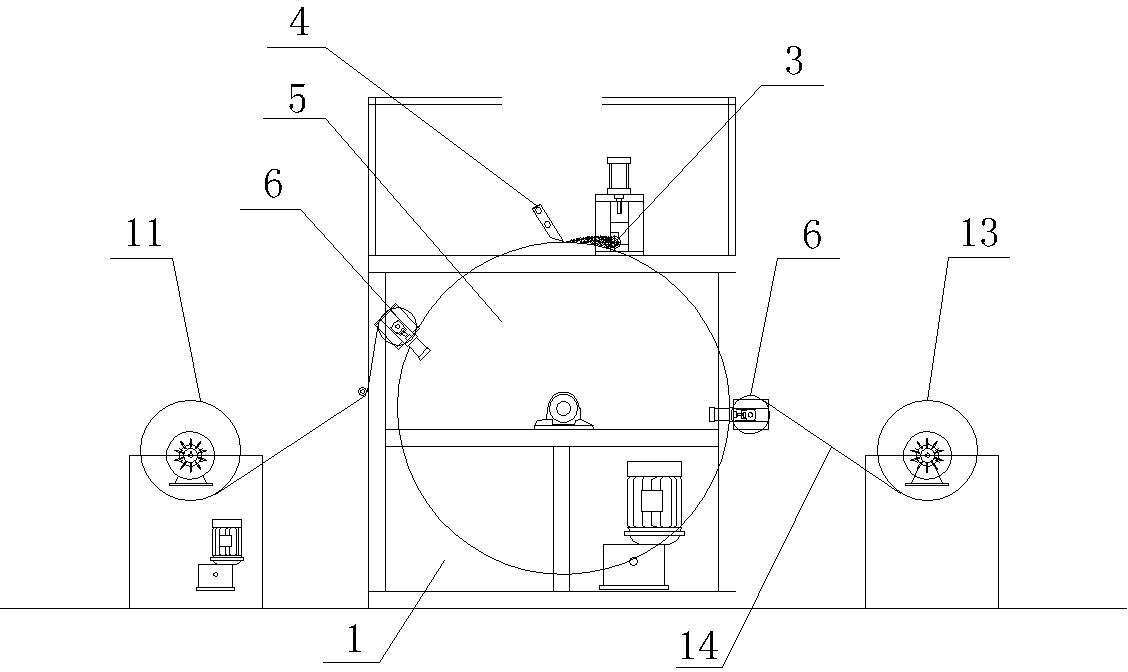

Dry artificial leather making machine

A kind of artificial leather and manufacturing machine technology, which is applied in special leather manufacturing, small raw hide/big raw hide/leather/fur mechanical treatment, leather drying, etc. It can solve the problems of huge equipment and high energy consumption, and achieve improved production environment with obvious effects. Obvious effects of environmental protection and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

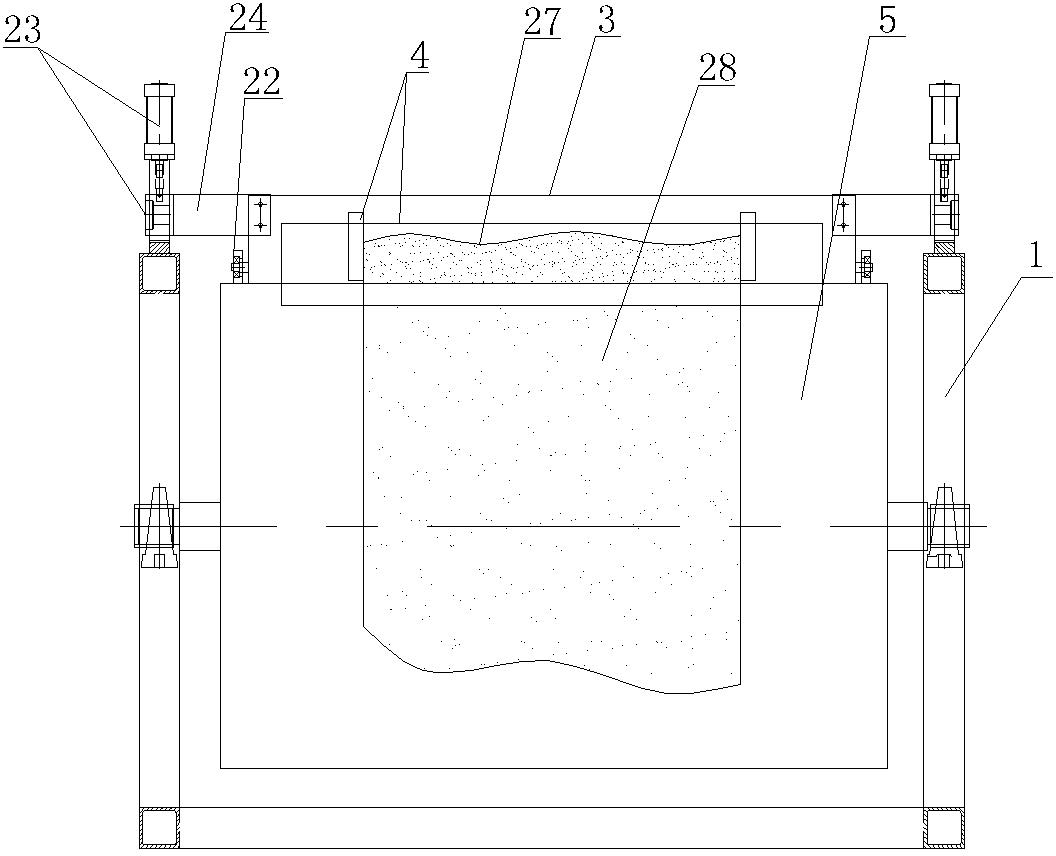

[0039] Such as image 3 As shown, the left and right ends of the scraper 3 are respectively provided with a first mandrel, the first mandrel is connected with a compensation wheel 22 through bearings, and the scraper 3 is connected with the pressure lifting mechanism 23 through the connection structure 24 fixedly connected at the left and right ends. The lifting mechanism 23 is connected with the frame 1 .

[0040] The pressure lifting mechanism 23 includes a cylinder, a slide block and a slide rail arranged on the frame 1, the cylinder includes a piston rod, the slide block is fixedly connected to the piston rod of the cylinder, and the slide block is slidably connected to the slide rail, and the slide block is fixed to the connection structure 24 connect.

[0041] Due to the existing technology, it is difficult to process the concentricity of the large-diameter heating wheel to a higher level, and after long-term heating and use, the heating wheel will be deformed, resultin...

Embodiment 2

[0045] Such as Figure 4 As shown, the left and right ends of the scraper 3 are respectively fixedly connected with connecting structures 24, and the connecting structures 24 are provided with a height adjustment mechanism 25. The mandrel and the second mandrel are connected with the compensating wheel 22 through bearings, and the scraper 3 is connected with the pressure lifting mechanism 23 through the connection structure 24 fixedly connected at the left and right ends, and the pressure lifting mechanism 23 is connected with the frame 1 .

[0046] The pressure lifting mechanism 23 includes a cylinder, a slide block and a slide rail arranged on the frame 1, the cylinder includes a piston rod, the slide block is fixedly connected to the piston rod of the cylinder, and the slide block is slidably connected to the slide rail, and the slide block is fixed to the connection structure 24 connect.

[0047] If you want to get different coating 28 thicknesses, you only need to adjust...

Embodiment 3

[0049] In this embodiment, a heating mantle 7, a material storage rack 18, a cooling wheel set 12 and an exhaust gas extraction device 8 are added on the basis of the above contents.

[0050] Such as Figure 5 As shown, an auxiliary heating cover 7 is added outside the heating wheel to improve the effect of heating and drying. In order to improve the speed and degree of automation, the present embodiment adds a storage rack 18 that can complete the replacement of unwinding rolls without stopping the machine, and adds a cooling wheel group 12 between the heating wheel mechanism 2 and the winding mechanism 11. Because some coatings 27 contain volatile solvents, so the present embodiment adds exhaust gas extraction device 8. In actual production, this waste gas extraction device 8 is connected in the solvent recovery device, in order to be beneficial to environmental protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com