Measuring chip for surface plasmon resonance biosensor and method for producing the same

a surface plasmon and biosensor technology, applied in the direction of liquid gas reaction, gas-gas reaction process, instruments, etc., can solve the problems of insufficient detection of inability to detect surface plasmon phenomena of the medium, and inability to use conventional methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

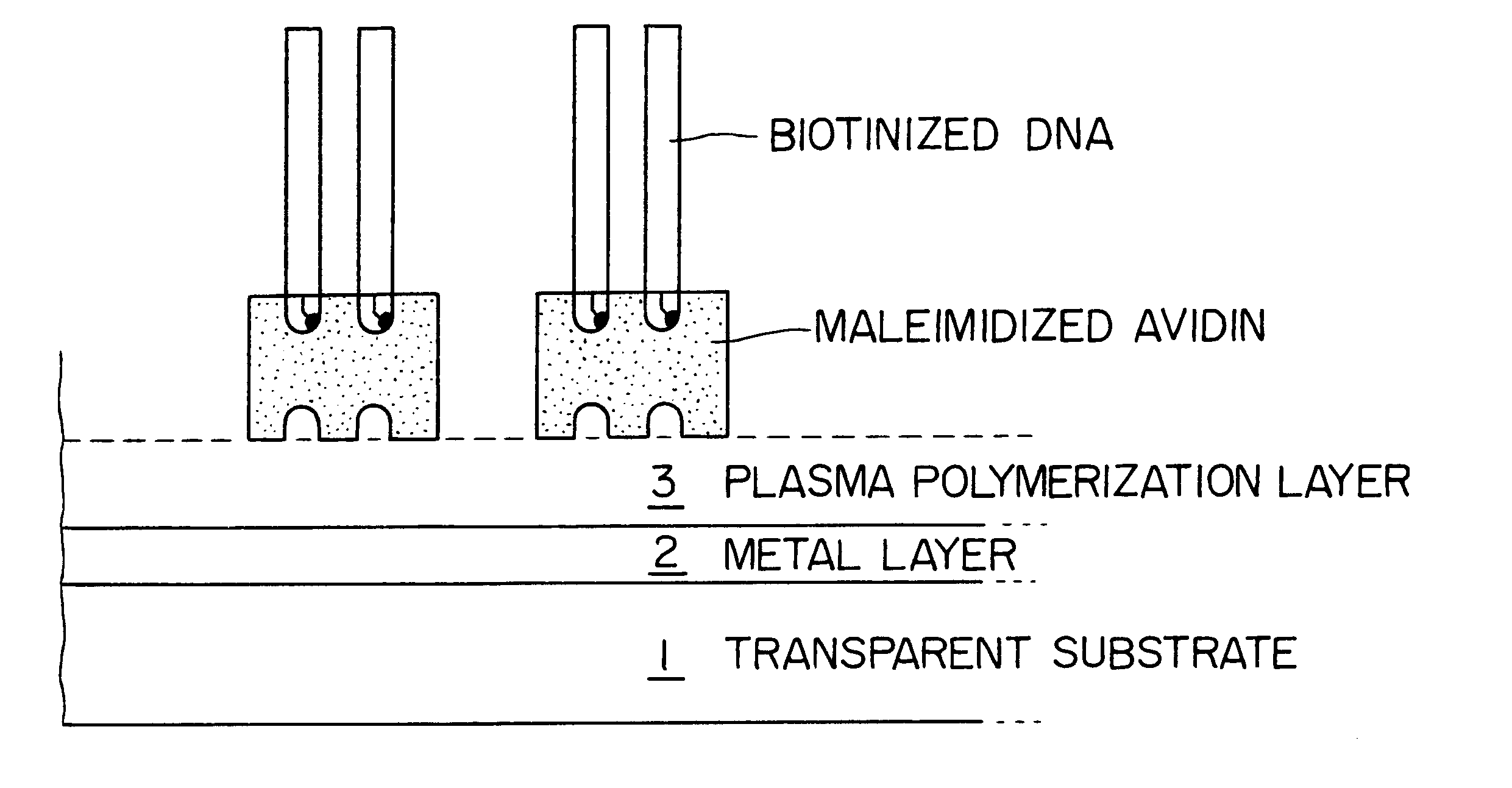

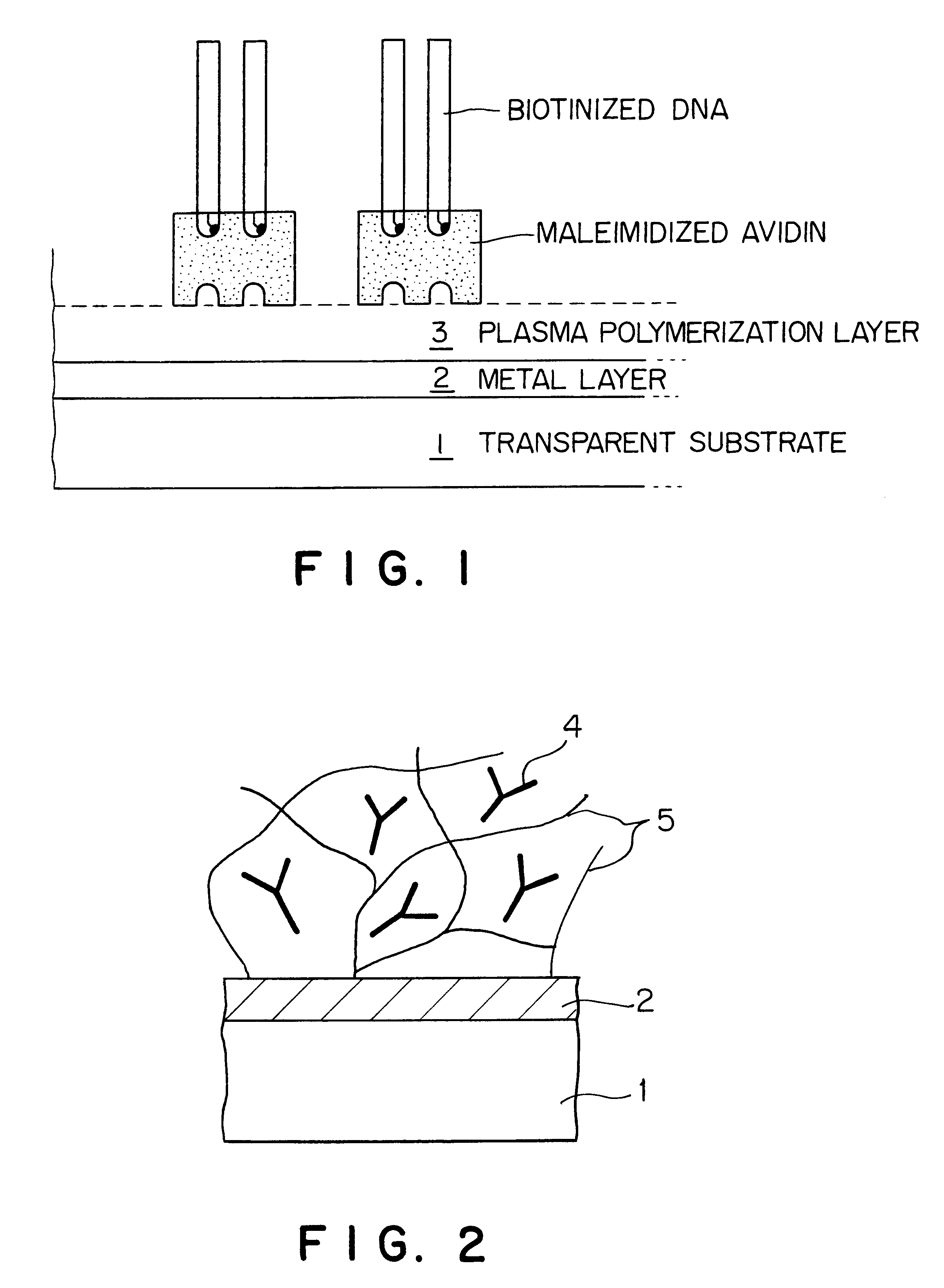

A measuring chip having layers shown in FIG. 1 on an optical recognition part was constructed.

A glass plate with a thickness of 0.15 mm (18 mm.times.18 mm) was used for a transparent substrate. A chrome layer and then a gold layer were deposited on this transparent substrate by sputtering. The sputtering was carried out at 100 W for 40 seconds for the chrome layer and at 100 W for 2 minutes and 30 seconds for the gold layer. The resulting chrome layer was 40 angstroms thick and the resulting gold layer was 500 angstroms thick.

A plasma polymerization layer was formed on the metal layers. An apparatus as shown in FIG. 7 was used for plasma polymerization. Ethanedithiol was used as a monomer material for the plasma polymerization layer to introduce a thiol group. Conditions for plasma polymerization were as follows:

Flow volume of monomer material: 15 sccm

Temperature: 15.degree. C.

Pressure: 4.7 Pa

Discharge electric power: 20 W

Discharge frequency: 10 MHz, FM modulation

Duration of dischar...

example 2

The same apparatus and method as in Example 1 were used.

Acetonitrile was used as a monomer material for the plasma polymerization layer. Conditions for plasma polymerization were as follows:

Flow volume of monomer material: 1.5 sccm+Ar dilution 15 (sccm)

Temperature: room temperature

Pressure: 4.7 Pa

Discharge electric power: 80 W

Discharge frequency: 13.56 MHz

Duration of discharge: 15 seconds.

Under the conditions described above, a plasma polymerization layer was formed. The sensor chip was mounted on the cartridge block of the surface plasmon resonance biosensor, 5% glutaraldehyde was poured through a flow route into the measuring cell at a flow rate of 5 .mu.l / min for 10 minutes and avidin (concentration: 20 .mu.g / ml) was also poured at a flow rate of 5 .mu.l / min to immobilize for 60 minutes. 10 .mu.M biotin-labeled probe RNA were then poured at a flow rate of 1 .mu.l / min to immobilize the probe RNA for 10 minutes. DNA (7.5.times.10.sup.-7 M) having a DNA sequence complementary to thi...

example 3

The same apparatus and method as in Example 1 were used.

Conditions for plasma polymerization layer formation were the same as in Example 2.

Under the conditions described above, a plasma polymerization layer was formed.

The sensor chip was mounted on the cartridge block of the surface plasmon resonance biosensor, 5% glutaraldehyde was poured through a flow route into the measuring cell at a flow rate of 5 .mu.l / min for 10 minutes and streptoavidin (concentration: 20 .mu.g / ml) was also poured at a flow rate of 5 .mu.l / min to immobilize for 60 minutes. 10 .mu.M biotin-labeled probe RNA was then poured at a flow rate of 1 .mu.l / min for 10 minutes to immobilize the probe RNA. DNA (7.5.times.10.sup.-7 M) having a DNA sequence complementary to this probe RNA was introduced and after the reaction, a signal of about 375 RU was obtained.

It was confirmed by the XPS analysis that the resulting membrane has a primary amine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com