Waterproof leather prepared via polymerization deposition of low-temperature plasmas and preparation method of waterproof leather

A low-temperature plasma and plasma technology, which is applied in special leather manufacturing, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather/fur mechanical treatment, etc., can solve the problems affecting the use value, life and Surface beauty and other issues, to achieve the effect of reducing processing procedures and processing costs, low monomer flow rate, and low material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

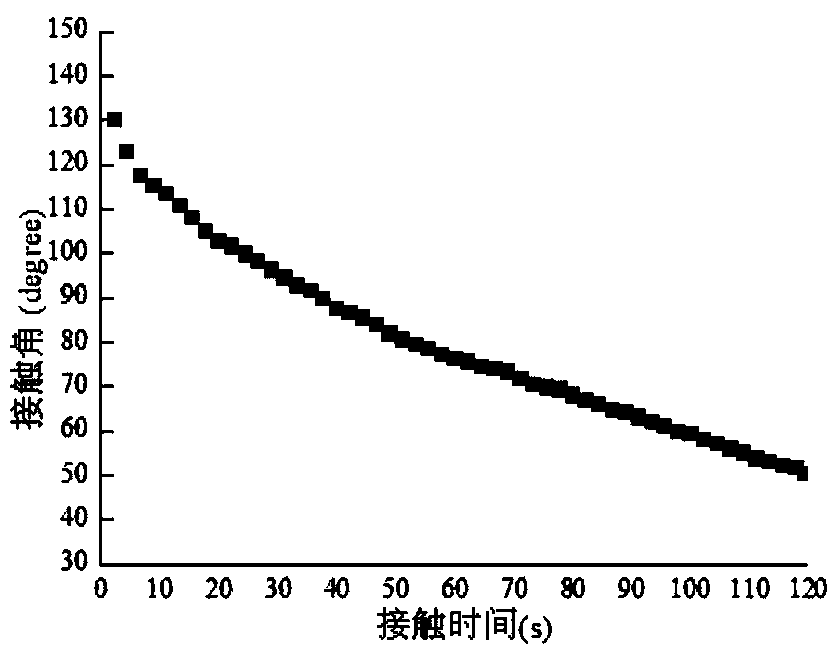

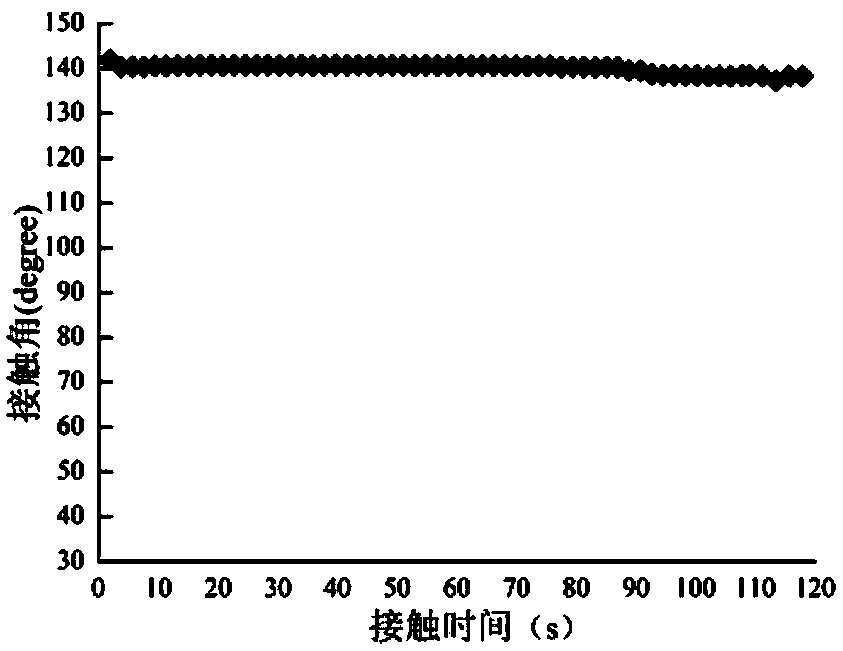

[0037] Put the hexamethylcyclotrisiloxane into the vaporization tank, and then put the nubuck leather with the frosted side up into the reaction chamber of the plasma equipment connected with the vaporization tank; pump the vacuum to 30Pa, and raise the temperature of the vaporization tank at the same time to 30°C, vaporize hexamethylcyclotrisiloxane, and add 7×10 -5 ml / min·cm 2 The flow rate enters the plasma reaction chamber, and then the discharge reaction power is 0.15W / cm 2 Next, continue the discharge reaction for 15 minutes, turn off the plasma discharge electrode, and fill the plasma reaction chamber with air to remove unreacted monomers on the surface of the cowhide nubuck leather.

[0038] The static contact angle of the waterproof cowhide nubuck leather obtained in this embodiment is 141°±1°, and the rolling angle is 15°±2°.

Embodiment 2

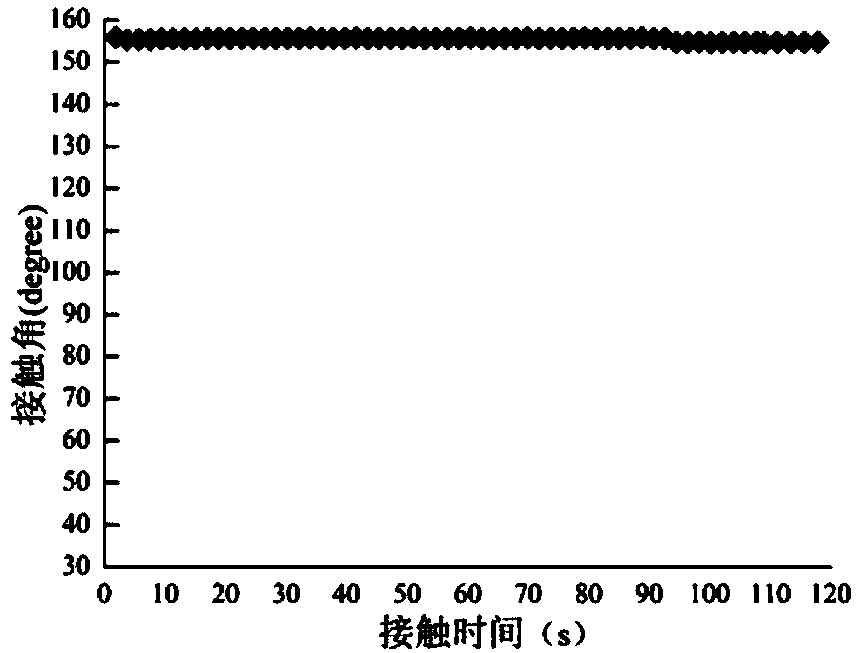

[0040] Put octamethylcyclotetrasiloxane into the vaporization tank, and then put the nubuck cowhide leather with the frosted side up into the reaction chamber of the plasma equipment connected with the vaporization tank; pump the vacuum to 30Pa, and raise the temperature of the vaporization tank at the same time to 30°C, vaporize octamethylcyclotetrasiloxane, and use 8×10 -5 ml / min·cm 2 The flow rate enters the plasma reaction chamber, and then the discharge reaction power is 0.5W / cm 2 Next, continue the discharge reaction for 10 minutes, turn off the plasma discharge electrode, and fill the plasma reaction chamber with air to remove unreacted monomers on the surface of the cowhide nubuck leather.

[0041] The static contact angle of the waterproof cowhide nubuck leather obtained in this embodiment is 155°±2°, and the rolling angle is 8°±2°.

Embodiment 3

[0043] Put decamethylcyclopentasiloxane into the vaporization tank, and then put the pigskin nubuck suede face up into the reaction chamber of the plasma equipment connected to the vaporization tank; vacuumize to 25Pa, and at the same time put the The temperature was raised to 25°C to vaporize the decamethylcyclopentasiloxane, and 1×10 -4 ml / min·cm 2 The flow rate enters the plasma reaction chamber, and then the discharge reaction power is 1W / cm 2 Then, continue the discharge reaction for 18 minutes, turn off the plasma discharge electrode, and fill the plasma reaction chamber with air to remove unreacted monomers on the surface of pigskin nubuck leather.

[0044] The static contact angle of the waterproof pigskin nubuck leather obtained in this embodiment is 145°±3°, and the rolling angle is 15°±2°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com