Method for producing frozen and dried scallion product

A technology of freeze-drying and production methods, which is applied in food preparation, food preservation, and preservation of fruits/vegetables by freezing/refrigerating, which can solve problems such as difficulty in degree, lack of sanitation, and reduction in commodity value, and achieve a small degree of damage. High commodity value and the effect of ensuring hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] Next, examples of the present invention will be described.

[0049] (Example)

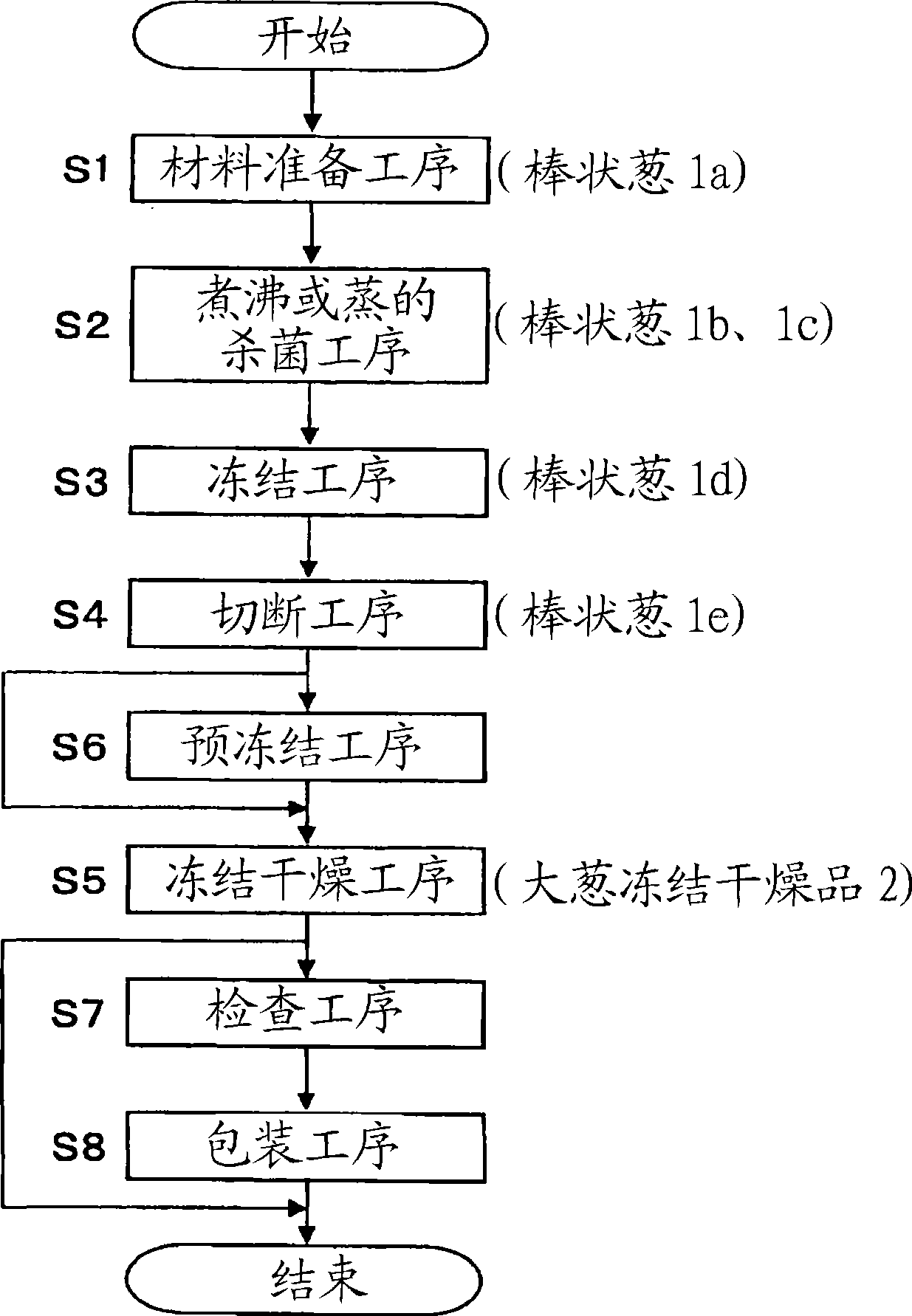

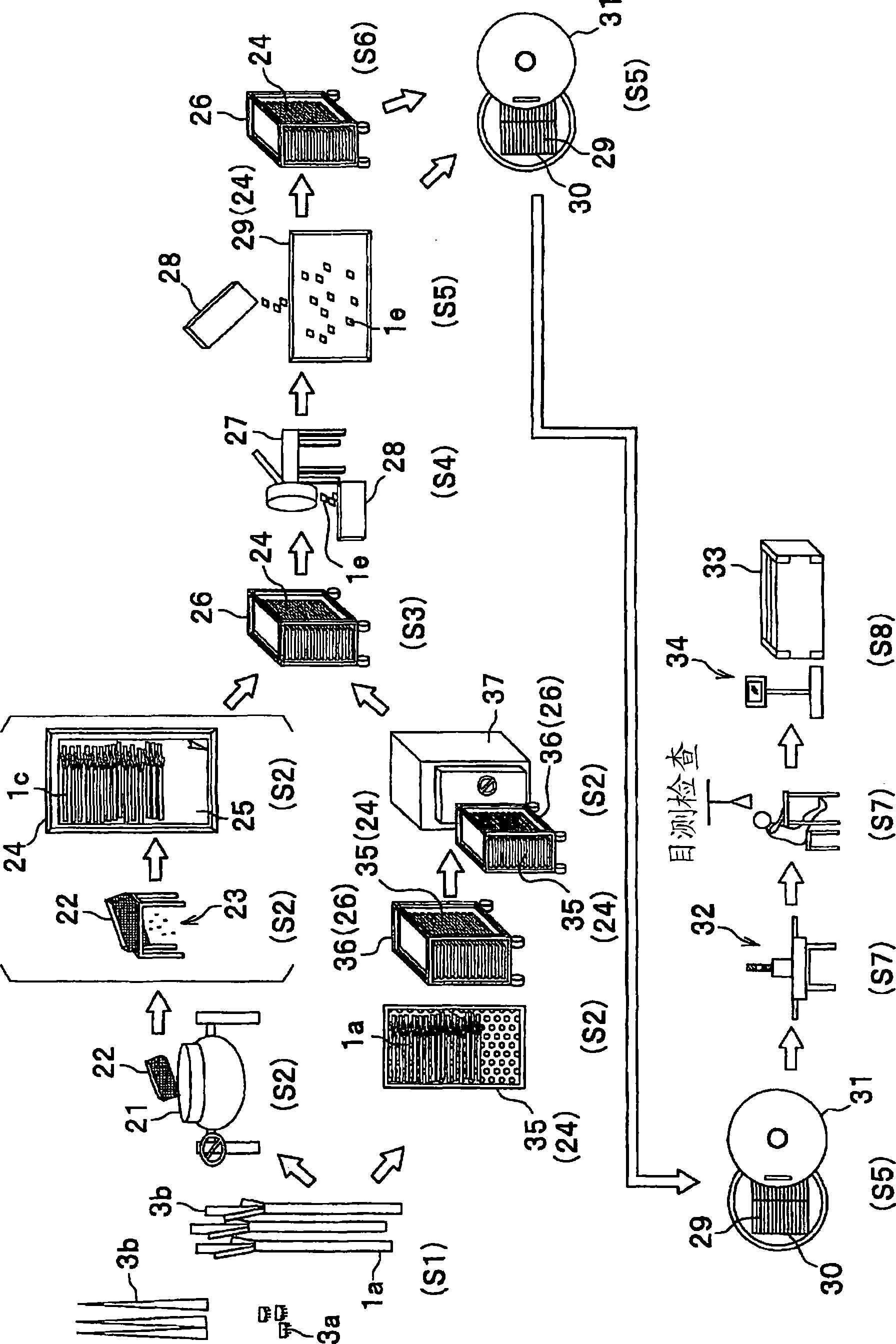

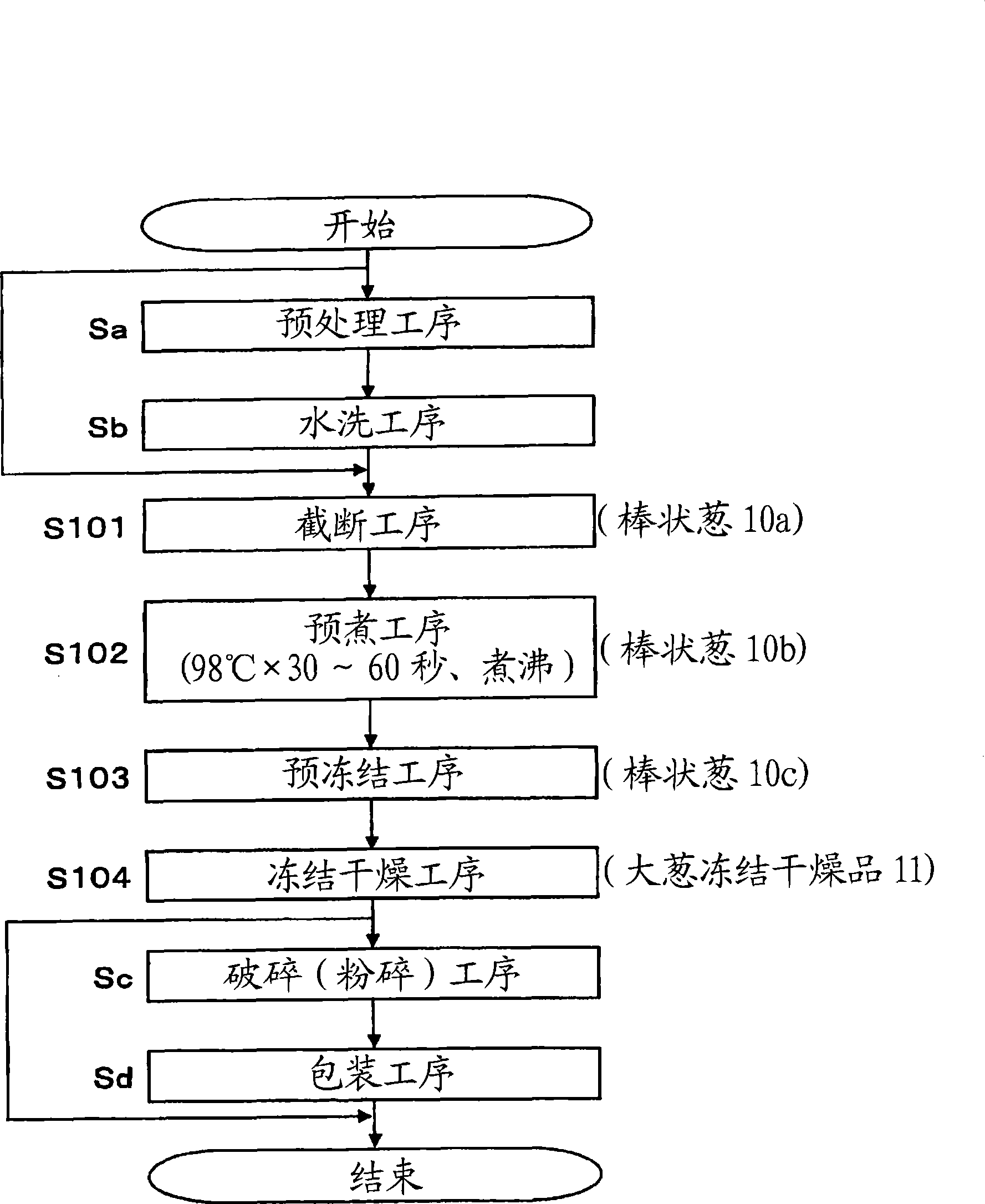

[0050] according to figure 1 The shown process flow produces the scallion freeze-dried product 2.

[0051] Concretely, after removing useless parts of green onions with a diameter of 20 mm, they were washed with water three times to obtain stick-shaped green onions 1a with a length of 200 mm (material preparation step S1 ). Put the stick-shaped spring onion 1a (3kg) into a boiling pot (boiling water 200kg), and boil in boiling water above 90°C for 5 minutes (when the internal temperature of the stick-shaped spring onion 1a is 75°C or above, boil for more than 1 minute). Next, the boiled stick-shaped shallot 1b is dewatered for about 5 minutes, and the dehydrated stick-shaped shallot 1c is placed on a predetermined freezing tray (sterilization step S2). After the freezing tray was carried into the freezer, the stick-shaped green onion 1c was placed at -25°C in the freezer for 5 hours of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com