Leather capable of changing surface color with temperature and preparation method thereof

A temperature-dependent leather technology, applied in the field of leather and its preparation, can solve the problems of not being able to remind users, reduce the user's driving experience, etc., to improve the grade and product aesthetics, improve operation safety, ensure integrity and safety. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation of leather with changing surface color with temperature:

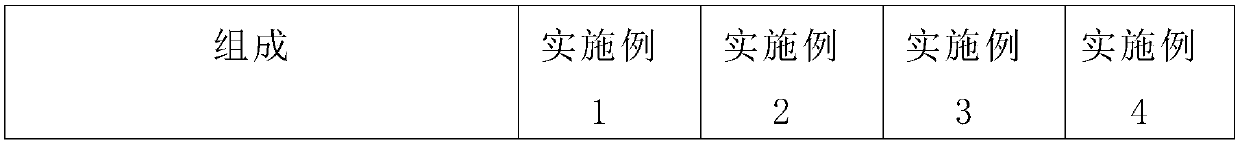

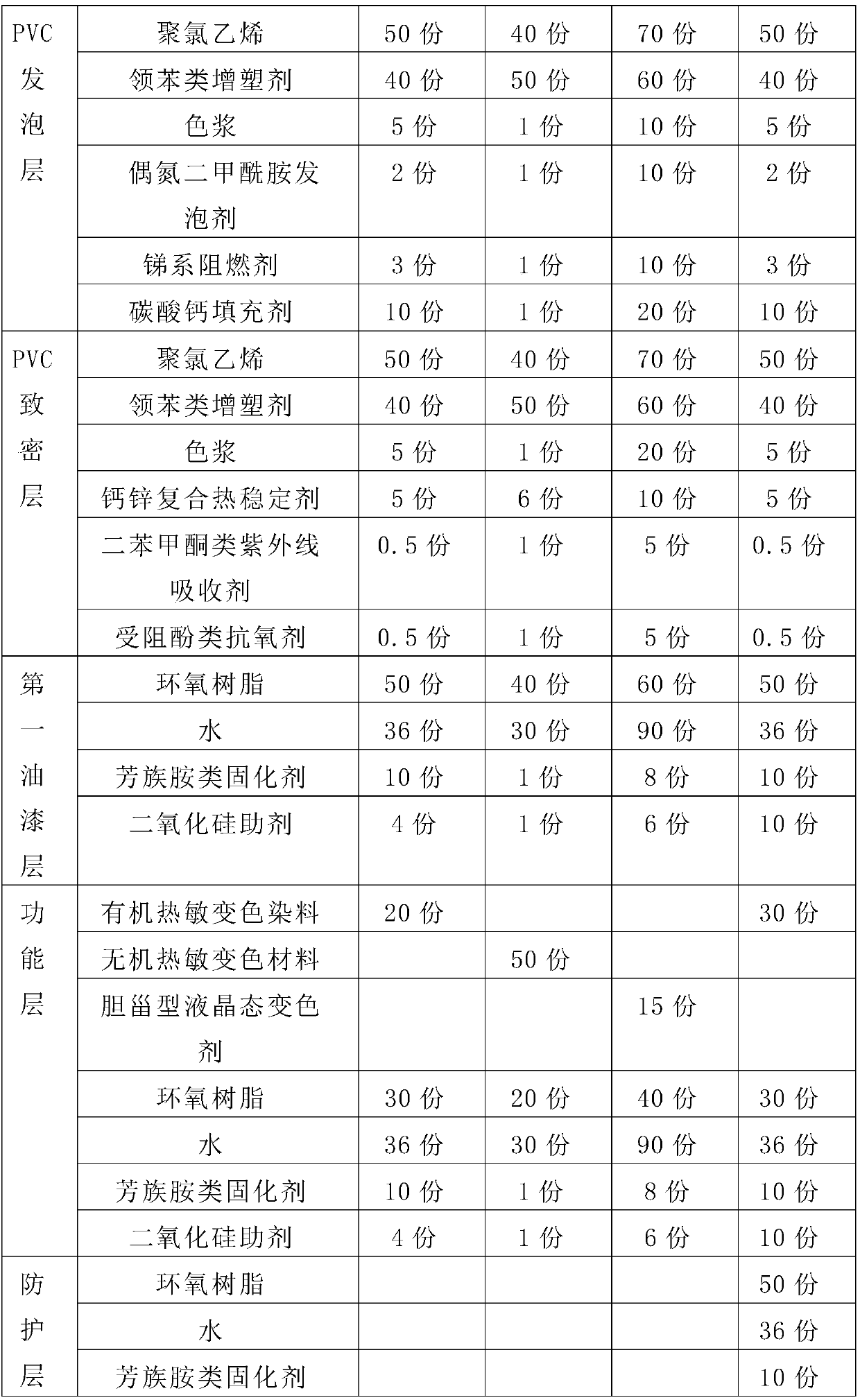

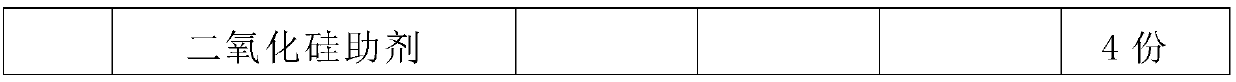

[0044] Mixing: according to the various material ratios shown in Table 1 below, the raw materials of the leather substrate were mixed by conventional stirring, and the slurry of the PVC dense layer and the slurry of the PVC foam layer were prepared respectively.

[0045] Coating: Send the release paper on the coating machine, coat the slurry of the PVC dense layer on the release paper, and bake in an oven at 170°C for 90 seconds; then coat the PVC foam layer on the PVC dense layer The slurry is baked in an oven at 170°C for 90 seconds; glue is applied to the surface of the PVC foam layer, and the base cloth is compounded. Then dry the PVC leather compounded with the base cloth in an oven at 180° C. for 3 minutes to complete the foaming of the PVC foam layer and the overall plasticization of the PVC leather to obtain the final required hardness. Finally, the release paper is torn off, thereby obtaini...

Embodiment 2

[0055] Leather was prepared according to the formulations of each layer in Table 1, and the preparation method was the same as in Example 1.

[0056] The layer structure of the thus obtained PVC leather is divided into successively: a paint layer, a PVC dense layer, a PVC foam layer and a base cloth layer. In this case, the paint layer comprises a first paint layer and a partial functional layer lying thereon. The functional layer that can change color is partially set on the leather surface in the form of LOGO. Wherein, the thickness of the PVC foam layer and the PVC dense layer can be adjusted freely, usually 0.5mm-2.0mm. The total thickness of the paint layer including the first paint layer and the functional layer is about 5 μm-20 μm.

[0057] The obtained PVC leather is used as a fabric for motor vehicle seats after being cut.

[0058] Most of the reversible inorganic heat-sensitive color-changing materials used in this example are metals and metal halides. Under the a...

Embodiment 3

[0061] Leather was prepared according to the formulations of each layer in Table 1, and the preparation method was the same as in Example 1.

[0062] The layer structure of the thus obtained PVC leather is divided into successively: a paint layer, a PVC dense layer, a PVC foam layer and a base cloth layer. In this case, the paint layer comprises a first paint layer and a partial functional layer lying thereon. The functional layer that can change color is partially set on the leather surface in the form of LOGO. Wherein, the thickness of the PVC foam layer and the PVC dense layer can be adjusted freely, usually 0.5mm-2.0mm. The total thickness of the paint layer including the first paint layer and the functional layer is about 5 μm-20 μm.

[0063] The obtained PVC leather is used as a fabric for motor vehicle seats after being cut.

[0064] The liquid crystal molecule of the cholesteric liquid crystal state discoloration agent that adopts in this embodiment has unique molec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com