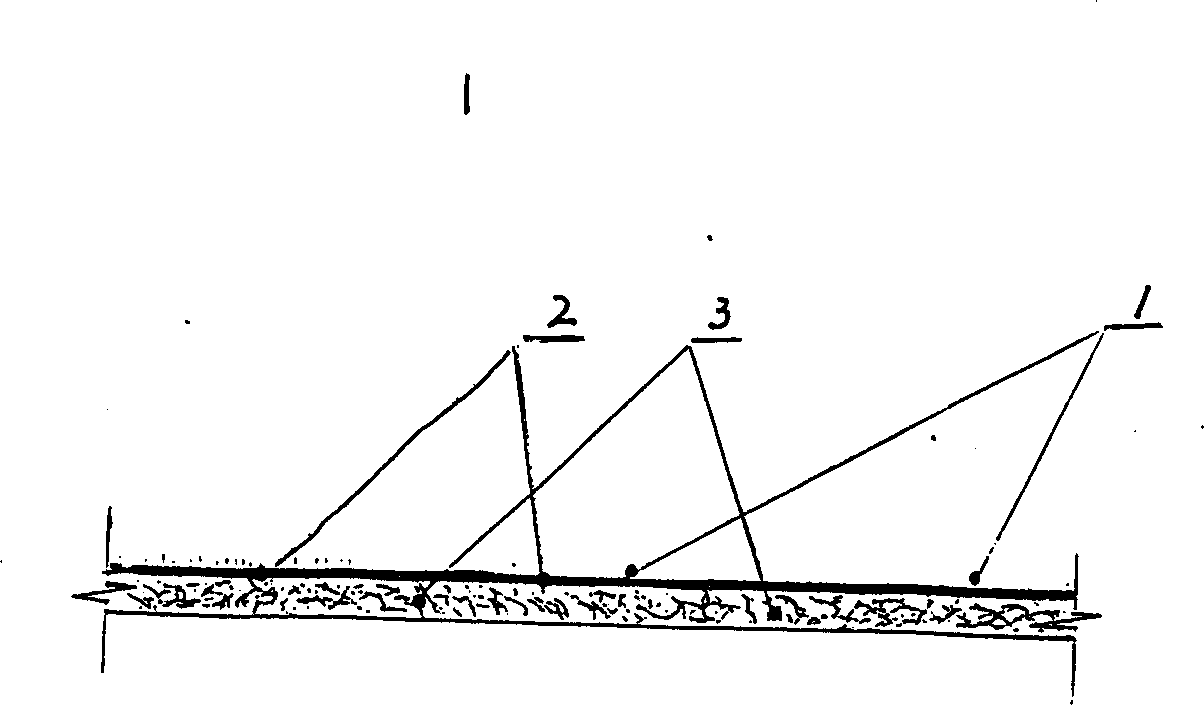

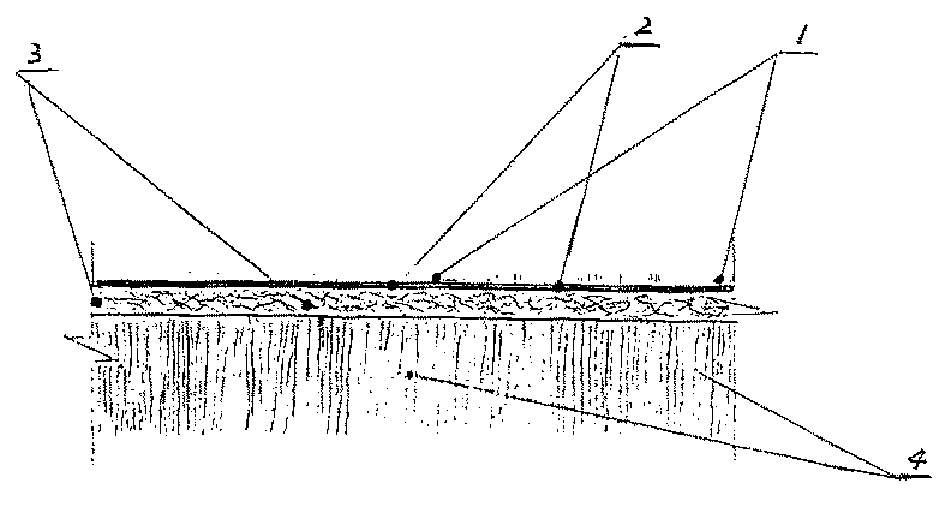

Forming in one time and spreadig technology of regenerated leather

The invention discloses a method of moulding and matting of the regenerative leather. The process is grinding, sheeting, drying, polishing and knurling and obtaining the product. The invention saves the process of getting rid of the feather and changes the existing base-making process into the direct sheet-making process and thus saves the process of sheet-making. At the same time, adding the fibre or non-fibre or fiber / non-fibre products to strengthen the intensity of the regenerative leather over 1.18mX1.68m for sofa of two (three) people.

Owner:吴端明

Production process of regenerated leather

InactiveCN107586895ACraftsmanship is softSimple preparation processSpecial leathers manufactureLeather surface mechanical treatmentFiberEmulsion

The invention discloses a production process of regenerated leather, wherein the regenerated leather is obtained by processes of crushing, fine grinding, material mixing, slurry holding, self draining, dehydration, drying, edge cutting, polishing, ironing and rolling. The invention relates to the production process of the regenerated leather; in the process of material mixing, leather fibers, an external crosslinking cationic organic silicon modified acrylate resin emulsion, a hand feeling agent, a rosin saponification liquid, aluminum sulfate and a dehydrating agent are put into a stirring barrel and are stirred uniformly to form slurry, and after slurry holding, full dehydration is performed so as to ensure that the obtained regenerated leather has soft hand feeling and high leather imitation degree, removed water can be reused, and the cost is saved. The production process of the regenerated leather is simple in process and low in cost, and the prepared regenerated leather has softhand feeling and high leather imitation degree.

Owner:福建省永建皮革科技股份有限公司

Waterproof leather prepared via polymerization deposition of low-temperature plasmas and preparation method of waterproof leather

InactiveCN103468835BKeep leatherGuaranteed hygienic performanceSpecial leathers manufactureFiberPolymer science

The invention discloses waterproof leather prepared via polymerization deposition of low-temperature plasmas and a preparation method of the waterproof leather. The method comprises the following steps: vaporizing siloxane monomers or crylic acid monomers or acrylate monomers or fluorinated acrylate monomers or fluorosilane monomers under the vacuum degree of 25Pa to 45Pa at the temperature of 25 DEG C to 50 DEG C; then adding the vaporized monomers into plasma reaction equipment according to a certain flow and reacting for 1 to 25 minutes under the discharge power within 0.15W / cm<2> to 1.5W / cm<2>; and depositing the monomers on the leather in the plasma reaction equipment, wherein the thickness of a waterproof membrane deposited on the surface of the leather in a polymerization manner is in a micron level or below the micron level, the static contact angle of the waterproof membrane is within 136 DEG to 155 DEG and the rolling angle of the waterproof membrane is within 7 DEG to 22 DEG, and stagger collagen fibers can be seen clearly by observing through a scanning electron microscope. The method is simple in treatment process, short in time, high in efficiency and low in energy consumption. The obtained waterproof membrane is thin, and not only can maintain the real leather feeling of the surfaces of stone washed leathers, suede leathers, double-purpose leathers and the like but also can maintain the sanitation performance of nature leathers.

Owner:SICHUAN UNIV

Forming in one time and spreadig technology of regenerated leather

InactiveCN1323172CCutting costsReduce operating costsSpecial leathers manufactureFiberProcess engineering

The invention discloses a method of moulding and matting of the regenerative leather. The process is grinding, sheeting, drying, polishing and knurling and obtaining the product. The invention saves the process of getting rid of the feather and changes the existing base-making process into the direct sheet-making process and thus saves the process of sheet-making. At the same time, adding the fibre or non-fibre or fiber / non-fibre products to strengthen the intensity of the regenerative leather over 1.18mX1.68m for sofa of two (three) people.

Owner:吴端明

A kind of preparation method and equipment of far-infrared material

InactiveCN103463739BEnhanced far-infrared functionWith far infrared health care functionCosmetic preparationsToilet preparationsEmissivityPhysical chemistry

The invention relates to the technical field of material manufacturing and particularly relates to a preparation method for a far-infrared material and a device. The preparation method includes steps of: S1: carrying out cooling and refrigeration treatment on a base material and keeping for a period of time t0 after a lowest temperature T0 is achieved; carrying out temperature-rising treatment on the refrigerated base material and carrying out polarization treatment in a temperature-rising period; S3: stopping the temperature-rising treatment and the polarization treatment, and naturally cooling the material to a normal temperature. The method is capable of greatly improving normal emittance of far-infrared rays, with a wavelength of 4 mum-16 mum, released by a common material, so that the normal emittance is approximate to or equal to a standard for the far-infrared material.

Owner:李旺菊 +1

Control method for synchronized fabric circulation in conveyor drive fabric dyeing machine

ActiveUS9873967B2Smooth circulationOperation of the machine is automatizedLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor treatment of propelled fabricsEngineeringVelocity controller

Disclosed is a control method for synchronized fabric circulation in a conveyer drive fabric dyeing machine. During a dyeing process of fabric, the fabric is driven by a fabric guide to move in a circulating manner and the time period for a cycle of circulation is set in consistency with the time period that a conveyor moving from a rear end to a front end so as to achieve synchronization that makes the circulation smooth. The control method is performed with a computer or a PLC control unit that is supplied with fabric length data or fabric weight data and fabric unit weight data and, based on such data, performs an automatic operation of computation and supply of a signal to speed controllers of the fabric guide motor and the conveyor motor to set the speeds thereof at a predetermined ratio with respect to each other for synchronized operations.

Owner:CHANG

Producing method for stretch-proof leather

ActiveCN103498014BImprove tensile propertiesAvoid deformationSpecial leathers manufactureWaxAcrylic resin

The invention relates to the technical field of leather production, in particular to a producing method for stretch-proof leather. The producing method comprises the sequential steps of taking soft leather materials, firstly coating the soft leather materials, drying the soft leather materials in a suspension mode, polishing the soft leather materials, lustering the soft leather materials and spraying color on the soft leather materials. Thus, the stretch-proof leather can be manufactured. In the first coat step, burned black wax and soft casein acrylic resin are dissolved into water to carry out roller coating treatment. In the polishing step, a polishing machine is used for polishing the soft leather materials. In the lustering step, a tumbling mill is used for lustering the soft leather materials. The stretch-proof leather obtained in the producing method is strong in stretch resistance and not prone to deforming in a using process.

Owner:漳州香洲皮革有限公司

A kind of leather mat patch processing method

ActiveCN113637809BNatural textureBeautiful textureSpecial leathers manufactureSpecial leather manufactureFiberPolymer science

The invention specifically discloses a method for processing cowhide mat patches, which includes the following steps: selecting leather materials, removing redundant fibers and hairs on the reverse side of cowhide, making and coloring process, mold opening and plate making and stamping forming, electric laser perforation, and mold Forming, sheeting, edge trimming, patching, precision routing, full edge wrapping of finished mats, trimming and shaping, flattening, and light emitting. The finished cowhide mat produced by the method of the invention has natural, beautiful, smooth, delicate, bright, good luster, good hand feeling, good air permeability, durable, can be flattened twice, is easy to take care of, and has the texture reproduced by genuine leather and texture. The cowhide mat patch is made of raw buffalo leather with the same material as the cowhide mat body, and the patterns and logo patterns are printed on the cowhide mat patch separately, which improves the quality and grade of the finished cowhide mat.

Owner:CHONGQING LONGFA LEATHER PROD

Dry artificial leather making machine

ActiveCN102011323BLong-term useAvoid noiseLiquid surface applicatorsLamination ancillary operationsEngineeringTransmission equipment

The invention provides a dry artificial leather making machine. The machine comprises a frame and a heat wheel mechanism arranged on the frame, wherein the heat wheel mechanism comprises a scraper mechanism, a heat wheel capable of rotating and an abutted wheel; the heat wheel is provided with a heat supply device; the outer circumferential surface of the heat wheel is a flat working surface; theworking surface of the scraper mechanism corresponding to the heat wheel is arranged above the heat wheel; and the working surface of the abutted wheel corresponding to the heat wheel is arranged at the lateral side of the heat wheel, and is arranged in front of the scraper mechanism on the rotating direction of the heat wheel. In the invention, scraper equipment, heat equipment, transmission equipment, joint equipment and molding equipment in the traditional process are ingeniously combined to the heat wheel mechanism, the heat wheel is shared in scraping, heating, transmitting, jointing andmolding processes, so that scraping, heating, transmitting, jointing and molding steps on paint and a matrix belt can be completed when the paint and the matrix belt pass through the heat wheel mechanism. The dry artificial leather making machine has short production line, and does not require release paper consumption in the producing process.

Owner:东莞市金银丰机械实业有限公司

Leather with creases

InactiveCN102559946ANatural fashion wrinkled effectPlay an elastic roleSpecial leathers manufactureFiberChemistry

The invention discloses leather with creases. The leather is characterized in that: polyurethane fiber filaments are sandwiched in the leather in the leather making process.

Owner:QINGDAO HENGDA CO LTD +2

Combination clothing from fabric and fur and production method thereof

The invention relates to a method for manufacturing wet-cleanable combination clothing of fabric and fur. In the method, the fur pelt (2) of the fur is moistened with an organic fluorochemical, and the pelt is dried and / or treated with heat, so that a permanent, microscopically thin water-repellent layer is formed onto the surface of the collagen fibre of the pelt. The fur hair (3) of the fur is also moistened with an organic fluorochemical and dried by using heat treatment, so that a permanent, microscopically thin water-repellent layer is formed onto the surface of the keratin fibre of the fur hair. Finally, the fur part (1), which has been processed to endure wet cleaning, is fastened to the wet-cleanable fabric part (5) of the clothing either fixedly or detachably. The invention also relates to the repeatedly wet-cleanable combination clothing of fabric and fur according to the introduction of claim (9).

Owner:皮尔乔·科特拉纳恩

A method for compounding leather on the surface of automobile door interior parts using a binder containing modified diatomite

ActiveCN103171232BImprove efficiencyHigh bonding strengthMineral oil hydrocarbon copolymer adhesivesLamination ancillary operationsEpoxyMicrocrystalline wax

The invention provides a method for compositing leather on the surface of a bonder used by car door interior parts and containing modified diatomite. The method is characterized by spraying the bonder on the interior part surface needing leather compositing and then composting leather, wherein the bonder is prepared from the following raw materials in parts by weight: 57-62 parts of EVA (ethylene-vinyl acetate copolymer), 8-12 parts of epoxy resin, 12-16 parts of C5 petroleum resin, 3-5 parts of microcrystalline wax, 0.5-1 part of WPP type polypropylene wax, 1-2 parts of dimethyl carbonate, 2-4 parts of nanometer celestite powder, 7-10 parts of modified diatomite, 2-3 parts of modified rice hull ash, 1.3-1.6 parts of a silane coupling agent KH560, 0.2-0.4 part of ferrocene, 0.3-0.6 part of n-butyl methacrylate, 0.4-0.6 part of epoxidized soybean oil, 0.4-0.6 part of an antioxidant 264, 0.2-0.4 part of an antioxidant 616 and 0.2-0.4 part of an antioxidant 333. The method has the beneficial effects that the method adopts a molding process, achieves automatic trimming and is high in efficiency; and meanwhile, the specific bonder is adopted, has high bonding strength, is flat and can not bubble after being used for a long time.

Owner:TAIZHOU JINSONG

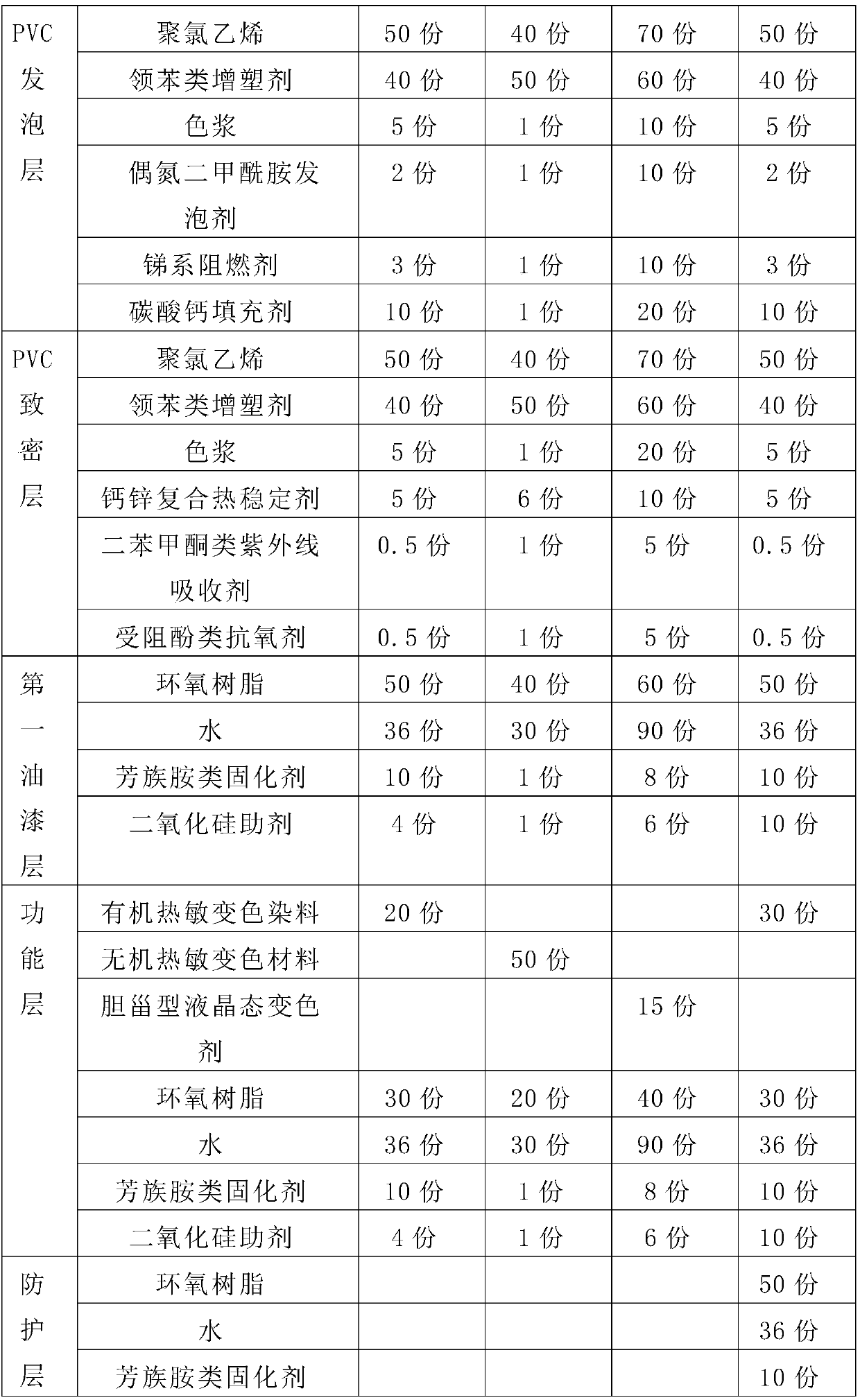

Leather capable of changing surface color with temperature and preparation method thereof

PendingCN110863362AAvoid the risk of uneven thickness or even damageEnsure integrityLiquid crystal compositionsLiquid surface applicatorsCar seatPolymer science

Owner:BENECKE CHANGSHUN AUTO TRIMZHANGJIAGANG

Splicing device for fur processing

InactiveCN111763779AEasy to storeEasy to displaySkins/hides/leather/fur manufacturing apparatusSpecial leathers manufactureGear driveScrew thread

The invention provides a splicing device for fur processing. The splicing device comprises a splicing table, a storage chamber is formed inside the splicing table, a threaded rod is arranged inside the storage chamber, the right end of the threaded rod is connected with the inner wall of the storage chamber through a bearing seat, a limiting block is mounted in the middle of the threaded rod, andthe left end of the threaded rod penetrates through the limiting block and a storage table and is provided with a rotating handle. According to the splicing device for fur processing, the rotating handle rotates to make the threaded rod rotate, and threads, on the two sides of the limiting block, of the threaded rod are opposite so that screw blocks can get close to each other or be separated fromeach other, and an extending table is convenient to store or display; a rotating rocker handle rotates to drive a second gear to rotate, so that a first gear drives a first screw rod to rotate, and amoving plate can move up and down; and through second sliding grooves, the moving plate moves smoothly, the height of the extending plate is convenient to adjust, the extending plate is adjusted to the position leveled with the splicing table, the operation area is increased, and using is facilitated.

Owner:孙海侠

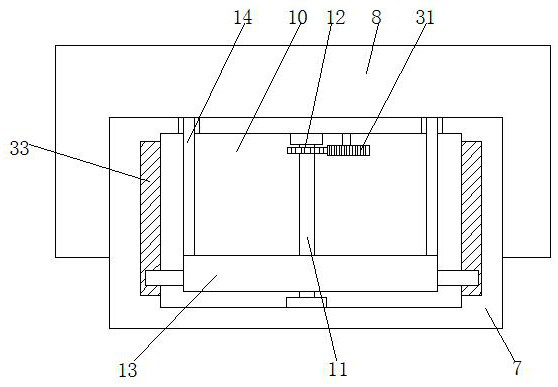

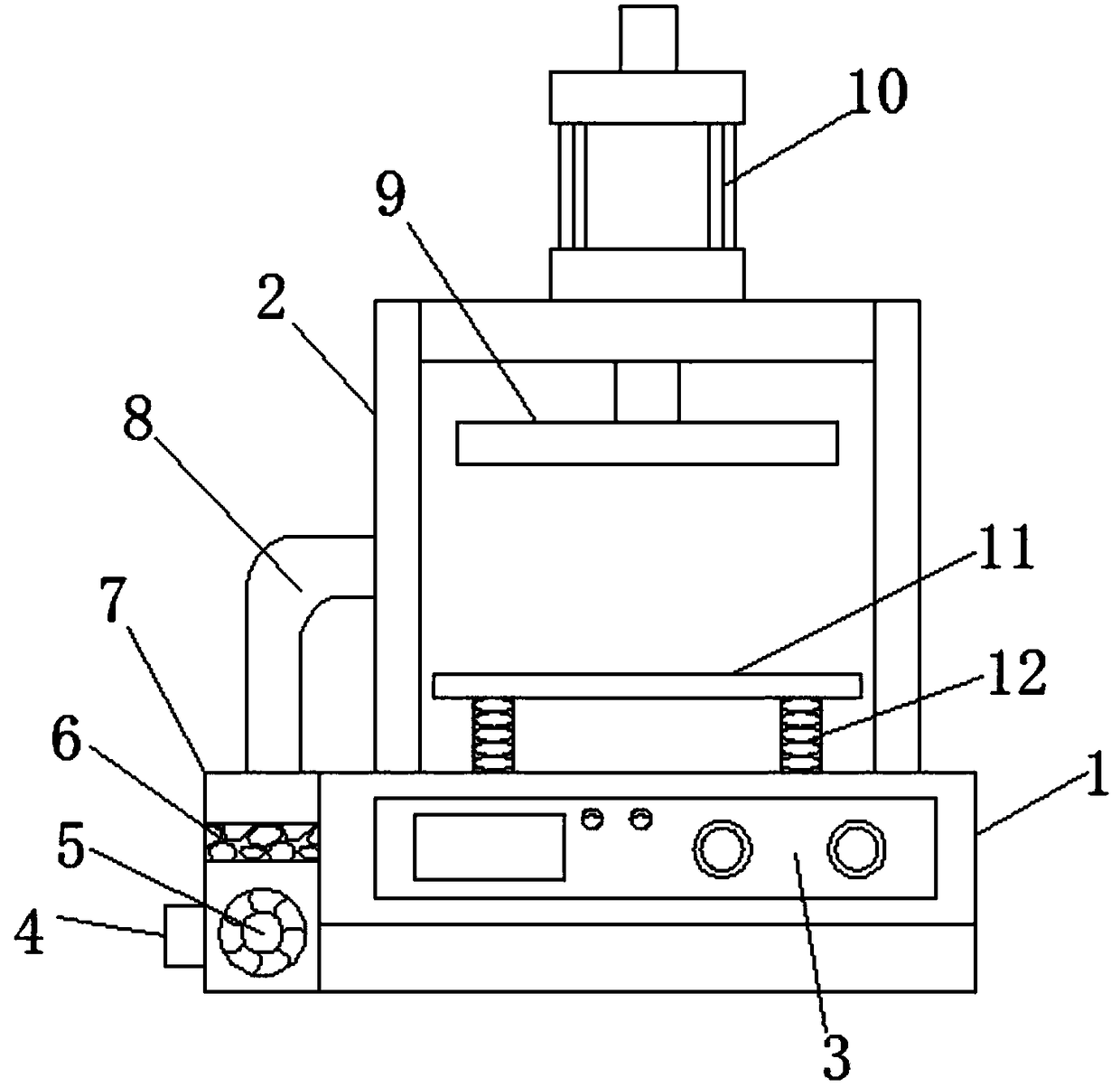

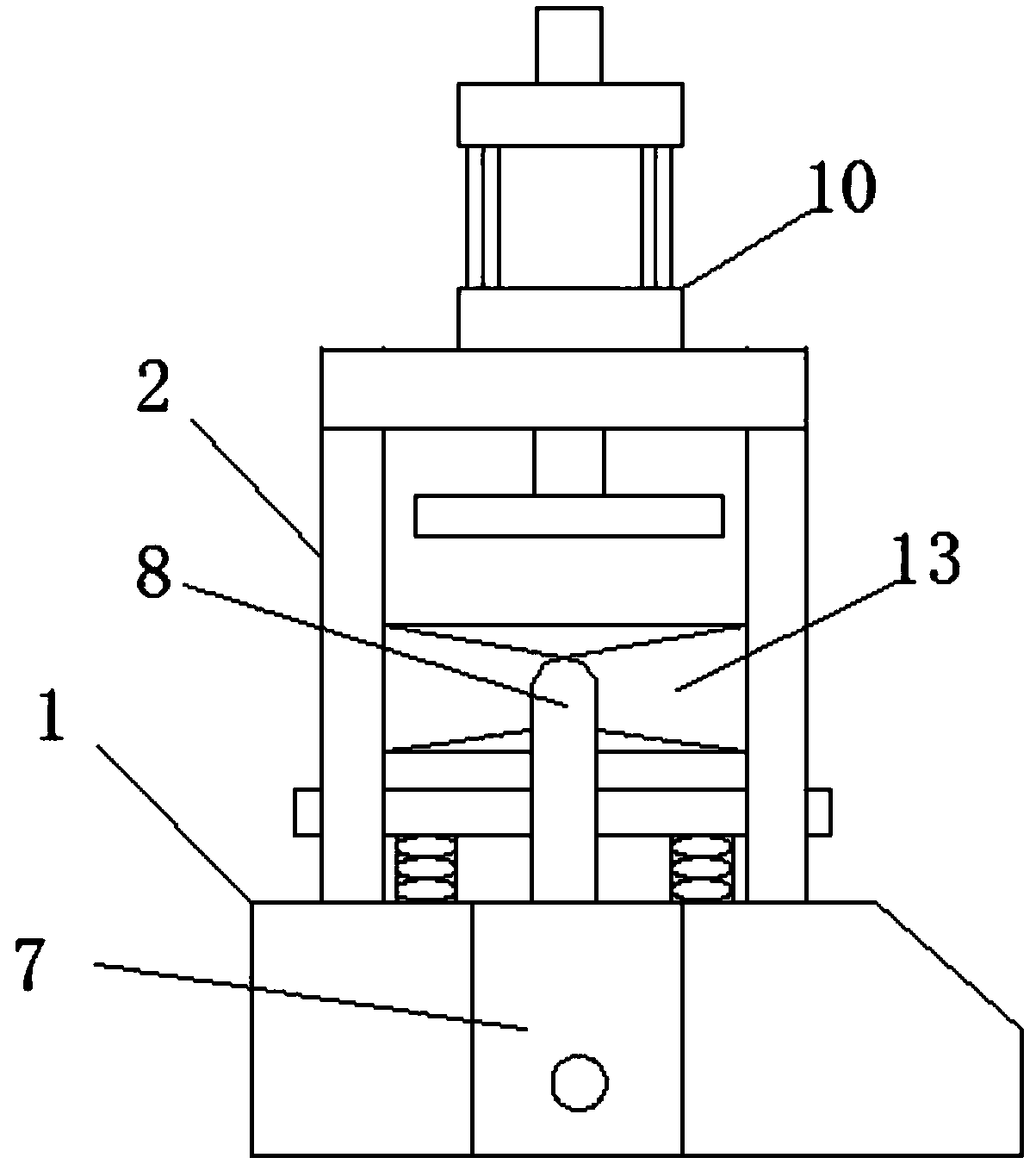

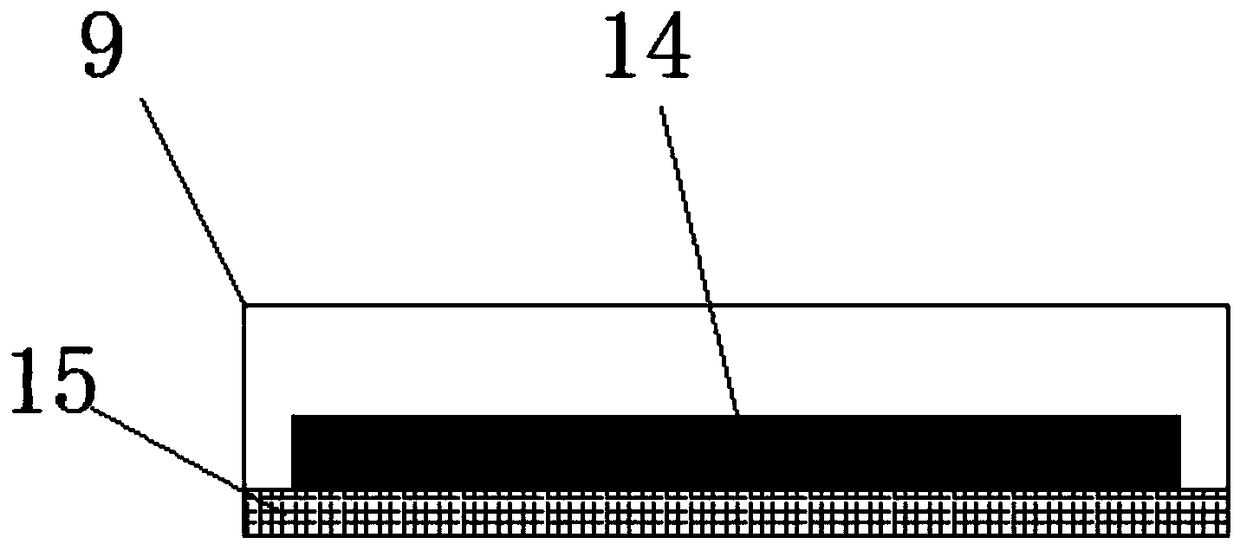

Pressing device for fire resistance sofa leather

PendingCN108179232ASimple structureEasy to processSkins/hides/leather/fur manufacturing apparatusSpecial leathers manufactureHigh volume manufacturingSemi automatic

The invention discloses a pressing device for fire resistance sofa leather. The pressing device for the fire resistance sofa leather comprises a base and supports; the supports are located at the upper and lower ends of the base and the base is fixedly connected with the supports; a control panel is arranged above one side of the base; the upper end of the base is fixedly provided with a spring shock absorber; and the upper end of the spring shock absorber is provided with a workbench, and the workbench is located below the inner sides of the supports. The pressing device for the fire resistance sofa leather is simple in structure, and good in processing effect; a semi-automatic process is adopted instead of traditional manual pressing, not only can the processing efficiency be effectivelyimproves, but also the labor intensity is greatly reduced; a first heating block and a second heating block are installed, not only can the quality of pressing be improved, but also the pressing timeis shortened, so as to improve the working efficiency; and a purifying box is installed, a good purifying effect is achieved, the harmful gas which the sofa leather sends out to cause harm to human body can be effectively avoided, and mass production and using is applicable.

Owner:杭州德洋高分子材料有限公司

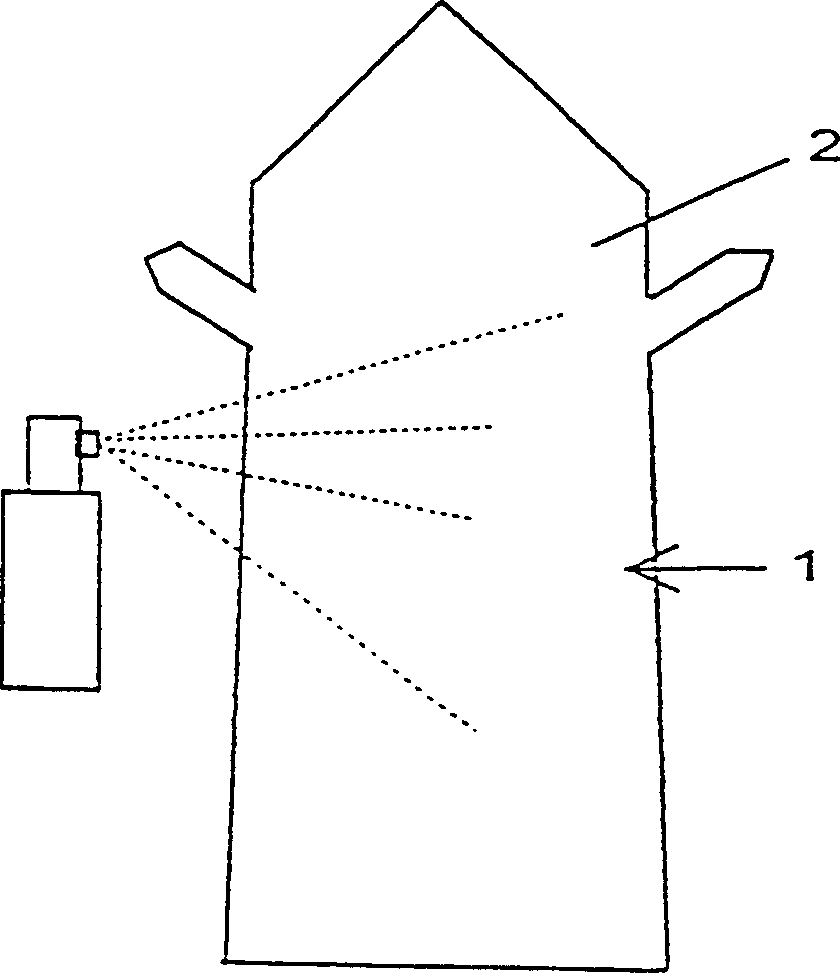

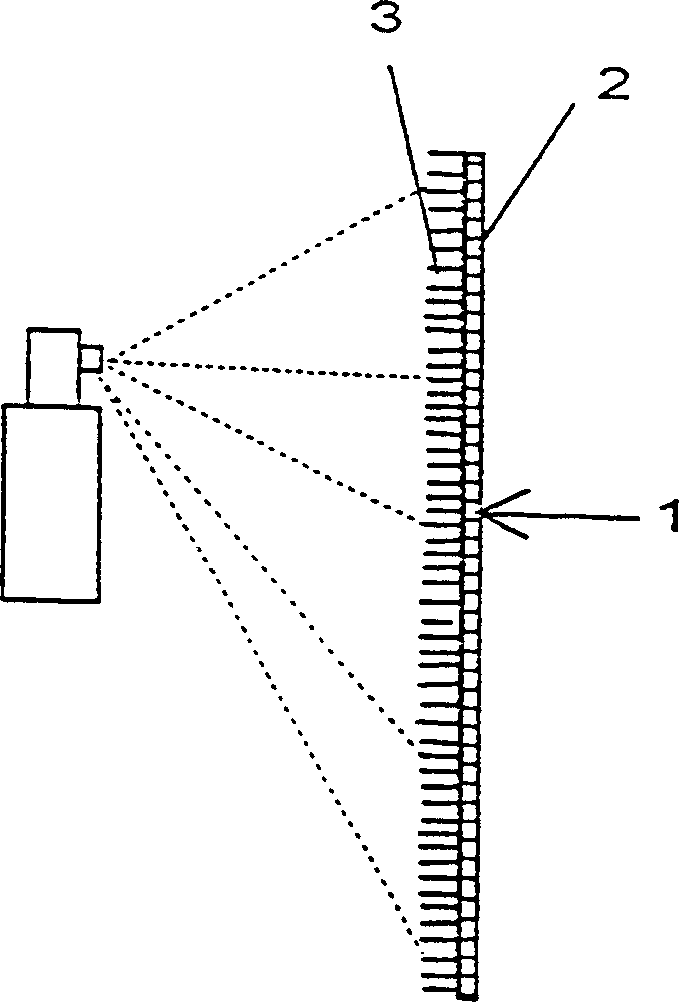

Method for manufacturing colour suede for product

InactiveCN1086423CAvoid Bubbling DefectsOvercome the technical difficulties of shrinkage degeneration in large areasSpecial leathers manufactureFur finishingEngineeringField intensity

The preparation method of furcoat product with colour pile face includes the following steps: selecting more than one kind of pile dyed with basic colour, mixing coloured piles according to a certain proportion to make colour of pile face uniform, and obtaining pre-designed colour. In order to make pile face colour uniform, flying up and screening every monochromatic pile under the condition of same field intensity to make flying-up capability and flying-up rate of all coloured piles uniform when leather surface is flocked, and making the piles flocked on the leather product keep relative verticality, this can be implemented by regulating field intensity, so that it can obtain furcoat product and leather product with predesigned colour.

Owner:陈文典

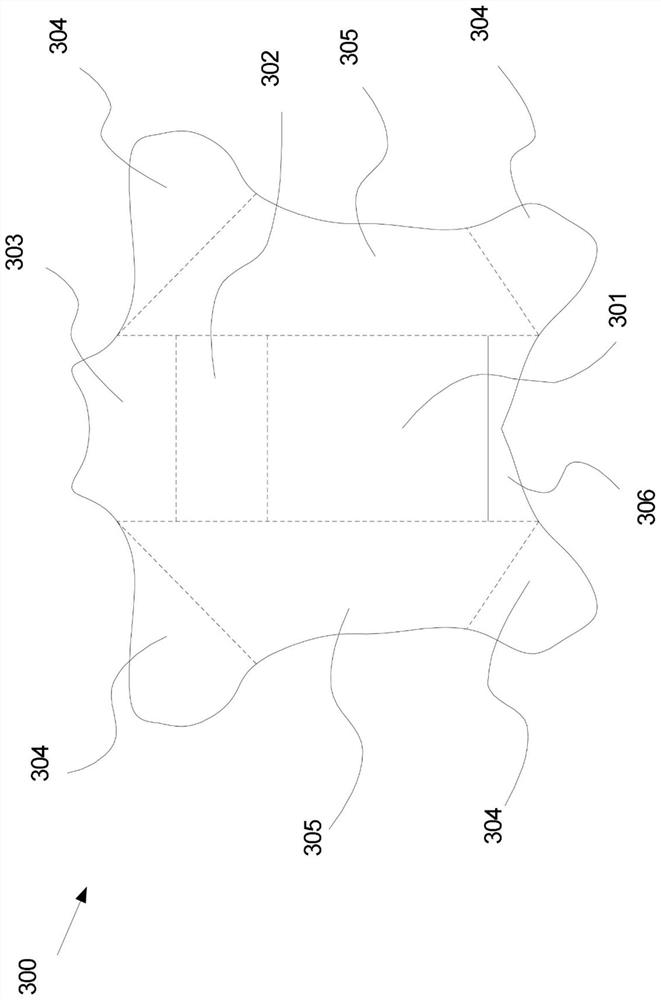

Equipment special for additionally arranging steel wires in strip-shaped leather

ActiveCN113061668ARealize deliveryImplement addLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusHeat sealerStructural engineering

The invention relates to the technical field of leather, in particular to equipment special for additionally arranging steel wires in strip-shaped leather. The equipment special for additionally arranging the steel wires in the strip-shaped leather comprises a mounting frame, wherein a moving device is arranged in the mounting frame and is used for moving a mounting block, a cutting device is arranged on the end wall of the side, far away from the mounting frame, of the mounting block, the cutting device is used for cutting and slitting leather, and the steel wires can be conveniently additionally arranged. The equipment special for additionally arranging the steel wires into the strip-shaped leather can achieve slitting on the leather by means of movement of the cutting device; the steel wires can be conveyed by means of the movement of a steel wire conveying mechanism; by means of movement of the steel wire additionally-arranging mechanism, the steel wires can be additionally arranged in a cut slit of the leather; by means of movement of a sealing device, the cut slit can be flattened and pressed; and by means of movement of a heat sealing mechanism, hot melting sewing of the cut slit can be achieved, and the steel wires and the leather are bonded together.

Owner:东莞市诚远皮革科技有限公司

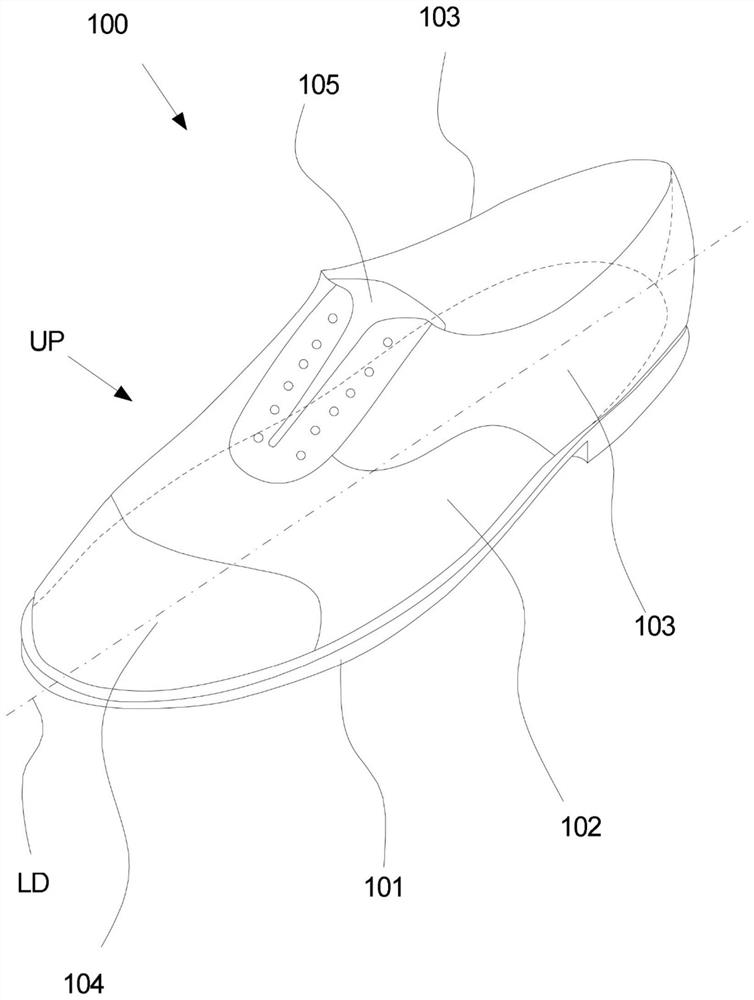

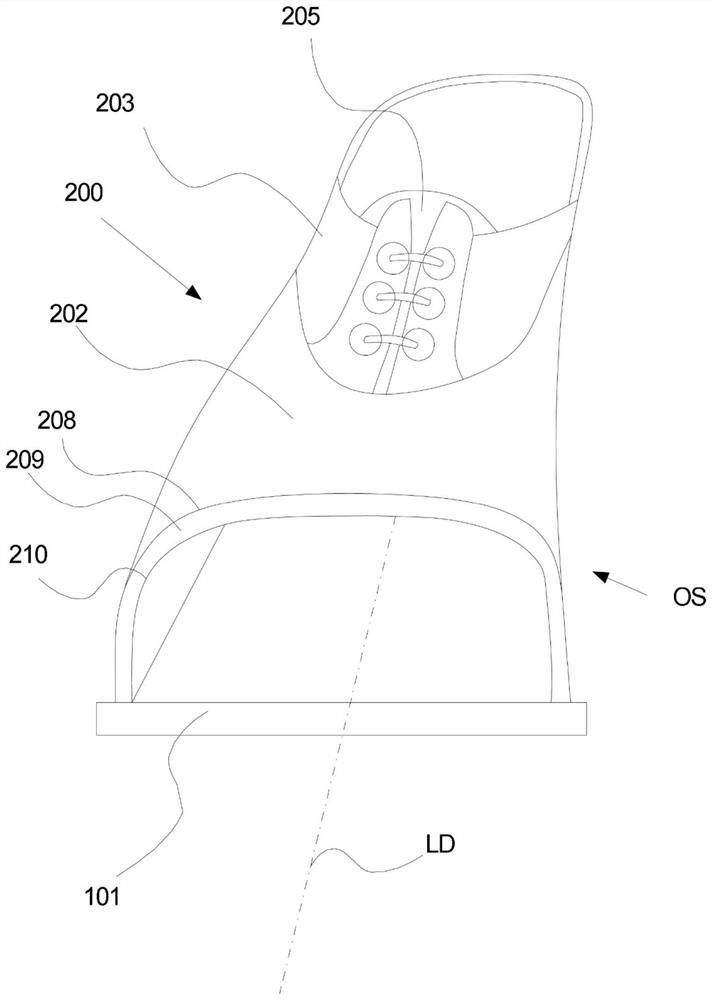

Leather-based footwear

Owner:ECCO SKO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com