Method for manufacturing colour suede for product

A leather product and color technology, applied in the field of preparation of colored suede leather products, can solve the problems of inability to meet the demand of popular colors, color restrictions, etc., and achieve the effect of overcoming large-area shrinkage and denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

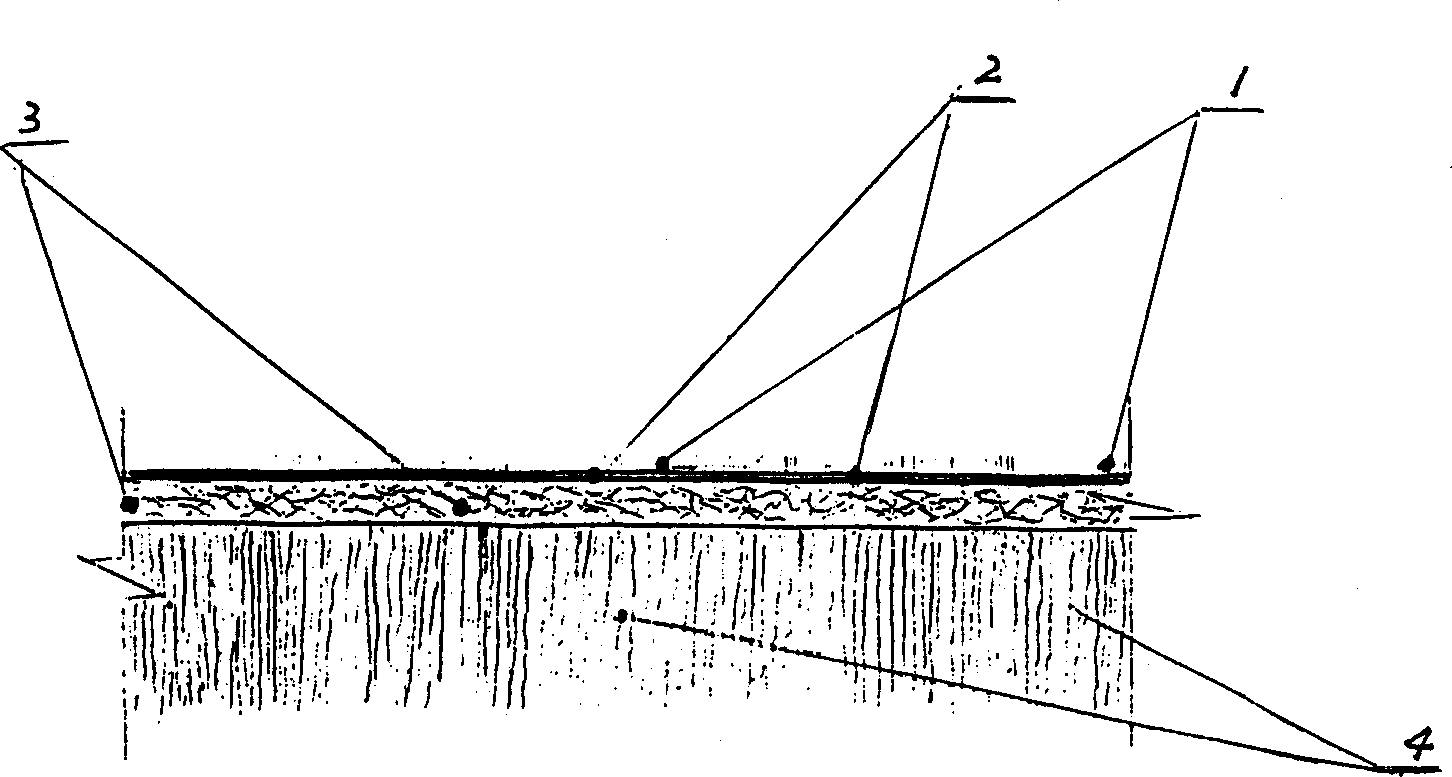

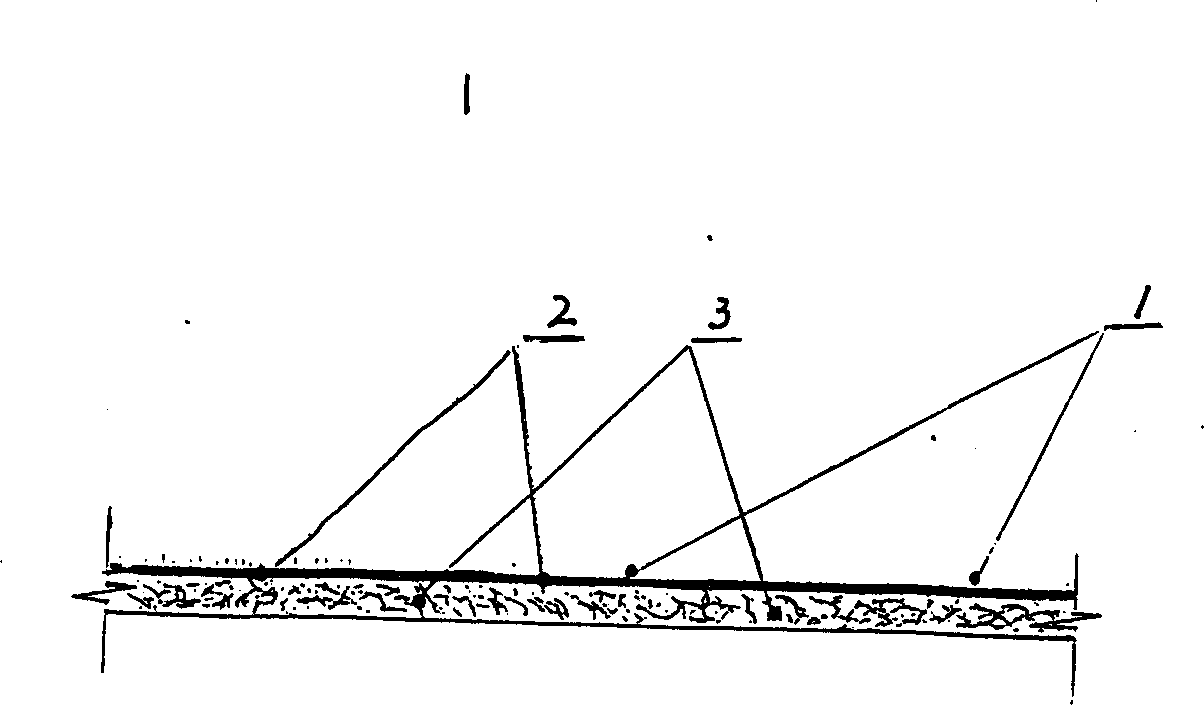

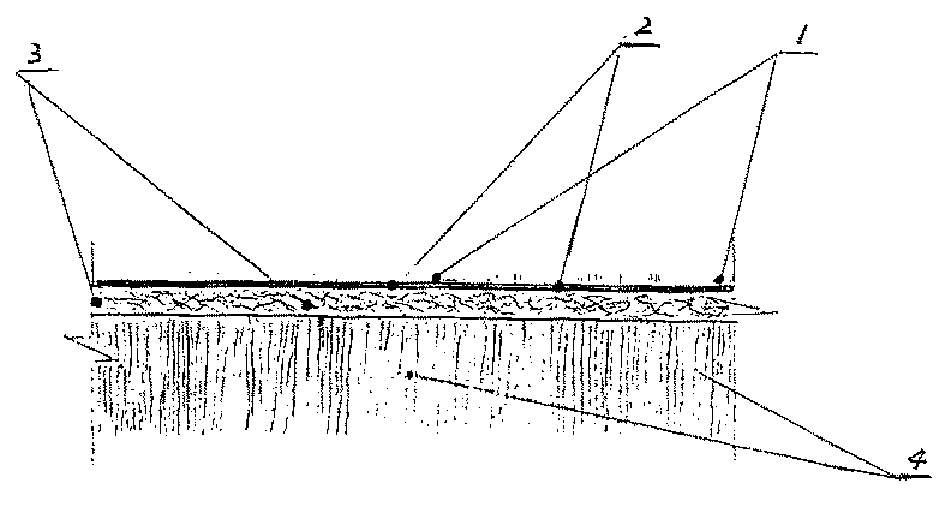

[0014] Below in conjunction with accompanying drawing (1-2) and embodiment illustrate the concrete detail and operation situation that the colored suede fur and colored suede leather that the present invention relates to implement.

[0015] The specific structure of the colored suede fur includes: a fur layer (4), a leather layer (3), an adhesive layer (2), and a colored fluff layer (1); the specific structure of the colored suede leather includes: a skin layer (3) ), viscose layer (2), colored fluff layer (1).

[0016] In the structure of colored suede fur, the coat layer (4) is the native fur coat of fur animals, which is obtained through usual tanning, cutting and ironing, and finishing; , the usual fur or leather panels, the tensile strength should be > 1kg / mm 2 , when selecting materials in the present invention, the tensile strength of the leather board after tanning> 0.6kg / mm 2 Get final product; Viscose layer (2) is to utilize manual brushing or machine-spraying on o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com