Patents

Literature

287 results about "Plasma polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

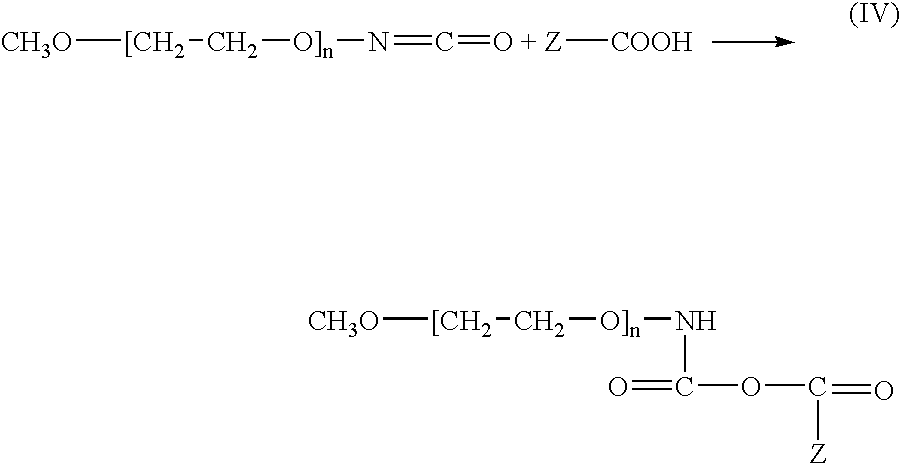

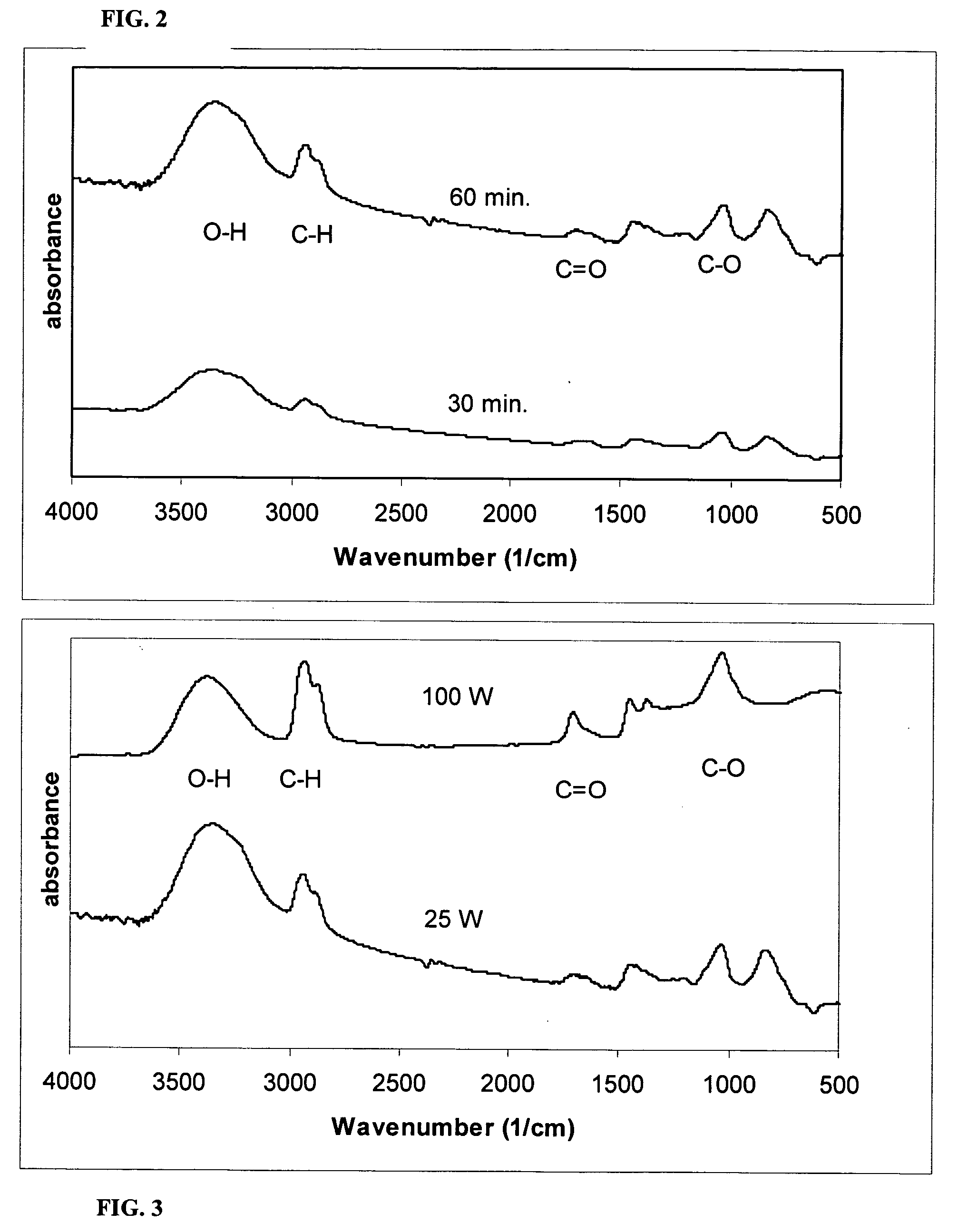

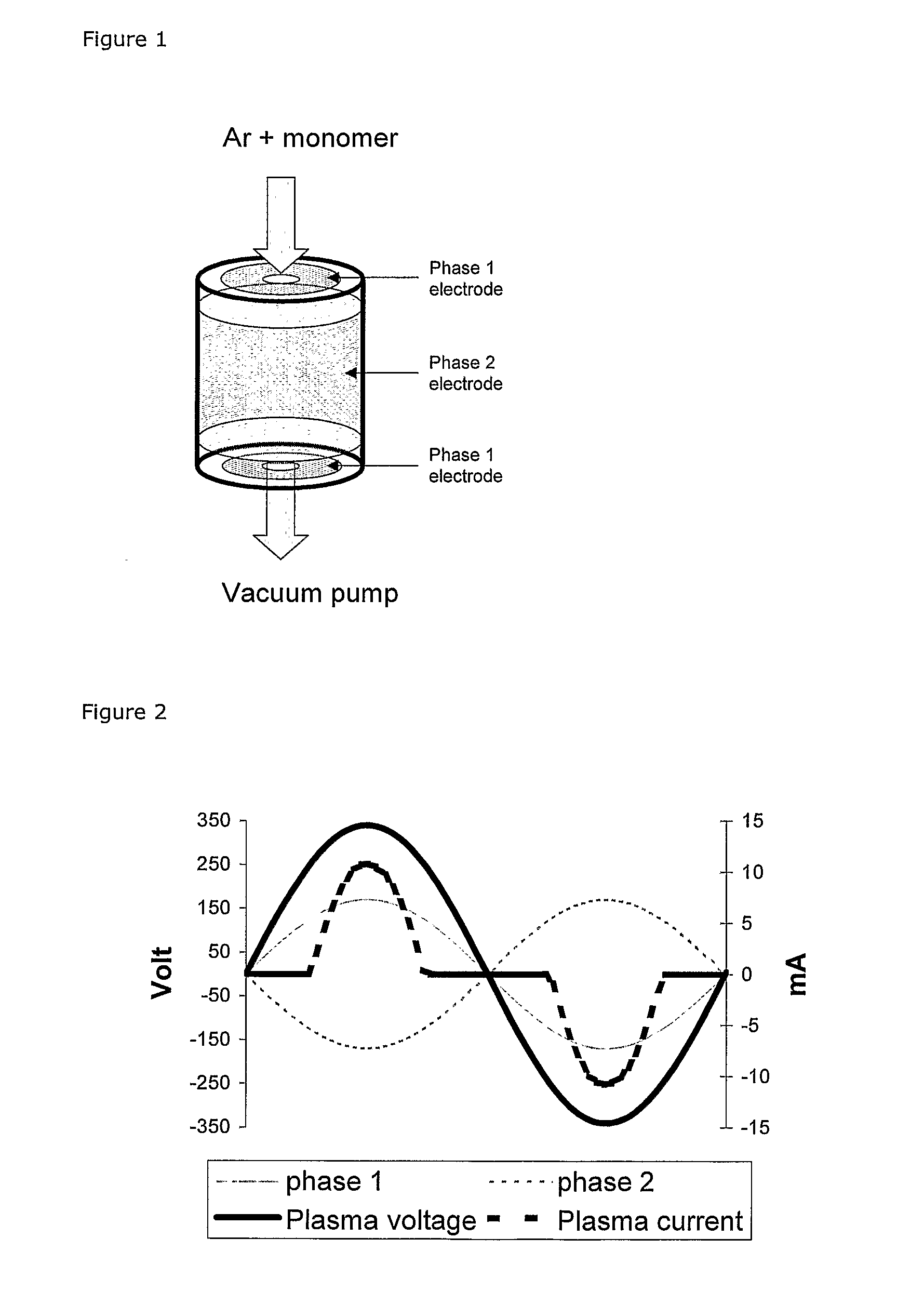

Plasma polymerization (or glow discharge polymerization) uses plasma sources to generate a gas discharge that provides energy to activate or fragment gaseous or liquid monomer, often containing a vinyl group, in order to initiate polymerization. Polymers formed from this technique are generally highly branched and highly cross-linked, and adhere to solid surfaces well. The biggest advantage to this process is that polymers can be directly attached to a desired surface while the chains are growing, which reduces steps necessary for other coating processes such as grafting. This is very useful for pinhole-free coatings of 100 picometers to 1 micrometre thickness with solvent insoluble polymers.

Method of forming a high transparent carbon film

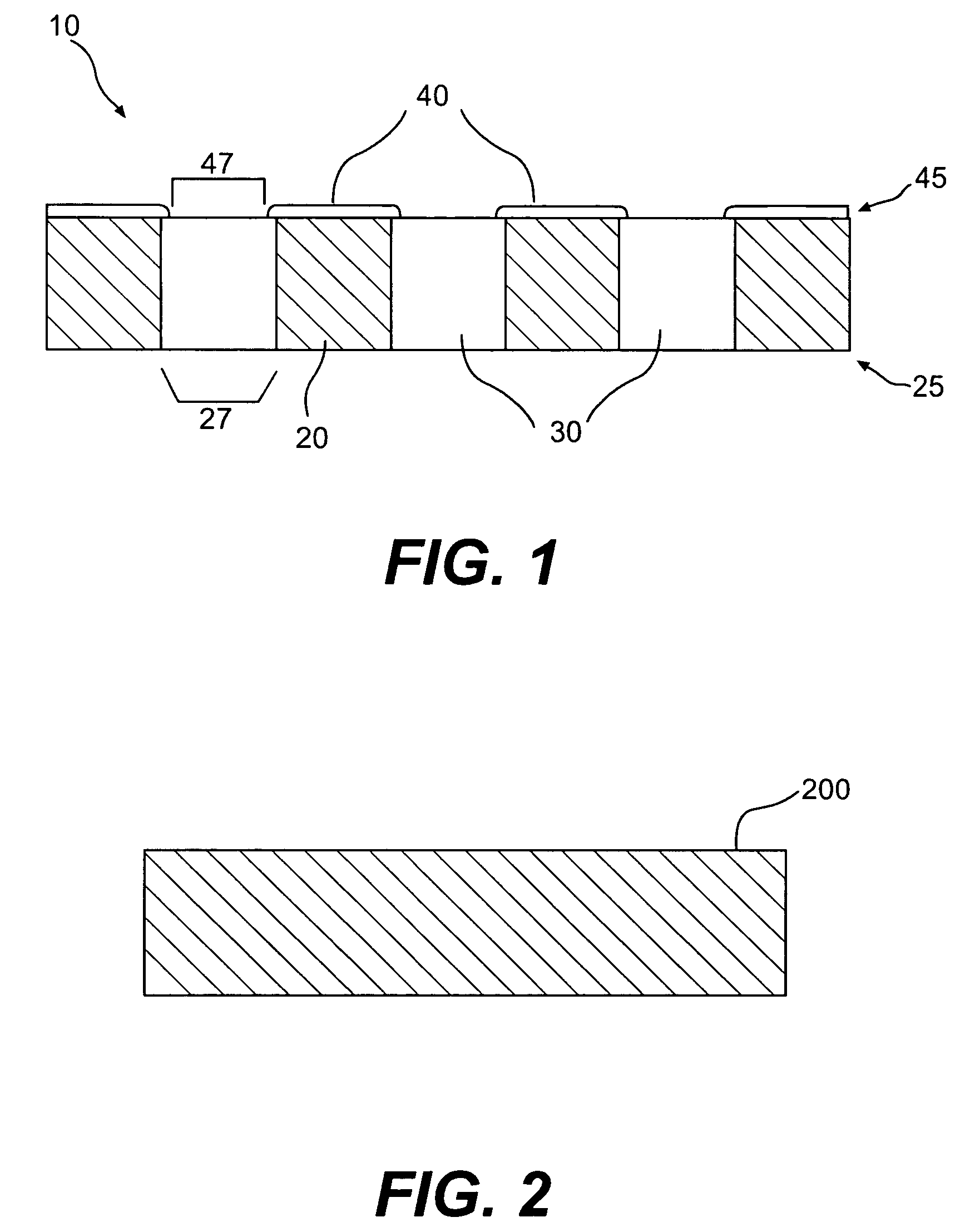

ActiveUS7632549B2Improve featuresRich varietyLiquid surface applicatorsSemiconductor/solid-state device manufacturingCarbon filmProduct gas

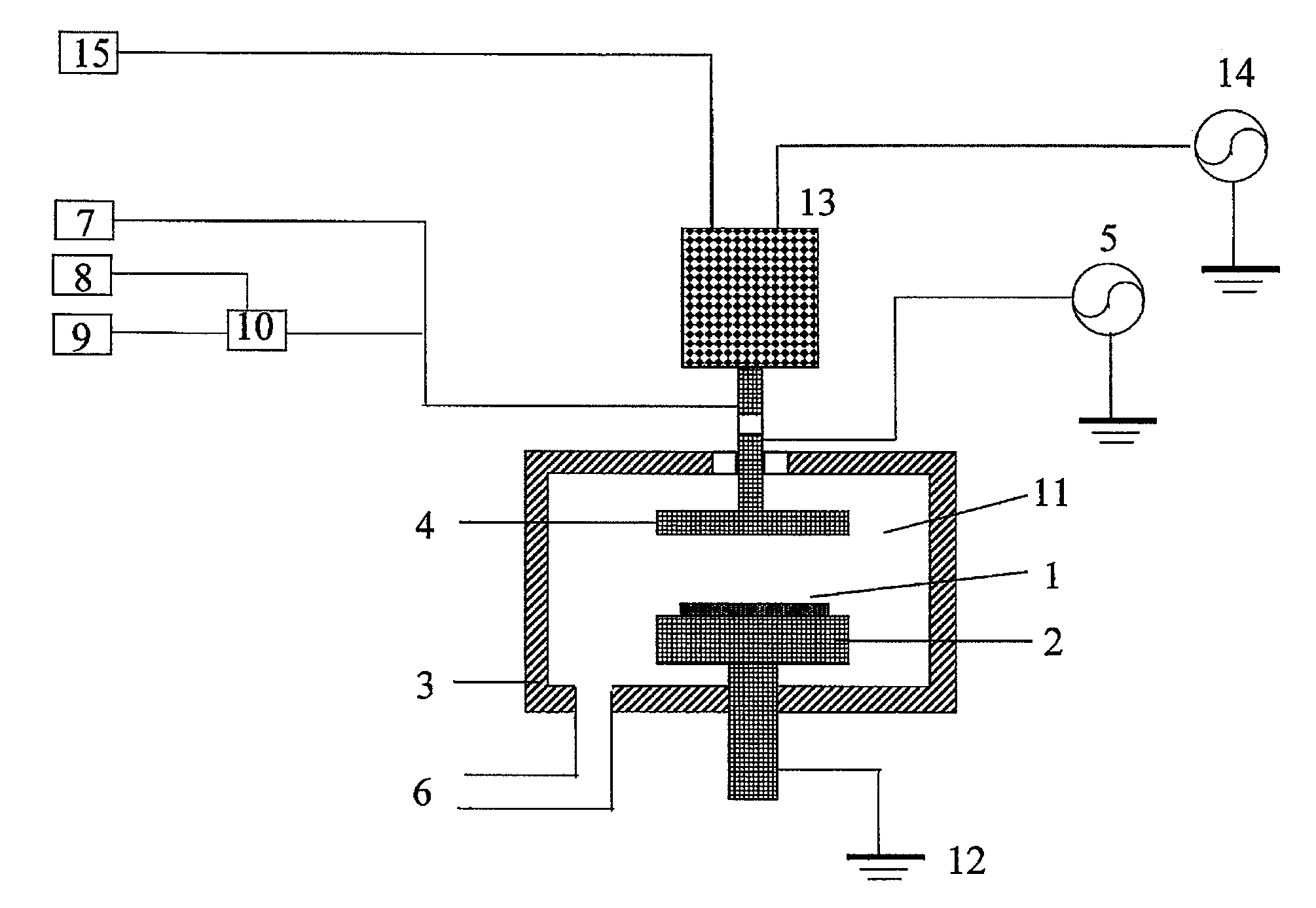

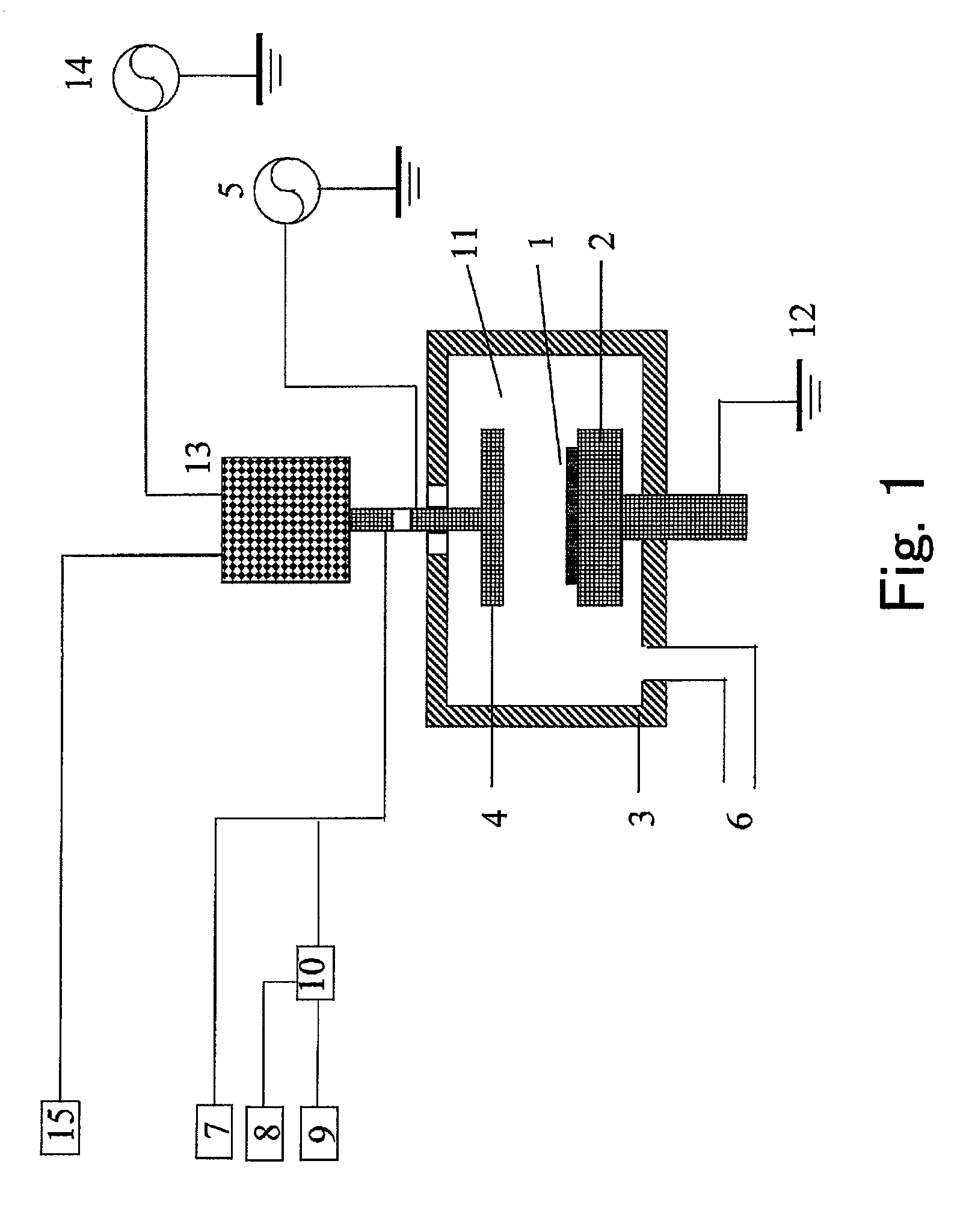

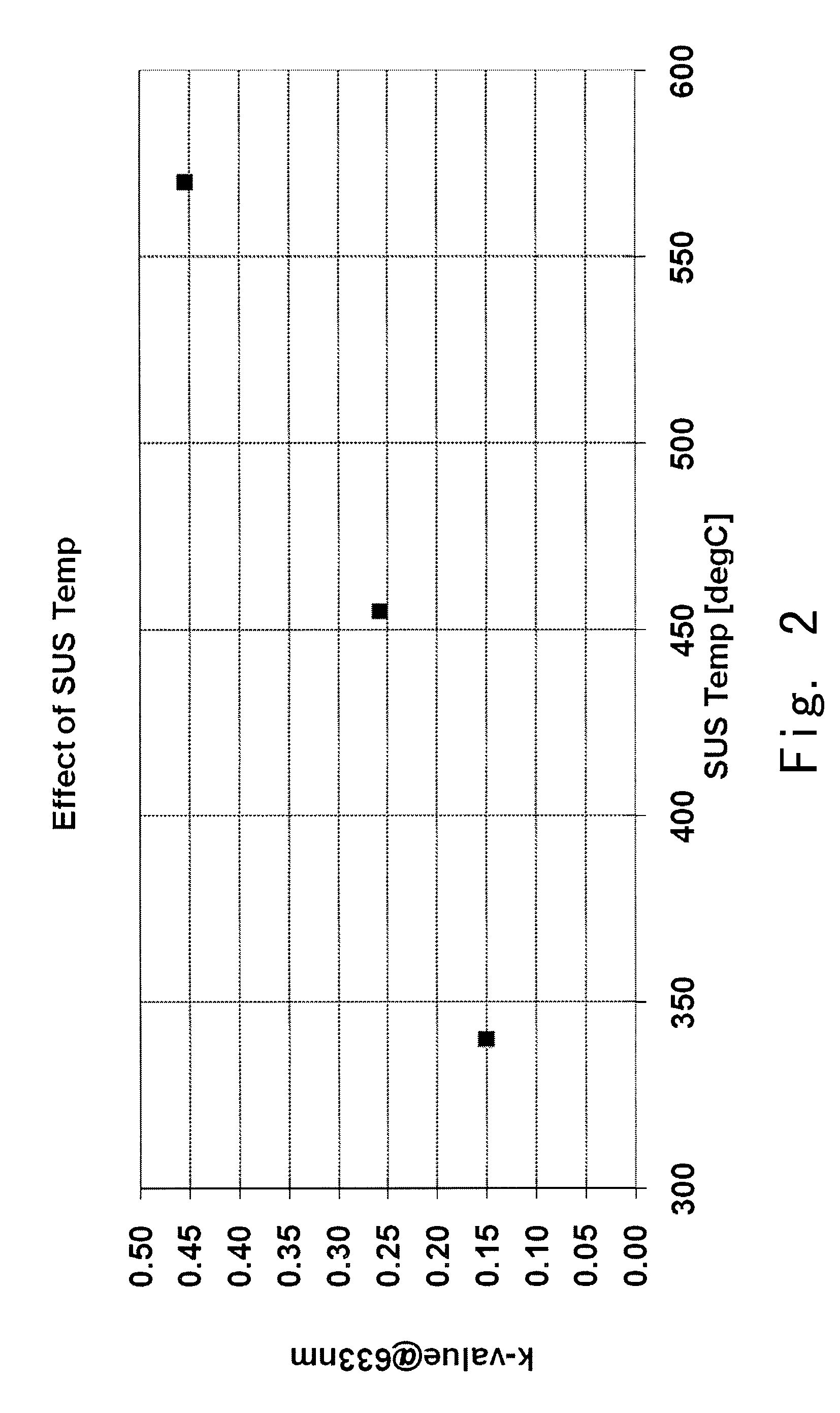

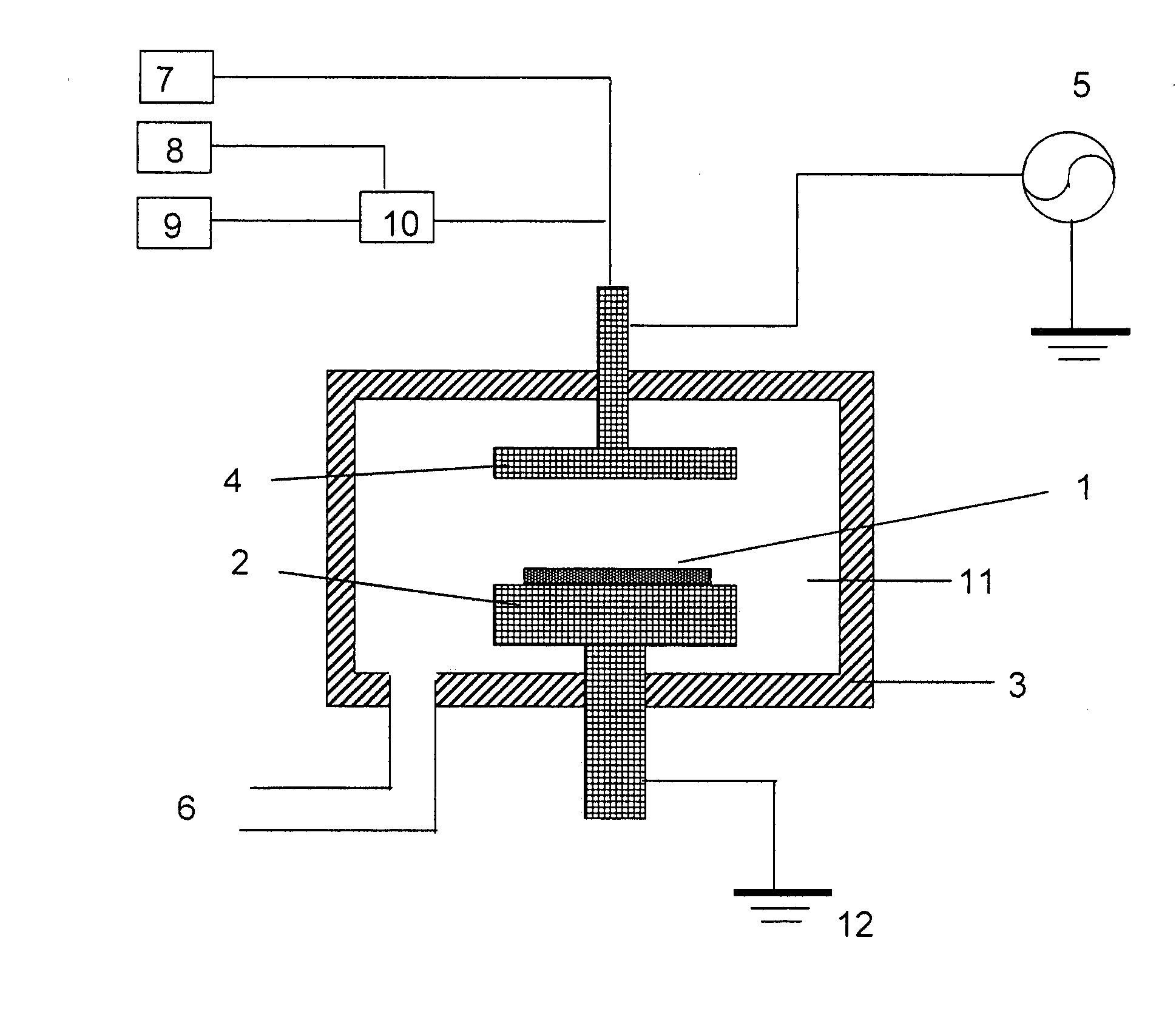

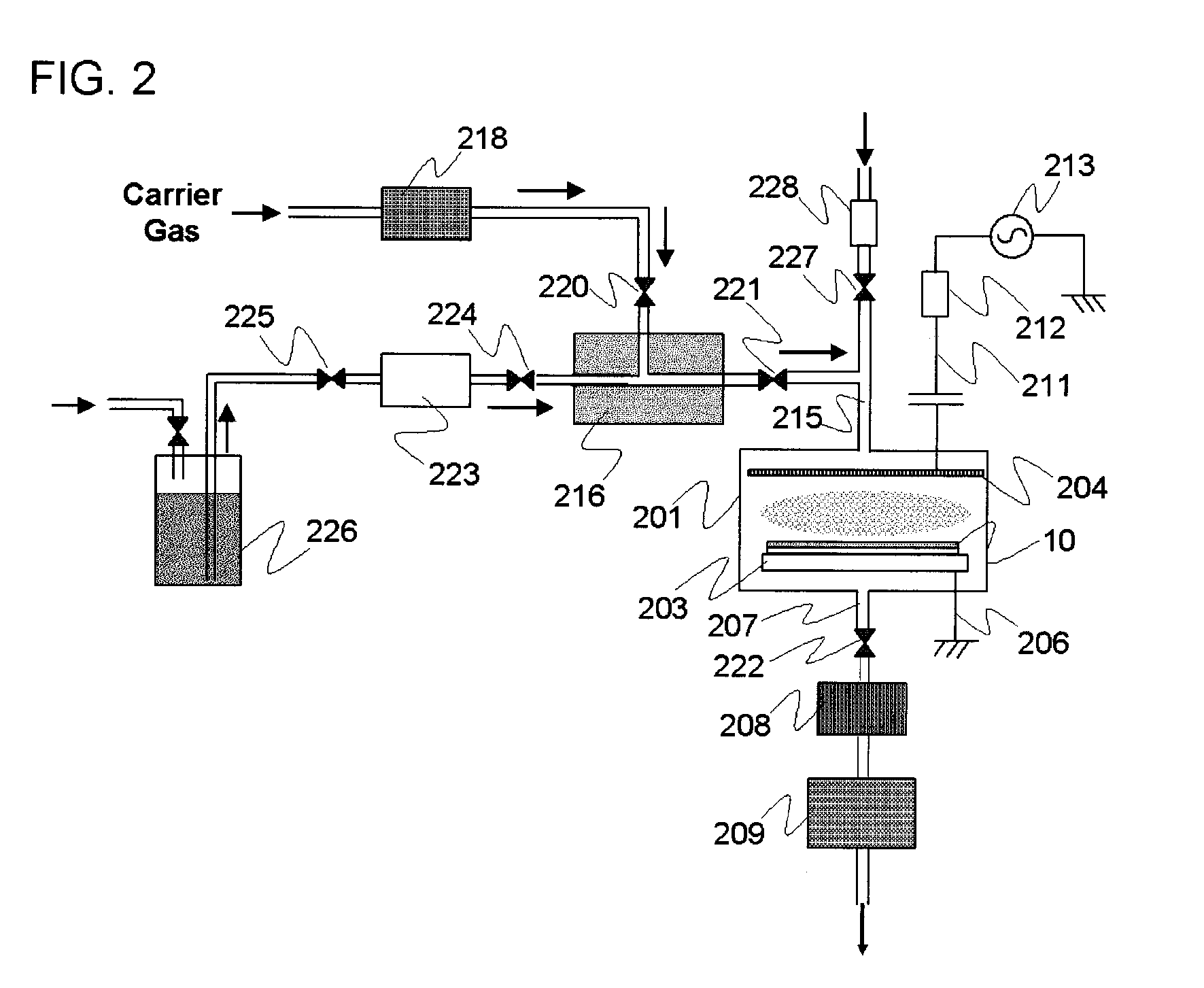

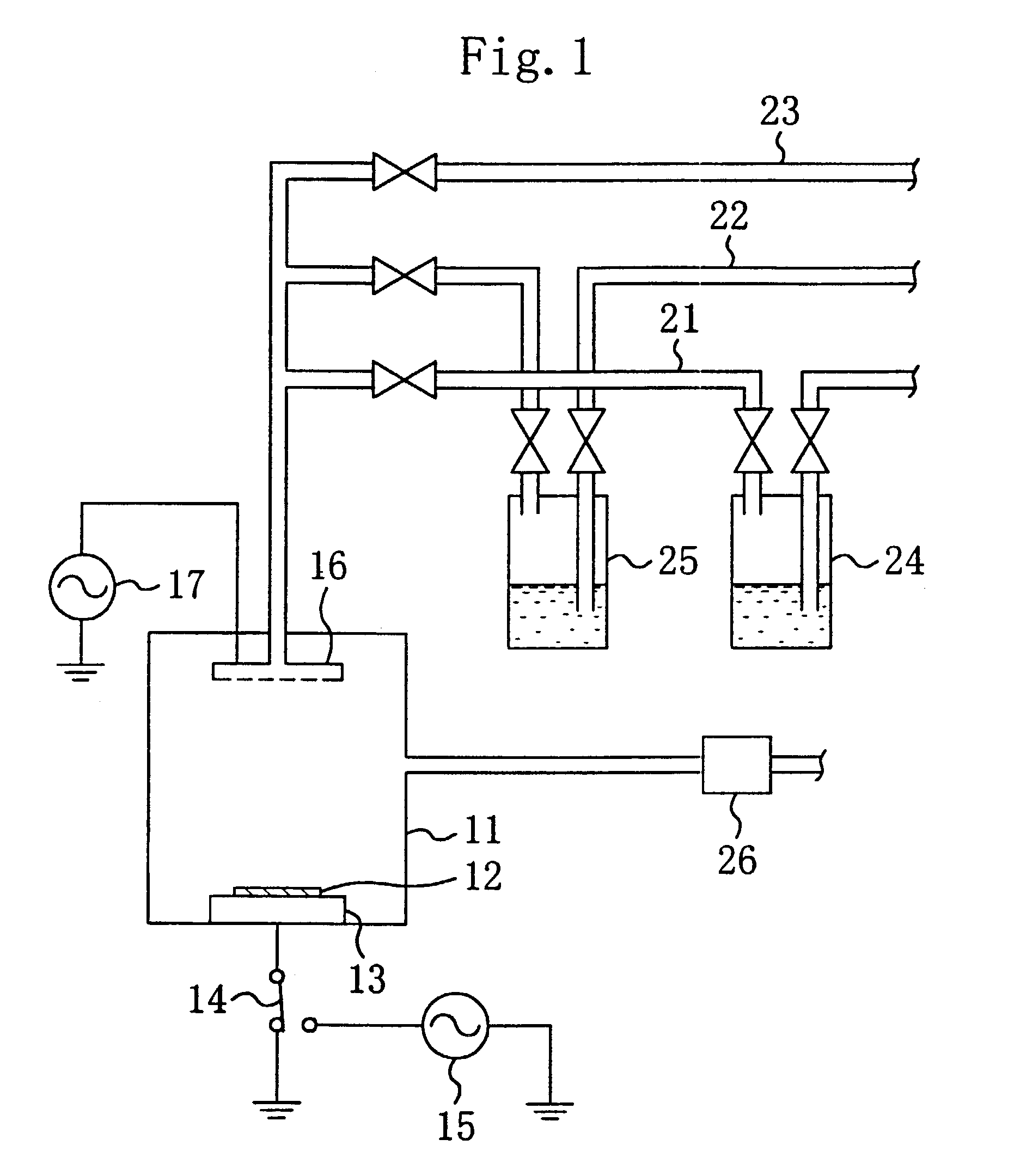

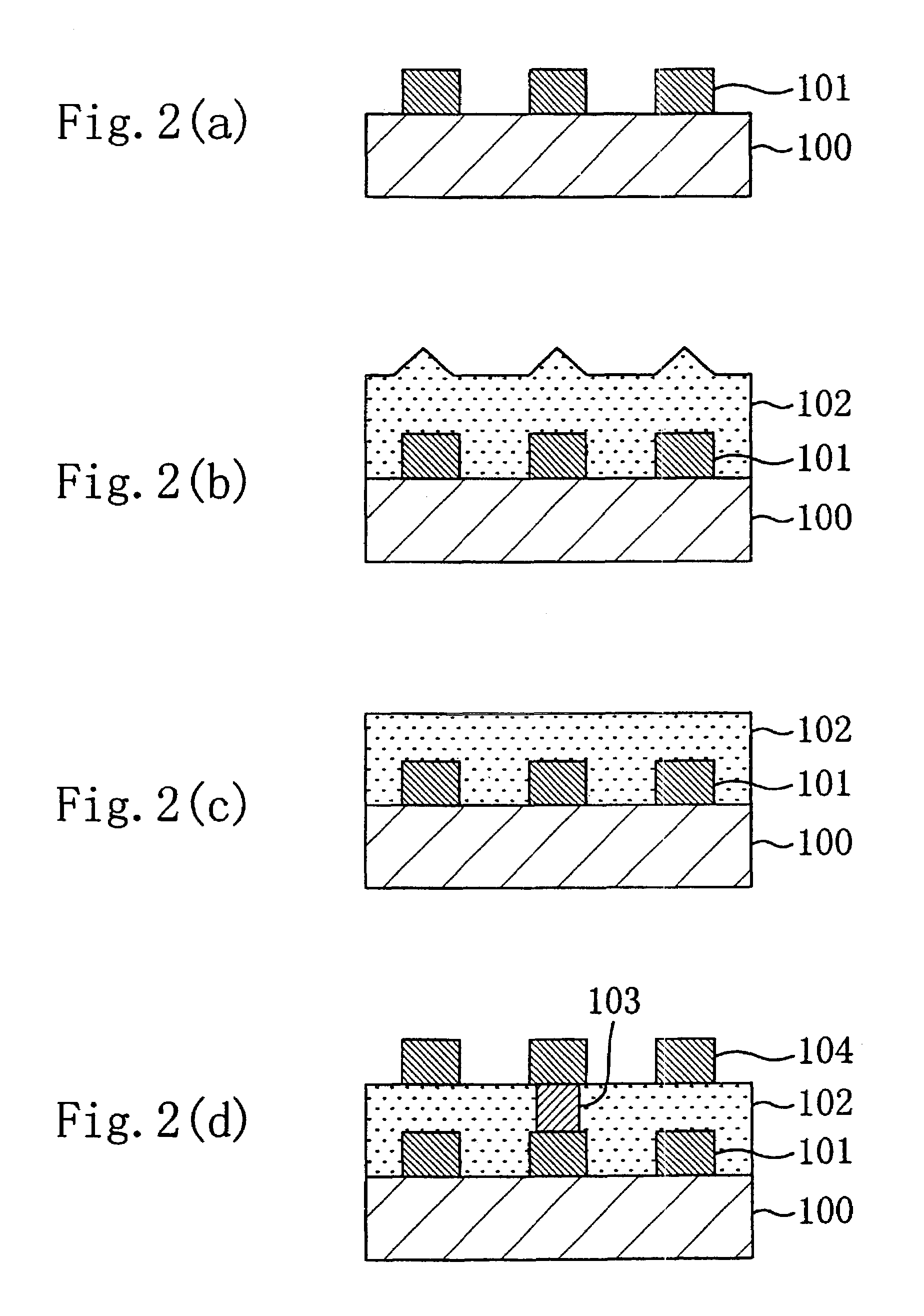

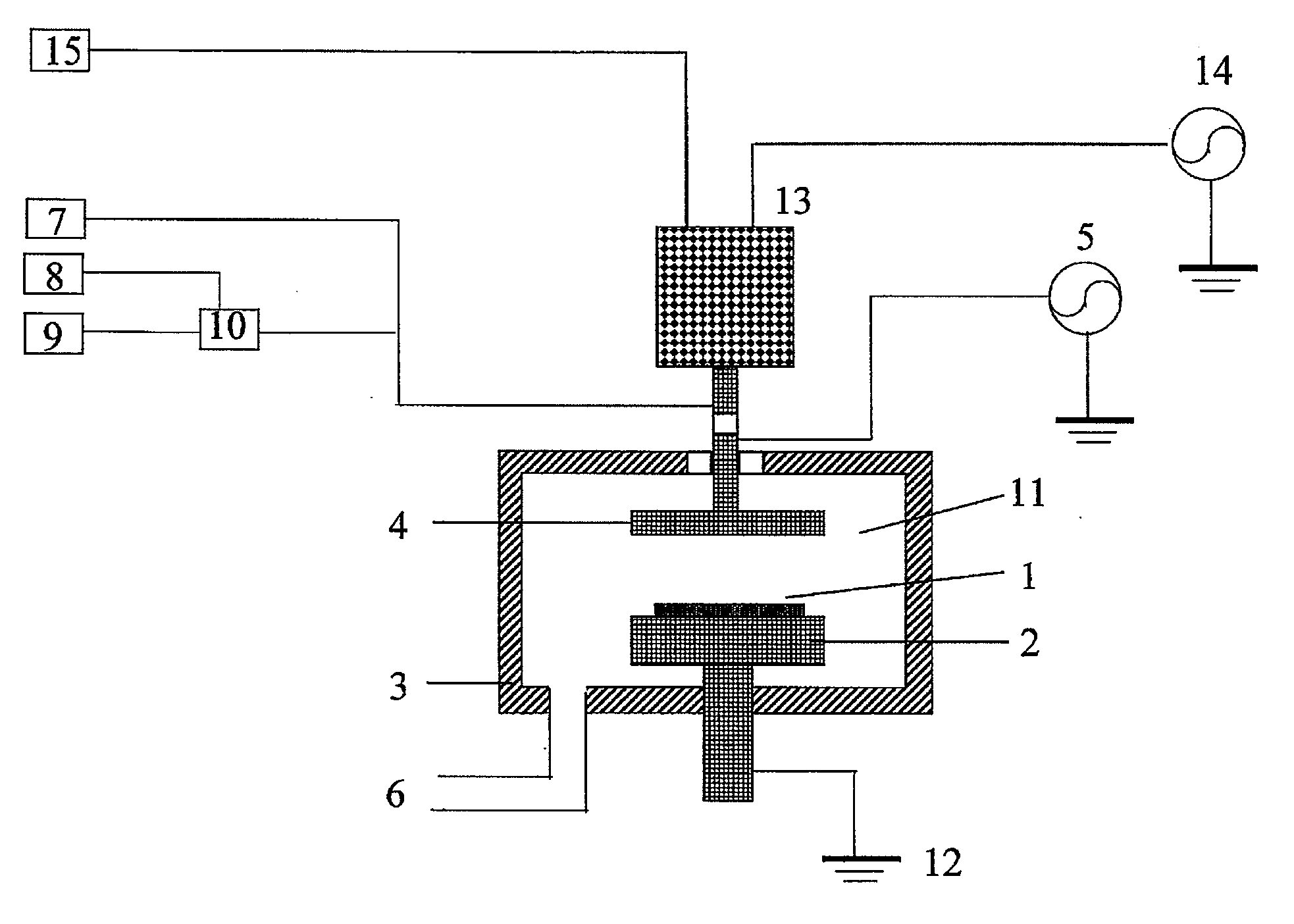

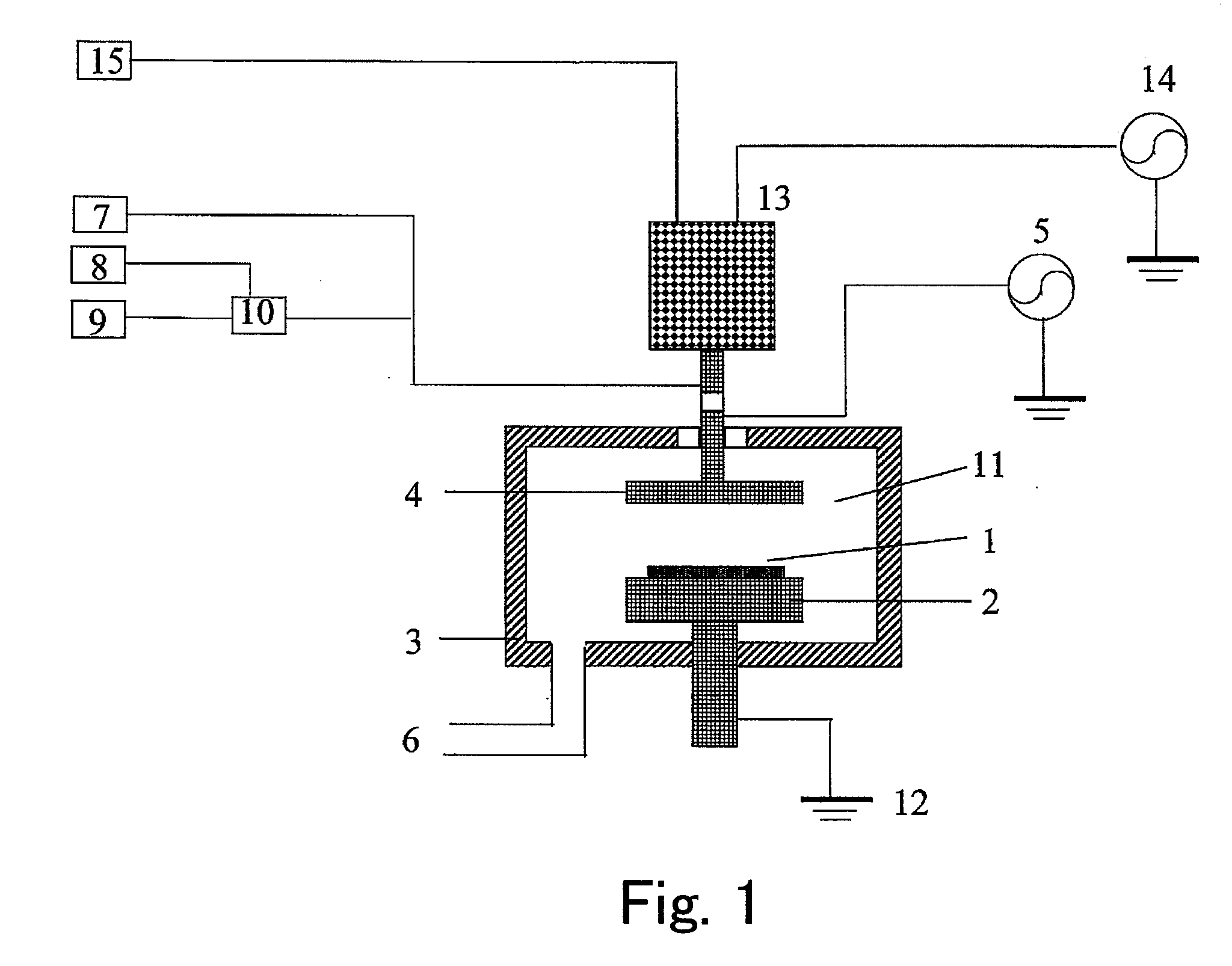

A method of forming a transparent hydrocarbon-based polymer film on a substrate by plasma CVD includes: introducing a main gas consisting of a hydrocarbon gas (CαHβ, wherein α and β are natural numbers) and an inert gas at a flow ratio (R) of CαHβ / inert gas of 0.25 or less into a CVD reaction chamber inside which a substrate is placed; and forming a hydrocarbon-based polymer film on the substrate by plasma polymerization of the gas at a processing temperature (T) wherein T≦(−800R+500).

Owner:ASM JAPAN

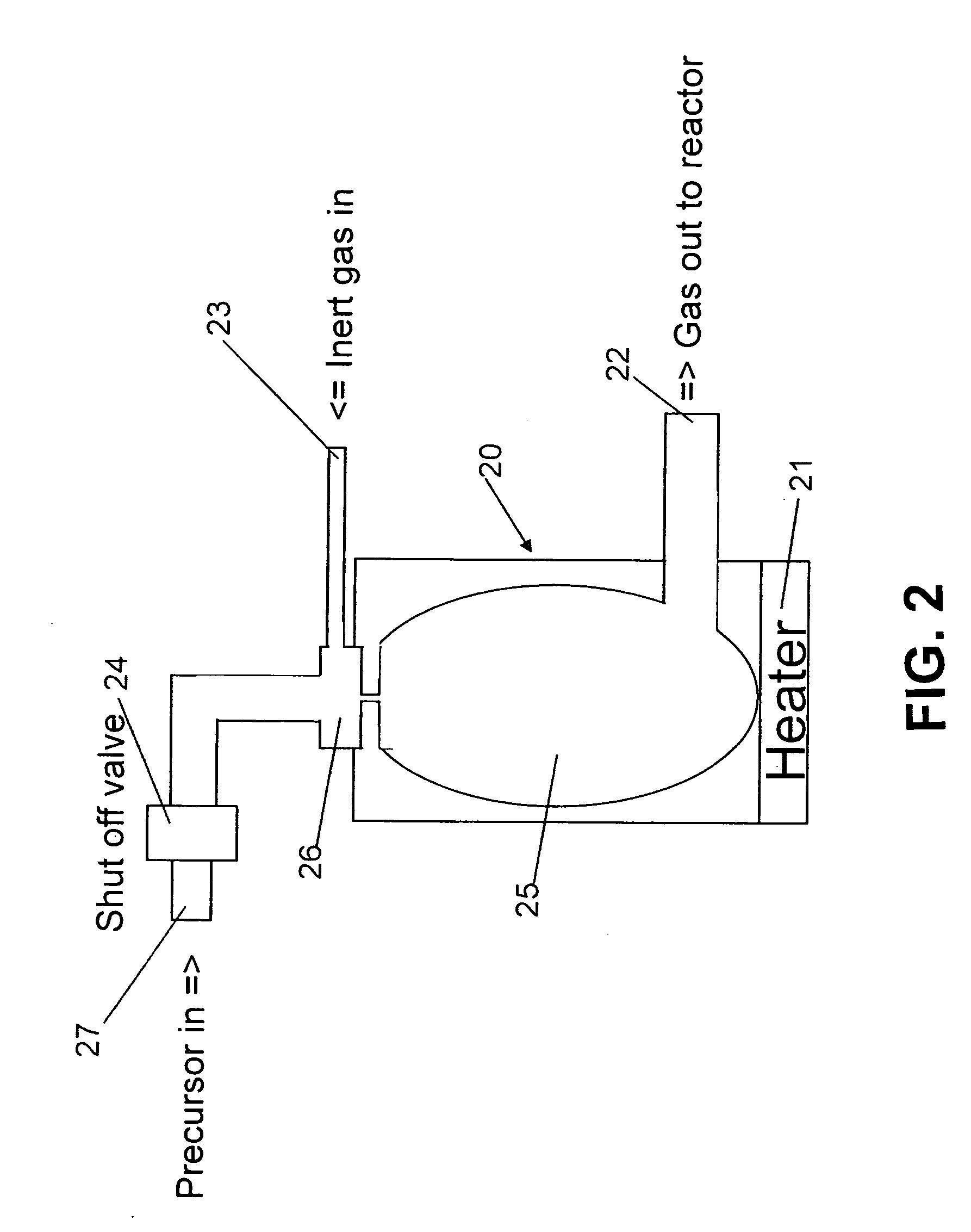

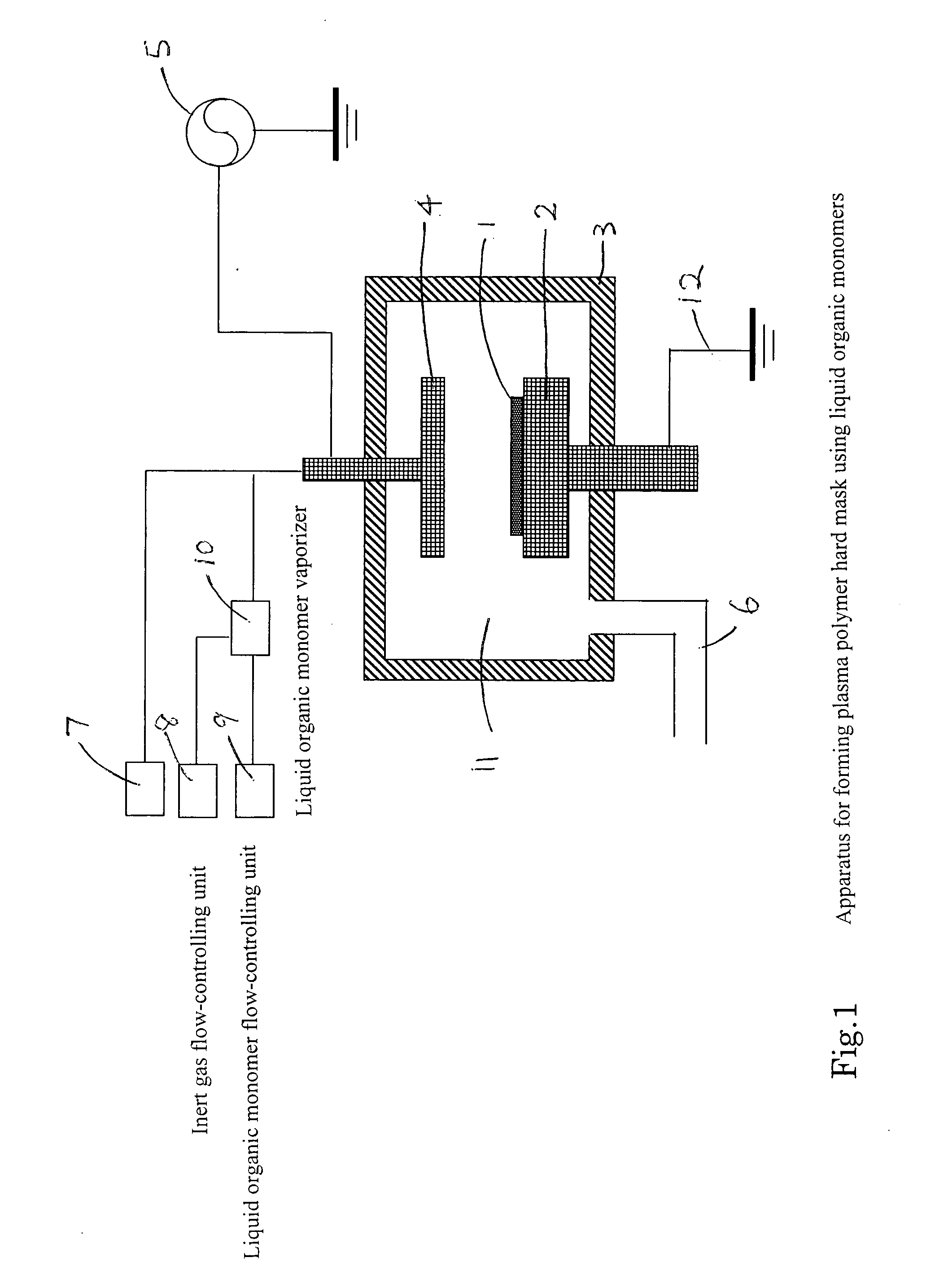

Method of forming a carbon polymer film using plasma CVD

ActiveUS20070218705A1Improve featuresFunction increaseLiquid surface applicatorsPhotomechanical apparatusCapacitanceBoiling point

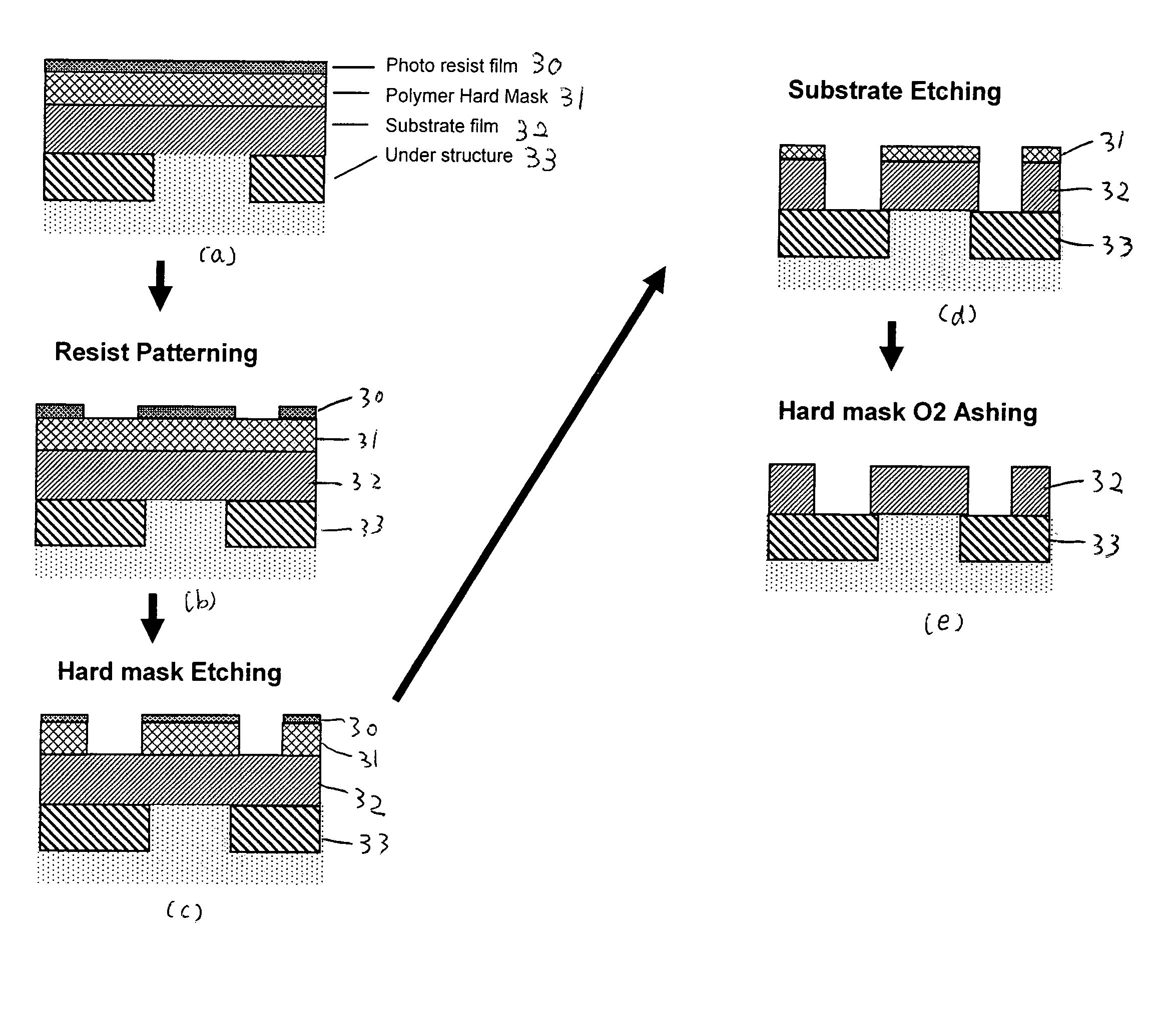

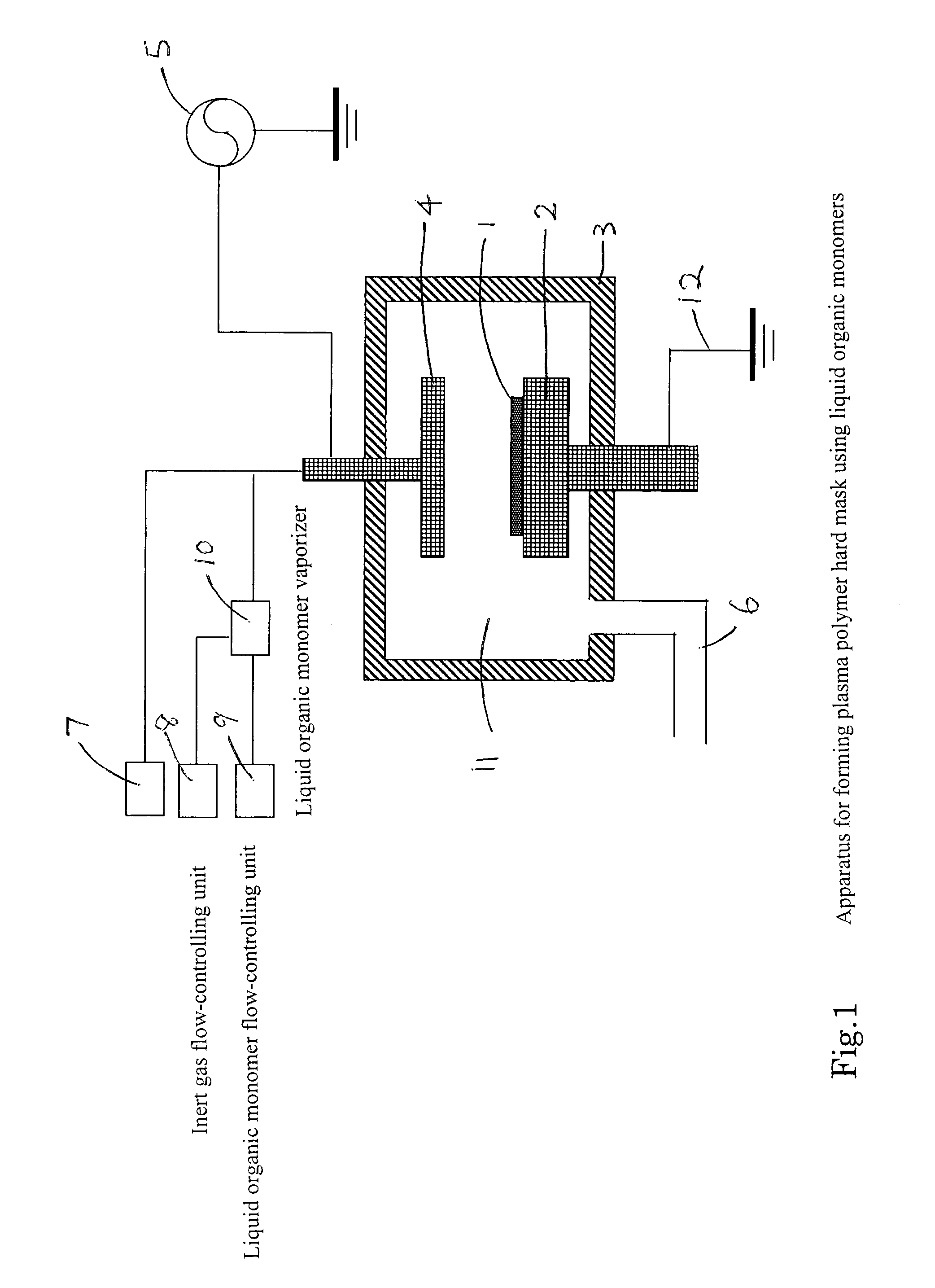

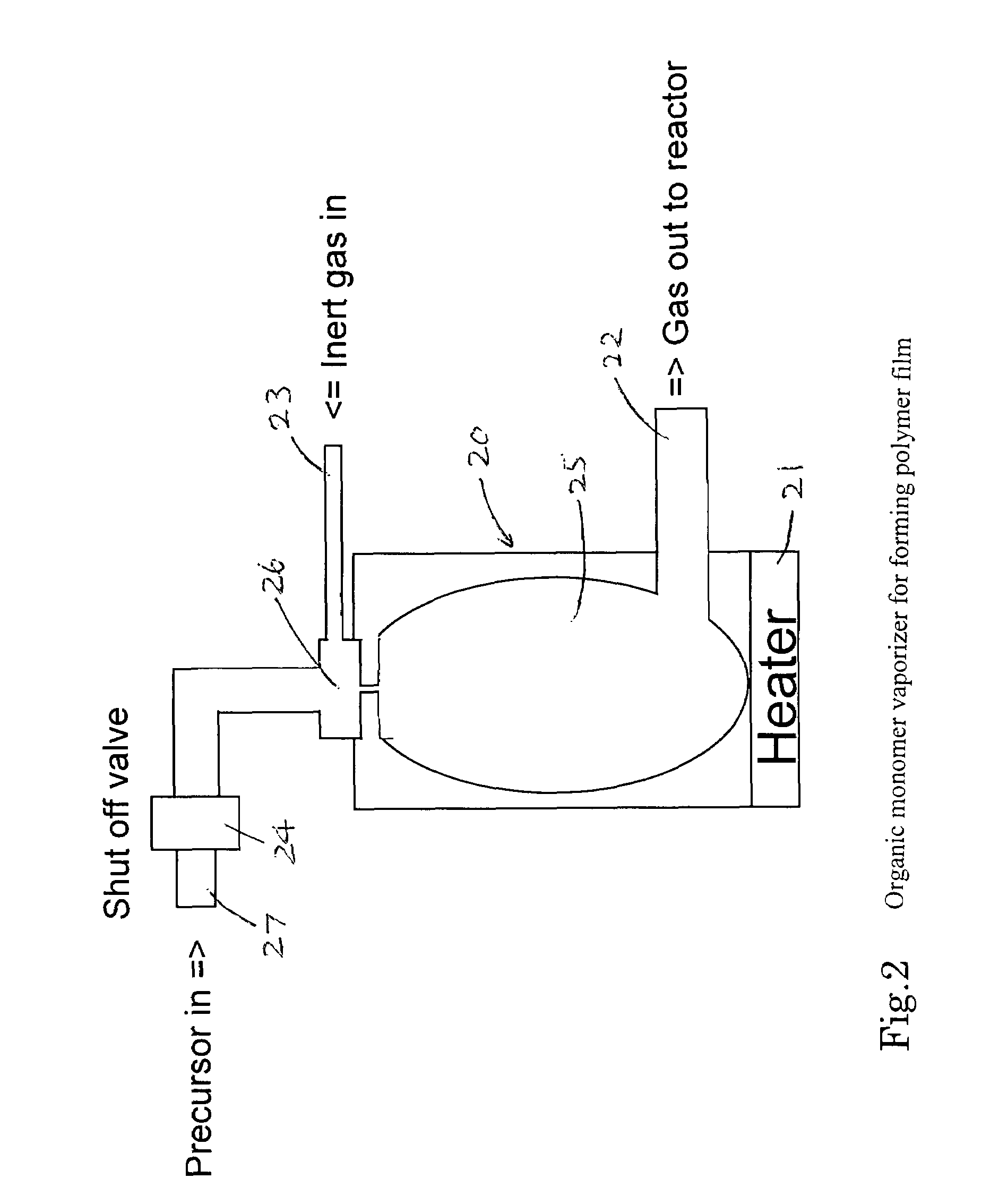

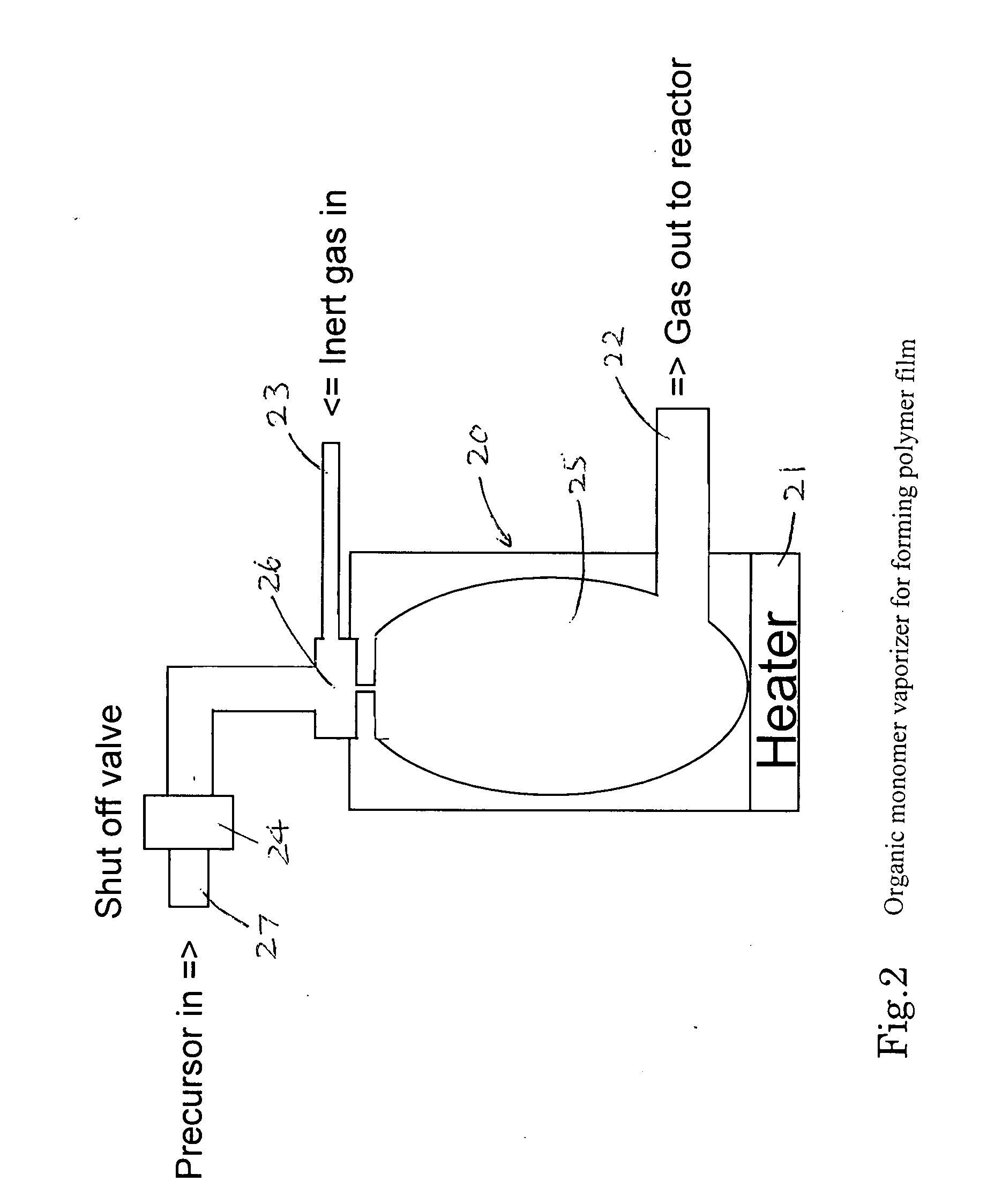

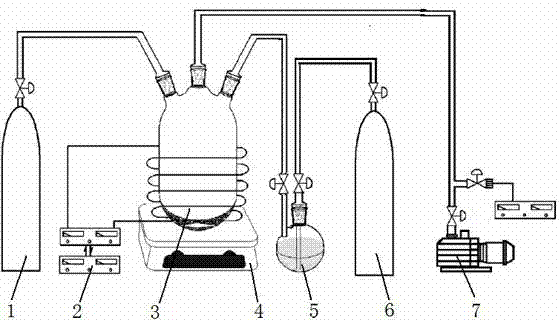

A method forms a hydrocarbon-containing polymer film on a semiconductor substrate by a capacitively-coupled plasma CVD apparatus. The method includes the steps of: vaporizing a hydrocarbon-containing liquid monomer (CαHβXγ, wherein α and β are natural numbers of 5 or more; γ is an integer including zero; X is O, N or F) having a boiling point of about 20° C. to about 350° C.; introducing the vaporized gas into a CVD reaction chamber inside which a substrate is placed; and forming a hydrocarbon-containing polymer film on the substrate by plasma polymerization of the gas.

Owner:ASM JAPAN

Method of manufacturing semiconductor device

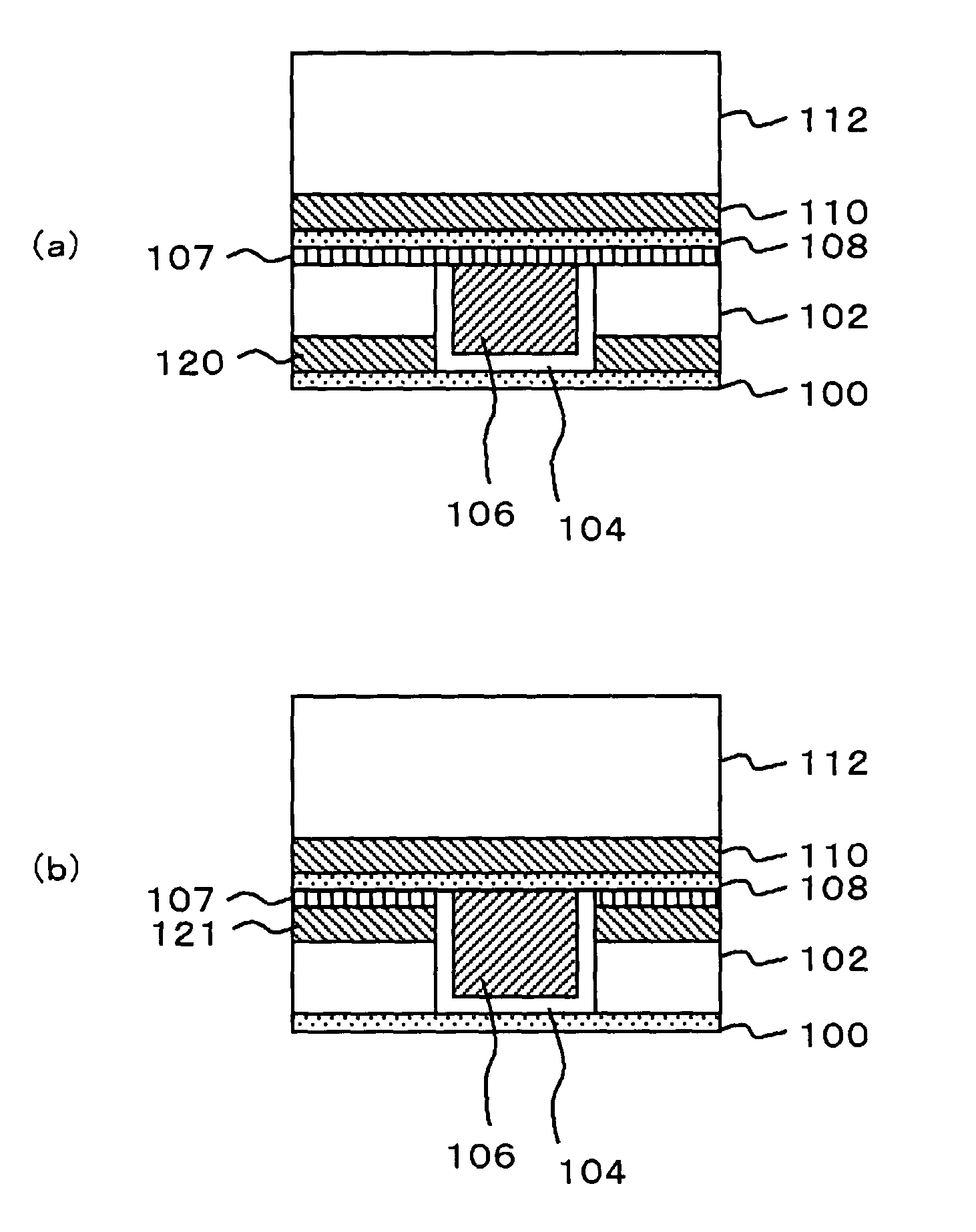

InactiveUS20110171775A1Without deteriorating reliability of deviceHigh bonding strengthSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorPlasma polymerization

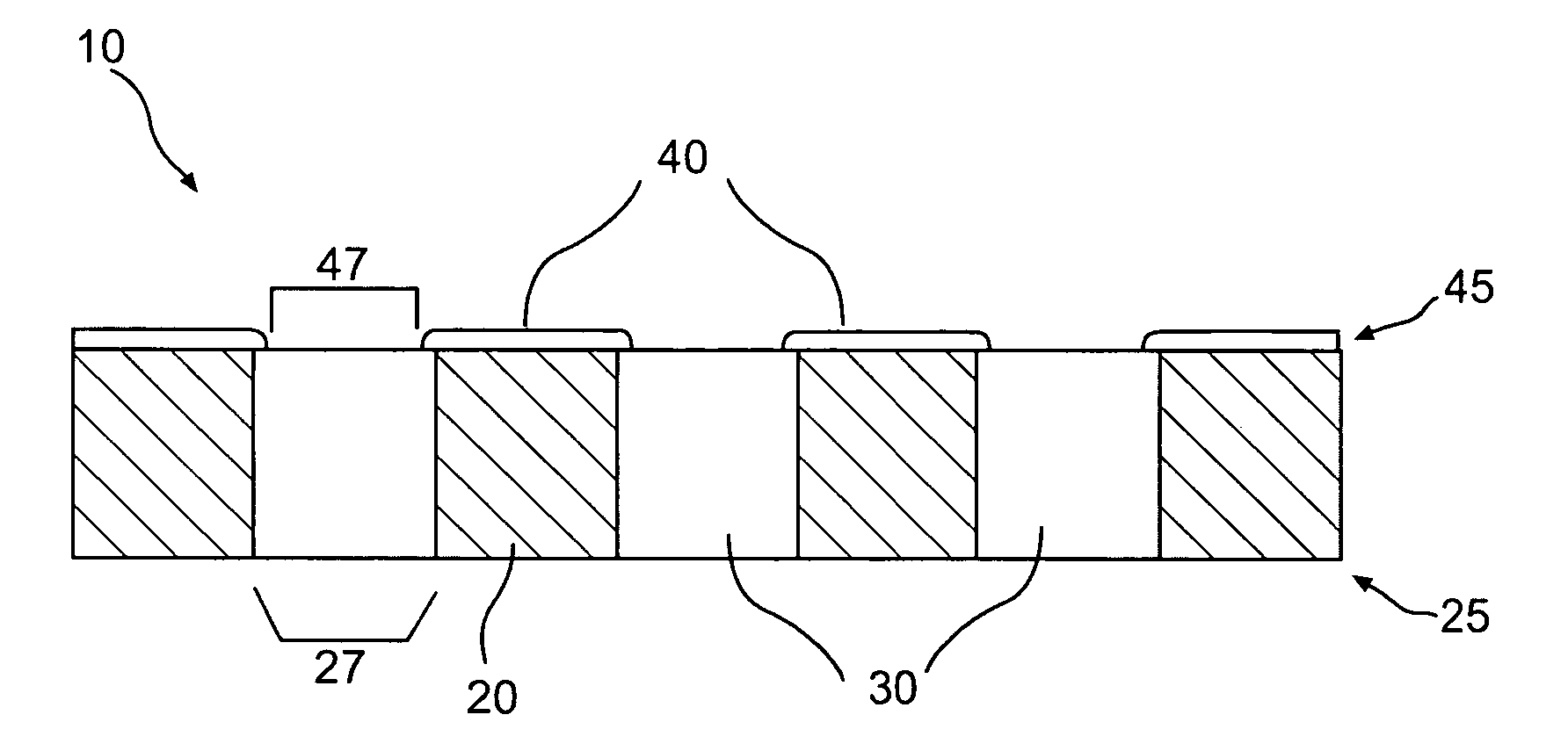

A method of manufacturing a semiconductor device includes forming a first insulating film over an underlying film by plasma polymerization of cyclic siloxane, and forming a second insulating film on the first insulating film by plasma polymerization of the cyclic siloxane continuously, after forming the first insulating film. The deposition rate of the first insulating film is slower than the deposition rate of the second insulating film.

Owner:RENESAS ELECTRONICS CORP

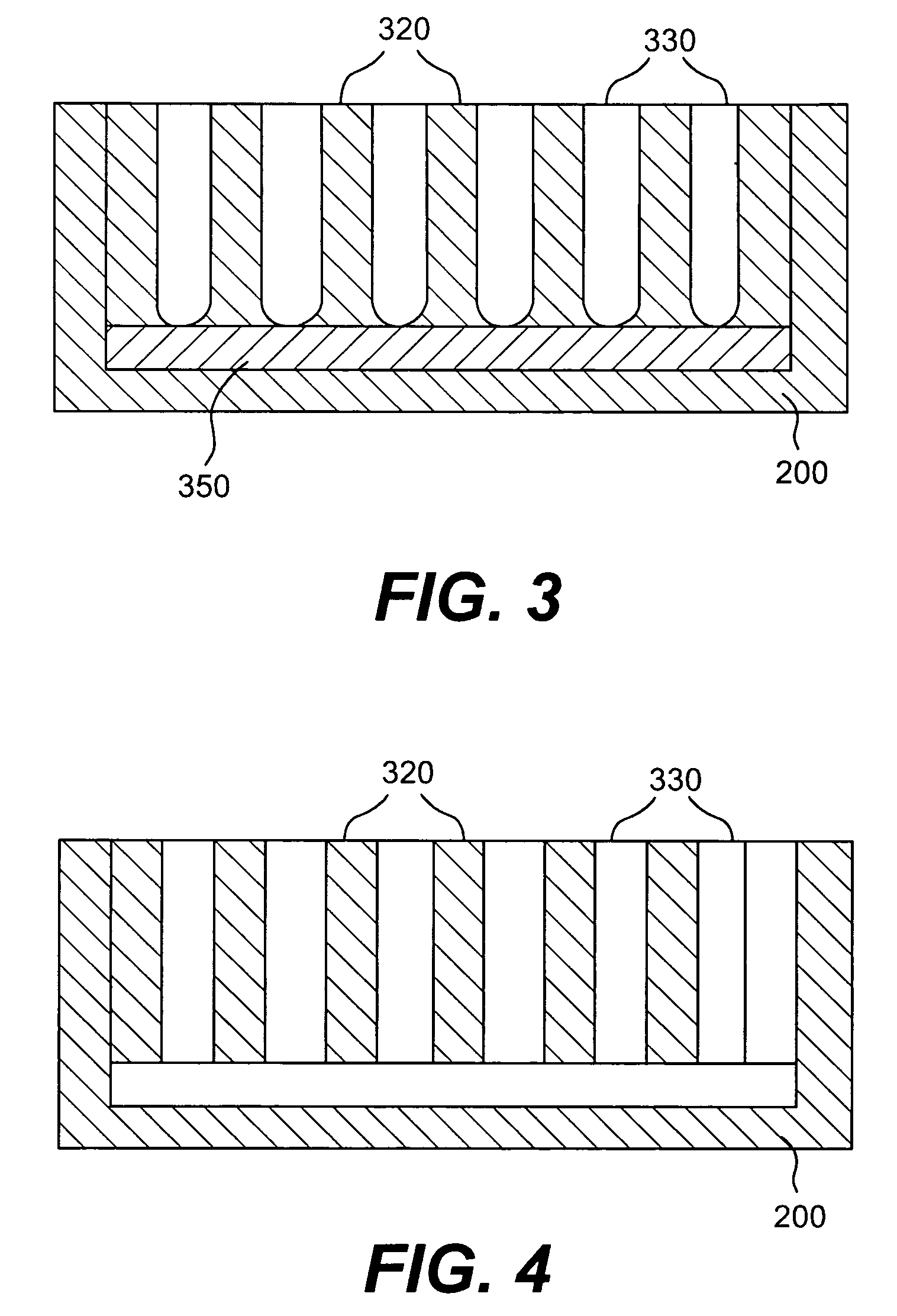

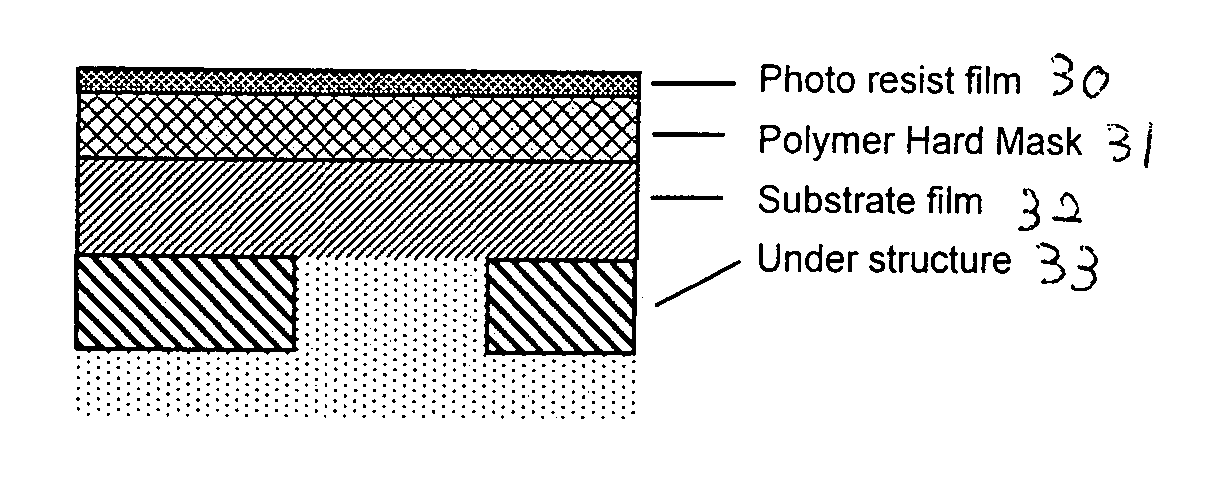

Method of forming a carbon polymer film using plasma CVD

ActiveUS7504344B2Improve featuresFunction increaseLiquid surface applicatorsPhotomechanical apparatusCapacitanceBoiling point

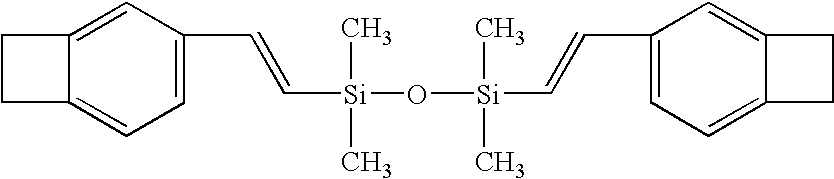

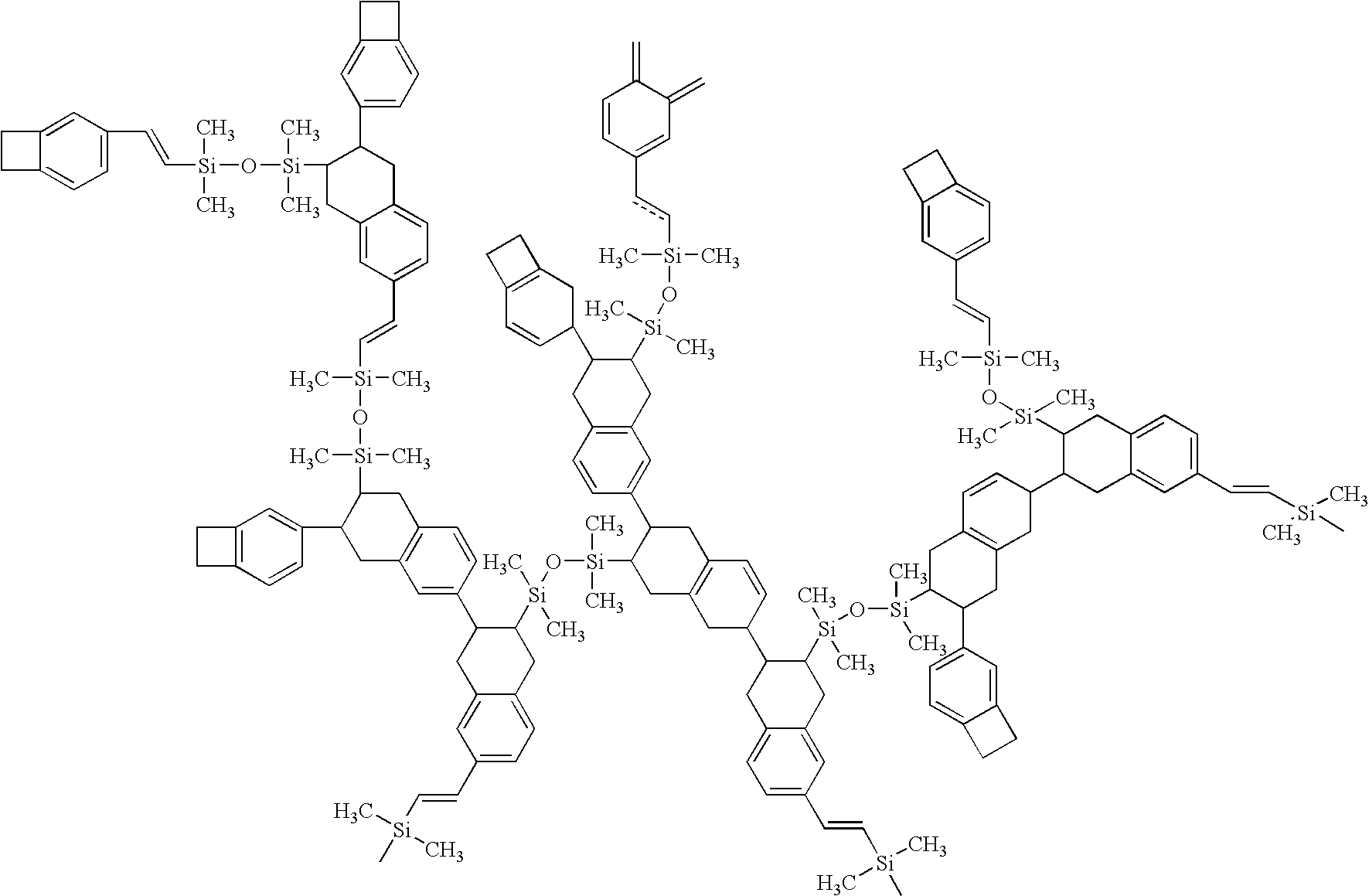

A method of forming a hydrocarbon-containing polymer film on a semiconductor substrate by a capacitively-coupled plasma CVD apparatus. The method includes the steps of: vaporizing a hydrocarbon-containing liquid monomer (CαHβXγ, wherein α and β are natural numbers of 5 or more; γ is an integer including zero; X is O, N or F) having a boiling point of about 20° C. to about 350° C. which is not substituted by a vinyl group or an acetylene group; introducing the vaporized gas into a CVD reaction chamber inside which a substrate is placed; and forming a hydrocarbon-containing polymer film on the substrate by plasma polymerization of the gas.

Owner:ASM JAPAN

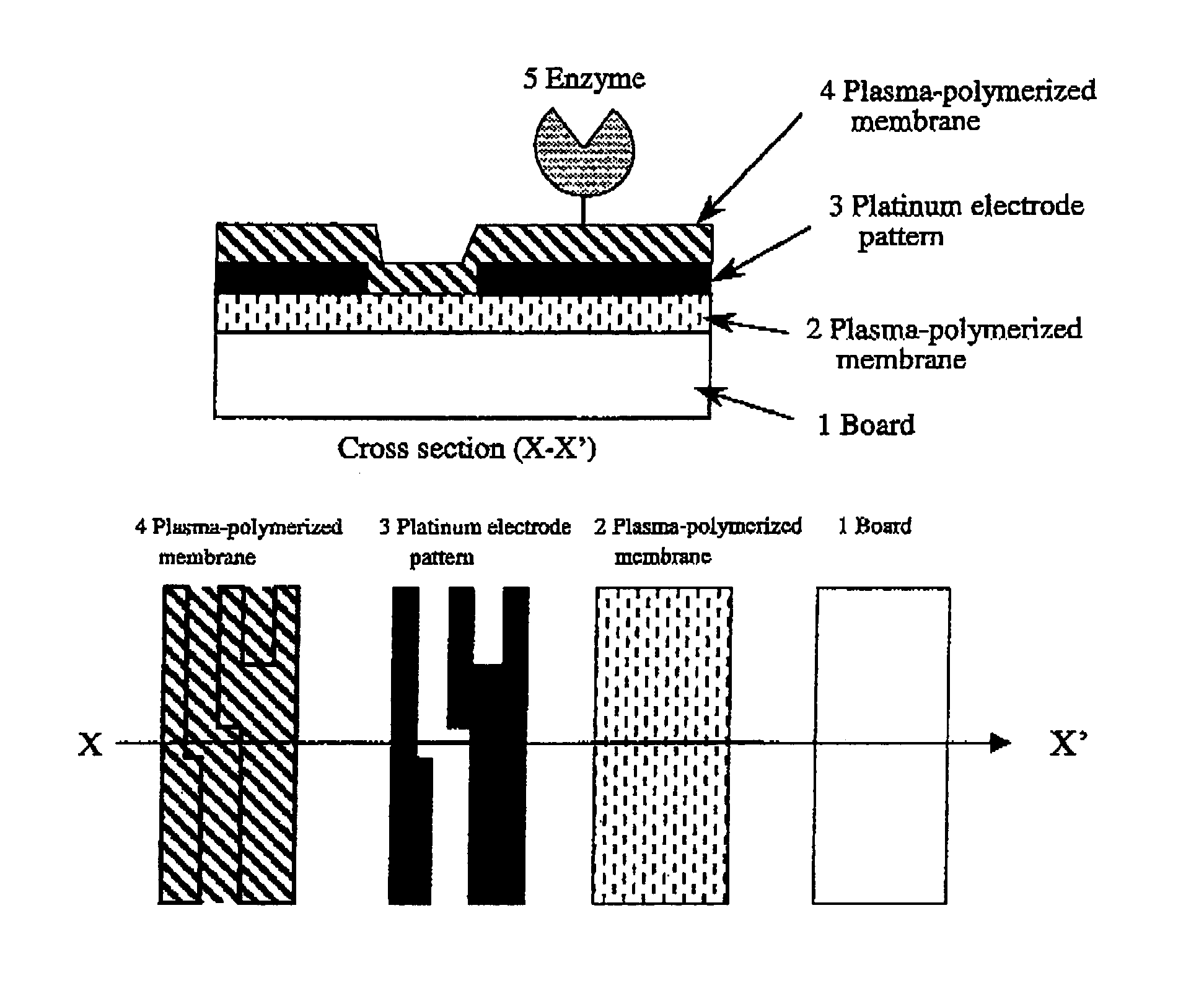

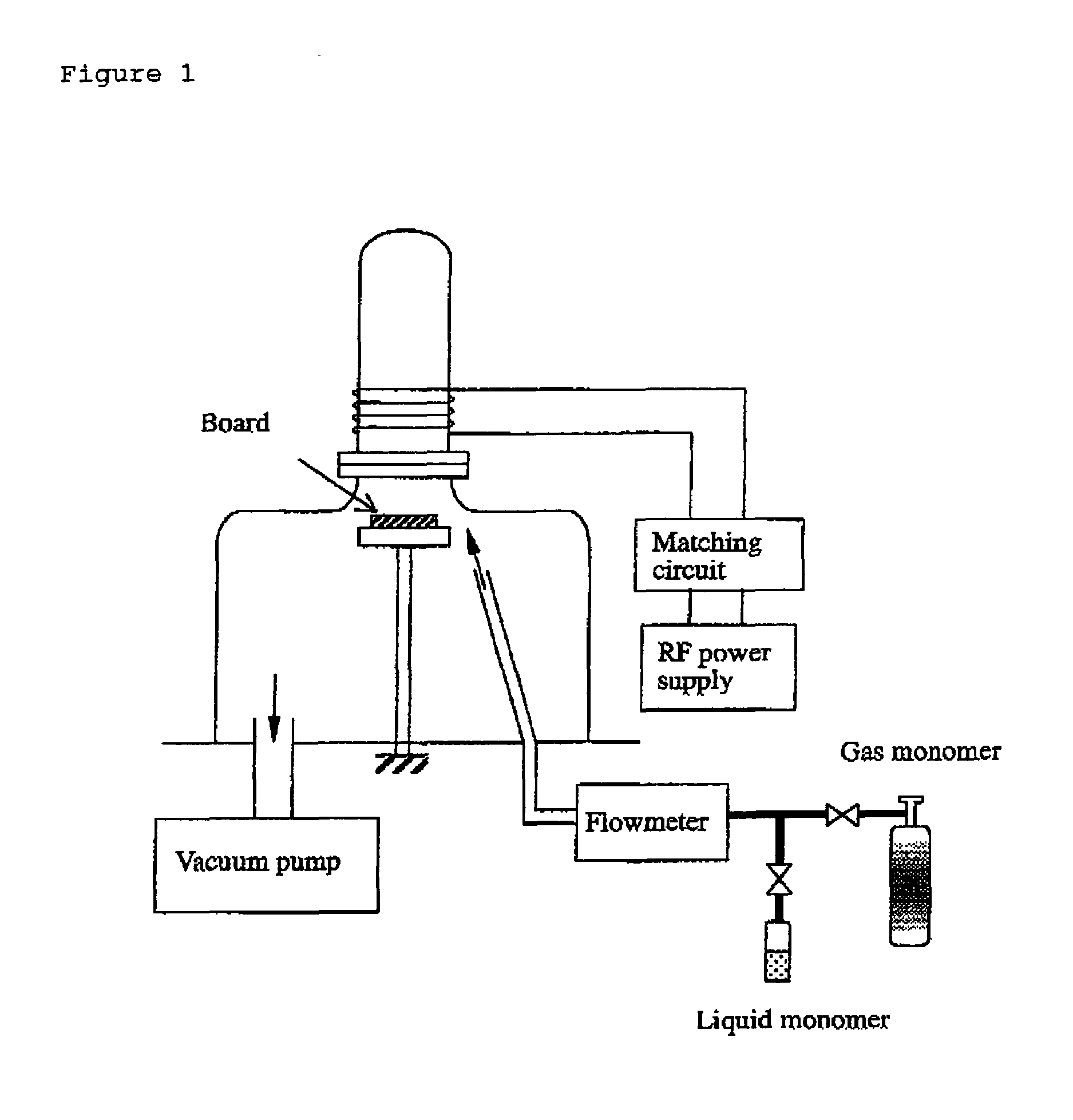

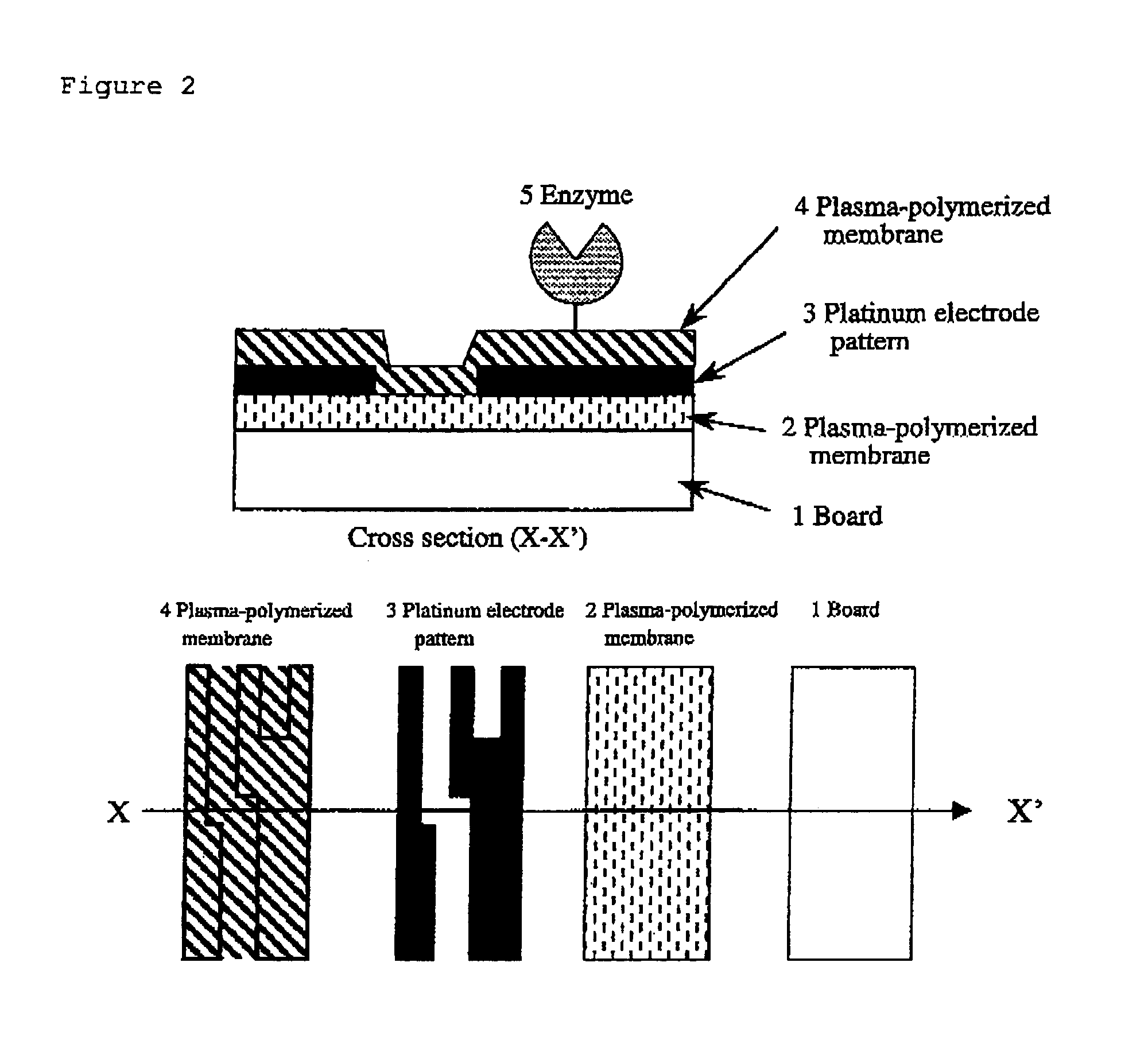

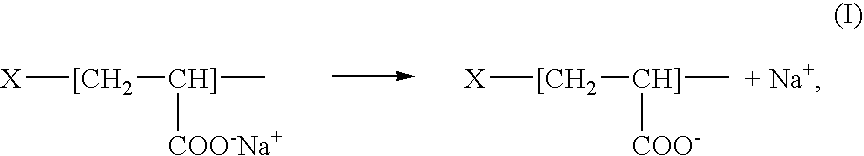

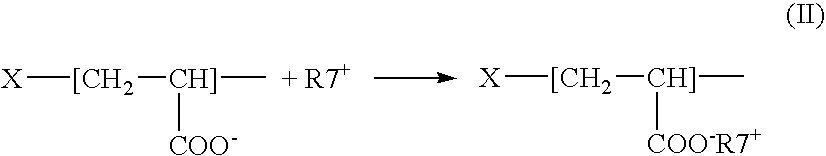

Biosensor

InactiveUS7087149B1Improve responseImprove batch productivityImmobilised enzymesBioreactor/fermenter combinationsMaterials sciencePlasma polymerization

Owner:KATAYANAGI INST

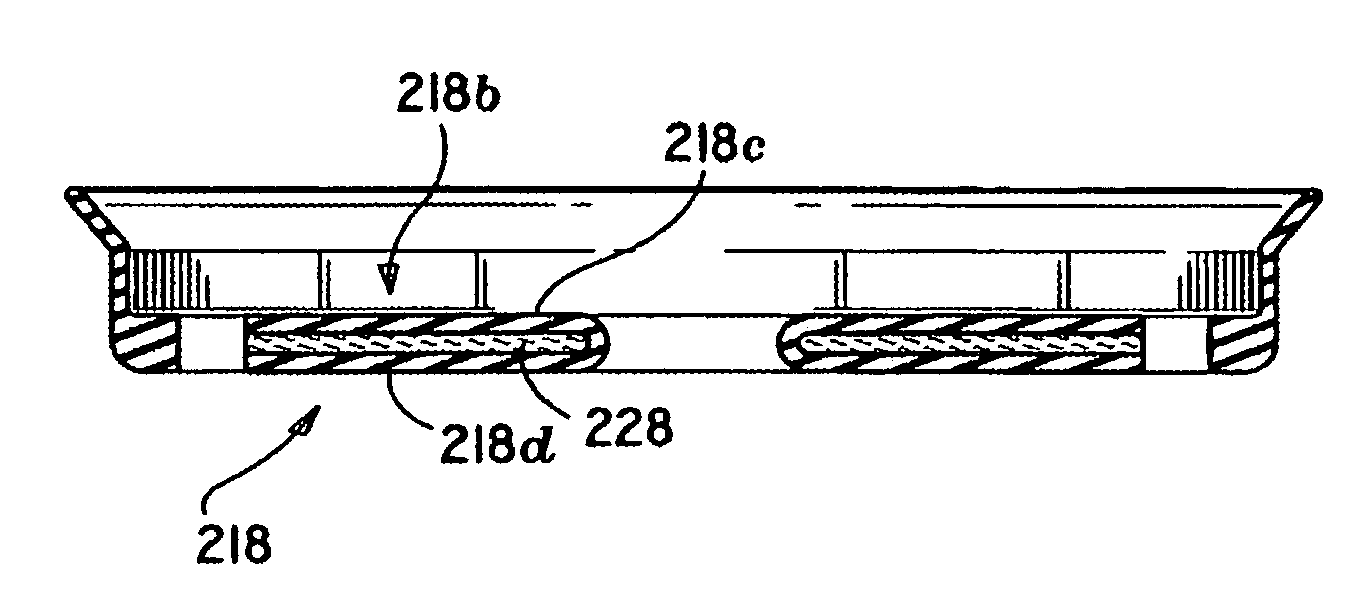

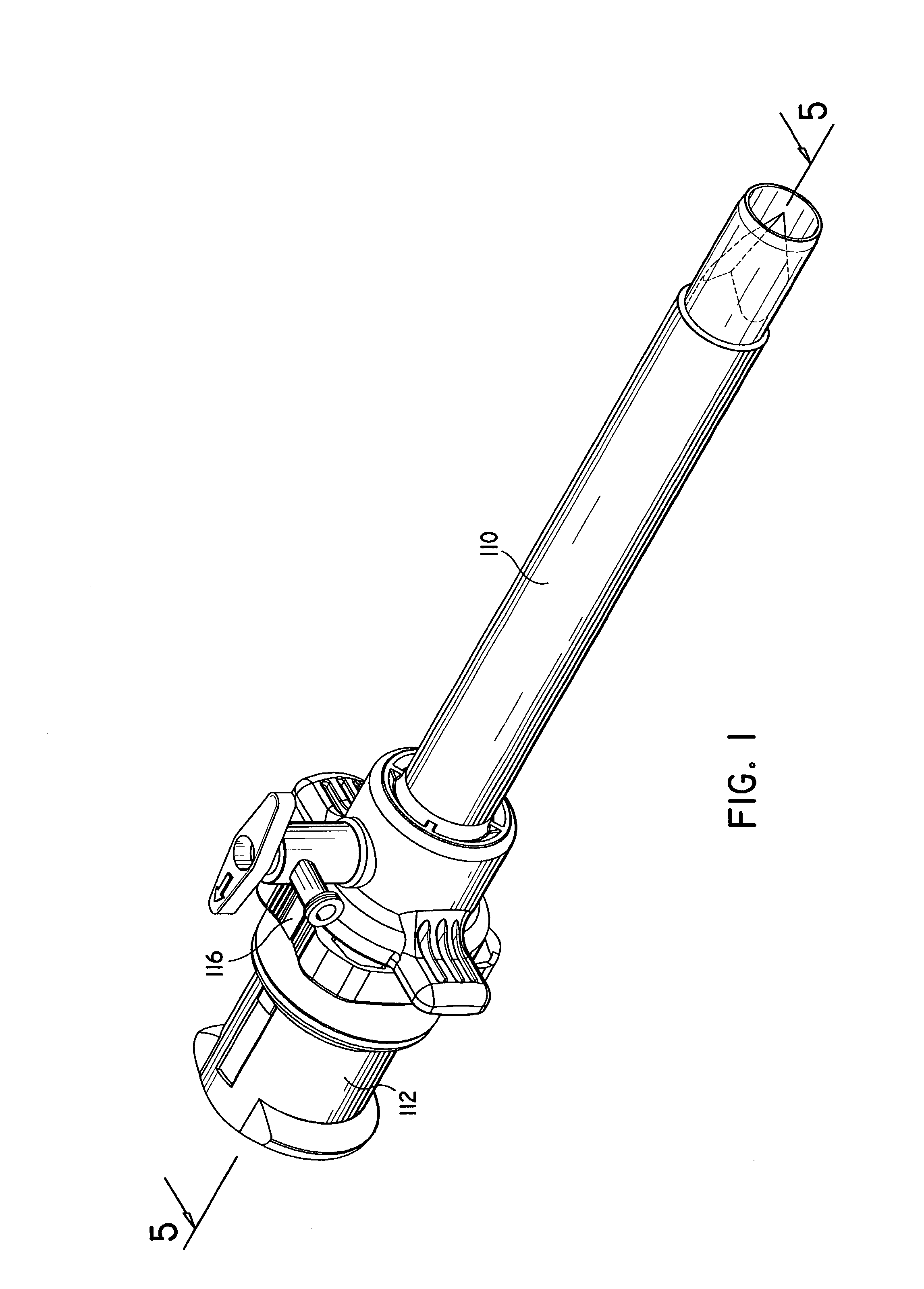

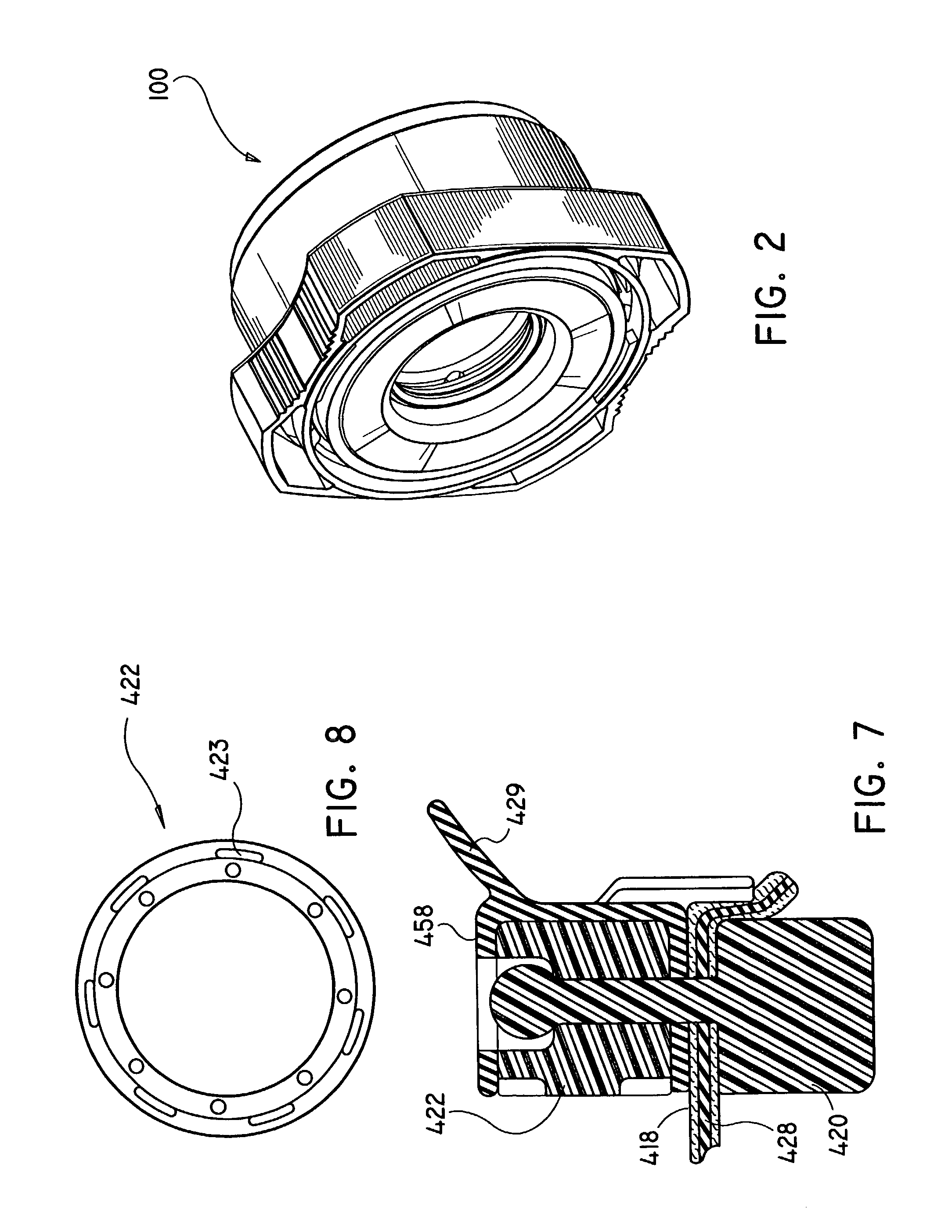

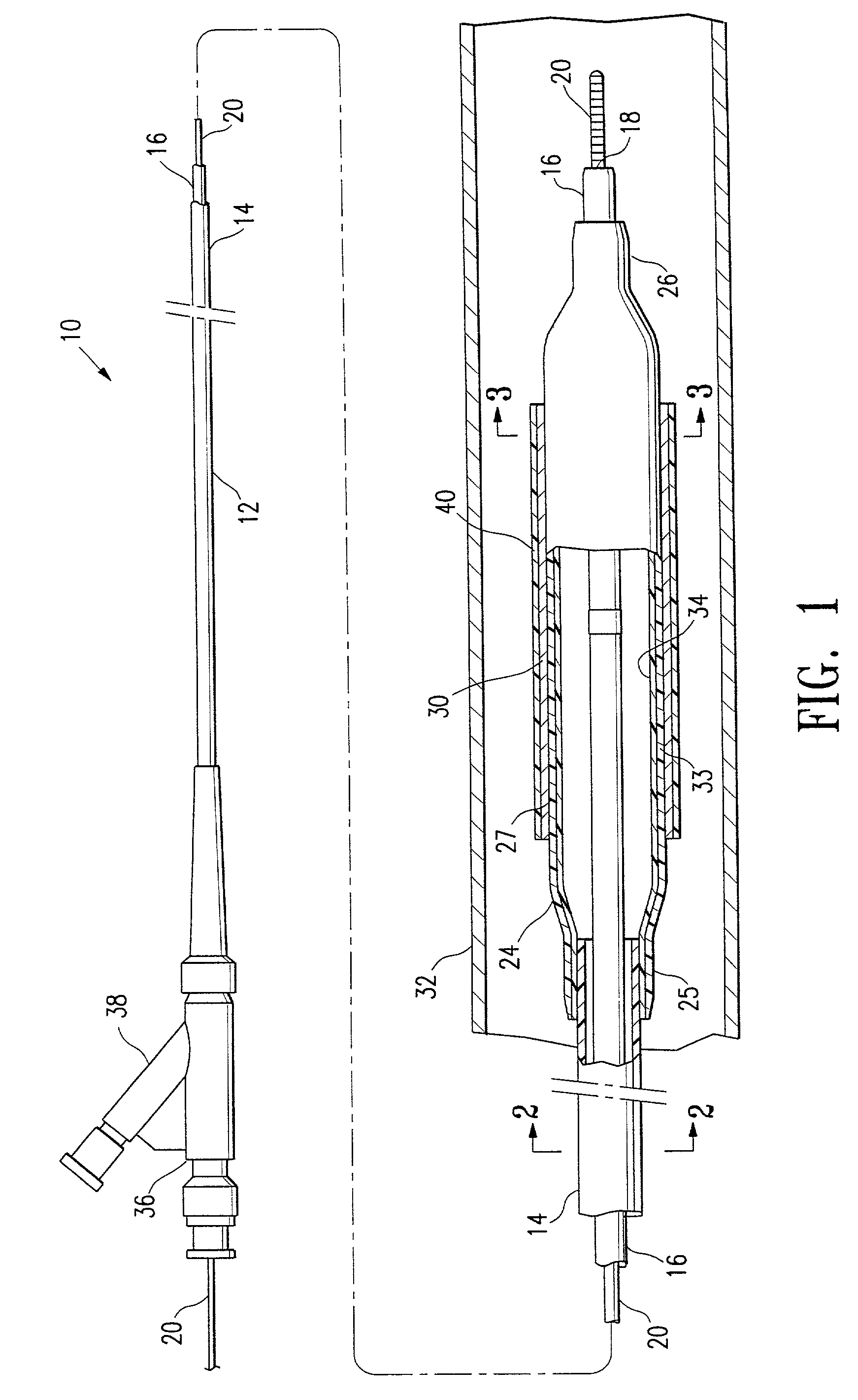

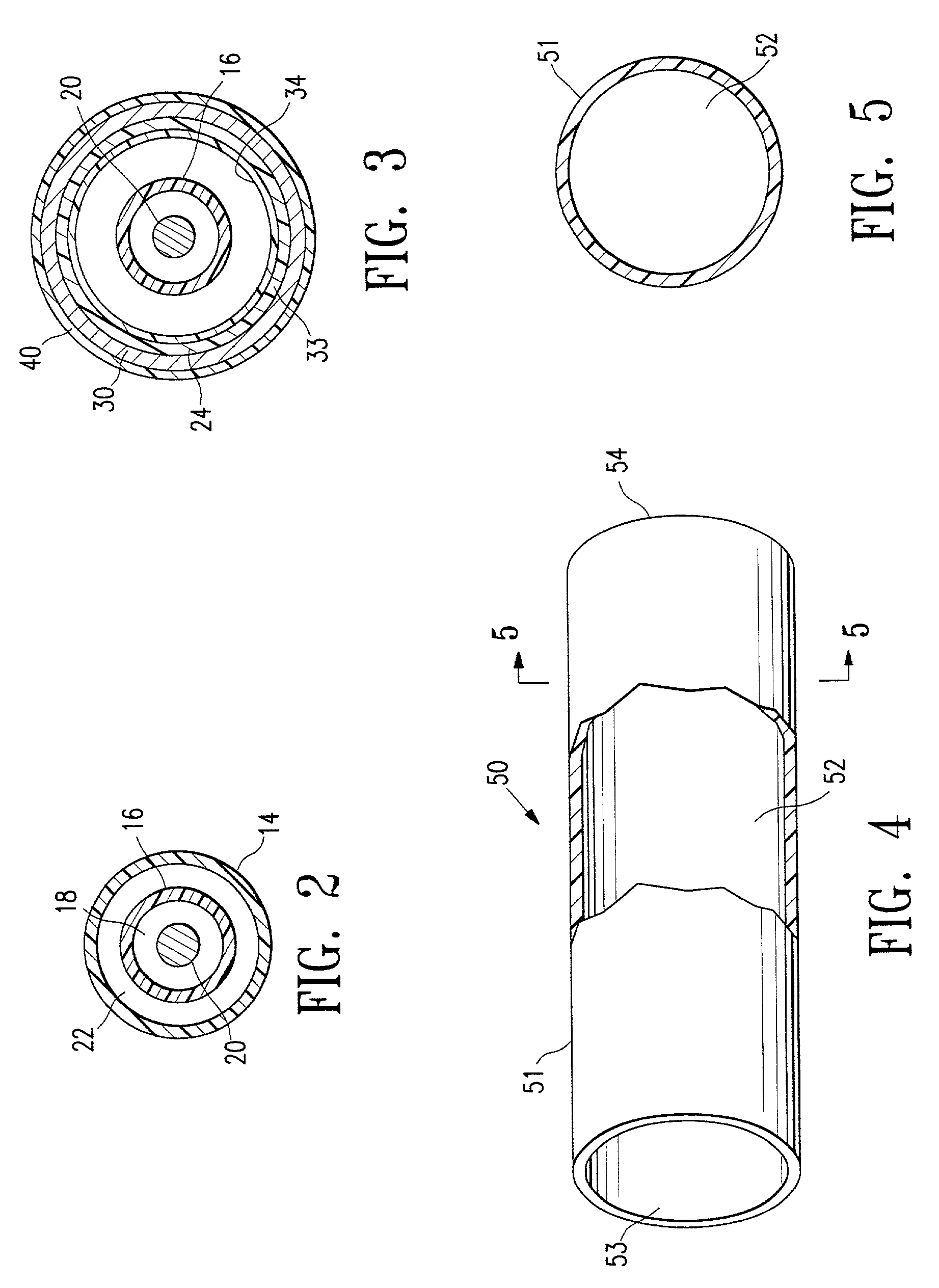

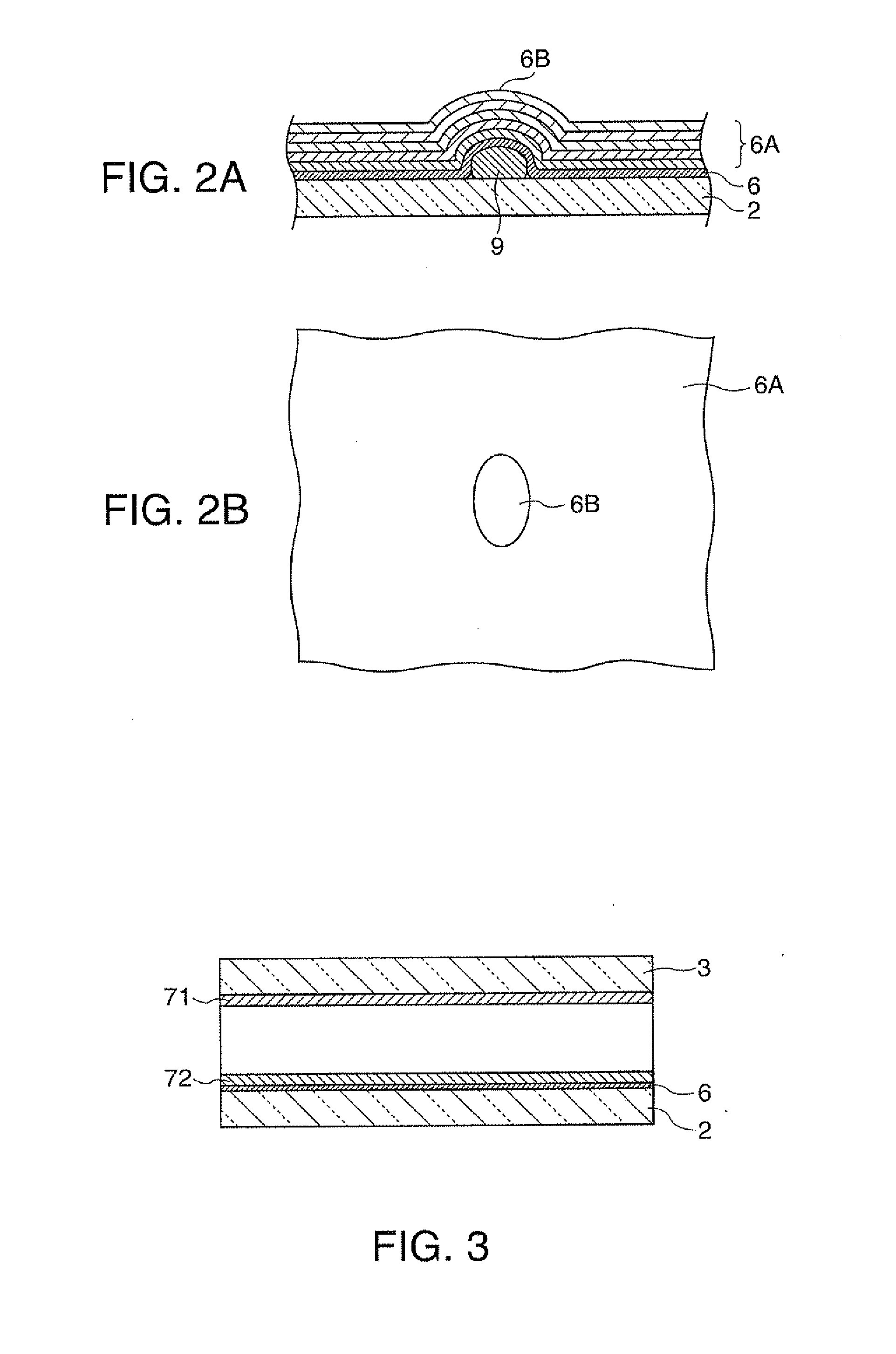

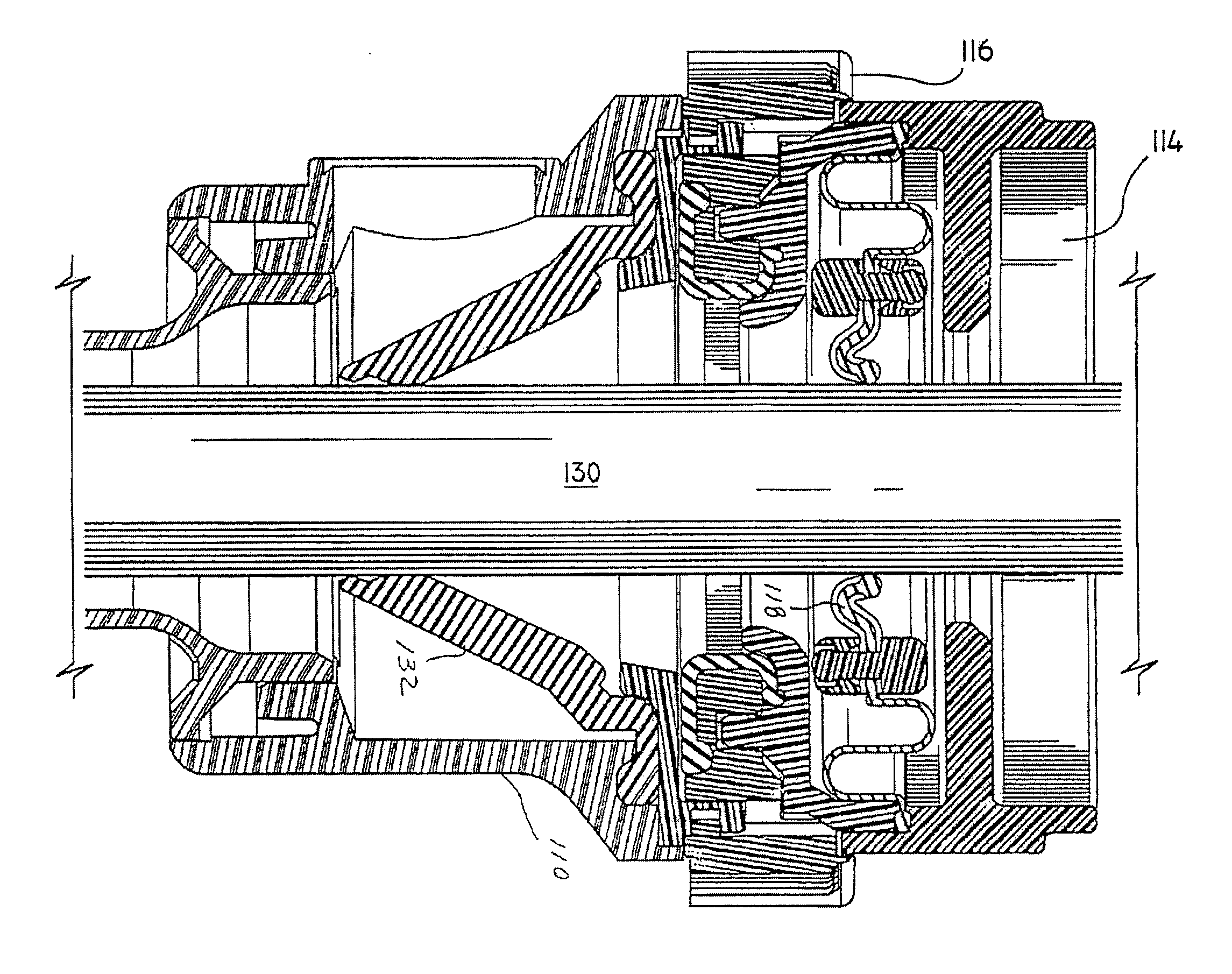

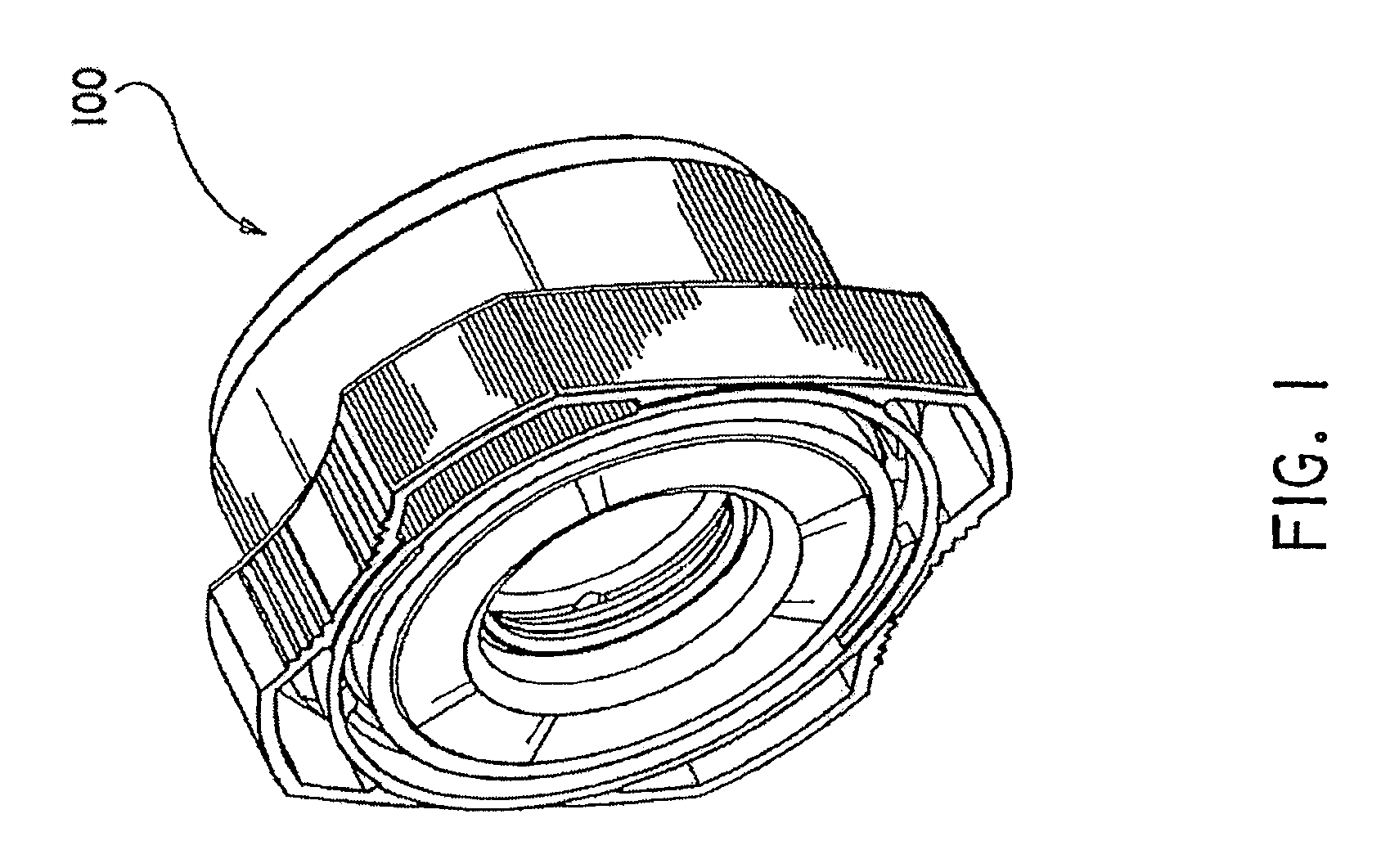

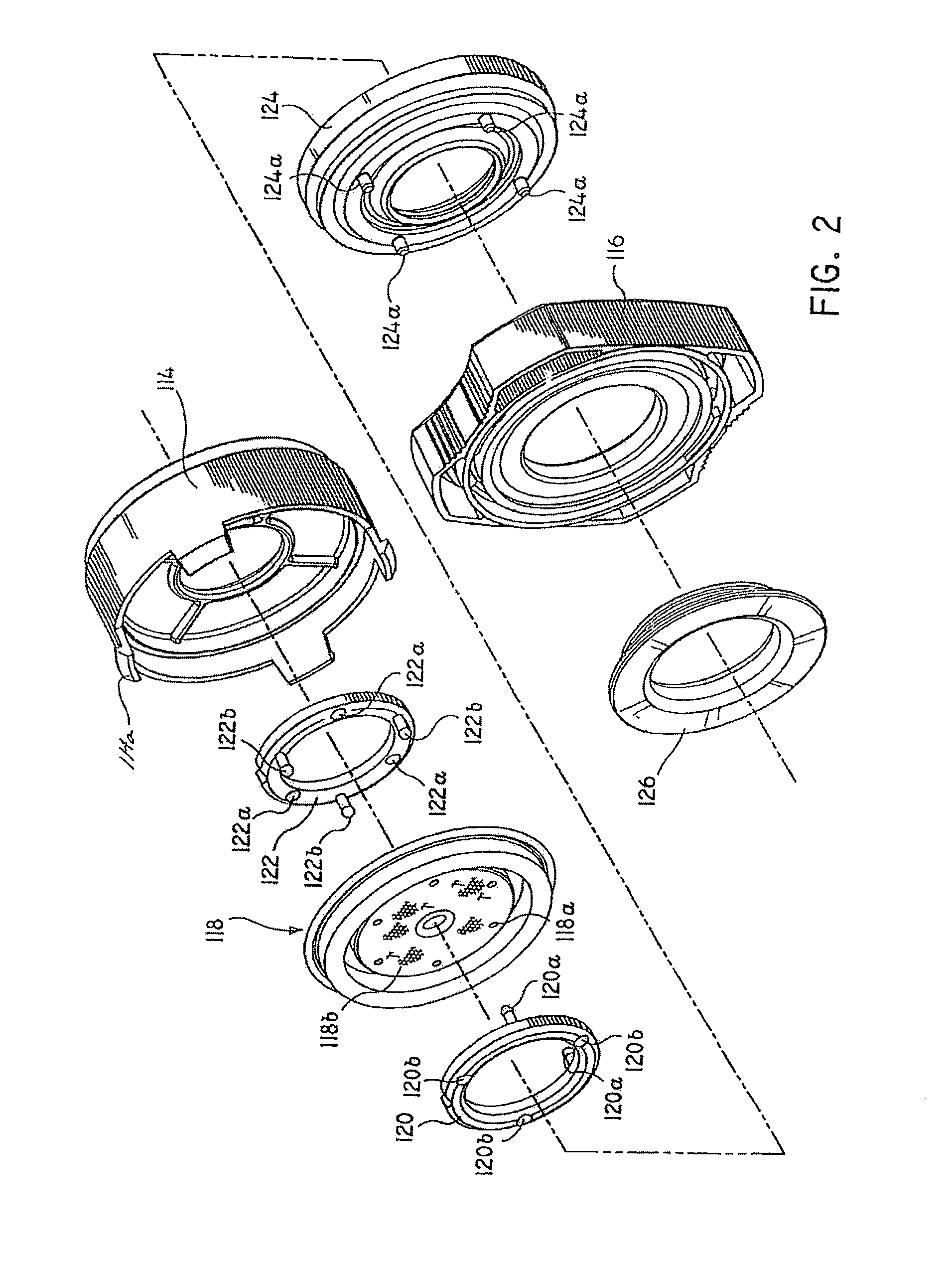

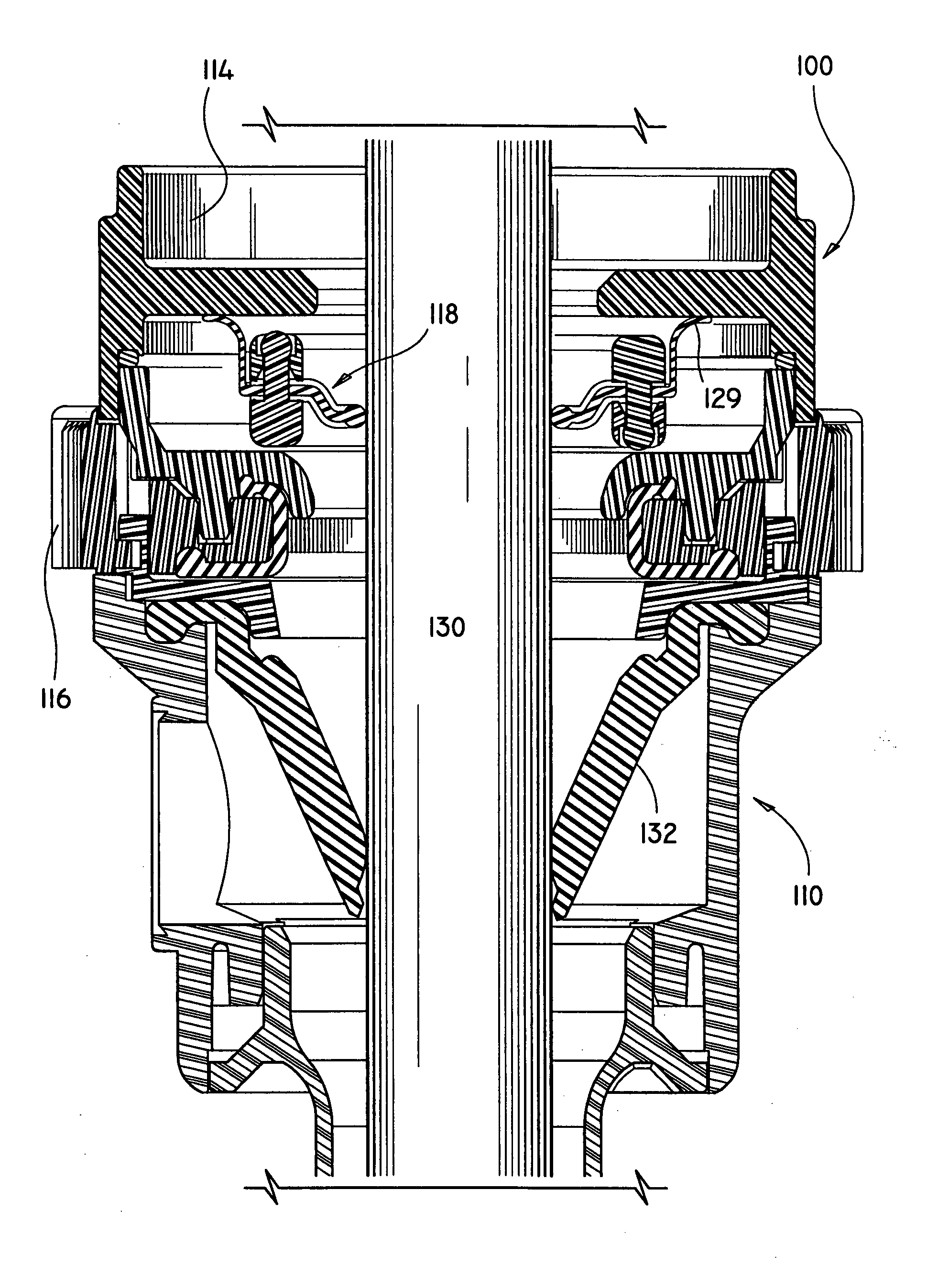

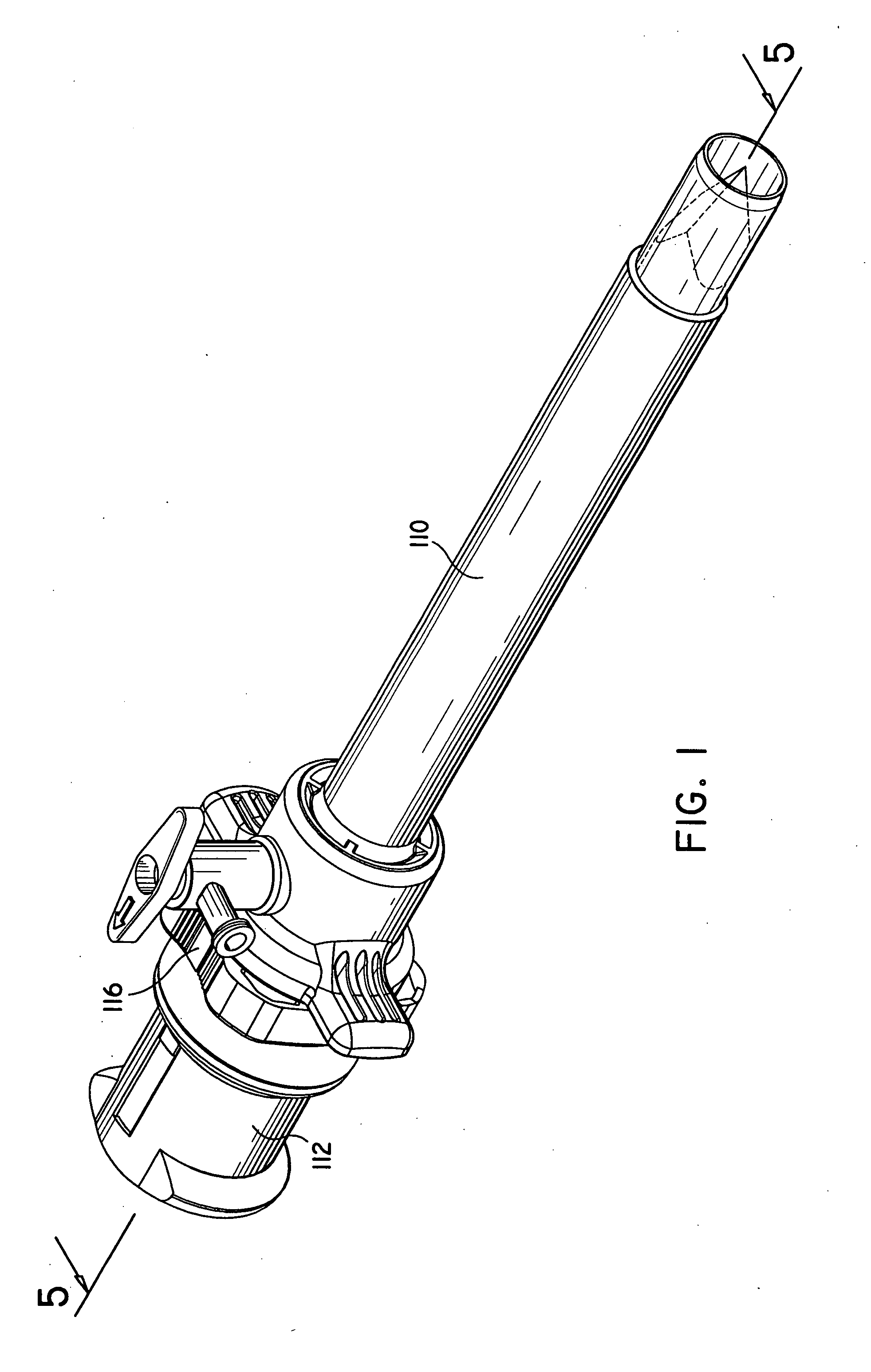

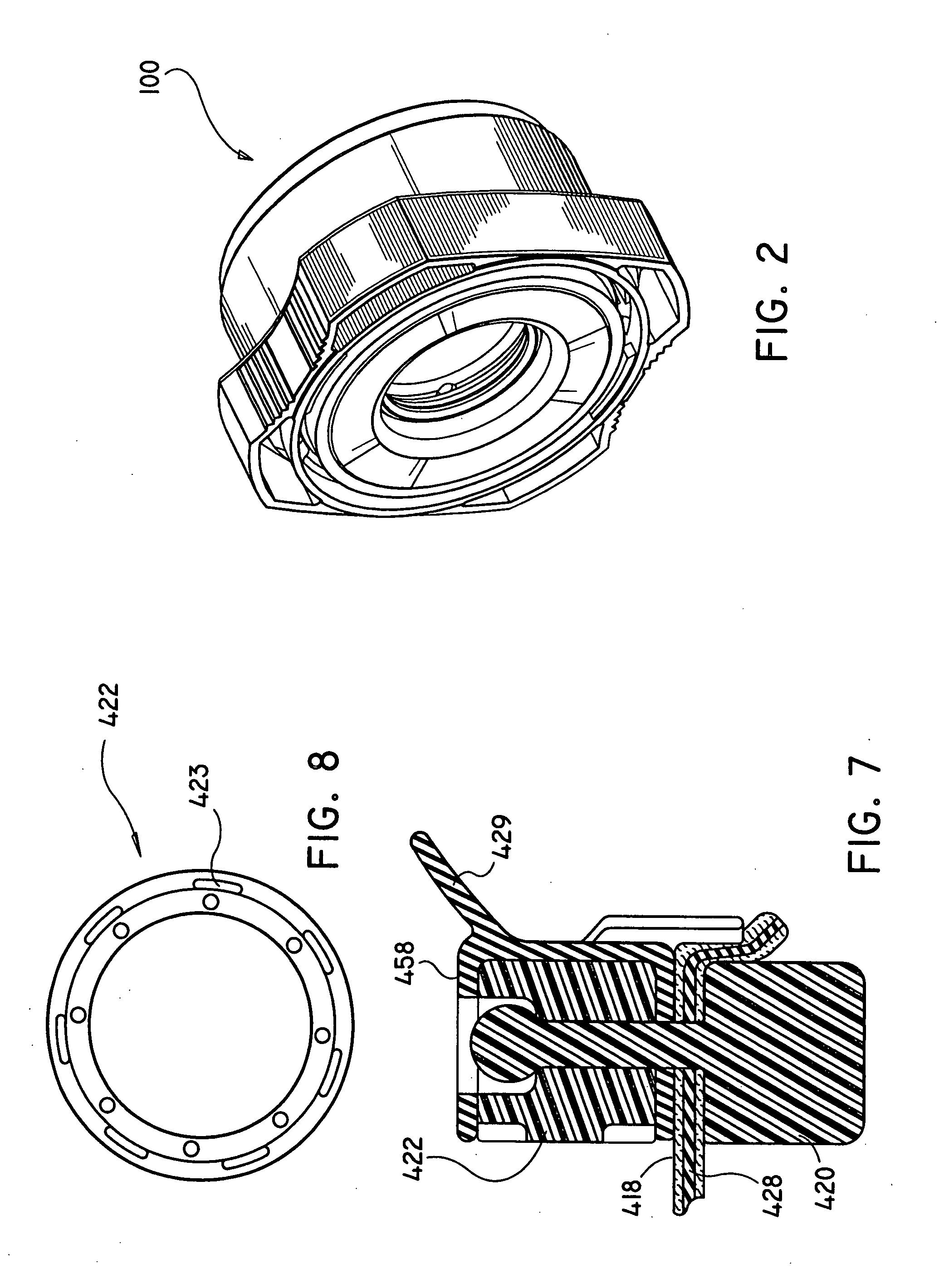

Trocar seal system

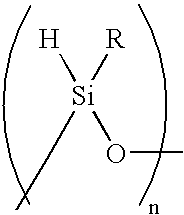

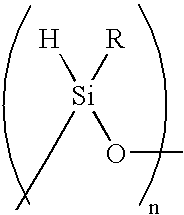

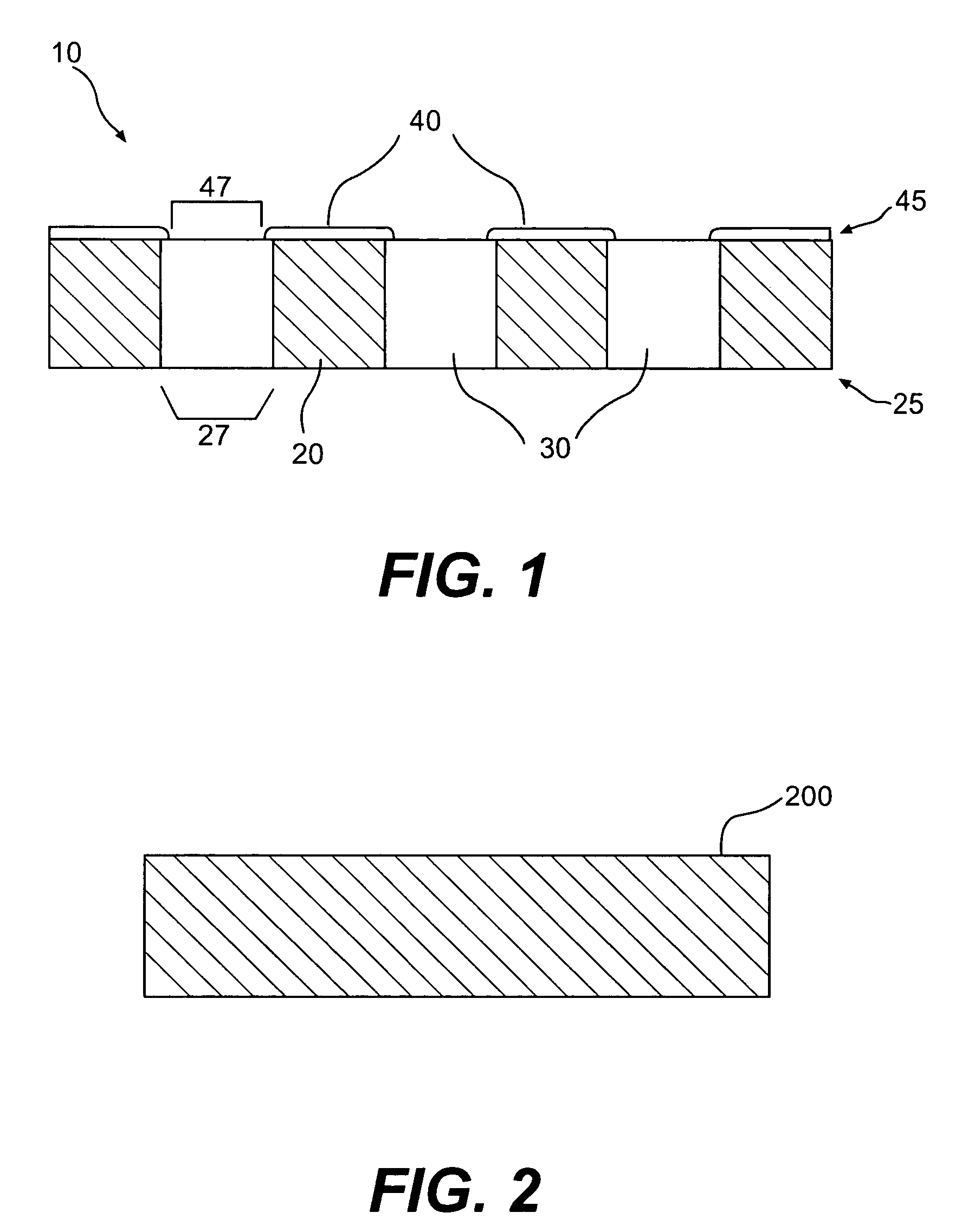

A seal assembly is provided for reception of an elongated surgical instrument, which comprises a body having at least one opening configured and dimensioned to permit entry of an elongated surgical instrument and defining a central longitudinal axis; a seal member formed of a resilient material and defining an aperture therein, the aperture being configured and dimensioned such that insertion of the surgical instrument into the aperture causes the resilient material defining the aperture to resiliently contact the outer surface of the surgical instrument in a substantially fluid tight manner, the seal member further including a peripheral flange element which contacts a surface of the body to form a contact seal therewith; and a fabric layer juxtaposed relative to the resilient material. The seal assembly may further include a coating applied to the seal member to reduce friction between the seal member and surgical instrumentation inserted therein. The coating is preferably a hydrocyclosiloxane membrane prepared by plasma polymerization process.

Owner:TYCO HEALTHCARE GRP LP

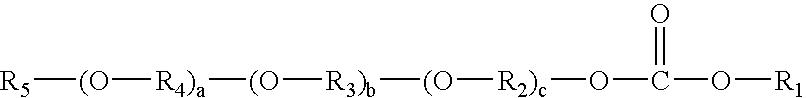

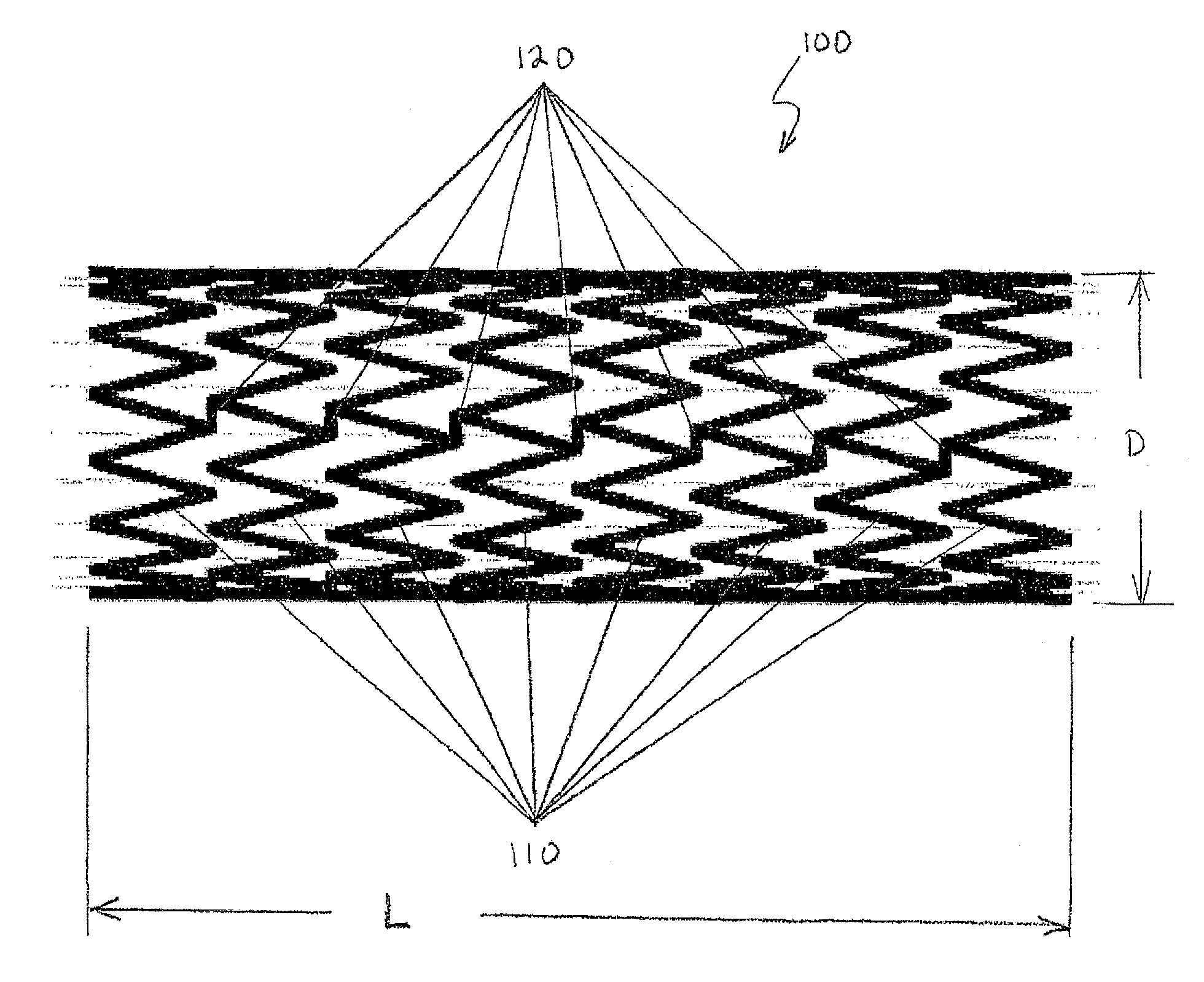

Plasma-generated coatings for medical devices and methods for fabricating thereof

Coatings for implantable medical devices, such as stents, and methods of coating the devices are disclosed. The method includes forming a coating by plasma polymerization of a monomer or a blend of monomers.

Owner:ABBOTT CARDIOVASCULAR

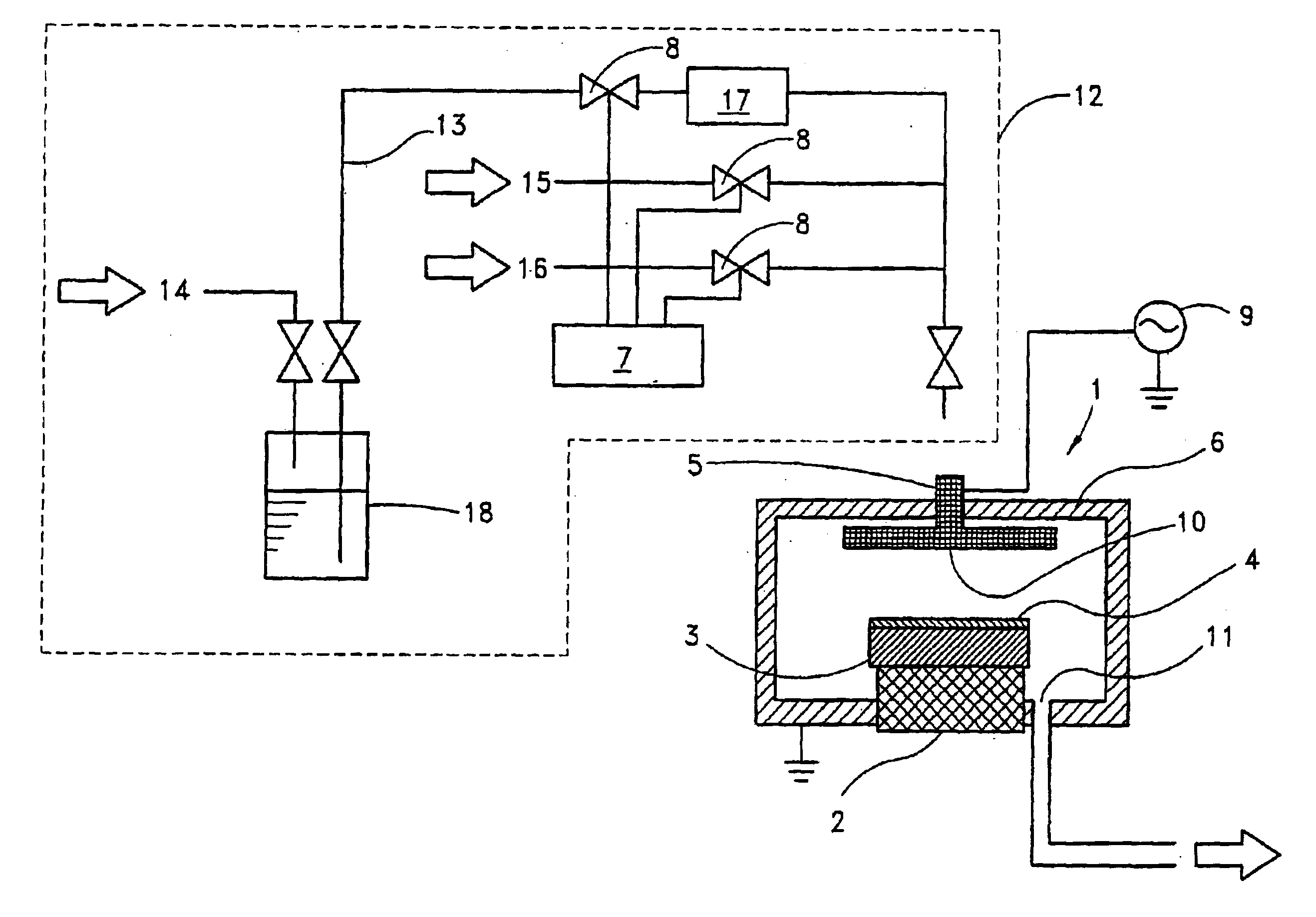

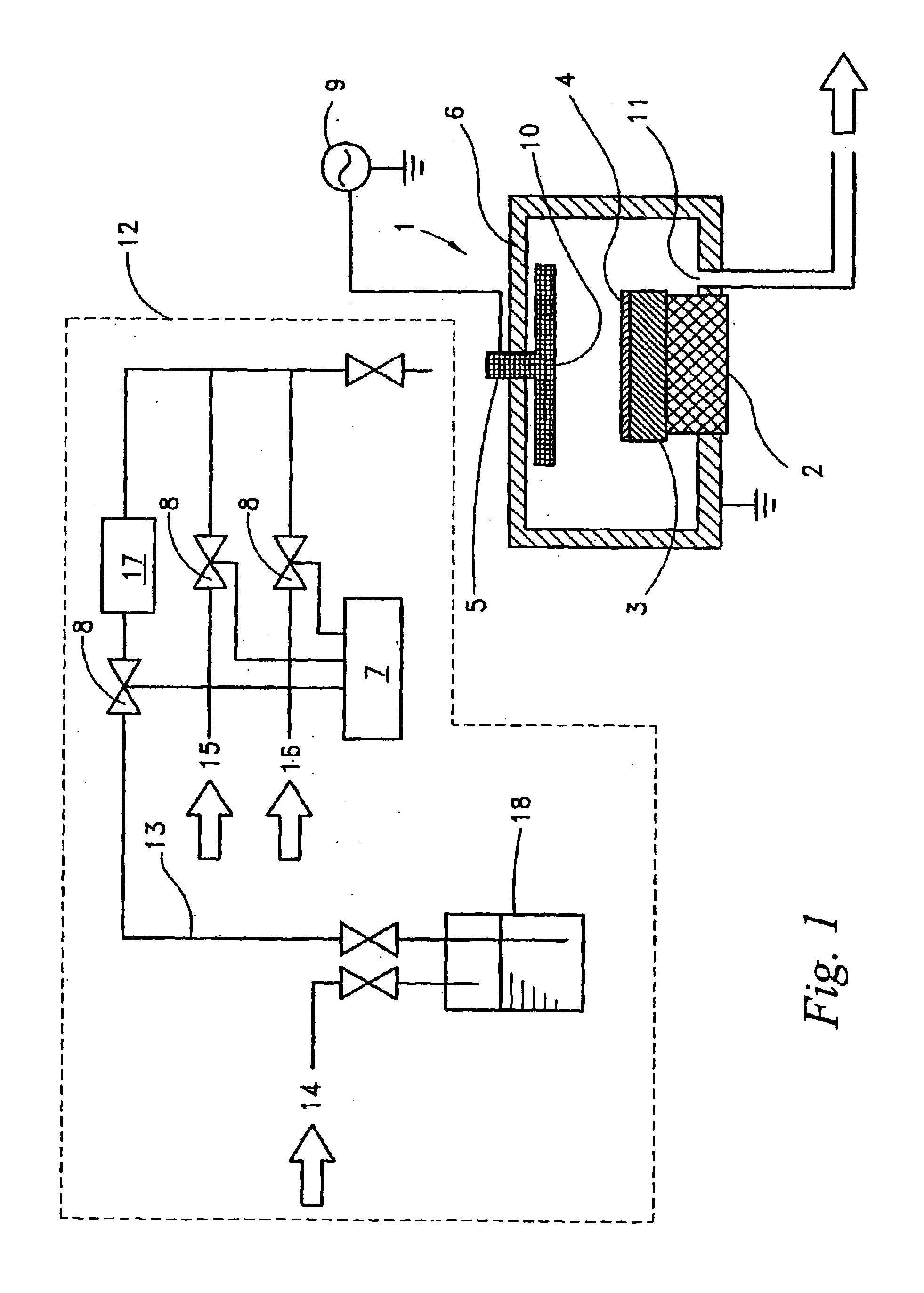

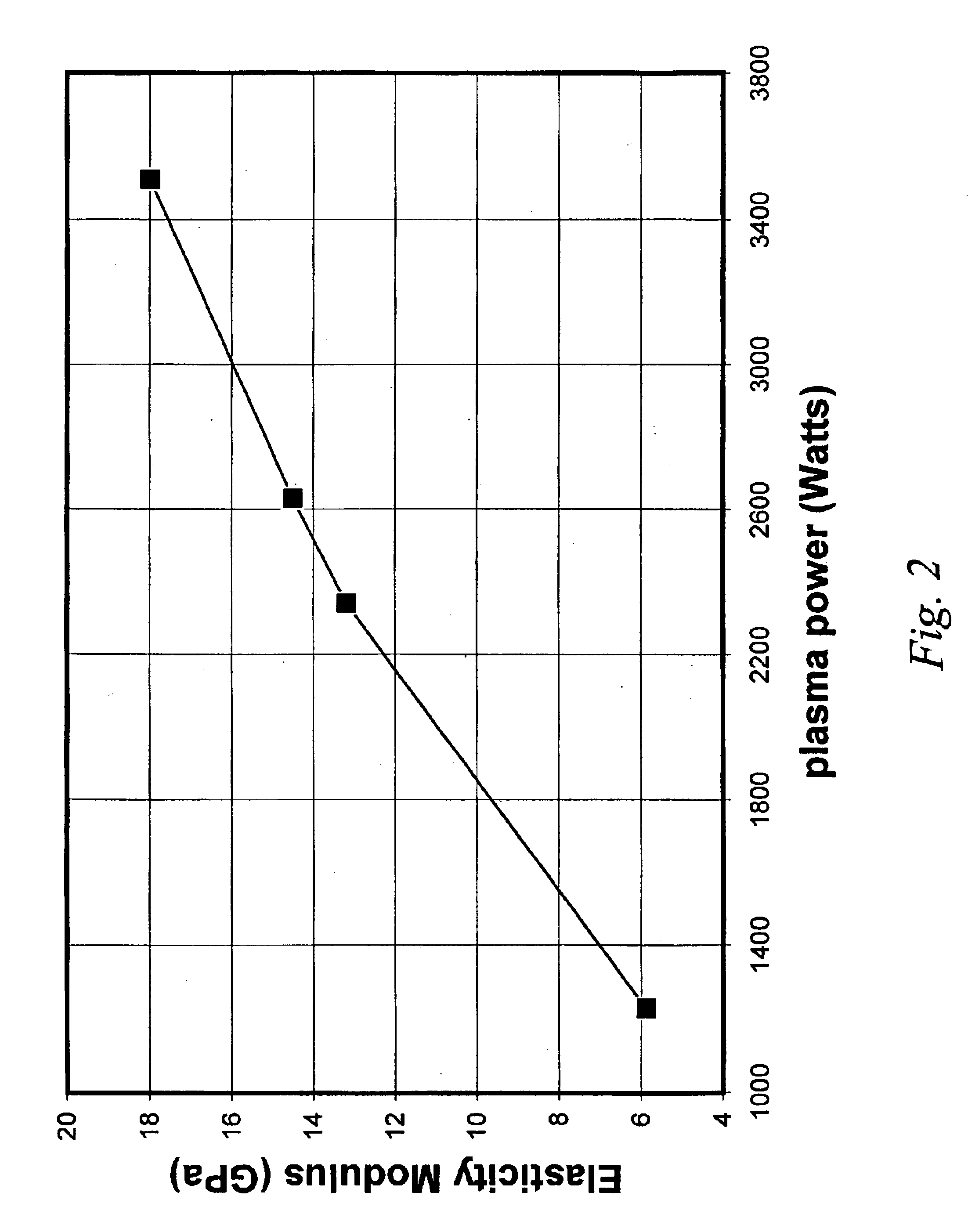

Method for forming low-dielectric constant film on semiconductor substrate by plasma reaction using high-RF power

InactiveUS6740602B1Liquid surface applicatorsSemiconductor/solid-state device detailsHardnessPlasma reaction

A method for forming a film having a low dielectric constant and high mechanical hardness on a semiconductor substrate by plasma reaction includes the steps of: (i) introducing a silicon-containing hydrocarbon gas as a source gas into a reaction space for plasma CVD processing wherein a semiconductor substrate is placed; and (ii) applying radio-frequency (RF) power of 1,000 W or higher to the reaction space while maintaining a pressure of the reaction space at 100 Pa or higher to activate plasma polymerization reaction in the reaction space, thereby forming a thin film on the semiconductor substrate.

Owner:ASM JAPAN

Plasma coated sutures

InactiveUS7294357B2Improve handlingImprove balanceSuture equipmentsFibre treatmentMedicinePlasma coating

Suture filaments coated by a plasma polymerization process exhibit a good balance of knot run down and knot security characteristics, superior tissue drag characteristics, and improved fray resistance.

Owner:TYCO HEALTHCARE GRP LP +1

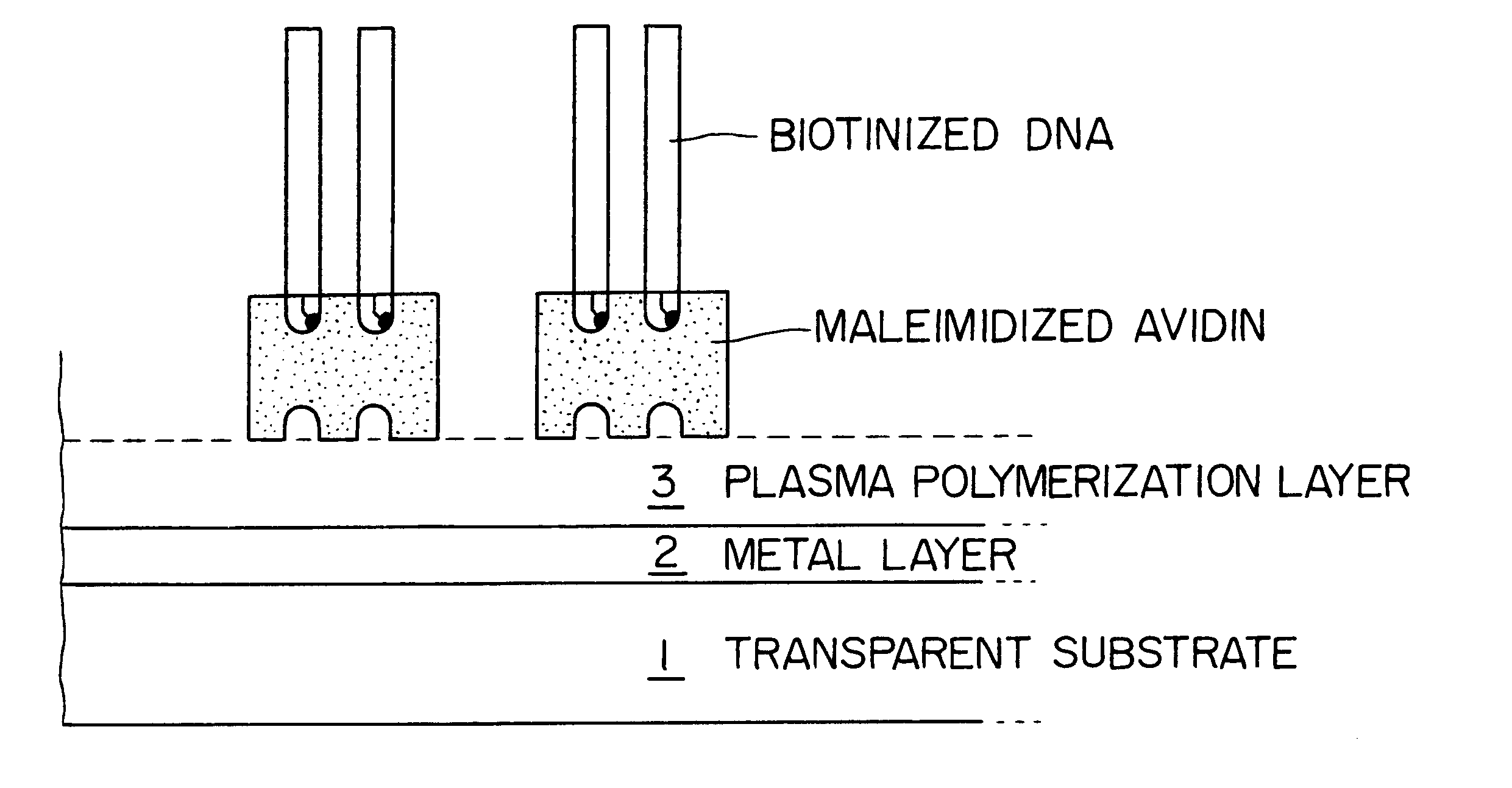

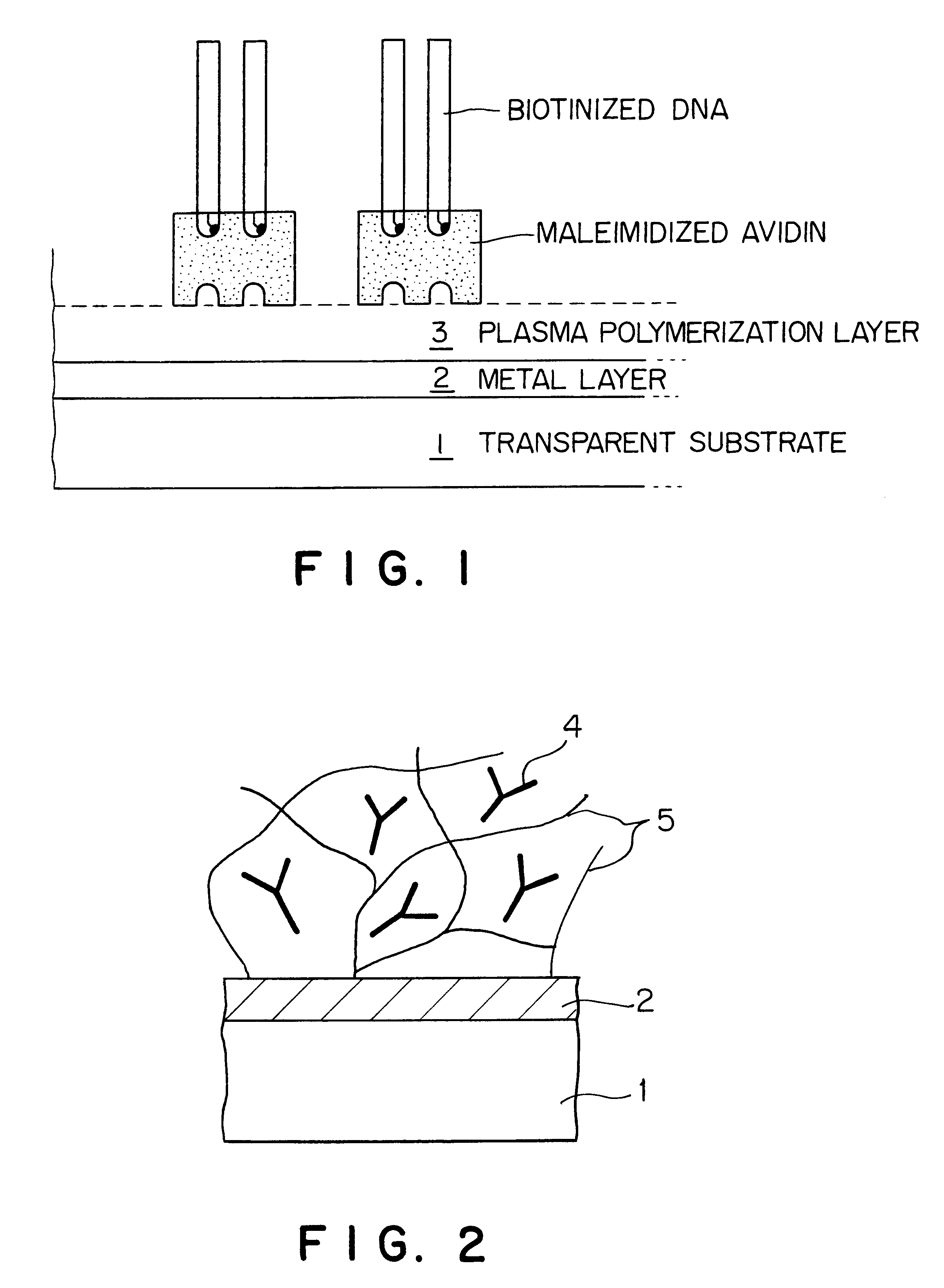

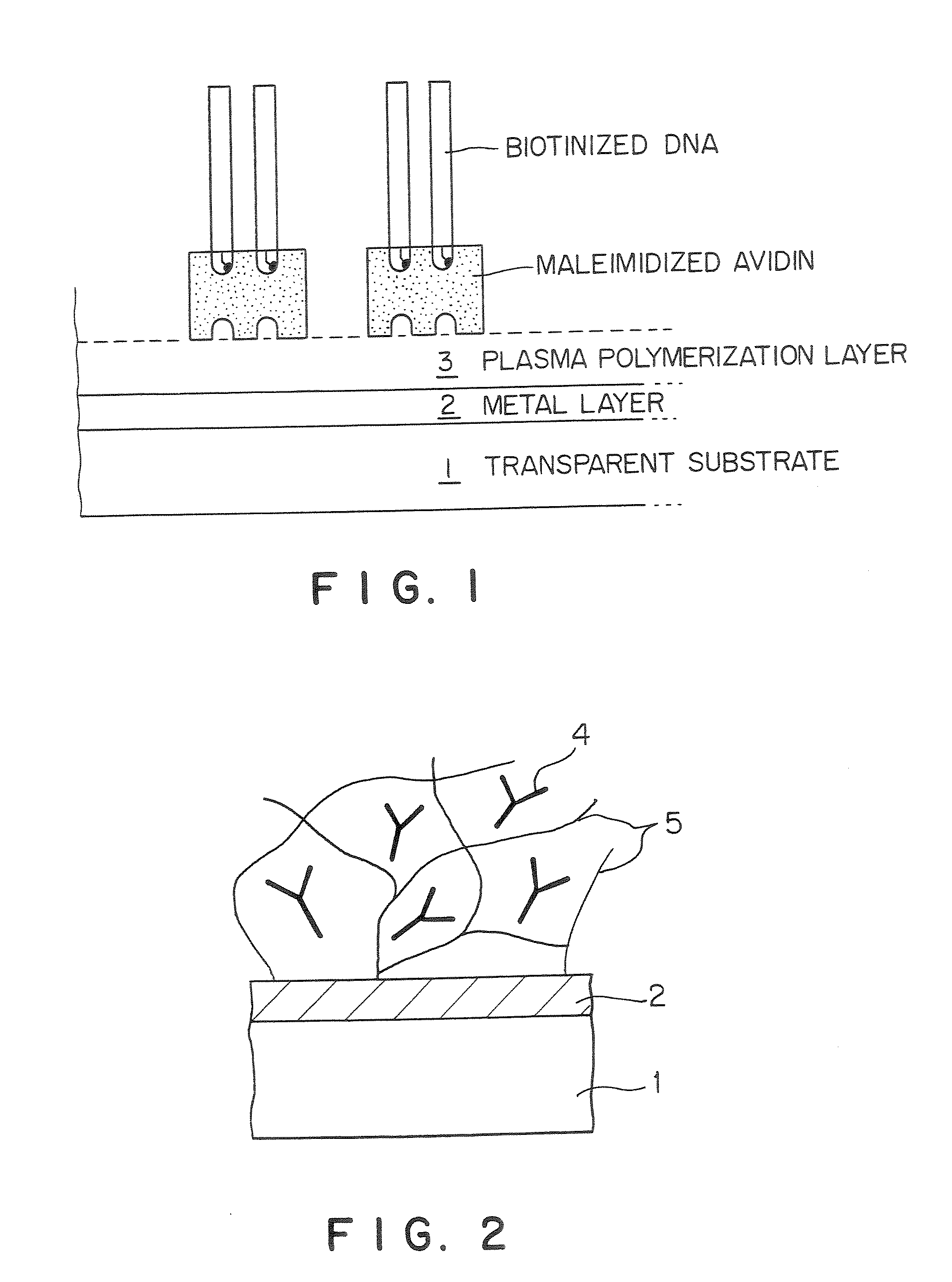

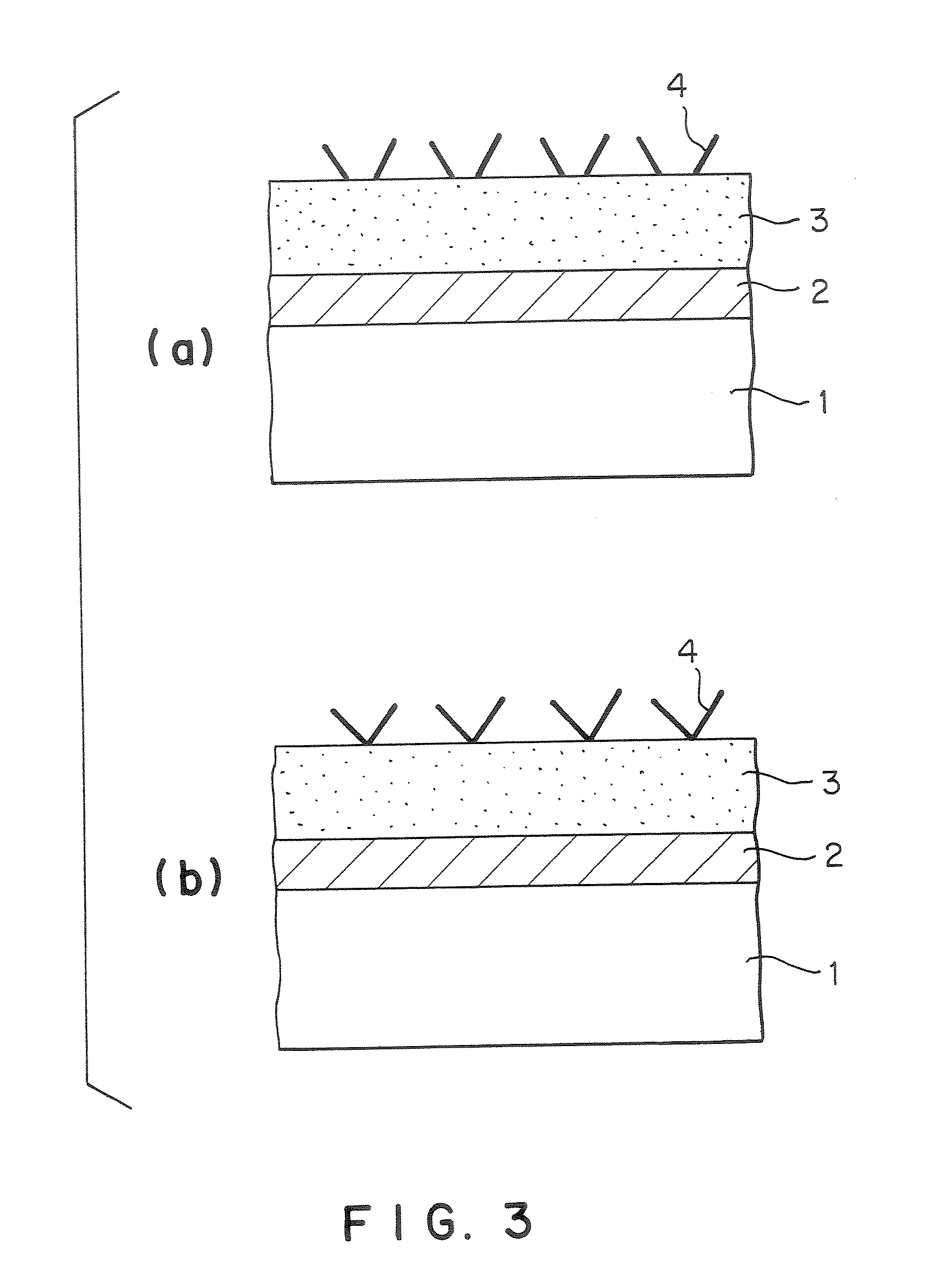

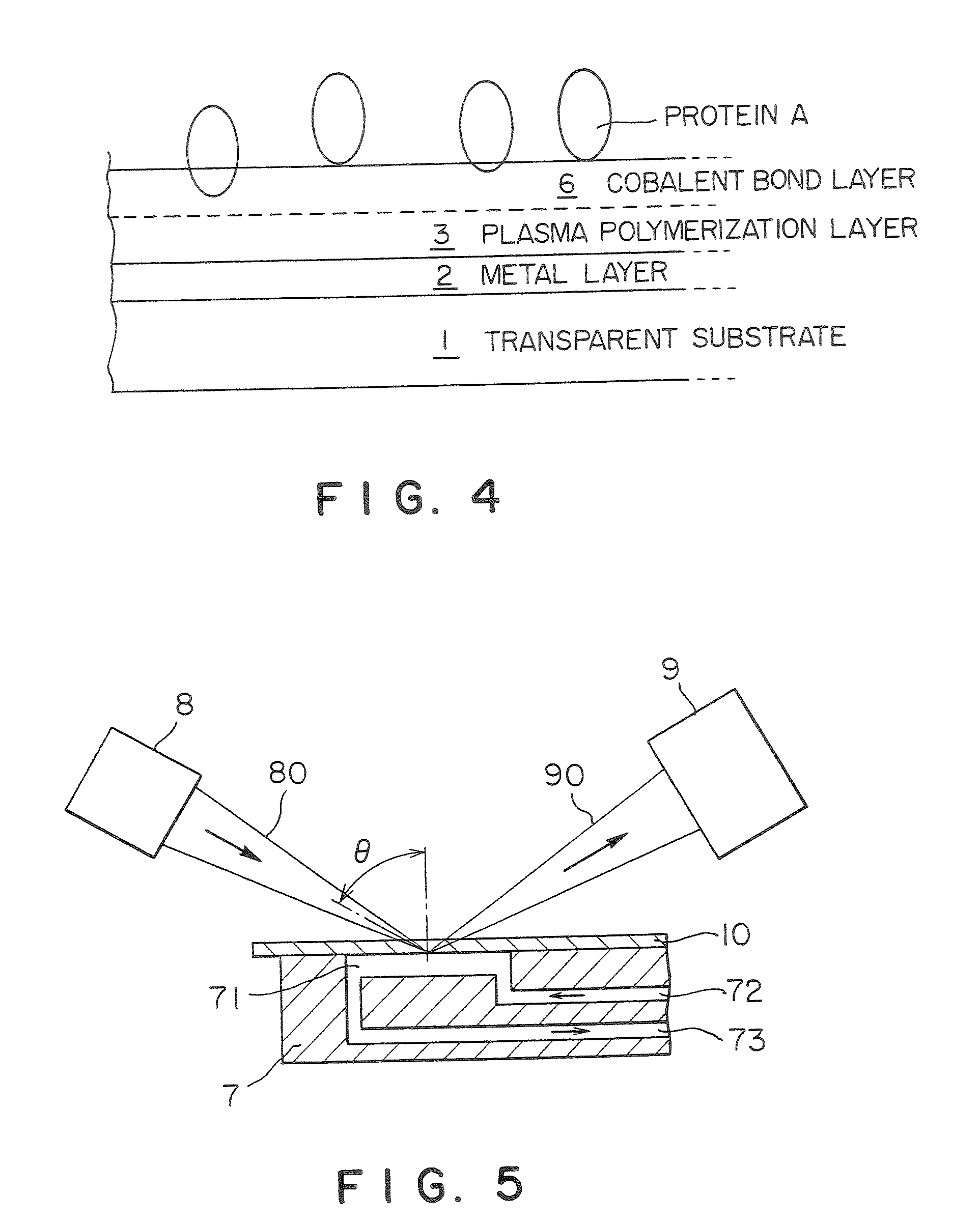

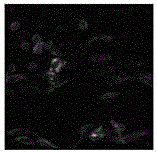

Measuring chip for surface plasmon resonance biosensor and method for producing the same

InactiveUS6627397B1High sensitivitySamplingMaterial analysis by observing effect on chemical indicatorSurface plasmon resonance sensorMetal

An objective of the present invention is to provide a measuring chip for a surface plasmon resonance sensor that can detect a small amount of target substances in high sensitivity. The present invention provides a measuring chip for a surface plasmon resonance sensor comprising a metal layer, one or more plasma polymerization layers formed on said metal layer, and a biologically active substance immobilized on the surface of said plasma polymerization layer.

Owner:DAI NIPPON PRINTING CO LTD +1

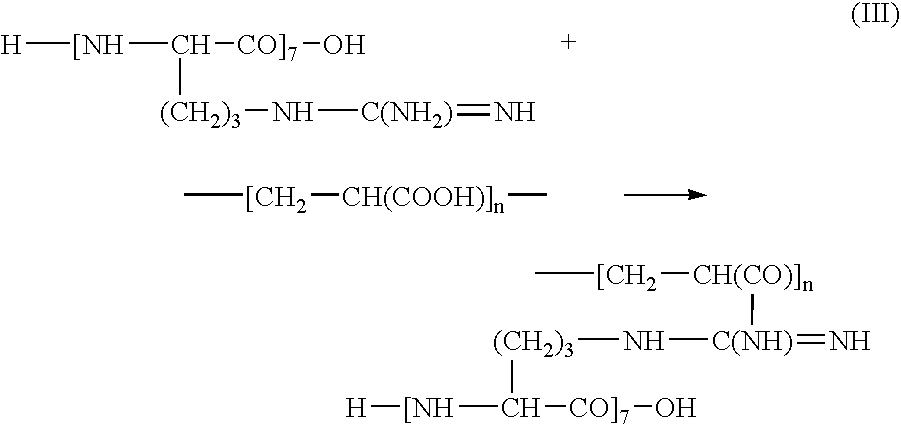

Implantable medical devices incorporating plasma polymerized film layers and charged amino acids

An implantable medical device, such as a stent, is disclosed comprising an amino acid or a polypeptide bonded to a plasma polymerized film layer formed on the device. A method of manufacturing the same is also disclosed.

Owner:ABBOTT CARDIOVASCULAR

Medical device chemically modified by plasma polymerization

InactiveUS7396582B2Facilitates fusion and adhesive bondingImprove adhesionLiquid surface applicatorsSurgeryMedical deviceMedical treatment

Medical devices, and particularly intracorporeal devices for therapeutic or diagnostic uses, having a component chemically modified by plasma polymerization. The medical device comprises a substrate with a plasma polymerized functionality bonded to a surface of at least a section thereof. The plasma polymerized film on a first component of the medical device allows for bonding an agent or a second component to the first component. In one embodiment, the plasma polymerized film facilitates fusion or adhesive bonding of a first component to a second component formed of a material which is dissimilar to, incompatible with, or otherwise not readily bondable to the substrate material of the first component. In another embodiment, a bioactive agent is bonded to the plasma polymerized film on the component, for presenting or delivering the bioactive agent within a body lumen of the patient.

Owner:ABBOTT CARDIOVASCULAR

Multi-layer coating system and method

A system and method for coating implantable medical devices so that they do not interfere with MR imaging are described. Using any of the coating processes well known to those skilled in the art, e.g., physical vapor deposition such as evaporation, sputtering, or cathode arc, or chemical vapor deposition, spraying, plasma polymerization, plasma enhanced chemical vapor deposition and the like, multiple sources, including at least one source of an electrically insulating material and at least one source of an electrically conducting material, are oriented and shielded so as to coat separate sections of the implantable medical device. The object being coated is then rotated so that overlapping spiral coatings of the materials from the different coating sources are produced on the object.

Owner:ISOFLUX

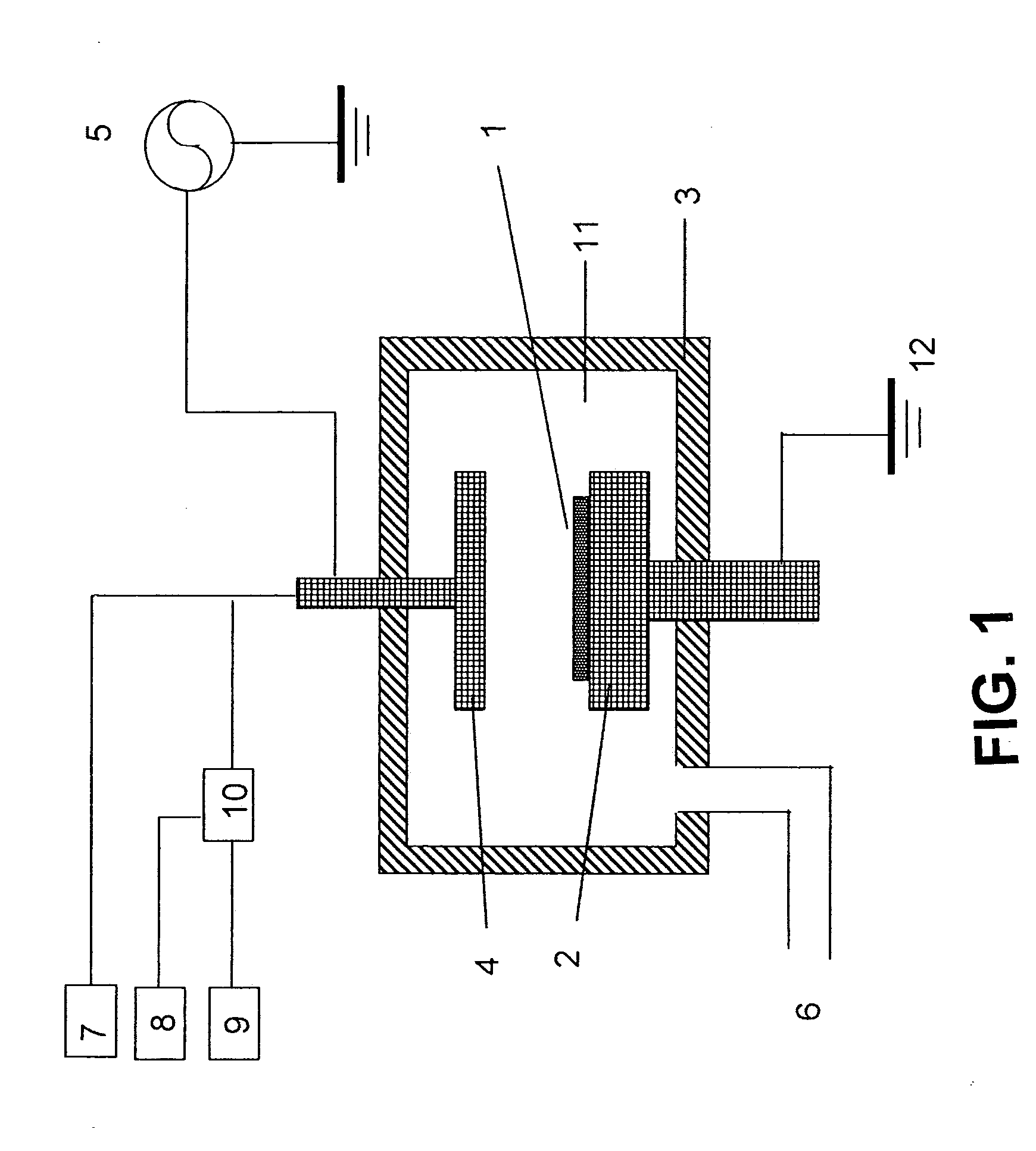

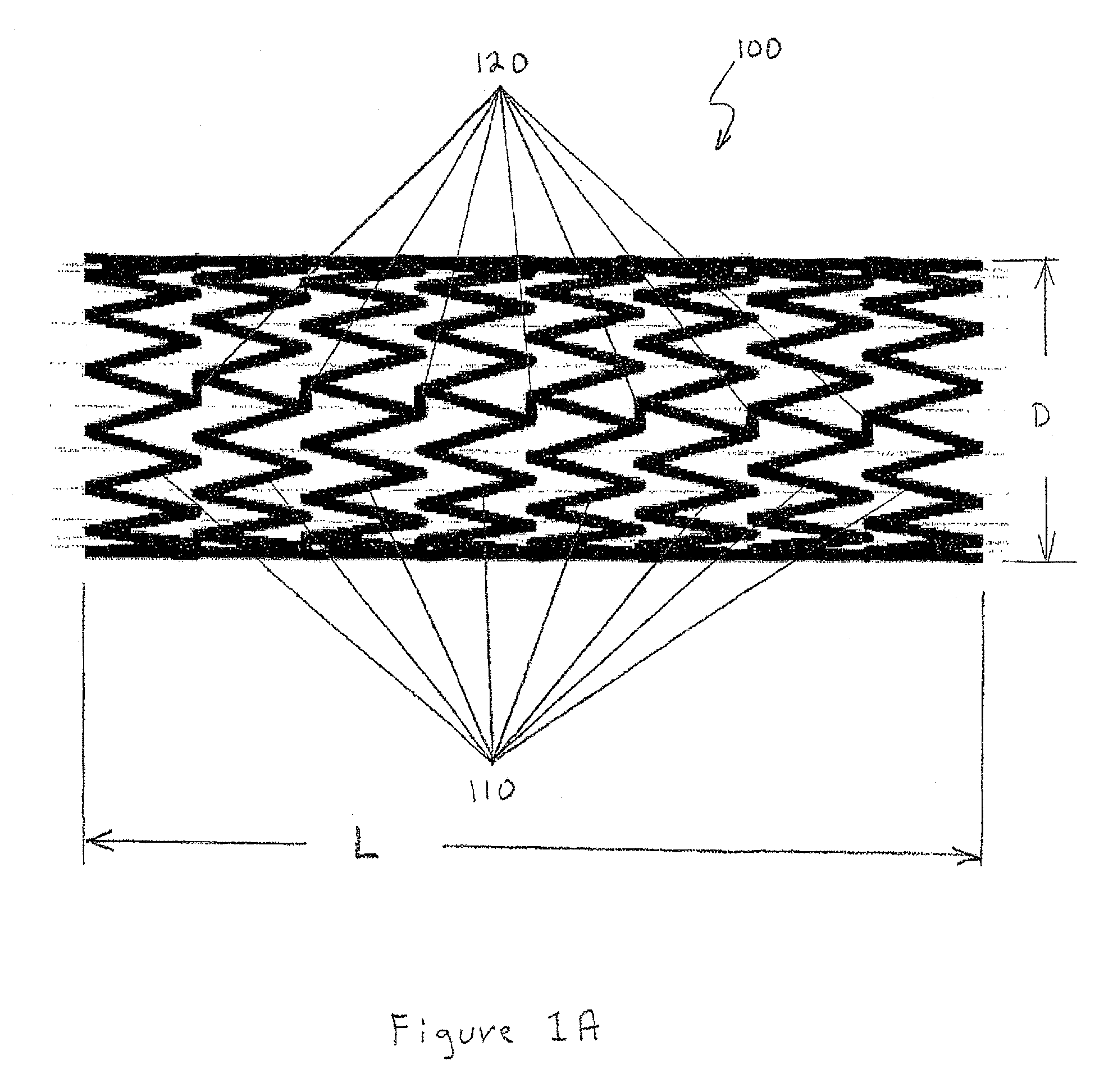

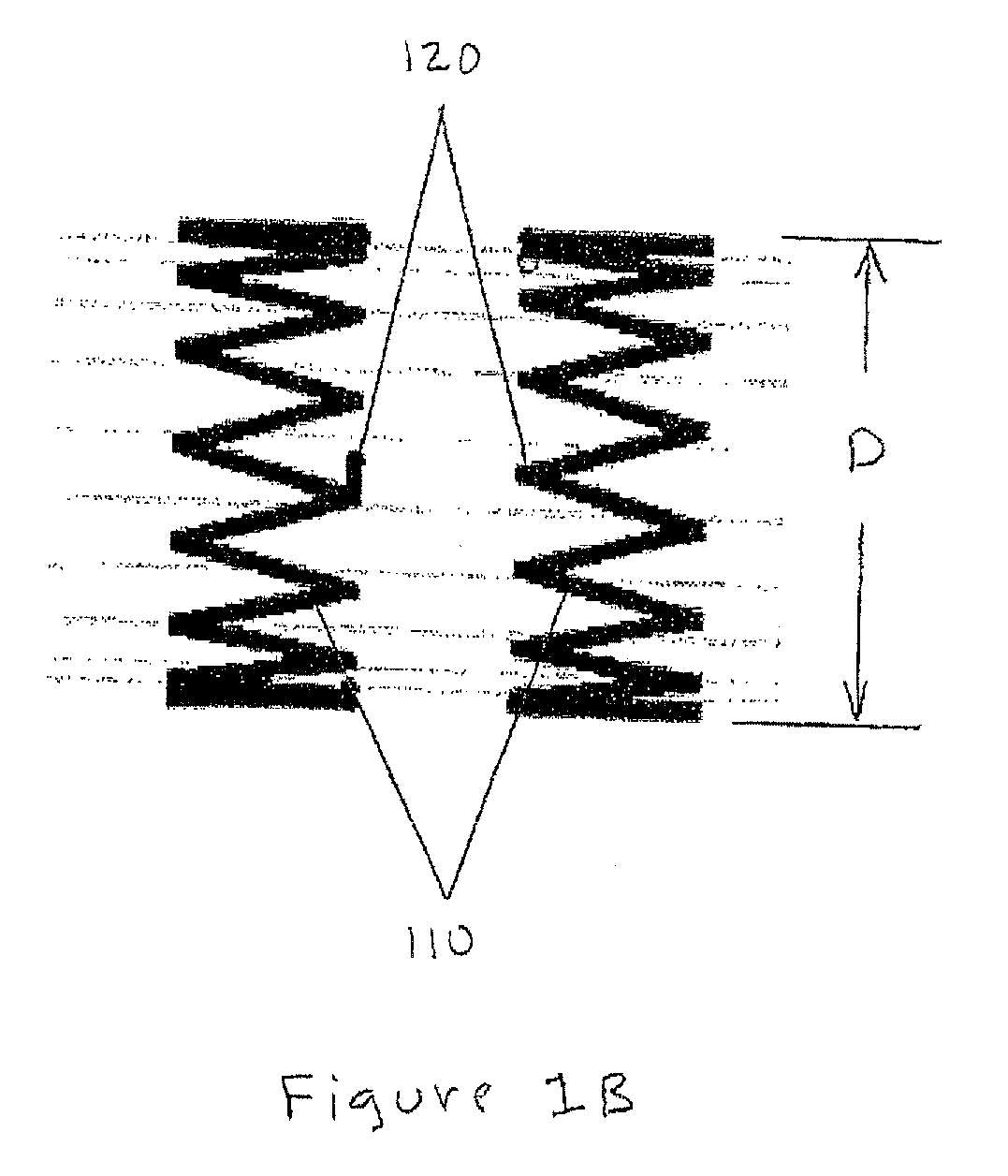

Plasma polymerization for encapsulating particles

InactiveUS20060045822A1Liquid surface applicatorsChemical/physical/physico-chemical processesChemical reactorCompound (substance)

The present invention includes systems, methods and compositions for the encapsulation of particles. In one form, the system comprises one or more particles, a rotatable reaction chamber in a plasma enhanced chemical reactor to accept one or more particles, and at least one carbonaceous compound to be used in the rotatable reaction chamber, wherein the carbonaceous compound is polymerized onto a surface of one or more particles forming a polymer film encapsulating one or more particles. Using systems, methods, and compositions of the present invention, any particle encapsulated with a degradable or nondegradable polymer film may be introduced and / or released into an environment. The polymer film as well as introduction of encapsulated particles and release therefrom into an environment are controlled by the present invention.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

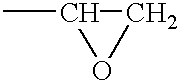

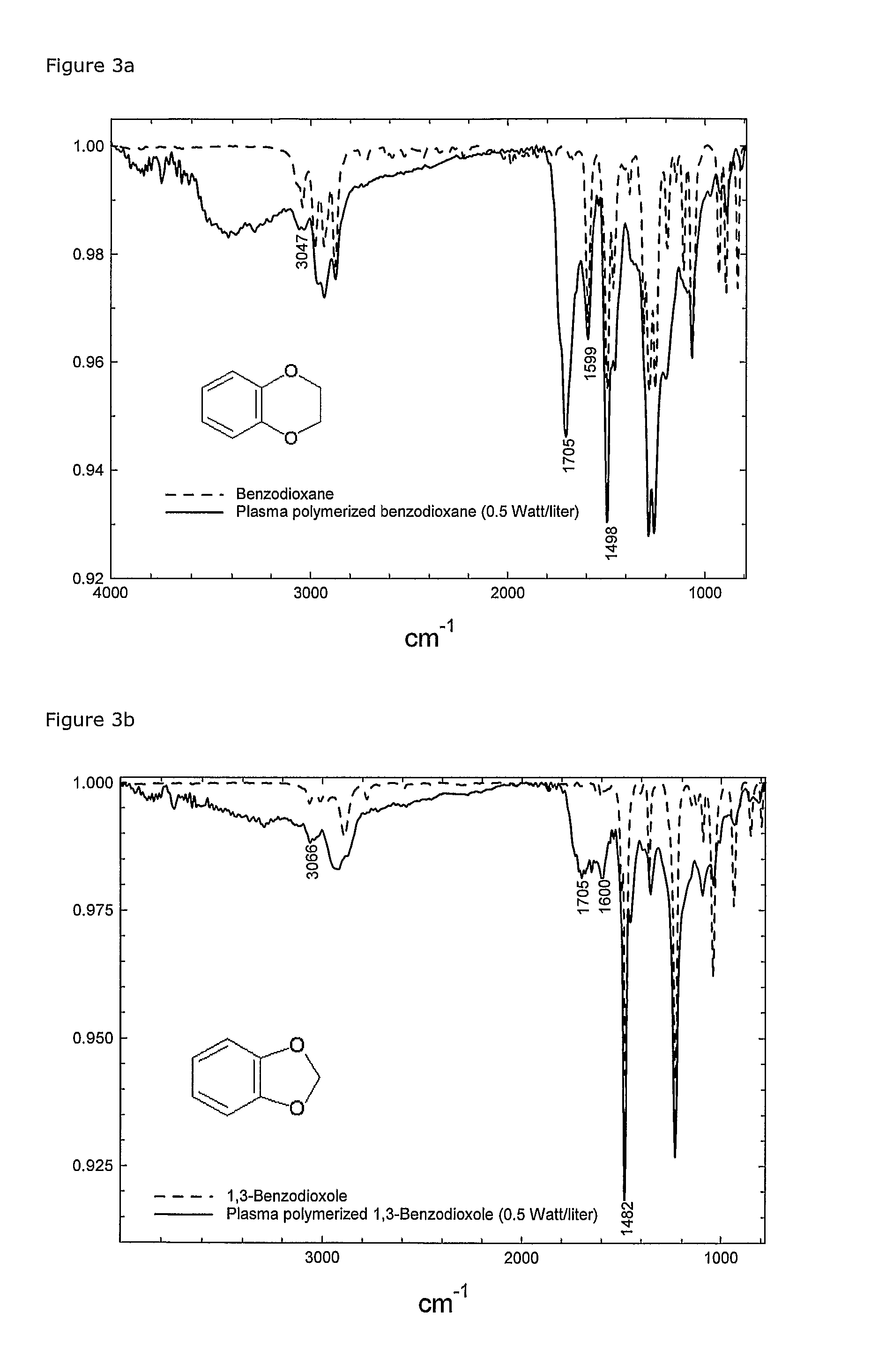

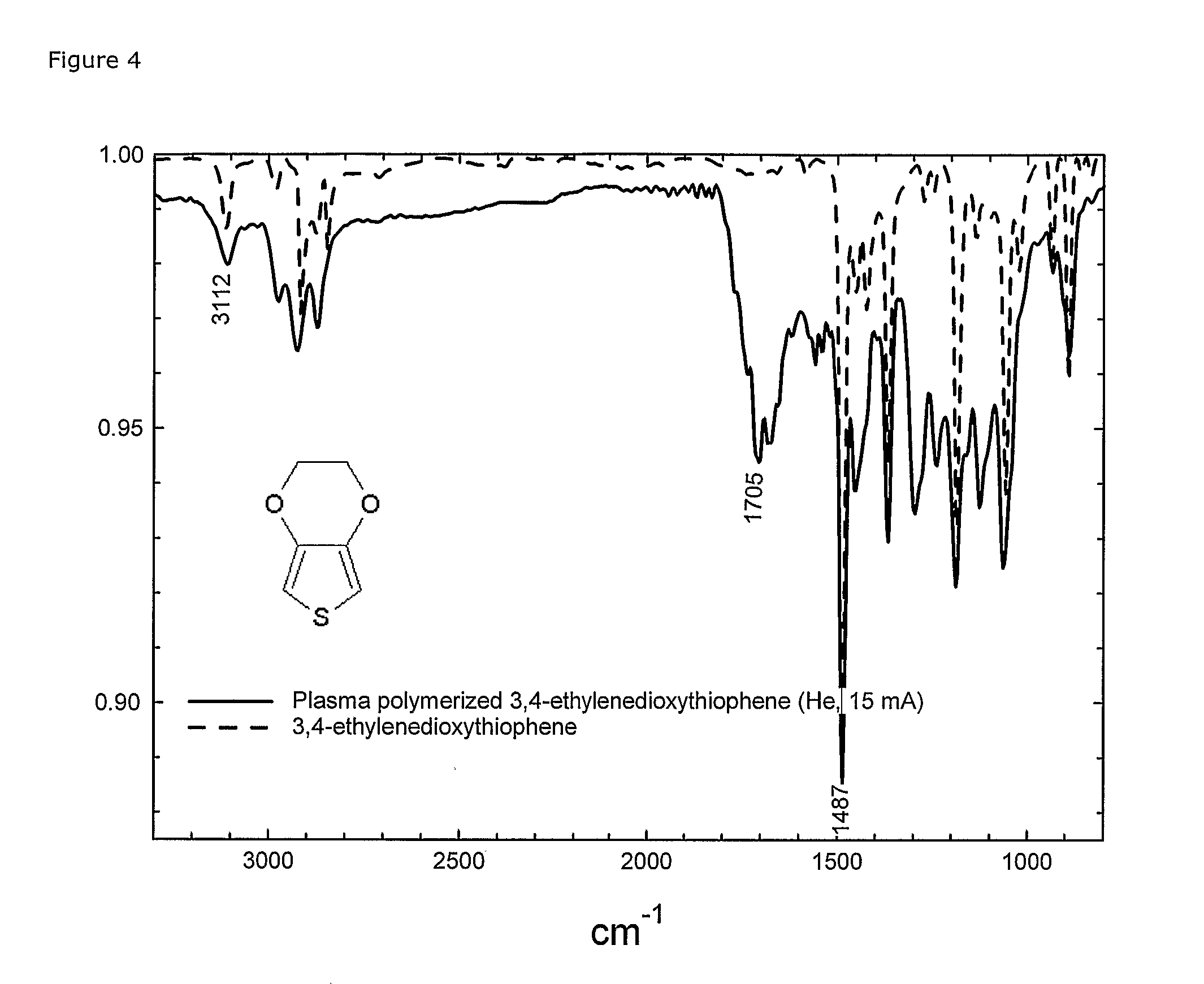

Plasma-Polymerisation Of Polycylic Compounds

InactiveUS20070202612A1Liquid surface applicatorsSynthetic resin layered productsPolycyclic compoundEthylenedioxy

The present invention relates to a method for the preparation of a layer of a plasma-polymerised material on the surface of a substrate, e.g. a substrate of a glass, an organosiloxane-based or polysiloxane-based material, silicon, fluoro-polymer (e.g. Teflon®), etc. The present invention also relates to novel objects and microstructured or micro-patterned devices, e.g. by lift-off techniques, in particular such objects and devices that have layers of electrically conducting materials providing a conductivity of at least 0.01 S / cm. A feature of the invention is the plasma-polymerization of a compound including at least one polycyclic compound, said polycyclic compound(s) comprising a non-aromatic heterocyclic ring fused to an aromatic or heteroaromatic ring or ring system. Examples of such compounds are 3,4-ethylenedioxythiophene (EDT) forming layers of poly(ethylenedioxythiophene) (PEDT), and piperonylamine, piperonyloyl chloride, safrole, 3,4-ethylenedioxypyrrole, 3,4-ethylenedioxy-N-methylpyrrole, and 3,4-methylenedioxythiophene.

Owner:DANMARKS TEKNISKE UNIV

Method of forming interlayer insulating film

InactiveUS7060323B2Improve cost efficiencyImprove film formabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxidePhenyl group

A material containing, as a main component, an organic silicon compound represented by the following general formula:R1xSi(OR2)4-x(where R1 is a phenyl group or a vinyl group; R2 is an alkyl group; and x is an integer of 1 to 3) is caused to undergo plasma polymerization or react with an oxidizing agent to form an interlayer insulating film composed of a silicon oxide film containing an organic component. As the organic silicon compound where R1 is a phenyl group, there can be listed phenyltrimethoxysilane or diphenyldimethoxysilane. As the organic silicon compound where R1 is a vinyl group, there can be listed vinyltrimethoxysilane or divinyldimethoxysilane.

Owner:PANASONIC CORP

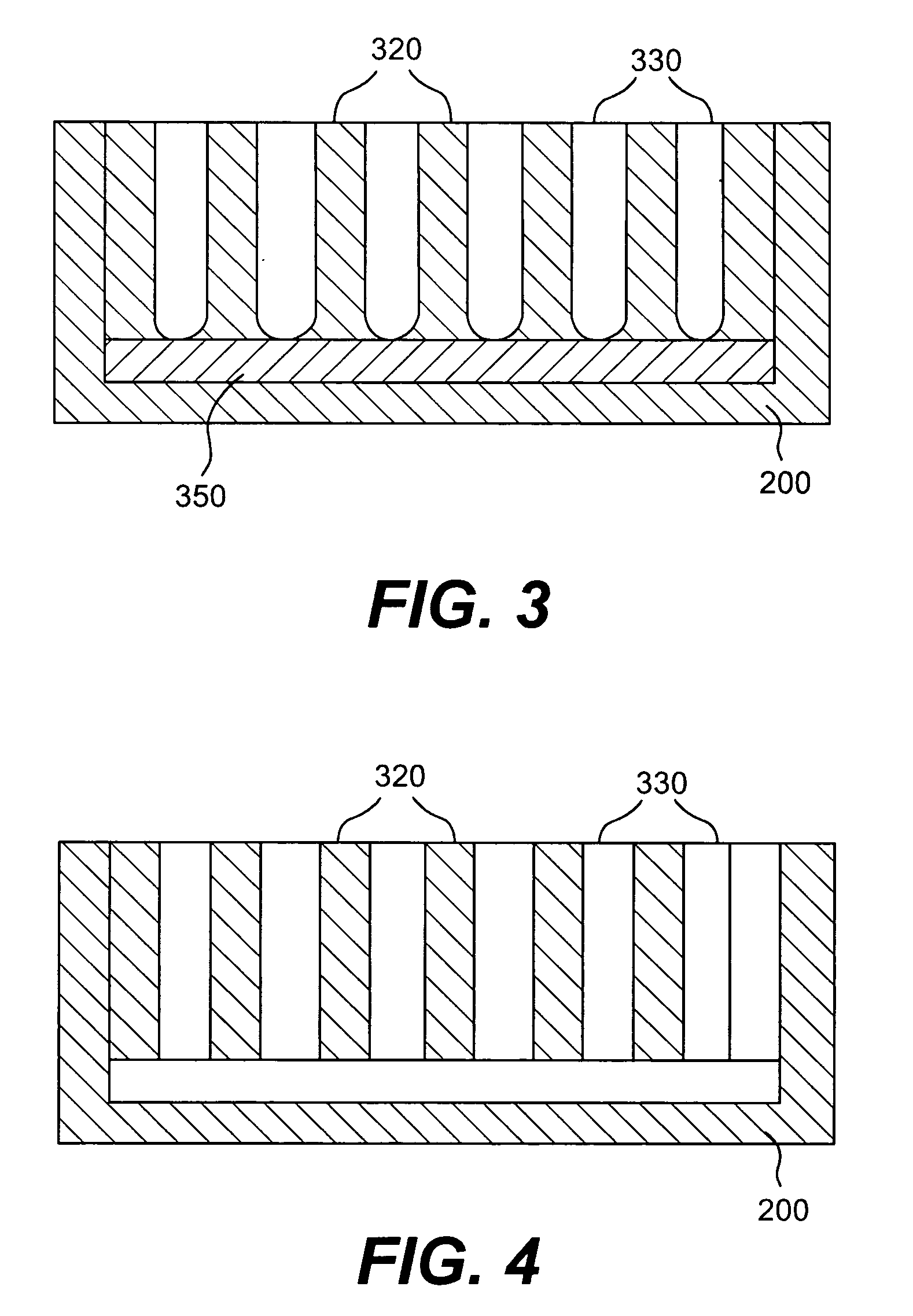

Fabrication of an anisotropic super hydrophobic/hydrophilic nanoporous membranes

ActiveUS20060037477A1Semi-permeable membranesSurface reaction electrolytic coatingNanoporous membraneFluorocarbon

Anisotropic hydrophobic / hydrophilic nanoporous membranes and methods of forming anisotropic hydrophobic / hydrophilic nanoporous membranes are disclosed. The method of forming the nanoporous membrane includes growing a nanoporous oxide film on a substrate. A nanoporous membrane having a top side and a bottom side can then be formed by partially separating the nanoporous oxide film from the substrate. A fluorocarbon film can be deposited on the top side of the nanoporous membrane by plasma polymerization. The disclosed anisotropic hydrophobic / hydrophilic nanoporous membranes can have extremely different hydrophobicity between the top side and the bottom side of the nanoporous membrane.

Owner:STC UNM

Measuring chip for surface plasmon resonance biosensor and method for producing the same

InactiveUS20070148702A1High measurement sensitivityHigh sensitivityBioreactor/fermenter combinationsBiological substance pretreatmentsSurface plasmon resonance sensorMetal

An objective of the present invention is to provide a measuring chip for a surface plasmon resonance sensor that can detect a small amount of target substances in high sensitivity. The present invention provides a measuring chip for a surface plasmon resonance sensor comprising a metal layer, one or more plasma polymerization layers formed on said metal layer, and a biologically active substance immobilized on the surface of said plasma polymerization layer.

Owner:KARUBE ISAO +1

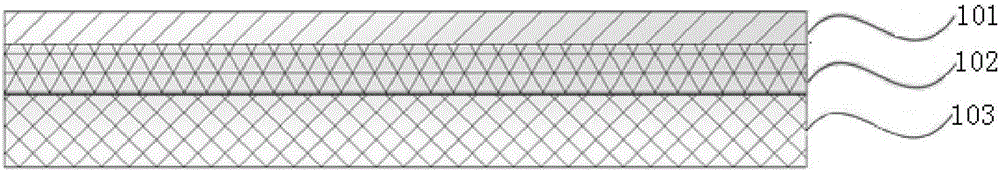

Anticoagulation high polymer biomaterial as well as preparation method and application thereof

ActiveCN106730051AGuaranteed persistenceGuaranteed stabilityPharmaceutical containersMedical packagingPlasma technologyAnticoagulant

The invention discloses an anticoagulation high polymer biomaterial which comprises a substrate layer, an anticoagulation coating, and a plasma polymerization layer positioned between the substrate layer and the anticoagulation coating, wherein the substrate layer is made of a biomedical material; the plasma polymerization layer is an allylamine plasma polymerization membrane layer deposited on the substrate layer; the anticoagulation coating is an anticoagulant layer fixed on the plasma polymerization layer; and the anticoagulants comprise hirudin, heparin and the like. Anticoagulant molecules are fixedly grafted on the material surface by utilizing the pulsed plasma technology and surface heparin grafting method, and effective molecule orientation is remained by heparin molecules, so the anticoagulant performance is close to the performance of heparin molecules in the solution. Meanwhile, the heparin molecules are difficultly scoured off by blood, the persistence and stability of the anticoagulation effect are guaranteed, and the service life is long. The invention further discloses a preparation method and application of the anticoagulation high polymer biomaterial.

Owner:スンナテクノロジーズシャンハイカンパニーリミテッド

Method of forming a high transparent carbon film

ActiveUS20090274851A1Improve featuresRich varietyLiquid surface applicatorsSemiconductor/solid-state device manufacturingCarbon filmPhotochemistry

A method of forming a transparent hydrocarbon-based polymer film on a substrate by plasma CVD includes: introducing a main gas consisting of a hydrocarbon gas (CαHβ, wherein α and β are natural numbers) and an inert gas at a flow ratio (R) of CαHβ / inert gas of 0.25 or less into a CVD reaction chamber inside which a substrate is placed; and forming a hydrocarbon-based polymer film on the substrate by plasma polymerization of the gas at a processing temperature (T) wherein T≦(−800R+500).

Owner:ASM JAPAN

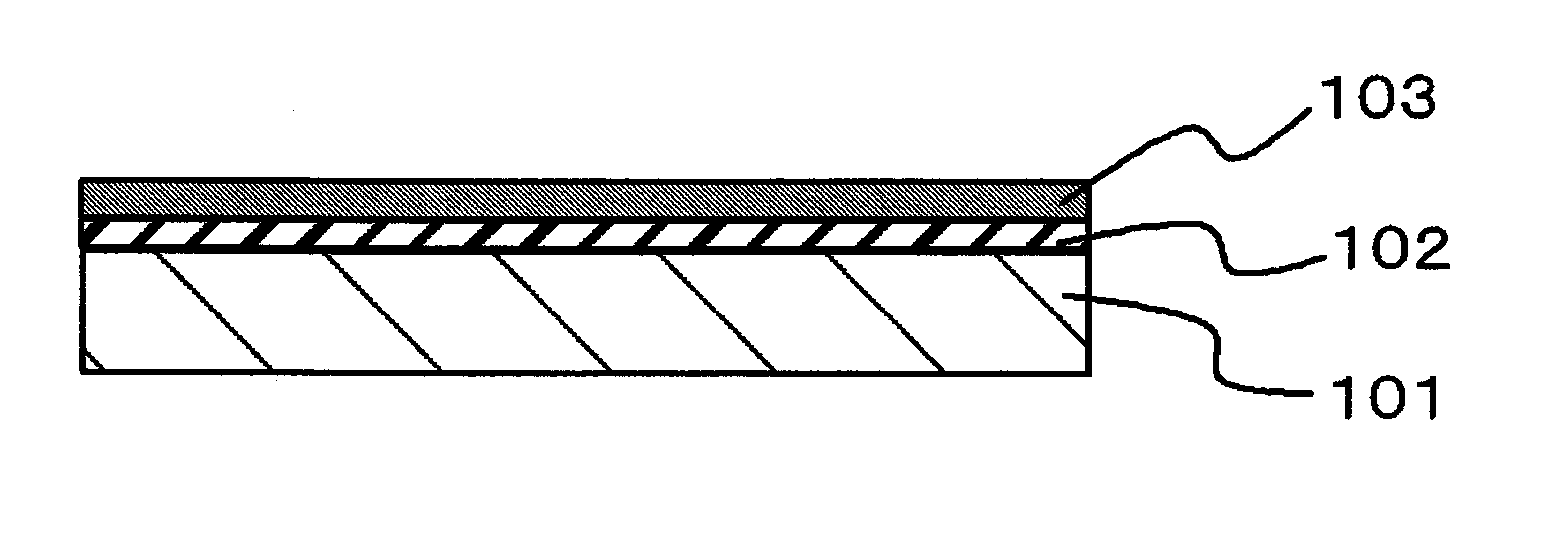

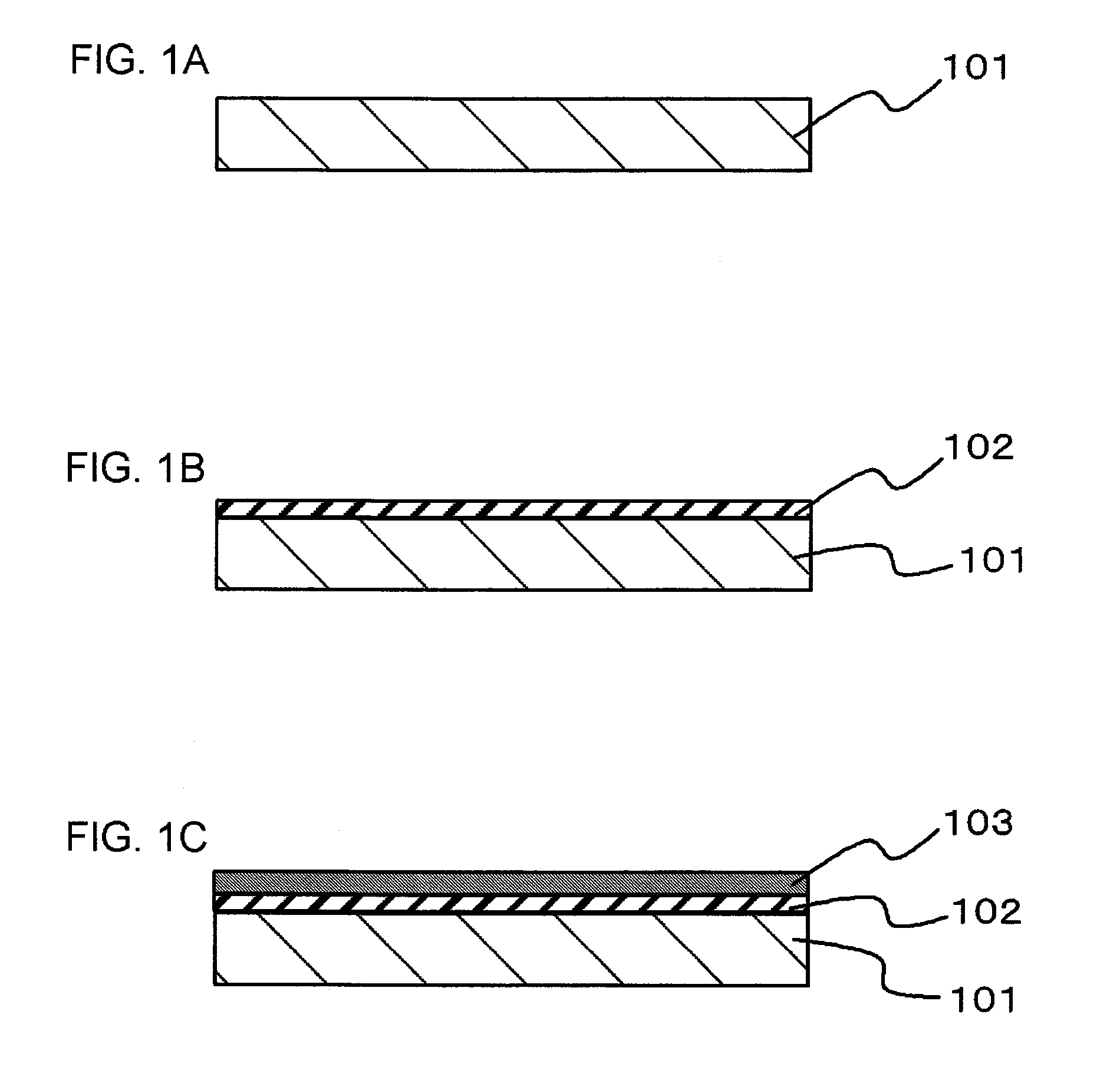

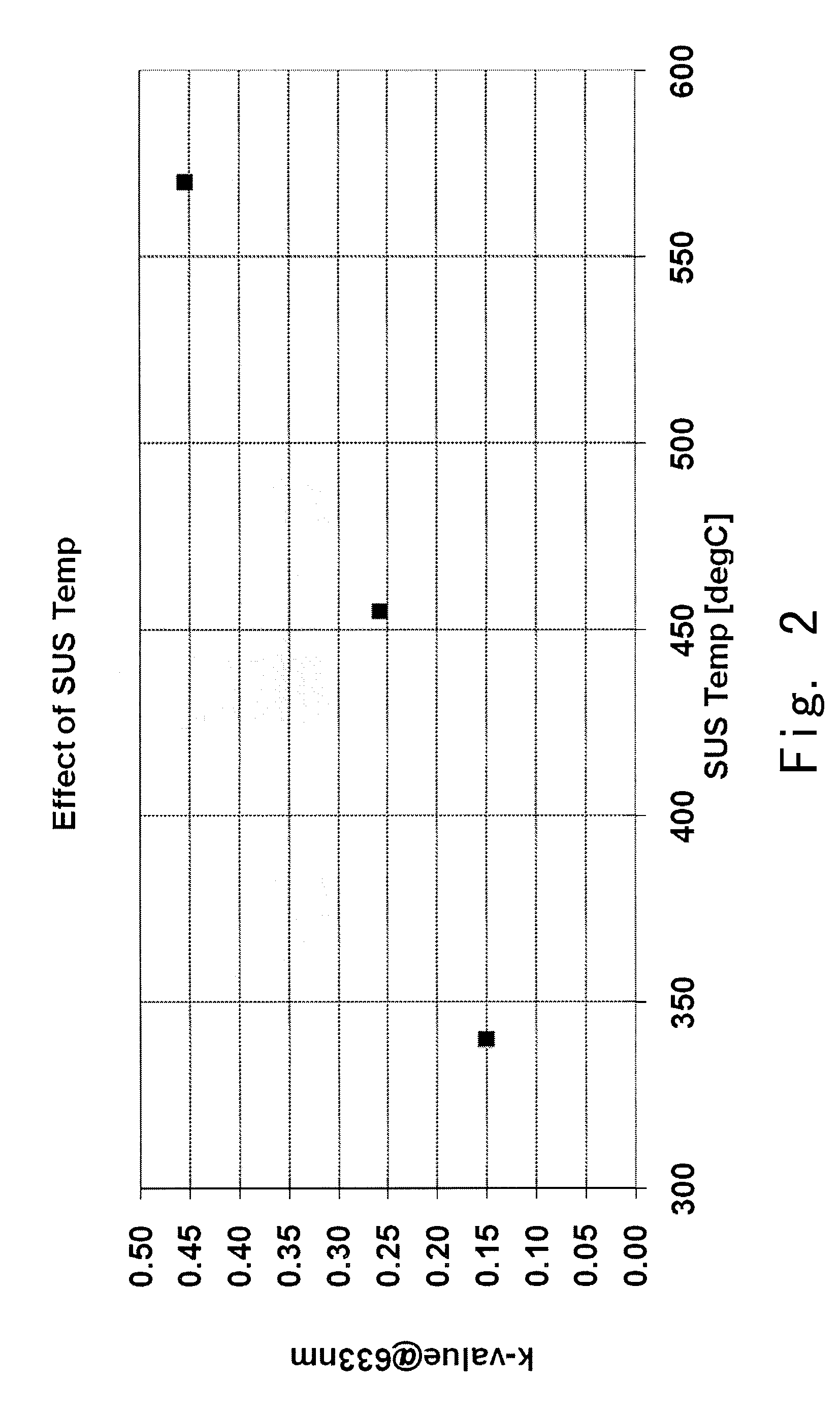

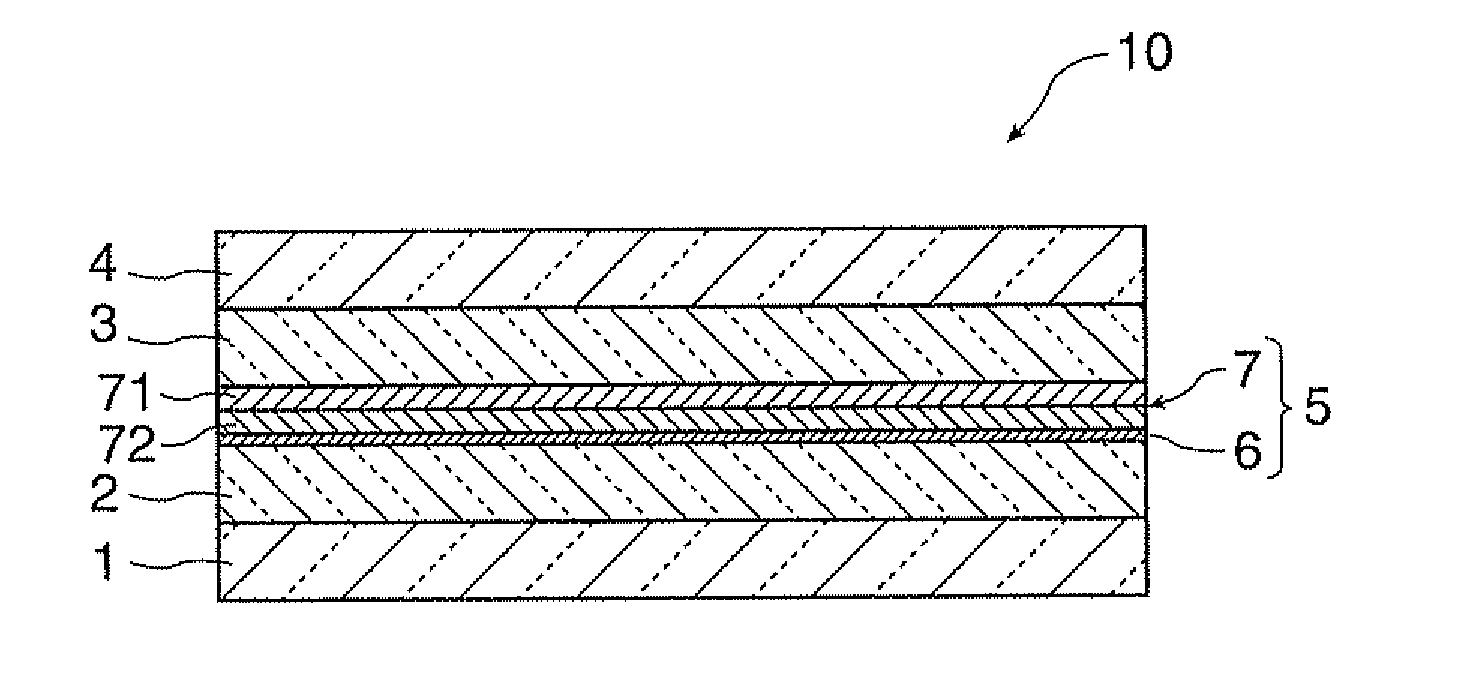

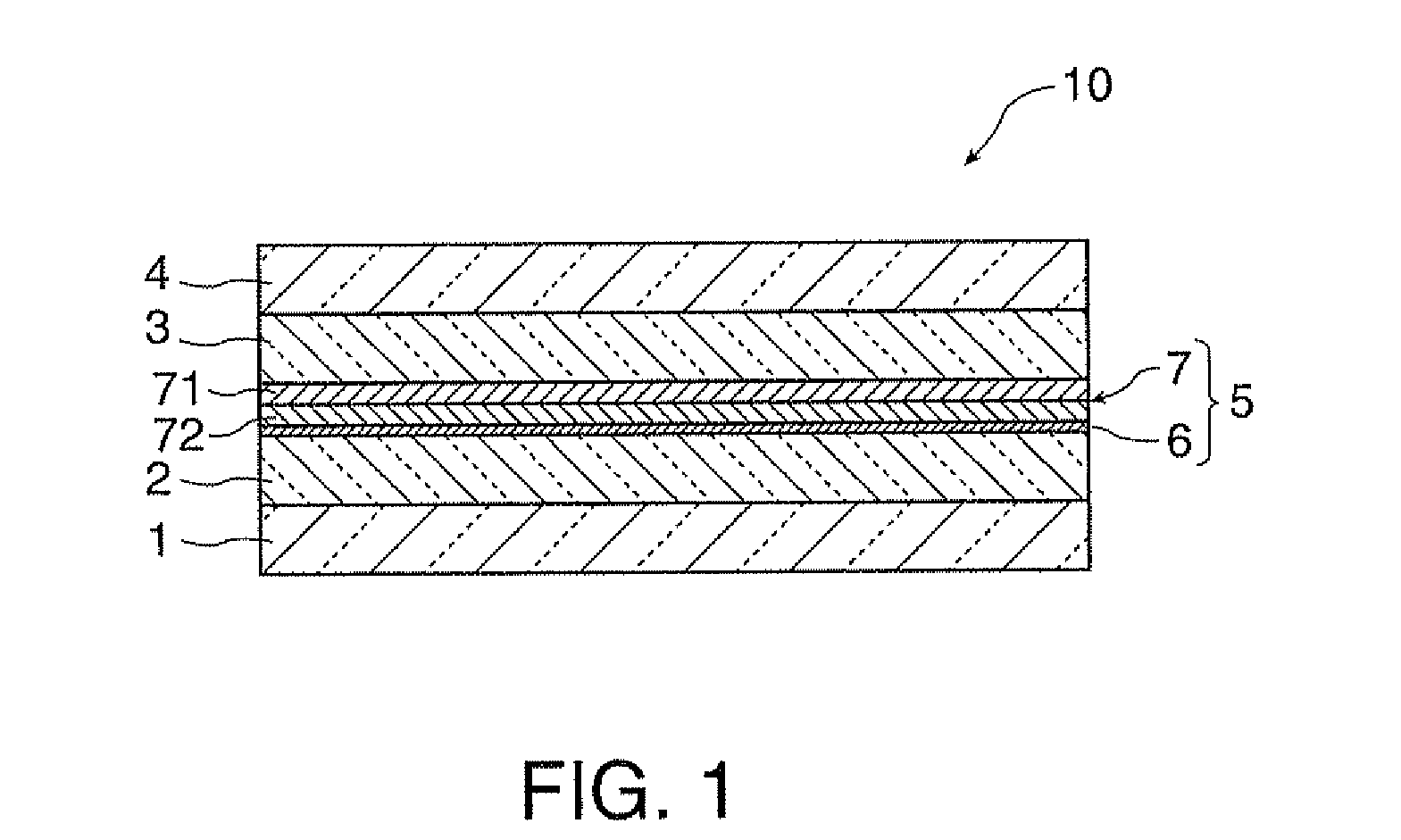

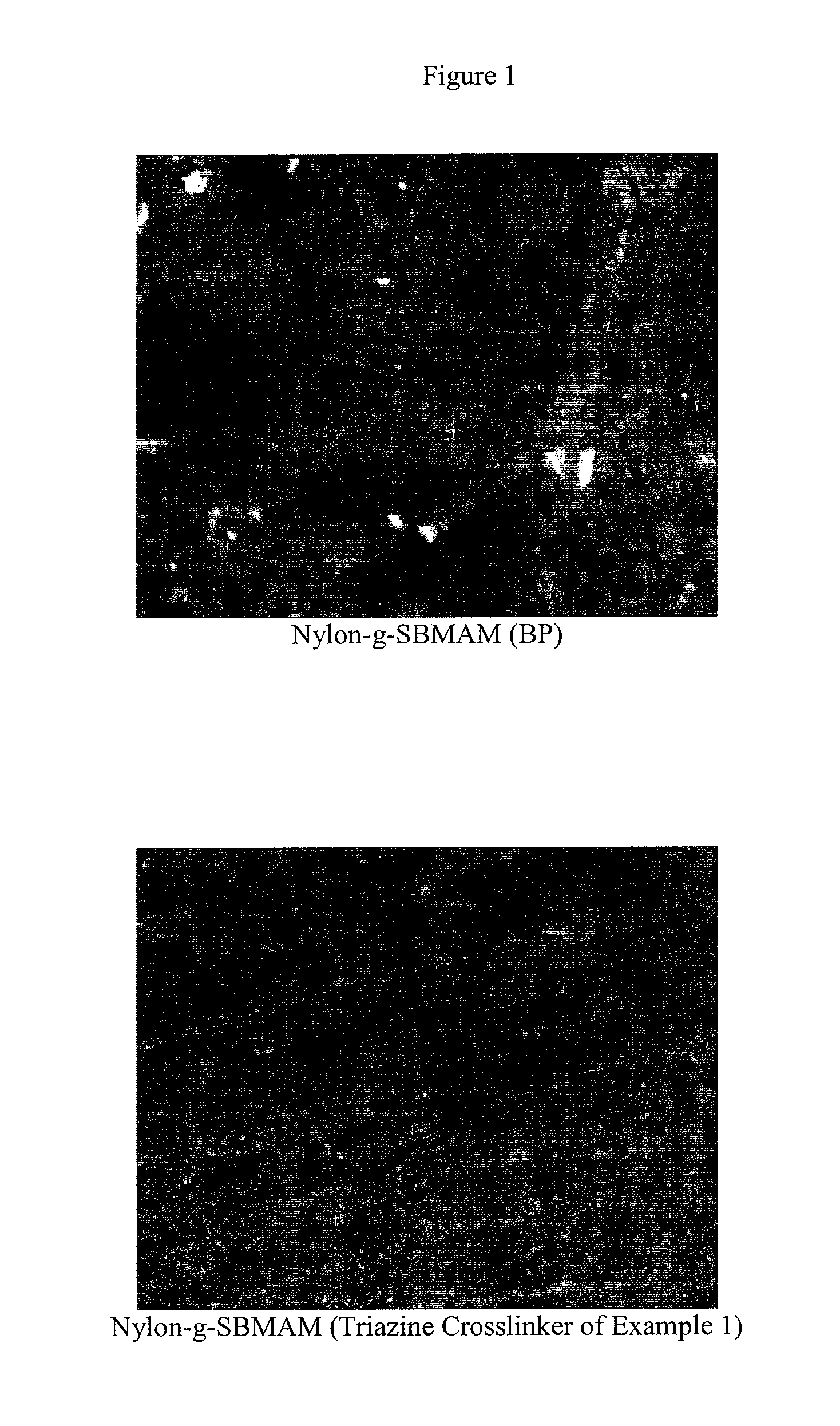

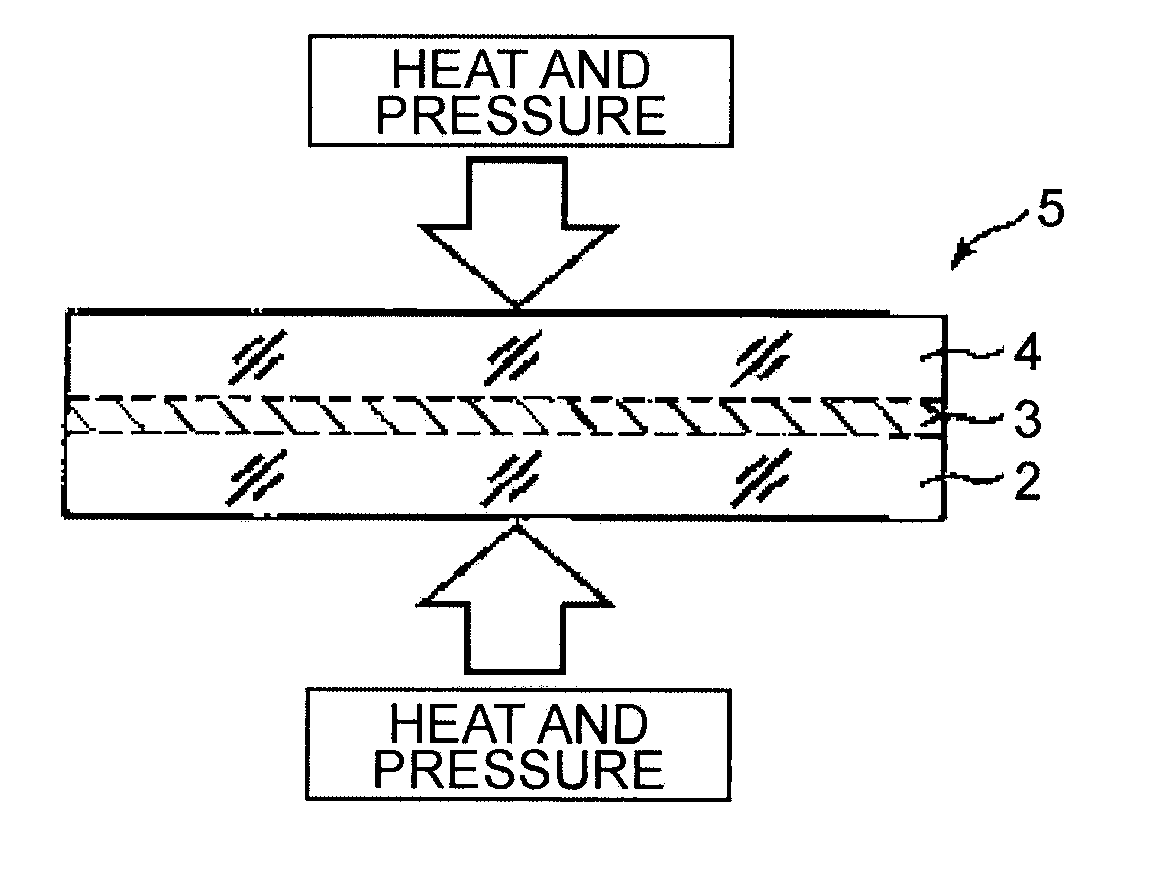

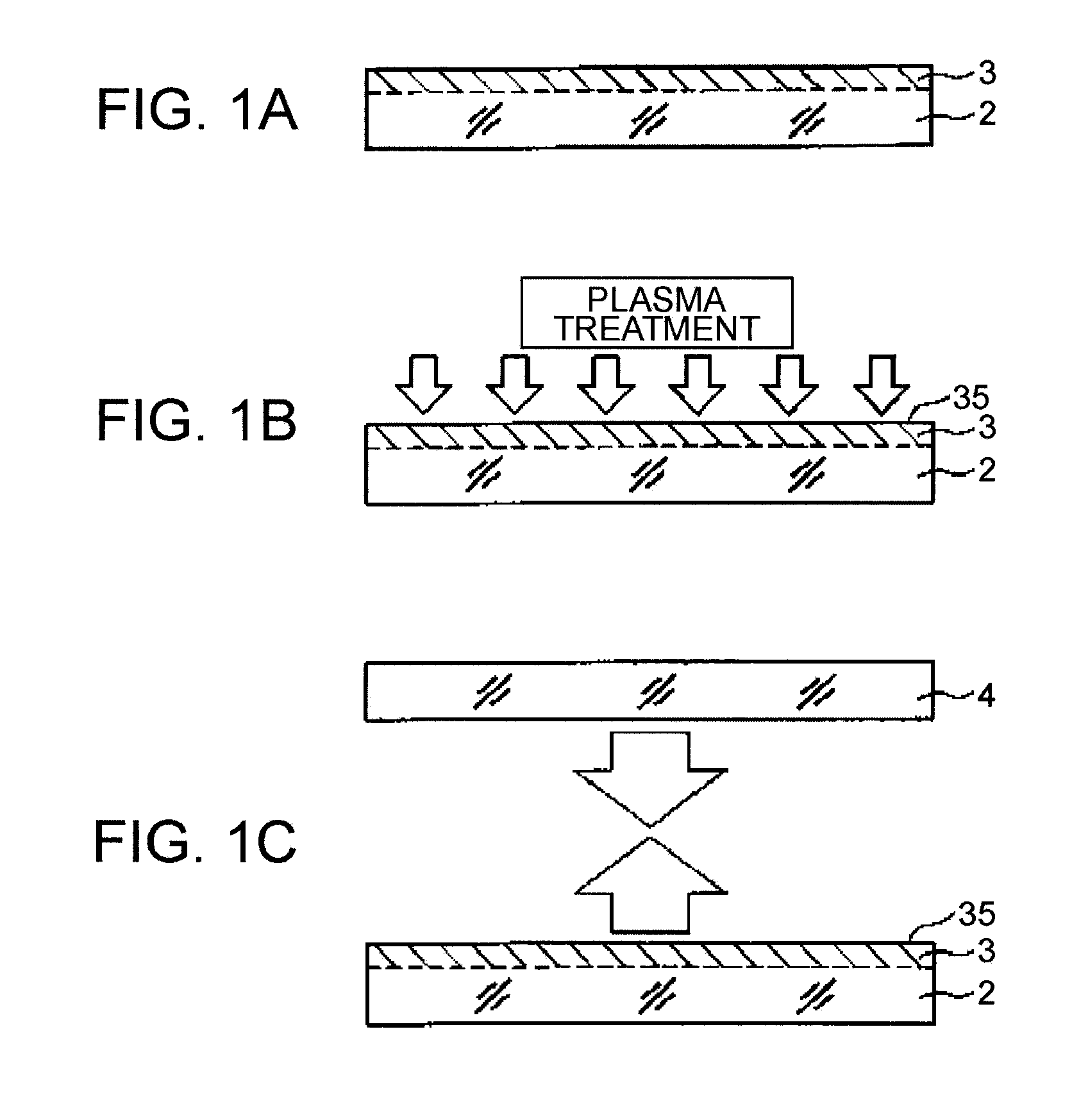

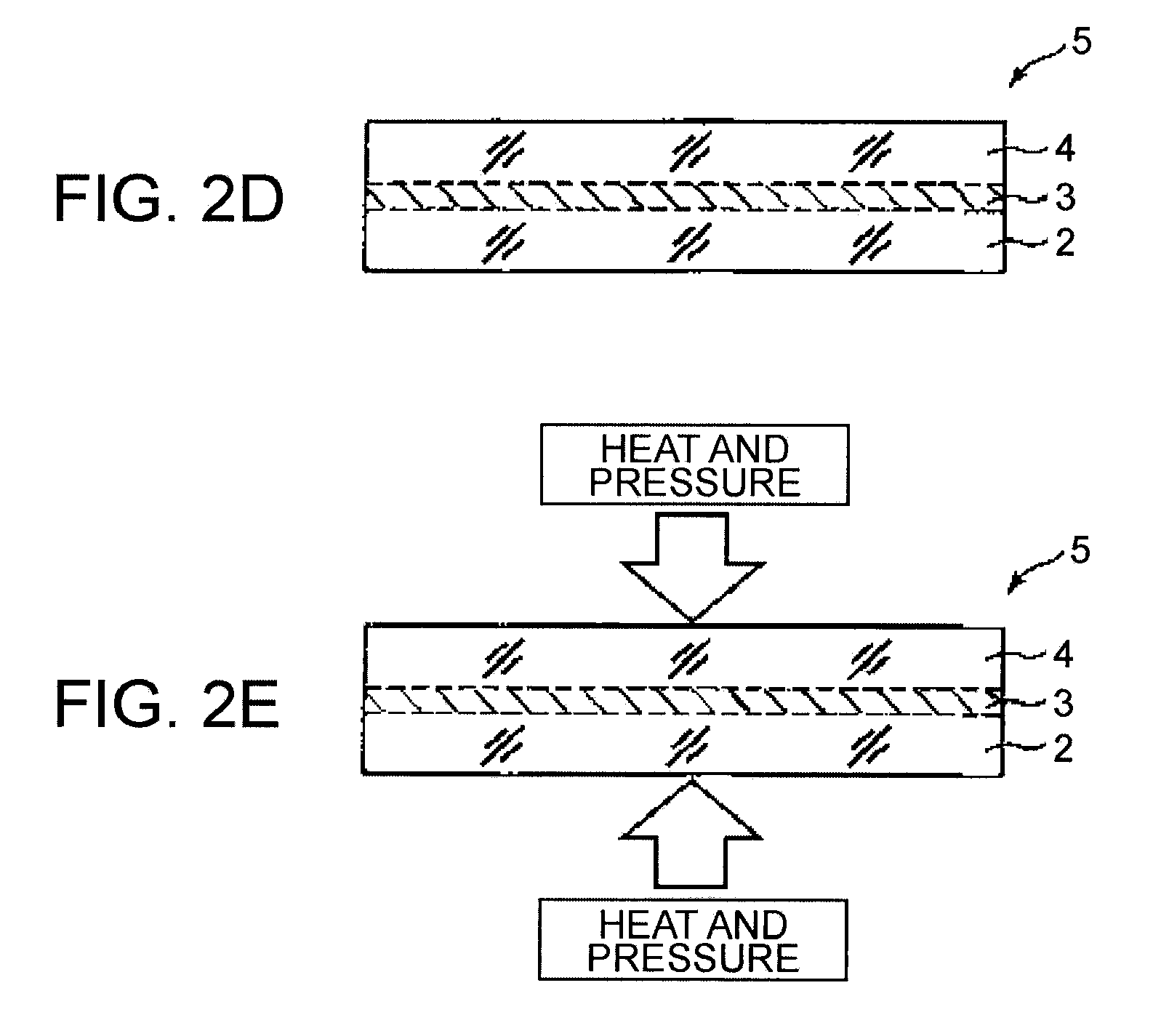

Bonding film-attached substrate and bonding film-attached substrate manufacturing method

InactiveUS20110256385A1Prevent precipitationLayered productsVacuum evaporation coatingOrganic groupSilicon oxide

A bonding film-attached substrate includes: a substrate whose main component is not silicon dioxide, or that does not have a Si-group skeleton; a silicon oxide film formed on a surface of the substrate and adjacent to the substrate using a vapor-phase deposition method, and that has a thickness of from 100 nm to 2,000 nm, inclusive; and a bonding film provided by plasma polymerization, wherein the bonding film includes (i) a Si skeleton that contains a siloxane (Si—O) bond, and has a crystallinity of 45% or less, and (ii) an elimination group that binds to the Si skeleton, the elimination group being an organic group.

Owner:SEIKO EPSON CORP

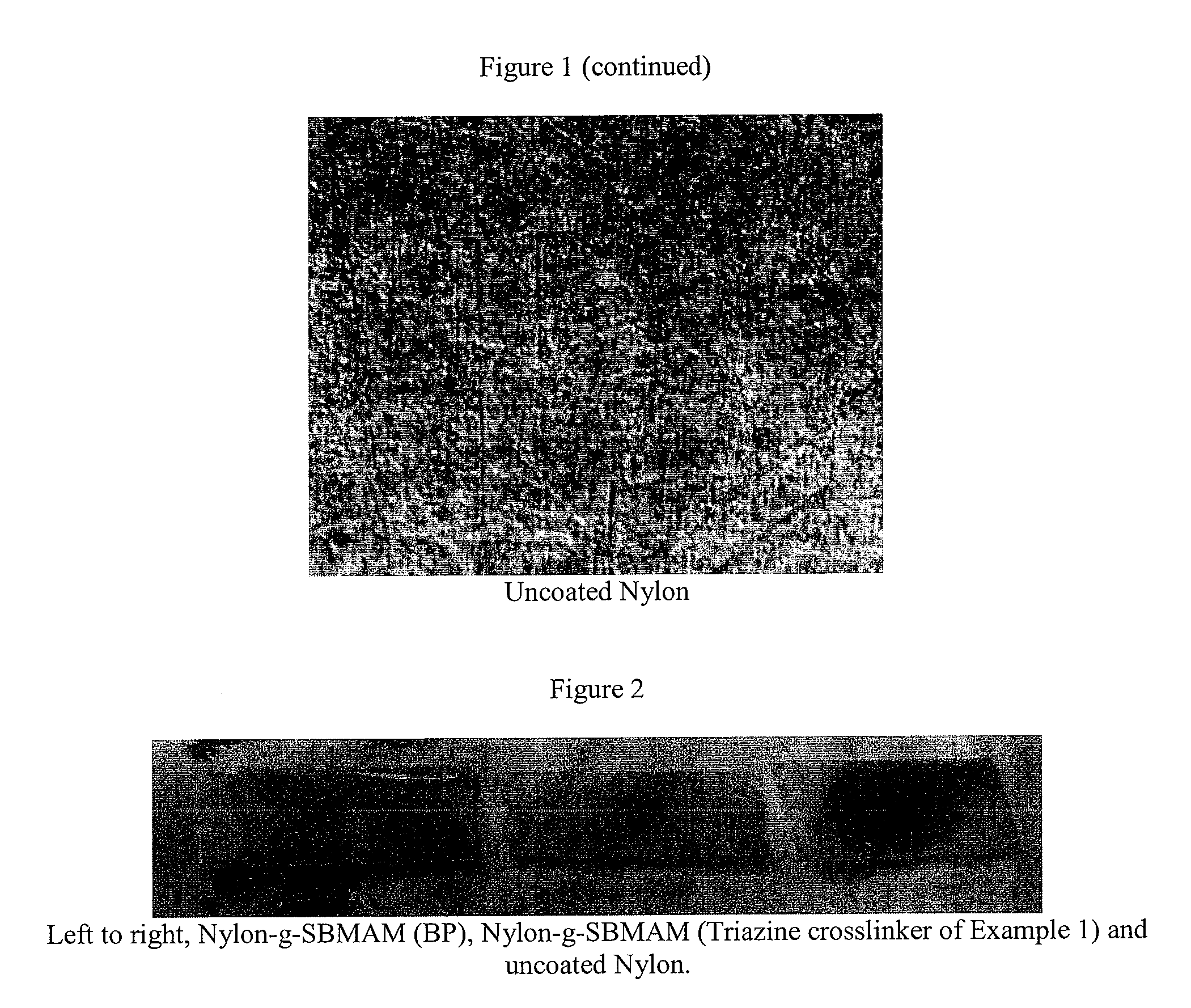

Brush polymer coating by in situ polymerization from photoreactive surface

InactiveUS20100227077A1Wide rangeDecrease) bacterial adhesionTissue regenerationCoatingsIn situ polymerizationDiaryl ketone

The invention provides compositions that include crosslinking agents having multiple photoactivatable groups, such as diaryl ketones, or a diaryl ketone, such as benzophenone, and at least one polymerizable monomer, such as a zwitterionic monomer. The compositions are useful as surface coating agents that provide brush type polymeric coatings. These polymeric coatings can be used on medical devices, such as artificial joints, to reduce wear and tear between the components of the joint and thus reduce or eliminate debris generated by friction between the joint components.

Owner:INNOVATIVE SURFACE TECHNOLOGIES LLC

Trocar seal system

InactiveUS20090318868A1Reduce frictionCannulasInfusion syringesSurgical instrumentationBiomedical engineering

A seal assembly for reception of an elongated surgical instrument is provided which includes a body having at least one opening configured and dimensioned to permit entry of an elongated surgical instrument and defining a central longitudinal axis; a seal member formed of a resilient material and defining an aperture therein, the aperture being configured and dimensioned such that insertion of the surgical instrument into the aperture causes the resilient material defining the aperture to resiliently contact the outer surface of the surgical instrument in a substantially fluid tight manner; and a fabric layer juxtaposed relative to the resilient material. A coating may be applied to the seal member to reduce friction between the seal member and surgical instrumentation inserted therein. The coating is preferably a hydrocyclosiloxane membrane prepared by plasma polymerization process.

Owner:TYCO HEALTHCARE GRP LP

Optical element and method for producing same

InactiveUS20100101719A1Improve light resistanceHigh dimensional accuracyLamination ancillary operationsLaminationLeaving groupRefractive index

An optical element includes a first optical component and a second optical component each having light transmission properties; and a bonding film bonding together the first and the second optical components. The bonding film is formed by plasma polymerization and includes an Si skeleton having a random atomic structure including a siloxane (Si—O) bond and leaving groups binding to the Si skeleton. The first and the second optical components are bonded together by the bonding film having adhesive properties provided by applying energy to at least a part of the bonding film to eliminate the leaving groups from the Si skeleton at a surface of the bonding film. Additionally, the bonding film is formed so as to have approximately the same refractive index as that of at least one of the first and the second optical components by adjusting a film forming condition of the plasma polymerization.

Owner:SEIKO EPSON CORP

Fabrication of an anisotropic super hydrophobic/hydrophilic nanoporous membranes

ActiveUS7393391B2Semi-permeable membranesSurface reaction electrolytic coatingNanoporous membraneFluorocarbon

Anisotropic hydrophobic / hydrophilic nanoporous membranes and methods of forming anisotropic hydrophobic / hydrophilic nanoporous membranes are disclosed. The method of forming the nanoporous membrane includes growing a nanoporous oxide film on a substrate. A nanoporous membrane having a top side and a bottom side can then be formed by partially separating the nanoporous oxide film from the substrate. A fluorocarbon film can be deposited on the top side of the nanoporous membrane by plasma polymerization. The disclosed anisotropic hydrophobic / hydrophilic nanoporous membranes can have extremely different hydrophobicity between the top side and the bottom side of the nanoporous membrane.

Owner:STC UNM

Method of forming a carbon polymer film using plasma CVD

ActiveUS20060084280A1Improve featuresFunction increaseLiquid surface applicatorsPhotomechanical apparatusCapacitanceBoiling point

A method of forming a hydrocarbon-containing polymer film on a semiconductor substrate by a capacitively-coupled plasma CVD apparatus. The method includes the steps of: vaporizing a hydrocarbon-containing liquid monomer (CαHβXγ, wherein α and β are natural numbers of 5 or more; γ is an integer including zero; X is O, N or F) having a boiling point of about 20° C. to about 350° C. which is not substituted by a vinyl group or an acetylene group; introducing the vaporized gas into a CVD reaction chamber inside which a substrate is placed; and forming a hydrocarbon-containing polymer film on the substrate by plasma polymerization of the gas.

Owner:ASM JAPAN

Surface modification method of lithium iron phosphate cathode material

ActiveCN102544505AImprove conductivityImprove low temperature performanceCell electrodesVulcanizationLithium iron phosphate

The invention relates to a surface modification method of a lithium iron phosphate cathode material. The surface modification method comprises conductive polymer cladding by plasma polymerization, surface fluorination, nitridation, vulcanization and so on. The method particularly comprises the steps of uniformly blending lithium iron phosphate powder with conductive polymer monomers, and placing the mixture into a discharge plasma reactor to clad the surface of lithium iron phosphate powder with the conductive polymer; or placing the lithium iron phosphate powder in the discharge plasma reactor, introducing working gas CF4, NH3, CS2 or H2S to generate F, N, S free groups by ionization, and subjecting lithium iron phosphate powder to surface fluorination, nitridation, vulcanization. The method provided by the invention has important meanings for improving the comprehensive performance of lithium iron phosphate cathode material, and particularly has significant effect in improving large-current charge-discharge capacity and low-temperature performance of the material. The modified material can be charged or discharged at 10C to 30C, and the discharge capacity at -20 DEG C is not less than 75% the normal temperature discharge capacity, so that the lithium iron phosphate cathode material is suitable for power cells.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

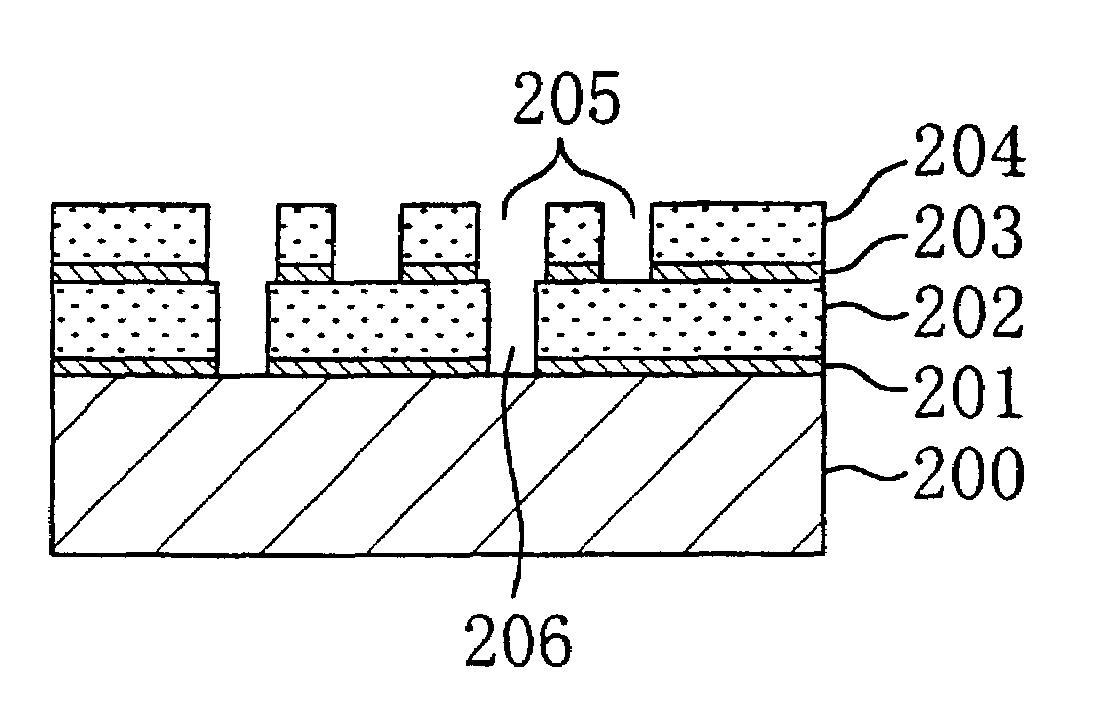

Semiconductor device and manufacturing method thereof

InactiveUS20040041269A1Semiconductor/solid-state device detailsSolid-state devicesCopper interconnectDevice material

Owner:NEC ELECTRONICS CORP

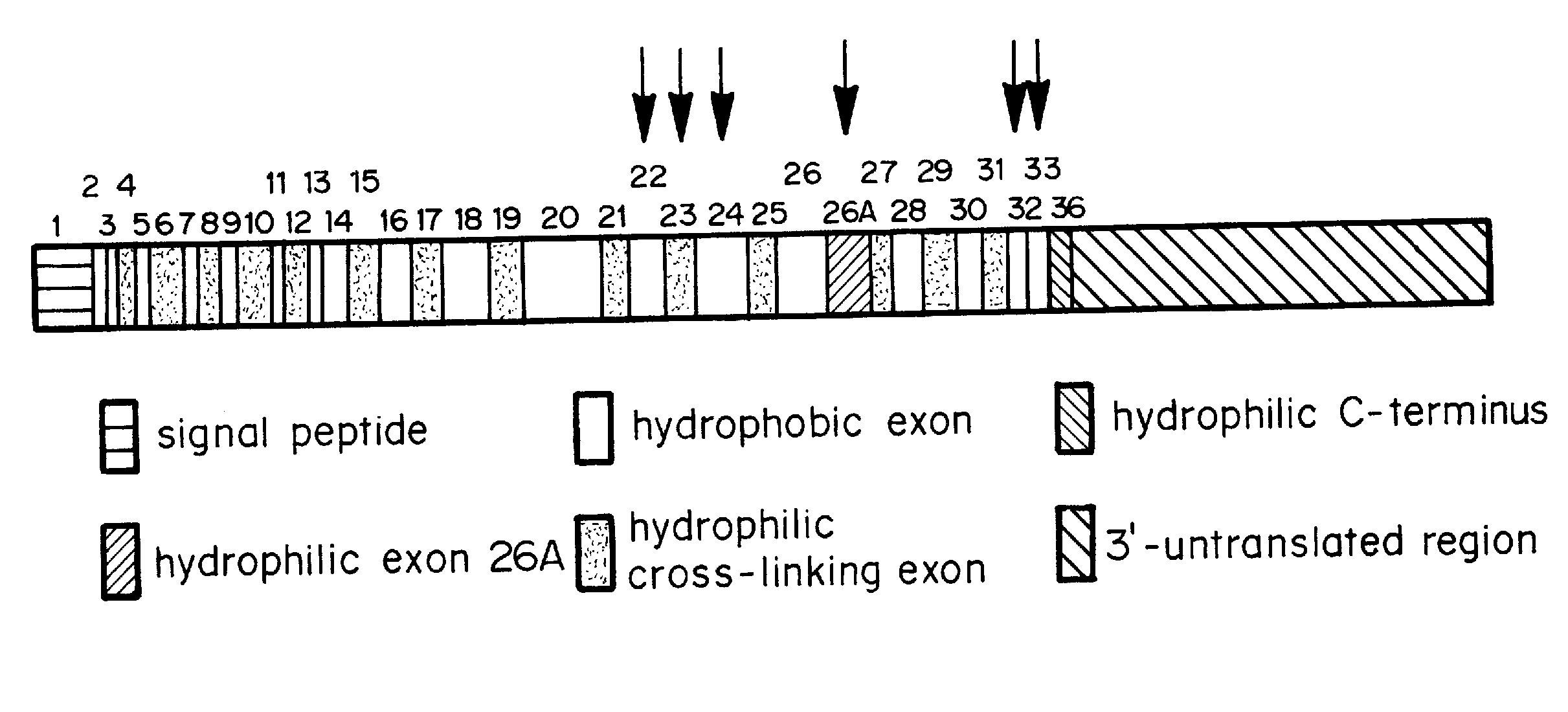

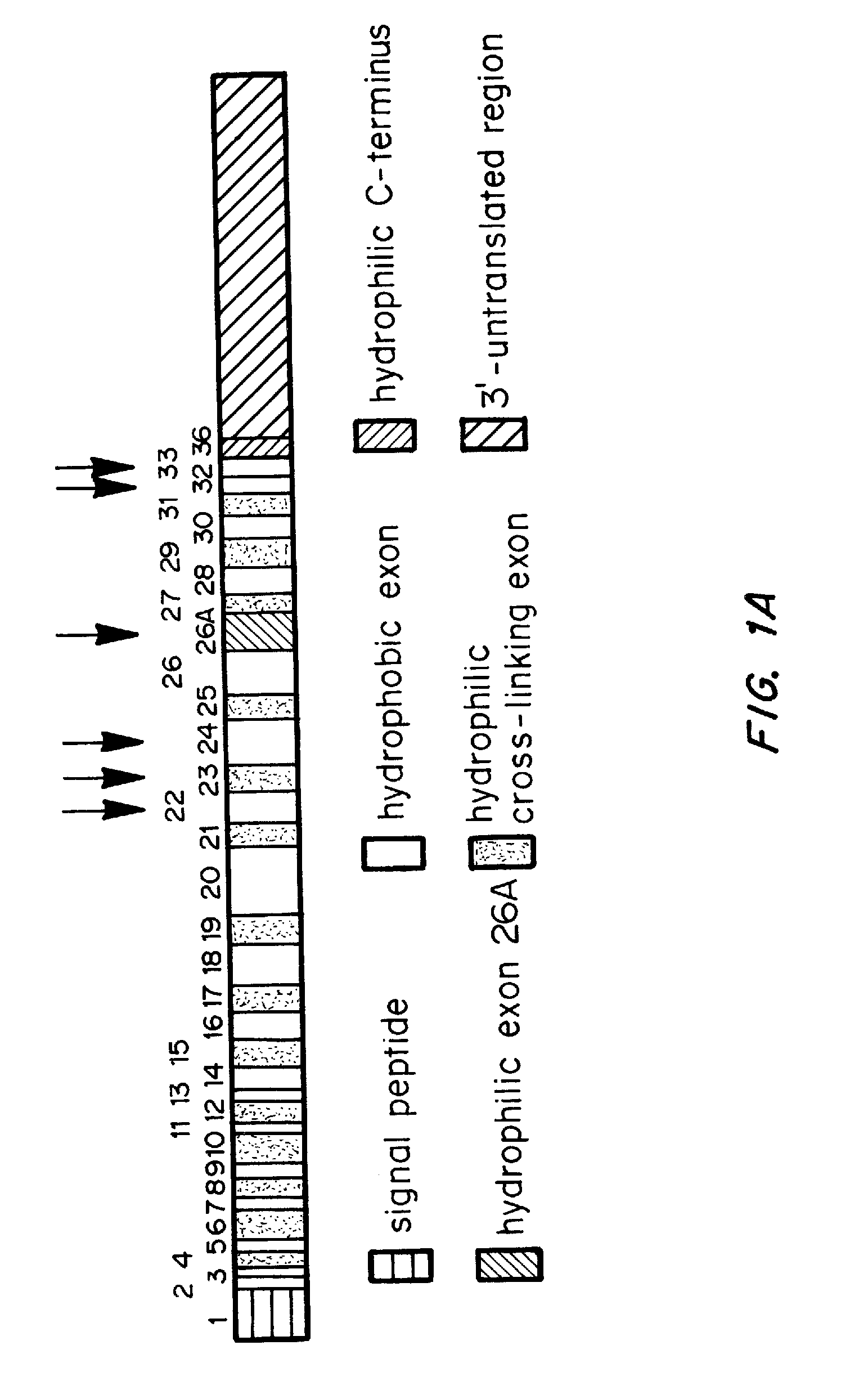

Chemically and biologically modified medical devices

ActiveUS20100174351A1Increased protease resistanceSignificantly reducedStentsBone implantBiocompatibility TestingThrombus

Biocompatible materials for use in vascular applications or for implantation have been engineered, combining human recombinant tropoelastin with other synthetic or natural biomaterials to form protoelastin. The materials can be in the form of elastin films on metal or polymer substrates, laminates of alternating polymer and elastin, blends of polymer and elastin, or elastin crosslinked with or tethered to polymer or metal. These are mechanically stable, elastic, strong and biocompatible (i.e., not thrombogenic and promoting adhesion of cells, especially human endothelial cells), not eliciting a foreign body response. Plasma polymerization of substrate is shown to enhance biocompatibility, especially when used to bind elastin or other protein to the substrate.

Owner:NG MARTIN KEAN CHONG +3

Trocar seal system

ActiveUS20070197972A1Reduce frictionCannulasSurgical needlesSurgical instrumentationBiomedical engineering

A seal assembly is provided for reception of an elongated surgical instrument, which comprises a body having at least one opening configured and dimensioned to permit entry of an elongated surgical instrument and defining a central longitudinal axis; a seal member formed of a resilient material and defining an aperture therein, the aperture being configured and dimensioned such that insertion of the surgical instrument into the aperture causes the resilient material defining the aperture to resiliently contact the outer surface of the surgical instrument in a substantially fluid tight manner, the seal member further including a peripheral flange element which contacts a surface of the body to form a contact seal therewith; and a fabric layer juxtaposed relative to the resilient material. The seal assembly may further include a coating applied to the seal member to reduce friction between the seal member and surgical instrumentation inserted therein. The coating is preferably a hydrocyclosiloxane membrane prepared by plasma polymerization process.

Owner:TYCO HEALTHCARE GRP LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com