Patents

Literature

67results about How to "Good environmental protection and energy saving effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

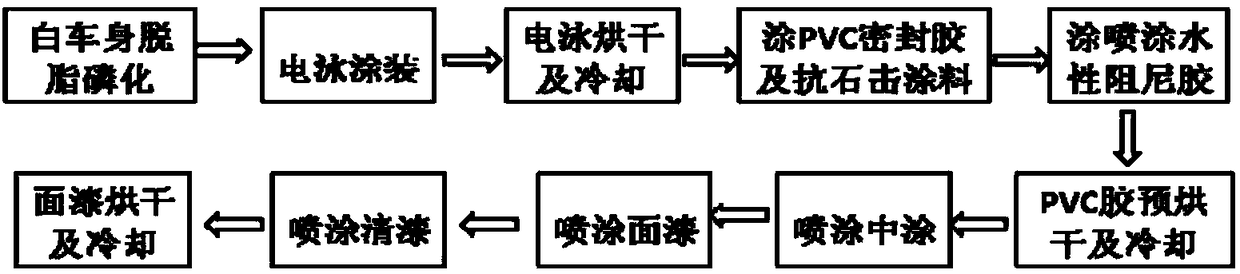

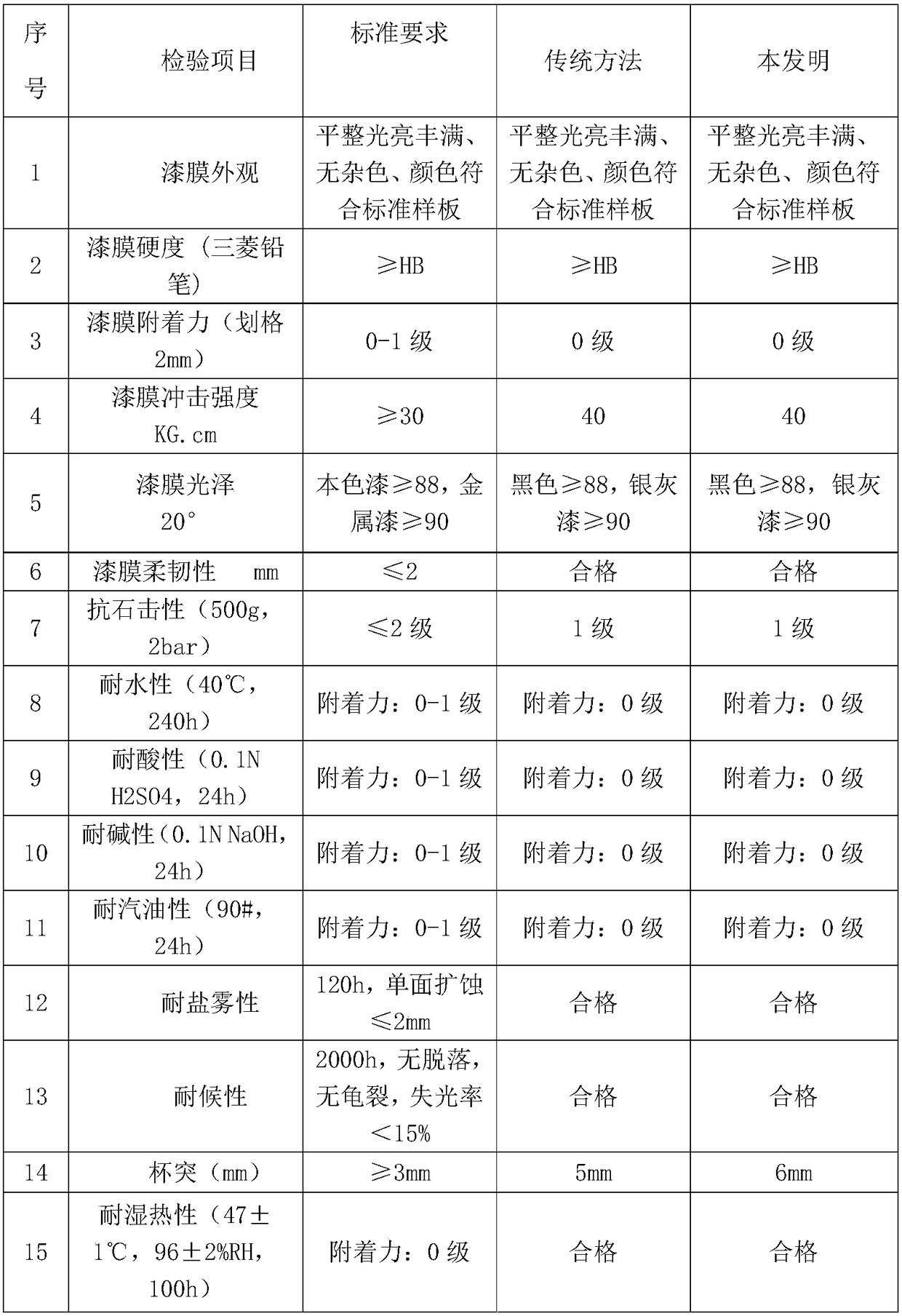

Automobile body coating method

InactiveCN108360043AReduce consumptionLow costLiquid surface applicatorsElectrophoretic coatingsCoated surfaceCooking & baking

The invention discloses an automobile body coating method. The automobile body coating method comprises the following steps of white automobile body coating degreasing and phosphating, electrophoreticcoating, electrophoretic drying and cooling, coating of a PVC sealant and anti-stone coating, spraying of damping adhesive, pre-drying and cooling of PVC adhesive, spraying of floating coat, sprayingof finishing coat, spraying of varnish and drying and cooling of the finishing coat. According to the automobile body coating method, medium-low-temperature degreasing is adopted, low-temperature phosphating is adopted for phosphating, and little or no steam heating is used according to room temperature conditions; high solid coat is used, the floating coat and the finishing coat are subjected towet-on-wet coating and then subjected to baking, and the floating coat drying process and the post-grinding process of the floating coat are omitted; through appropriate processes, equipment design and reasonable process parameter setting and monitoring, the coating surface quality state of the automobile body in each process is controlled; and the energy-saving automobile body coating method hasthe low energy consumption and low VOC.

Owner:HUNAN GEELY AUTOMOBILE COMPONENTS +1

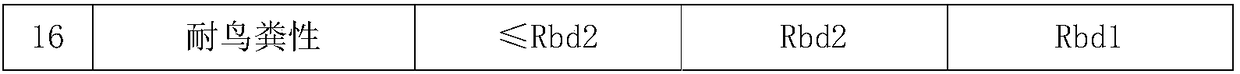

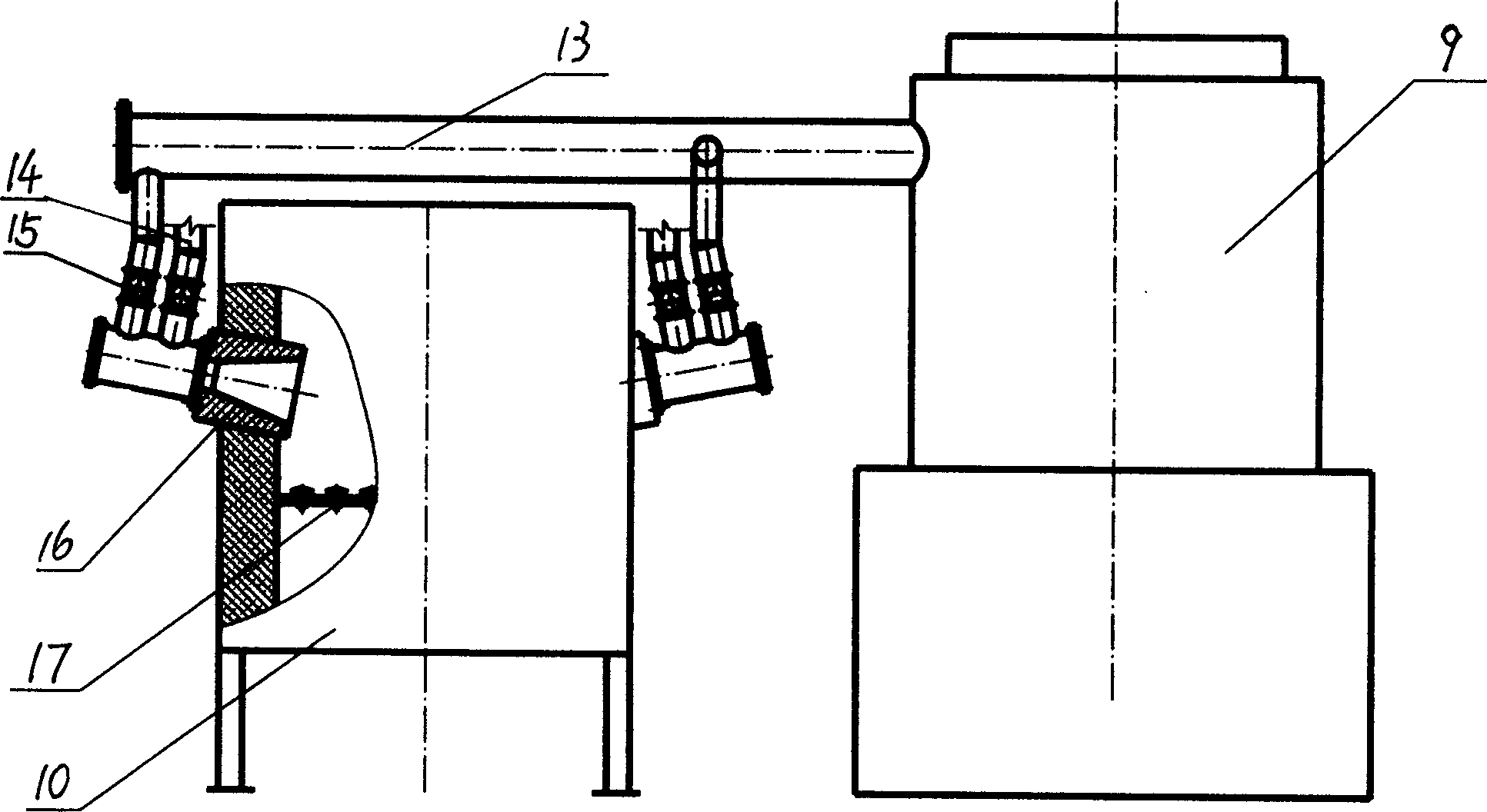

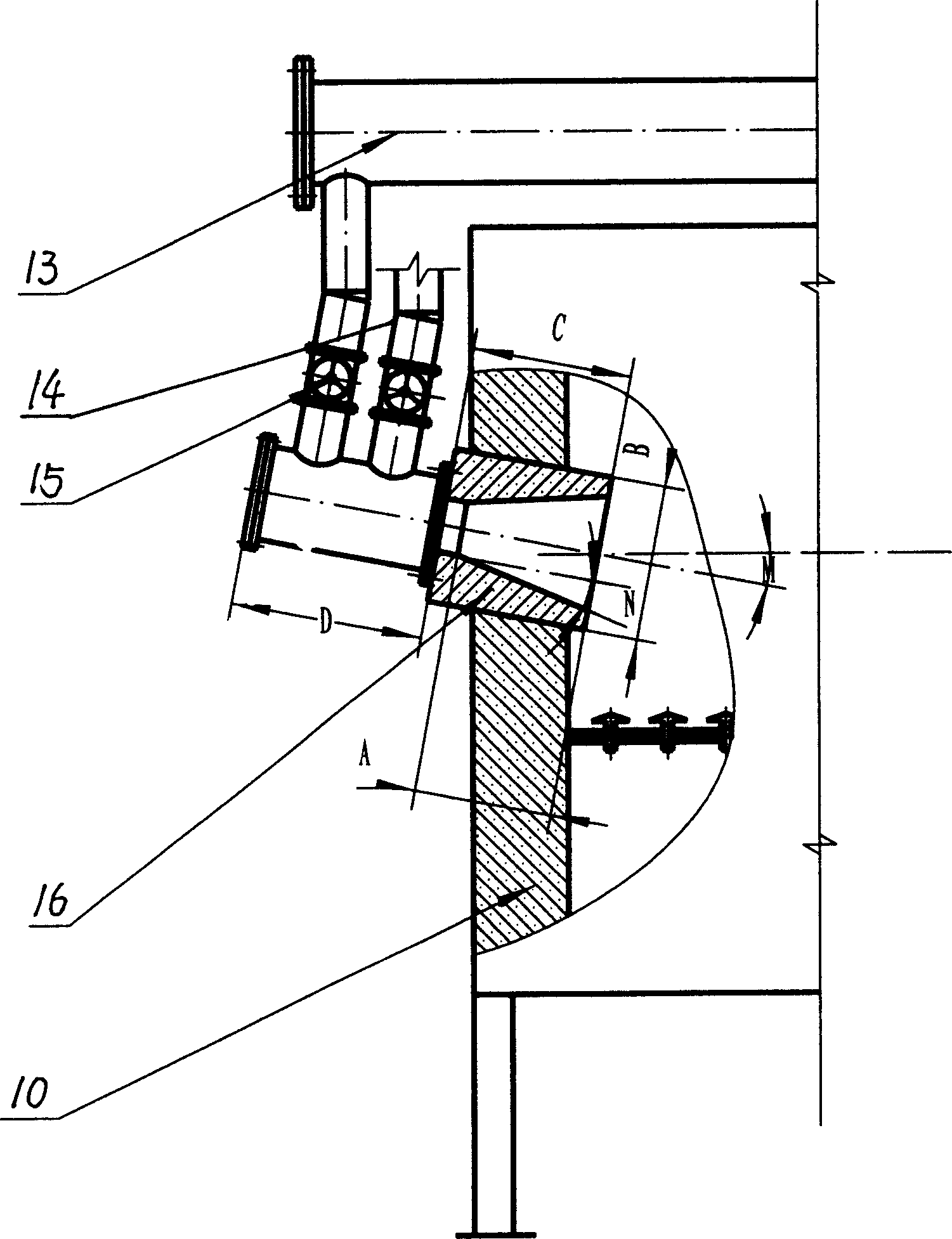

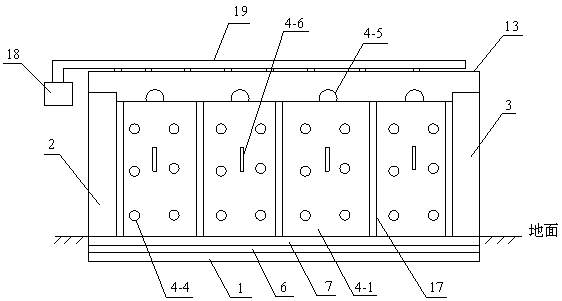

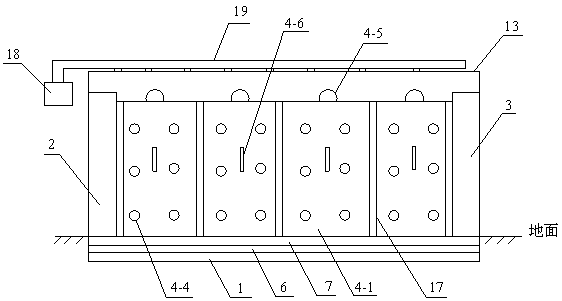

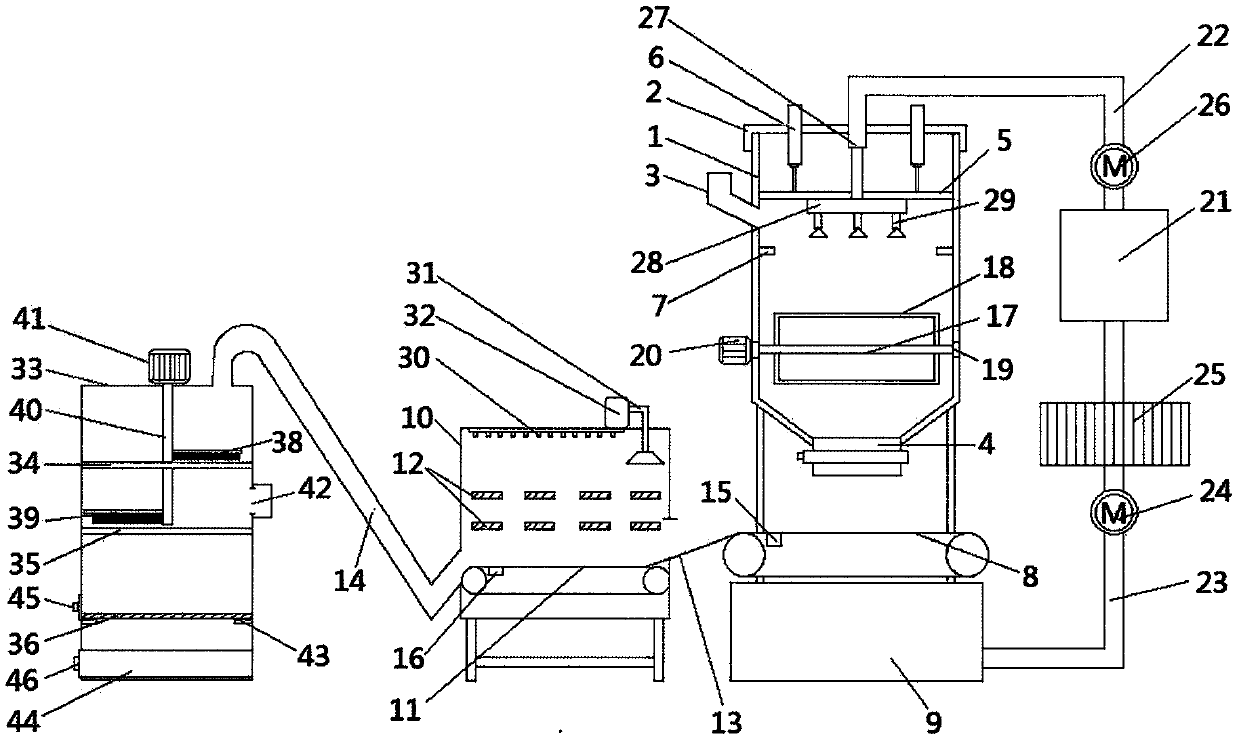

Hot process regenerative apparatus for tectorial sand using for casting

InactiveCN1481951AEasy to control and transportGuaranteed gas volumeMould handling/dressing devicesFluidised-bed furnacesEngineeringFuel supply

The coated sand heating regeneration apparatus includes crushing mechanism, feeding mechanism, preheating mechanism, fuel supplying mechanism, fluidizing roast furnace, cooling discharge mechanism and sand storing bin. The fuel supplying mechanism includes one low pressure hot gas generating furnace and one secondary blast blower; and the fluidizing roast furnace has on its wall two multiple-flow gas-burning nozzles connected to the gas generating furnace and the blast blower via pipeline. With low pressure gas as heat source, the present invention has convenient gas control and conveyance, stable burning, obvious environment protecting and energy saving effect and low cost.

Owner:NINGGUO CITY WEAR RESISTANCE MATERIAL GENERAL FACTORY ANHUI PROV

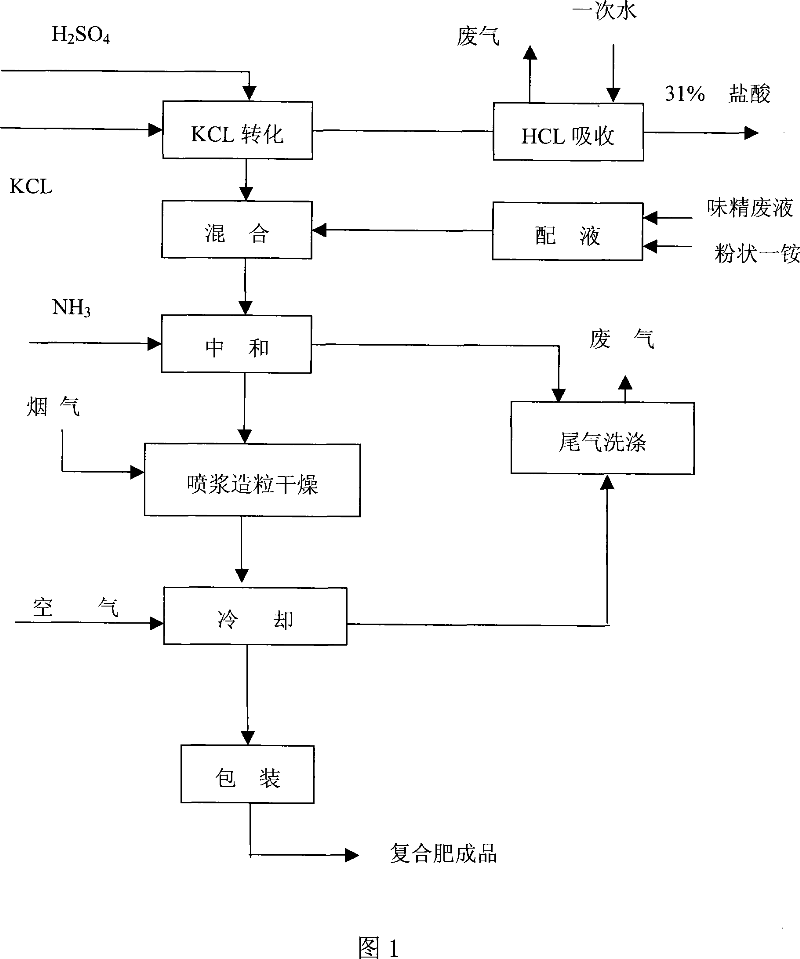

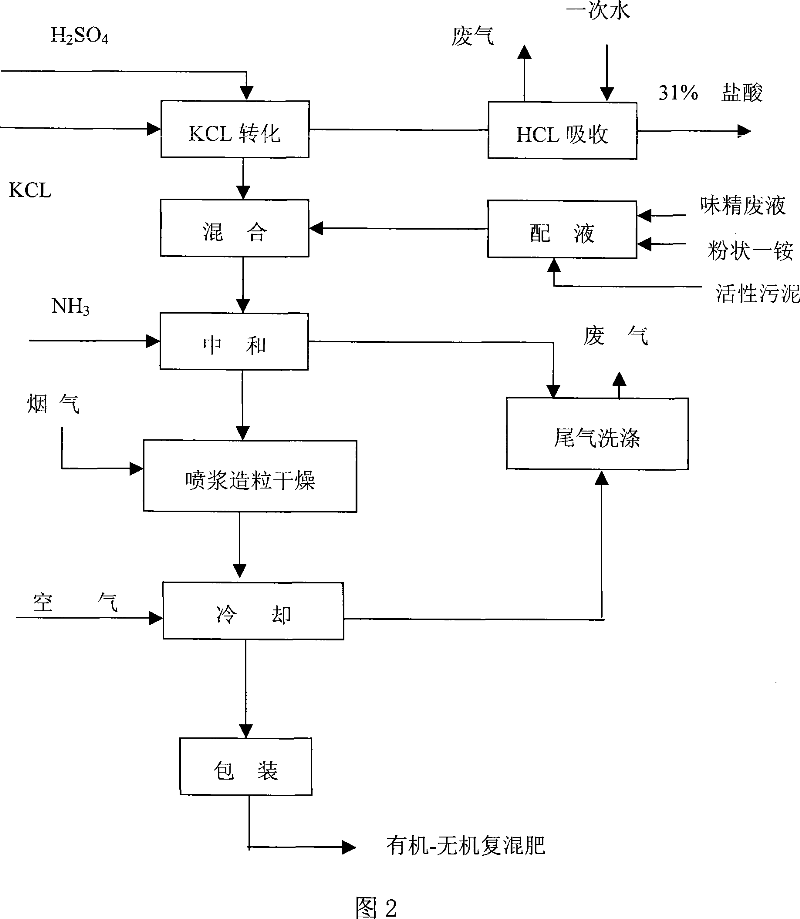

Method for producing agricultural fertilizer by using waste liquid of monosodium glutamate

InactiveCN101037353AReduce consumptionIncrease profitSuperphosphatesClimate change adaptationMonosodium glutamateHigh concentration

The invention discloses a method for producing farm fertilizer by monosodium glutamate tail washings with a primary raw materials: monosodium glutamate tail washings containing a solid content of 8-50%, active sludge with an organic matter content more than 50%, sulphuric acid with a concentration of 90-98%, potassium chloride with a pureness of 95-98%, powdered monoammonium phosphate with a total nutrition of 55-60%, liquid ammonia. The potasium bisulfate is got by a reaction of potassium chloride and concentrated sulfuric acid. A mixing ammonium liquid is obtained by introducing the powdered monoammonium phosphate and active sludge into the monosodium glutamate tail washings. The mixing ammonium liquid mixes with the potasium bisulfate to form mixed acid. Slurry is produced by feeding the gas ammonia into the mixed acid for a neutralization reaction. The slurry produces the compound fertilizer of potassium sulfate style and organic-mineral compound fertilizers by spouting of stock, prilling and drying. The method can make the material fully mix and get an even slurry liquid with an excellent flowability which fits for the spouting of stock and prilling. Therefore, it may produce standard compound fertilizer containing organic matters and organic-mineral compound fertilizers in potassium sulfate style with a low, medium, high concentration.

Owner:梅花生物科技集团股份有限公司

Graphitization technology of Acheson furnace for producing anode materials

ActiveCN105502361AQuality improvementImprove performanceProductsReagentsThermal insulationPetroleum coke

The invention provides a graphitization technology of an Acheson furnace for producing anode materials, and belongs to the technical field of anode material preparation. The graphitization technology comprises the steps that a furnace base is paved with quartz sand and carbon in sequence, the upper portion of the carbon black is paved with petroleum coke, tamping is conducted, and the upper portion of the petroleum coke is pared with calcined coke; the anode materials are put in crucibles and arranged layer by layer till the requirement of a designed furnace core is met, the upper portion and the periphery of each crucible are paved with and filled with the calcined coke, the upper portion of the calcined coke and the space between a forming plate and a steel plate are paved with and filled with the petroleum coke, and the upper portion of the forming plate and the space between each furnace wall plate and the forming plate are paved with and filled with thermal insulation materials, after furnace charging is completed, a gas-collecting hood is additionally installed, energizing is conducted to raise temperature, and cooling and product discharging are conducted. By adopting the graphitization technology to produce the anode materials of lithium batteries, the graphitization degree of the products is higher, power consumption for obtaining each ton of the anode materials is reduced, the yield of carburant is doubled, cooling of a furnace body is rapid, product discharge is rapid, and the environmental protecting and energy saving effects are significant.

Owner:HENAN JIULONG NEW ENERGY MATERIAL CO LTD

Phosphate rock grinding aid and preparation method thereof

ActiveCN102965079AGood dispersionReduce intensityOther chemical processesPhosphoriteOleic Acid Triglyceride

The invention discloses a phosphate rock grinding aid and a preparation method thereof, which are mainly suitable for ore grinding production of flotation magnesium-removal phosphate rock. The phosphate rock grinding aid is prepared from the oleic acid, the lauryl amine and the triethanolamine at the weight ratio of (300-410):(150-190):(120-190). The phosphate rock grinding aid is good in dispersion effect, improves the grinding efficiency of phosphate rock, increases the ore grinding yield, reduces the energy consumption, increases the new surfaces of particles and reduces the dosage of the flotation magnesium-removal phosphate rock.

Owner:SINOFERT HOLDINGS

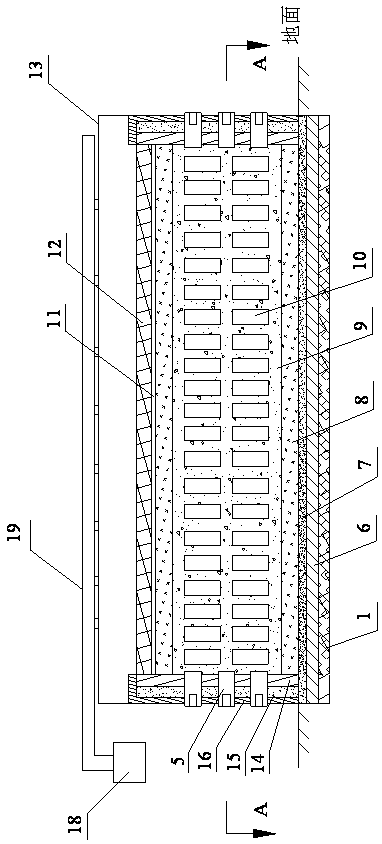

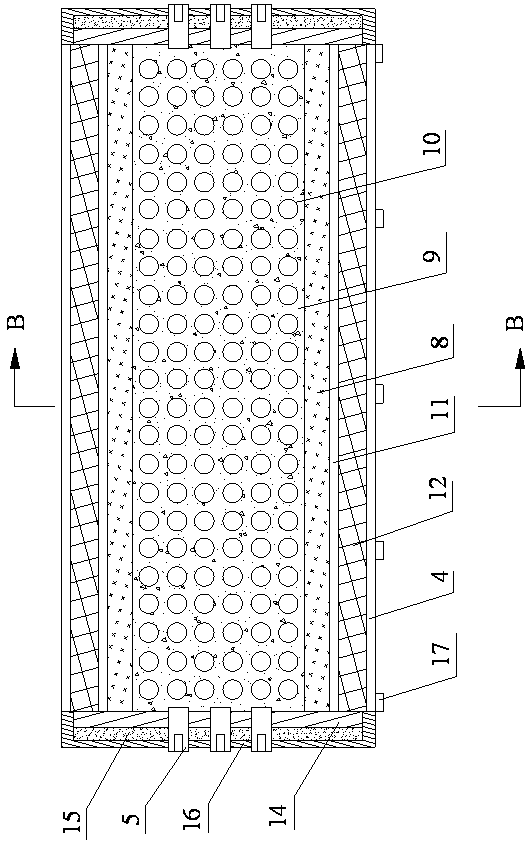

Acheson furnace for producing graphite anode materials and furnace charging technology of furnace

ActiveCN105502362ARapid coolingReduce power consumptionChemical industryThermal insulationCarbon black

The invention provides an Acheson furnace for producing graphite anode materials and a furnace charging technology of the furnace, and belongs to the technical field of anode material preparation. The Acheson furnace for producing the graphite anode materials comprises a furnace body formed by a furnace base, a furnace head wall, a furnace tail wall and furnace wall plates in an enclosing mode; a quartz sand layer and a carbon black layer are sequentially arranged on the upper portion of the furnace base from bottom to top, a furnace core is arranged on the upper portion of the carbon black layer, the furnace core comprises multiple layers of crucibles, a calcined coke layer arranged on the outer surfaces of the crucibles and a petroleum coke layer arranged on the outer surface of the calcined coke layer, forming plates are arranged on the top and the side faces of the furnace core, a thermal insulation material layer is arranged on the top and the side faces of the forming plates, and a gas-collecting hood is arranged on the top of the furnace body. According to the Acheson furnace for producing the graphite anode materials and the furnace charging technology of the furnace, the furnace core of the Acheson furnace can reach higher temperature, the graphitization degree of the products is higher, power consumption for obtaining each ton of the anode materials is reduced, the yield of carburant is doubled, cooling of the furnace body is rapid, product discharge is rapid, and the environmental protecting and energy saving effects are significant.

Owner:HENAN JIULONG NEW ENERGY MATERIAL CO LTD

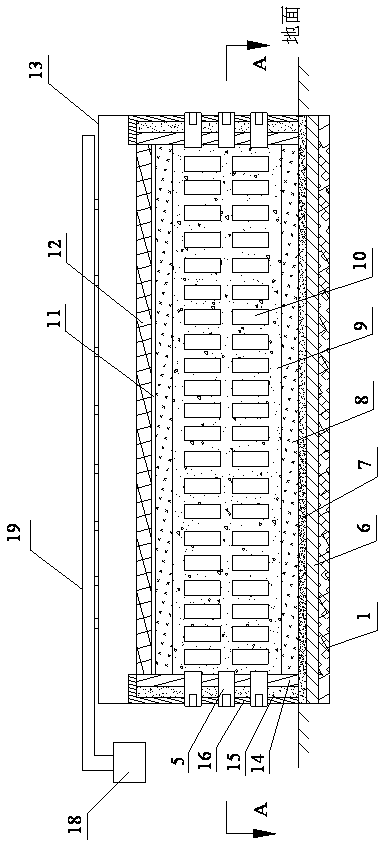

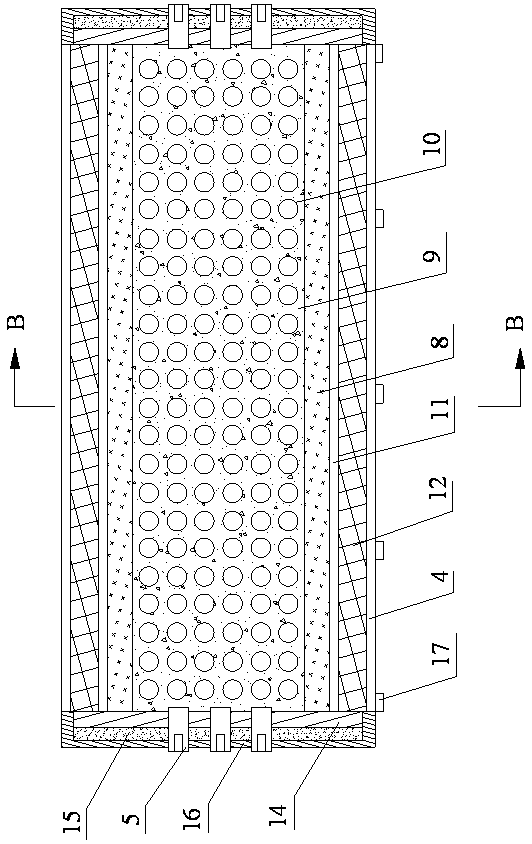

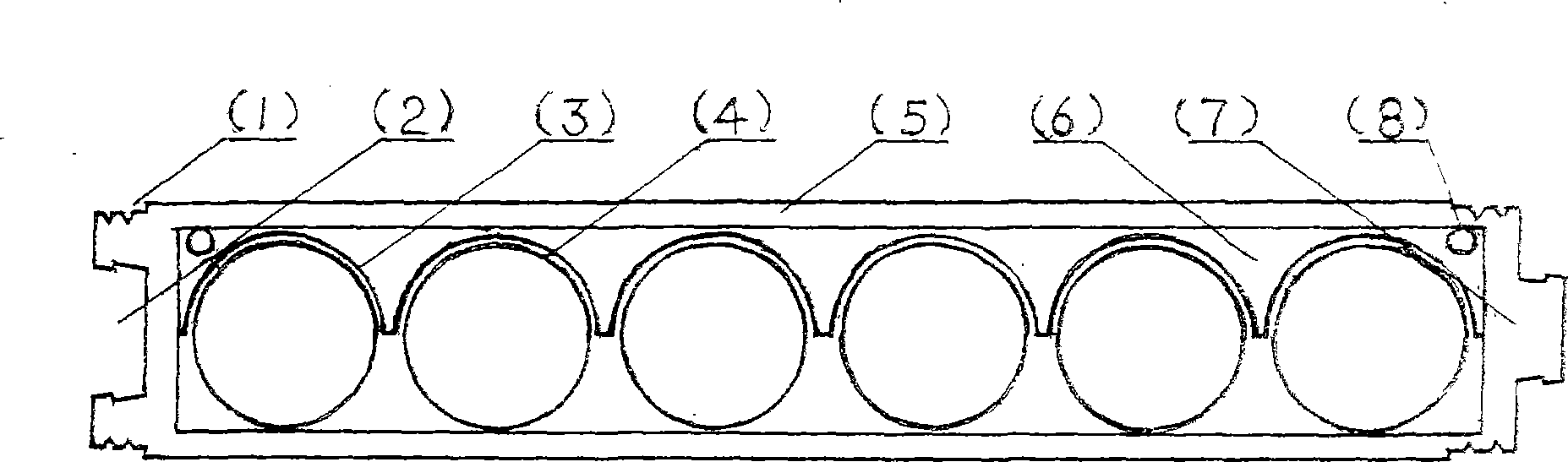

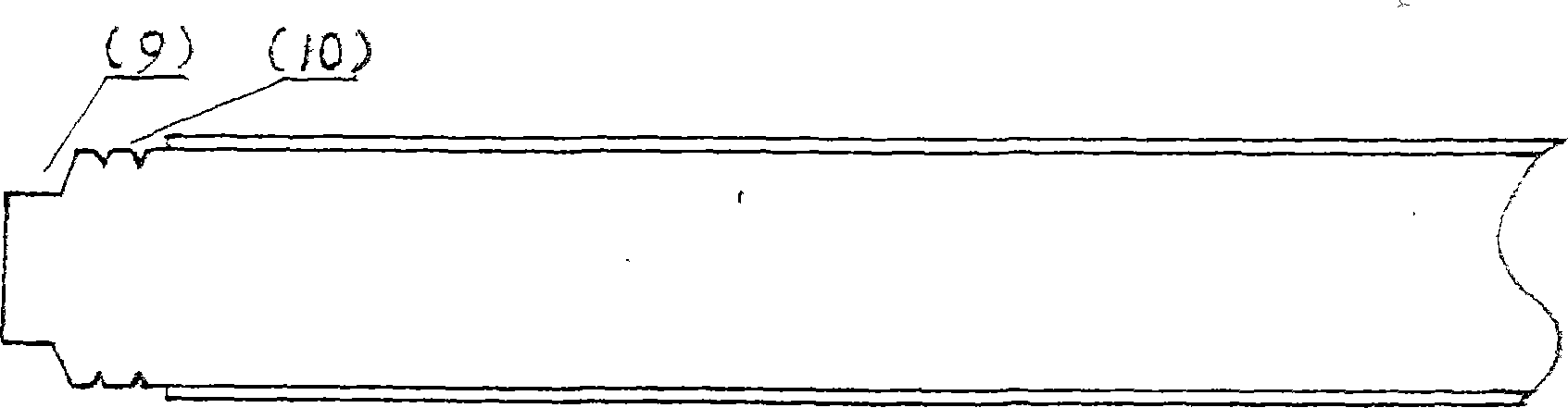

High-heat preserving high-sound insulation high-strength seamless ultra-hollow wall board and technique thereof

InactiveCN101245652AReduce weightReduce high loadMixing operation control apparatusCeramic shaping plantsHigh densitySurface layer

The invention relates to a beamless and super-hollow wall board with high heat preservation, noise insulation and strength and a manufacturing technique thereof, belonging to the field of light building walls, which is characterized in that: the invention comprises an internal structure and an external structure of the board; the internal structure of the board consists of a surface layer (5) of the wall board, an inner layer (6) of the wall board, and a super-hollow air cylinder with high density or a vacuum air cylinder (4); the external structure of the board consists of a convex spindle (7) and a groove (2) locked with each other through a barb, lockstitch parts (1) and (10) with shallow slots that are further provided with transverse trenches, and a longitudinal threading hole (8), etc. The beamless and super-hollow wall board with high heat preservation, noise insulation and strength, in particular the super-hollow structure, is scientifically designed, thus has the advantages of lighter weight, more excellent performance in heat preservation, heat insulation and noise insulation, better wind and shock resistant loading, lower cost, remarkable effects of environment protection and energy saving, and is suitable for mechanized production and large-scale production.

Owner:王景满

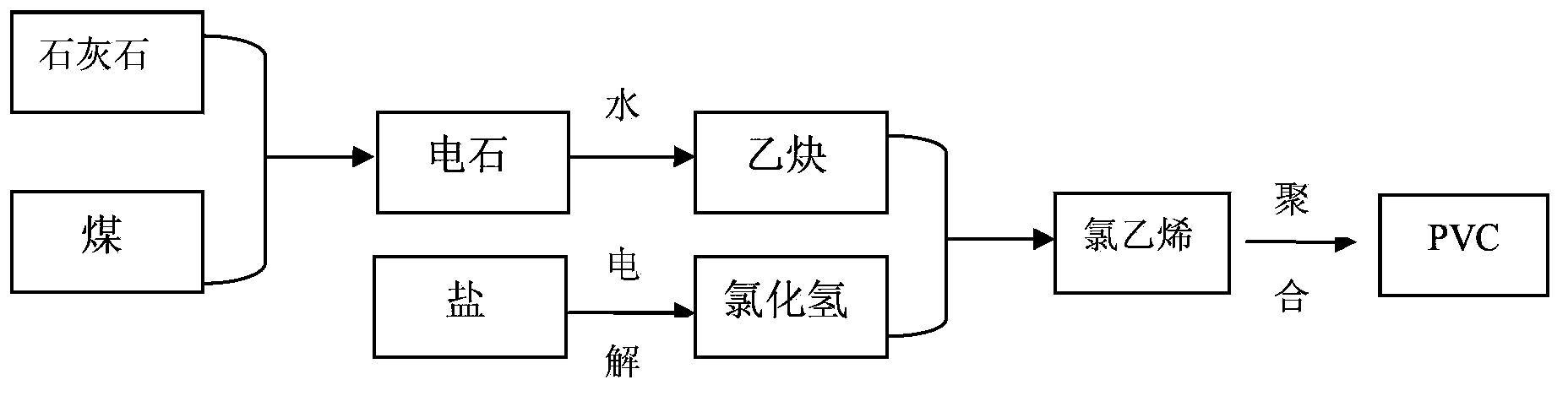

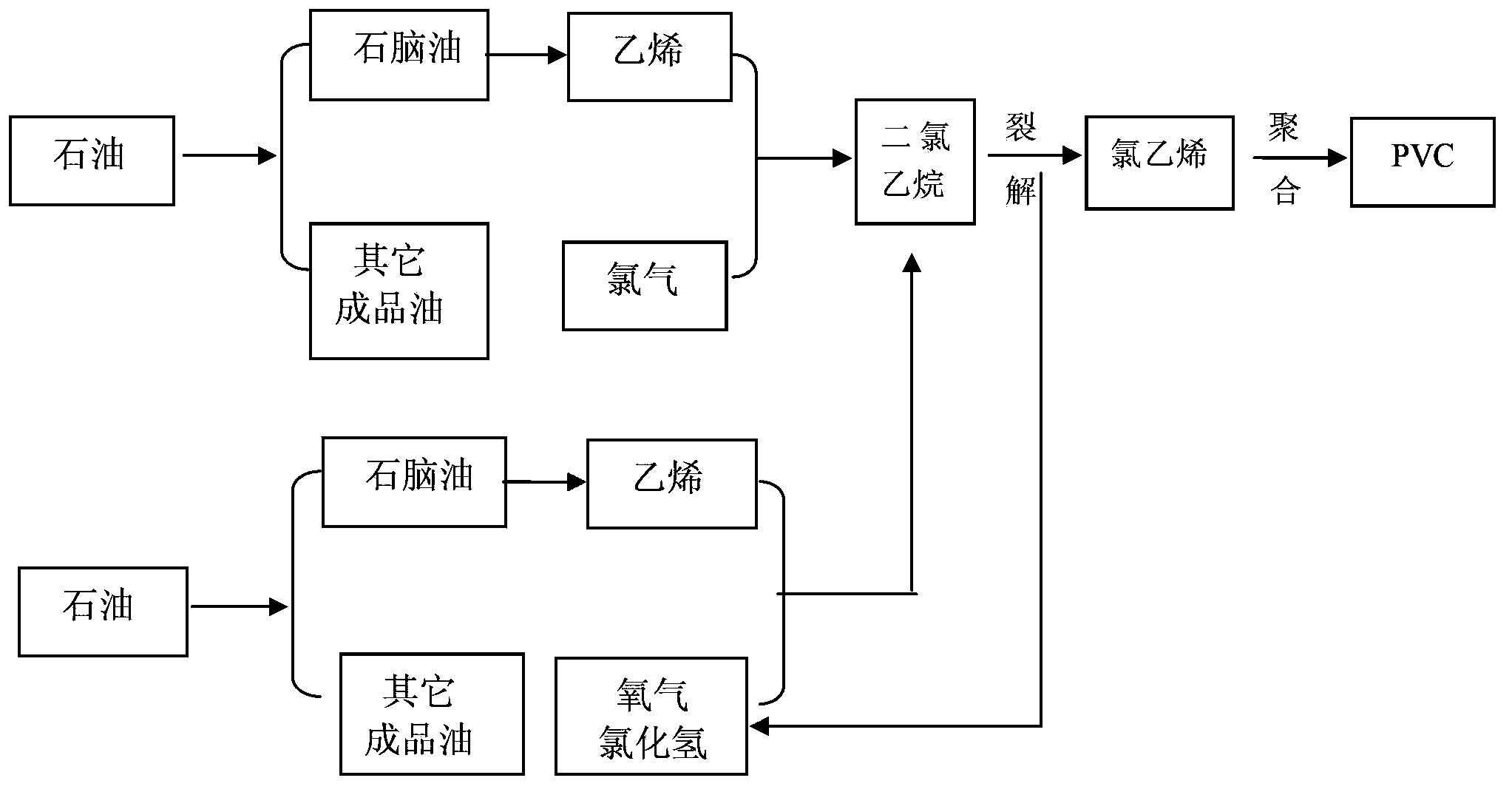

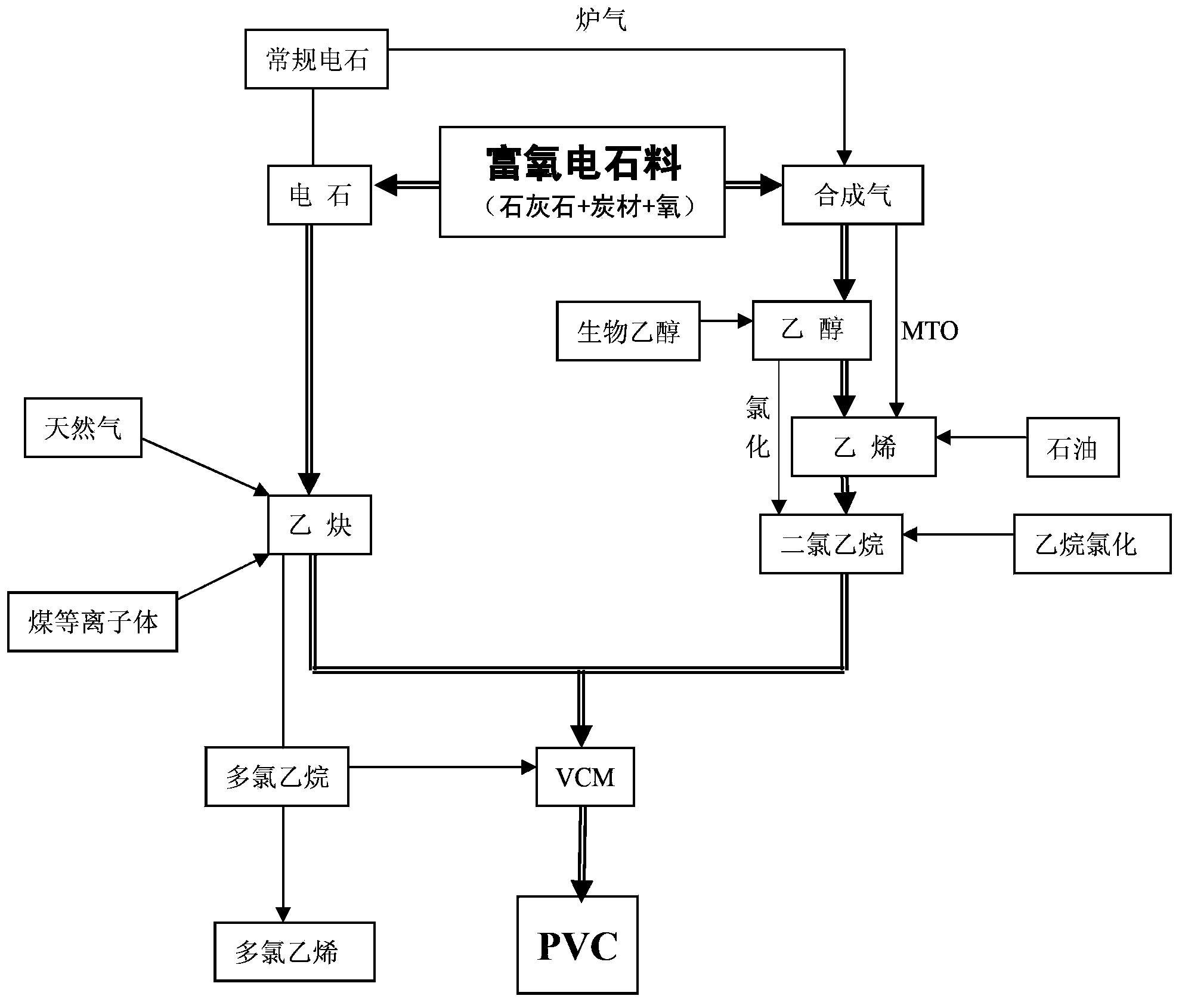

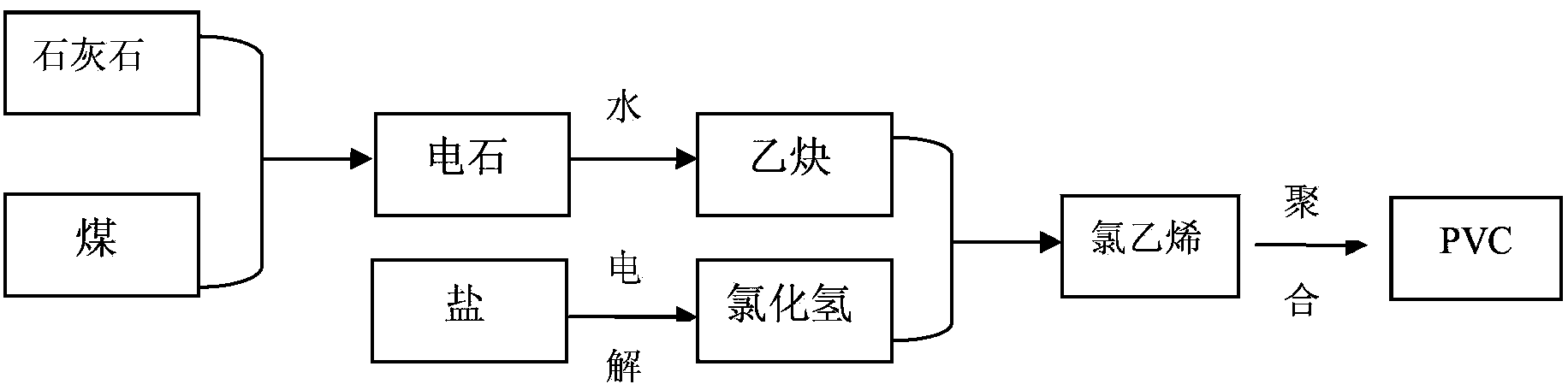

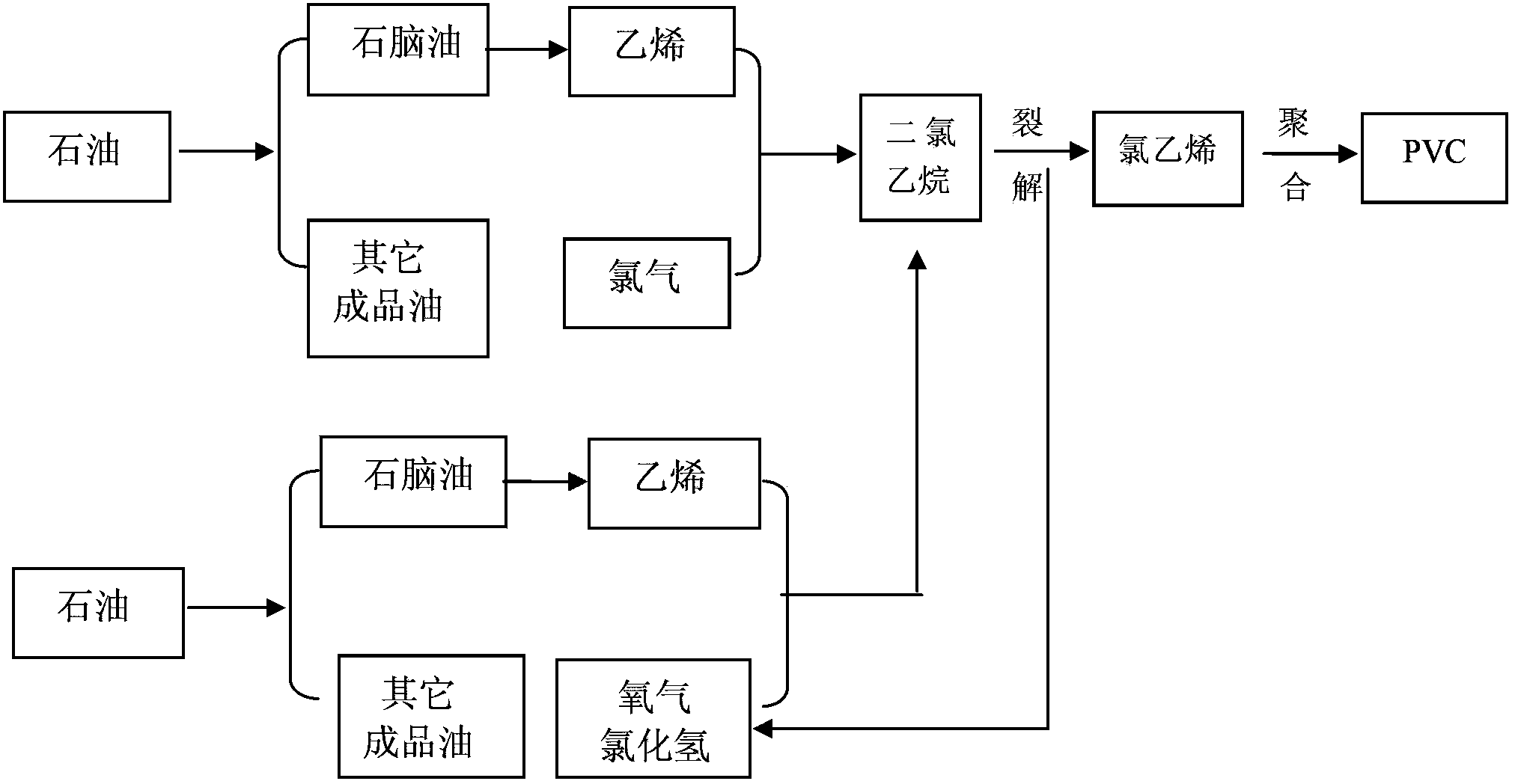

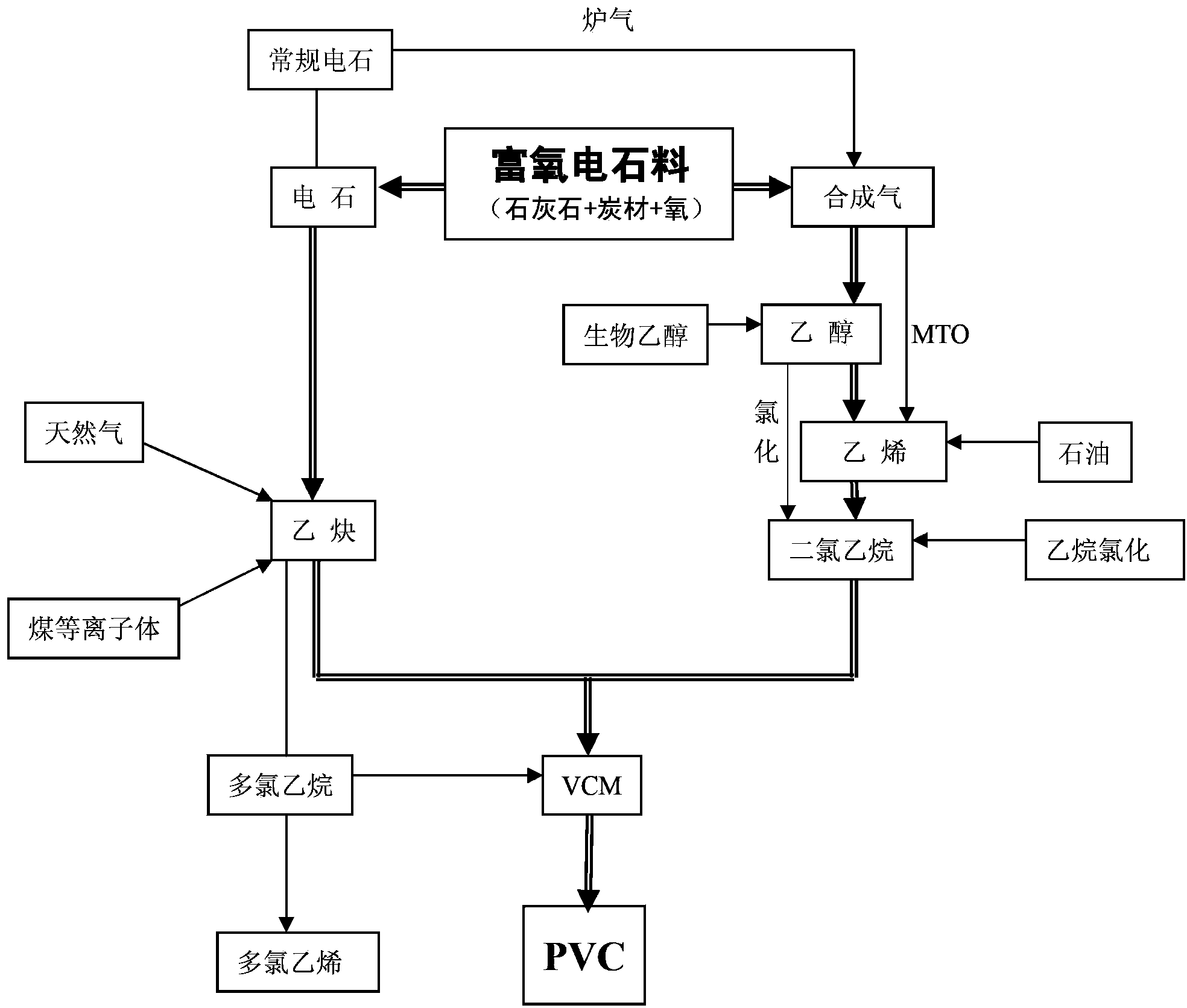

Polyvinyl chloride loop route production method

InactiveCN103408392AReduce usageSolve the problem of mercury pollution and environmental protectionPreparation by hydrogen halide split-offPreparation by halogen halide additionPolyvinyl chlorideClosed loop

The invention provides a polyvinyl chloride loop route production method (short for loop route method), and belongs to the field of new coal chemical industry materials and the technical field of polymer material science and engineering, and relates to a polyvinyl chloride green production technology with characteristics of high efficiency, energy saving, and environmental protection. According to the method, actual production starts from an oxygen-rich calcium carbide high temperature reaction furnace, oxygen-rich calcium carbide reacts in the high temperature reaction furnace to obtain a solid product calcium carbide and synthesis gas carbon monoxide, the subsequent process is divided into two branches, one branch process is preparing acetylene from the calcium carbide, the other branch process is preparing ethanol from the synthesis gas carbon monoxide, and then preparing dichloroethane through ethanol chlorination, a closed loop is formed after the two branch reactions are completed and combined, both end products acetylene and dichloroethane can be subjected to a reaction by using a mercury-free catalyst to prepare a vinyl chloride monomer, and the existing technology can be adopted to prepare the PVC from the vinyl chloride monomer. According to the present invention, the reacting calcium carbide residue can be used for producing cement, and the synthesis gas CO can completely participate in the subsequent reactions so as to achieve zero emission; and the expansion loop method can be adopted to achieve multi-function and multi-efficacy co-production operation.

Owner:BEIJING UNIV OF CHEM TECH

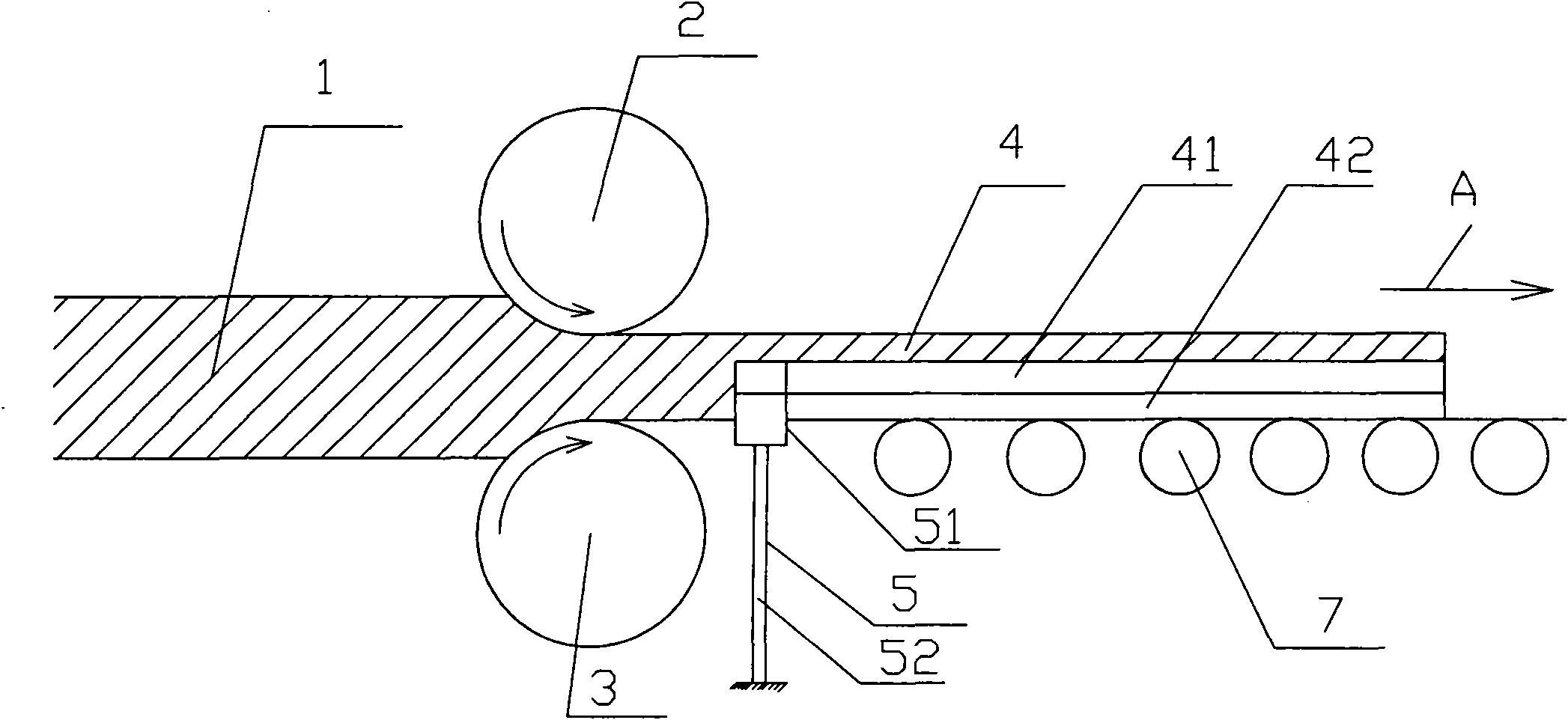

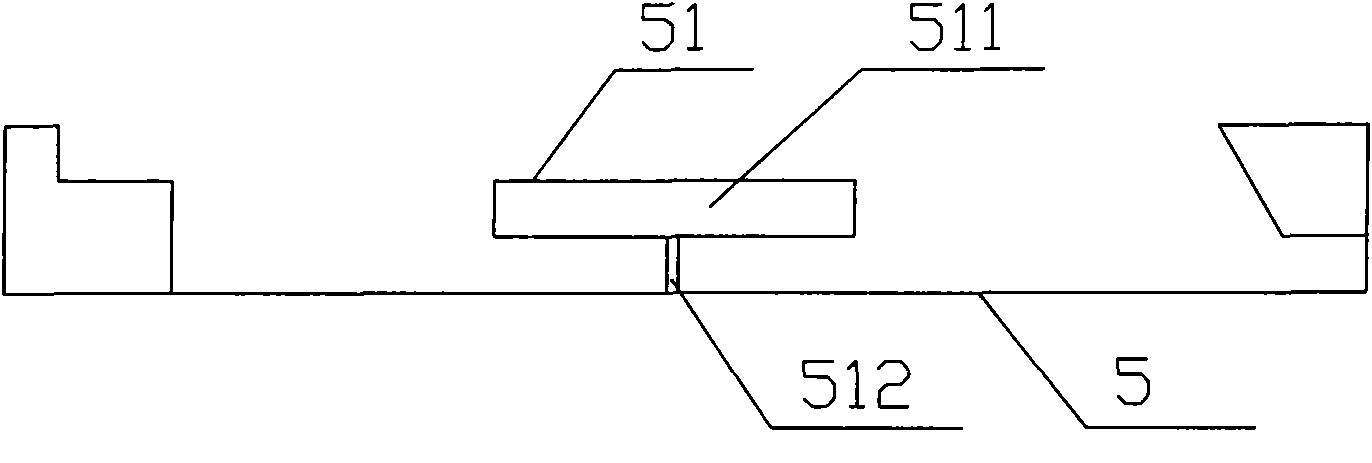

Dry artificial leather making machine

ActiveCN102011323ALong-term useSave costsLiquid surface applicatorsLamination ancillary operationsEngineeringTransmission equipment

The invention provides a dry artificial leather making machine. The machine comprises a frame and a heat wheel mechanism arranged on the frame, wherein the heat wheel mechanism comprises a scraper mechanism, a heat wheel capable of rotating and an abutted wheel; the heat wheel is provided with a heat supply device; the outer circumferential surface of the heat wheel is a flat working surface; the working surface of the scraper mechanism corresponding to the heat wheel is arranged above the heat wheel; and the working surface of the abutted wheel corresponding to the heat wheel is arranged at the lateral side of the heat wheel, and is arranged in front of the scraper mechanism on the rotating direction of the heat wheel. In the invention, scraper equipment, heat equipment, transmission equipment, joint equipment and molding equipment in the traditional process are ingeniously combined to the heat wheel mechanism, the heat wheel is shared in scraping, heating, transmitting, jointing and molding processes, so that scraping, heating, transmitting, jointing and molding steps on paint and a matrix belt can be completed when the paint and the matrix belt pass through the heat wheel mechanism. The dry artificial leather making machine has short production line, and does not require release paper consumption in the producing process.

Owner:东莞市金银丰机械实业有限公司

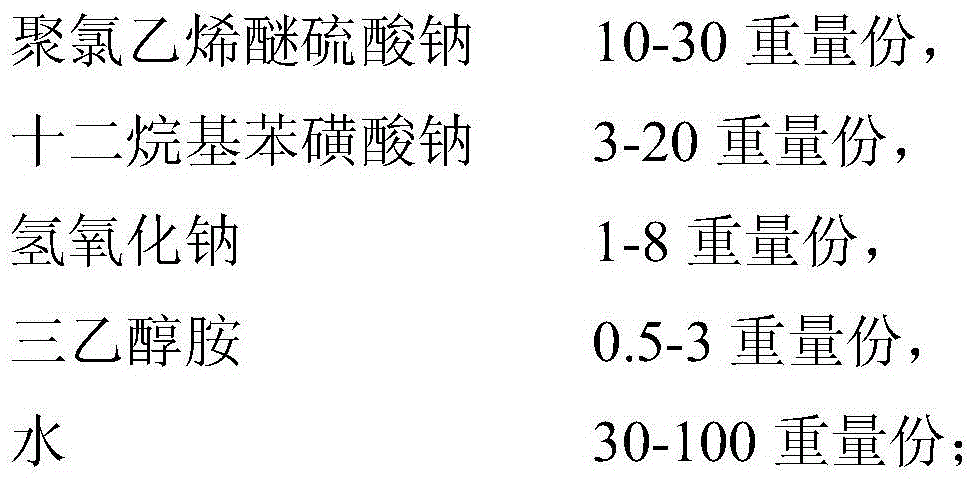

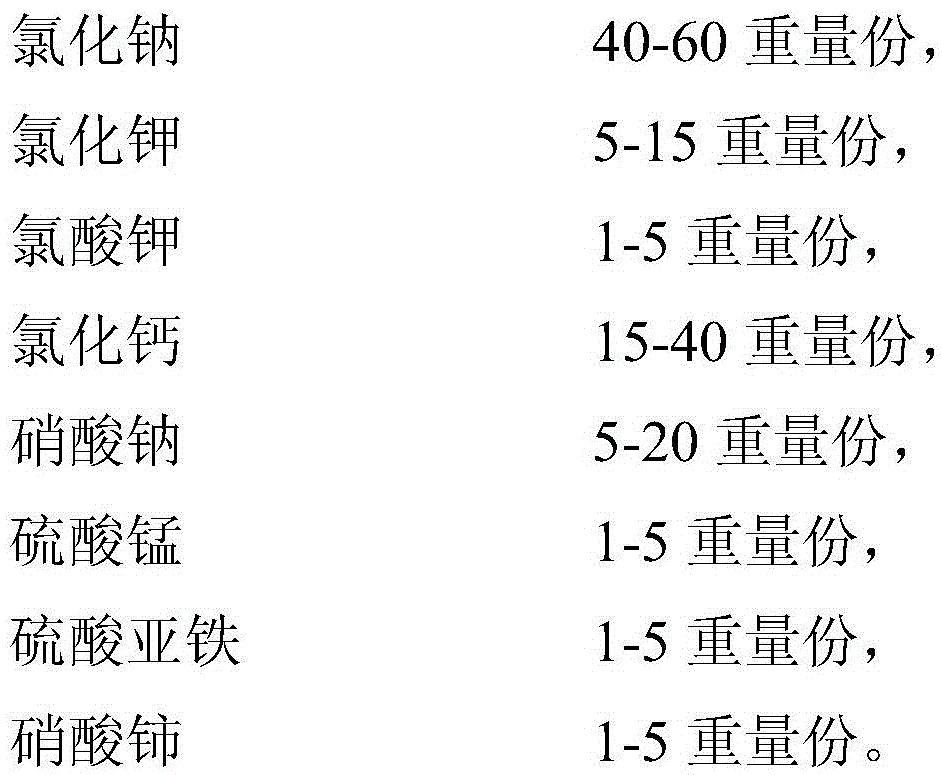

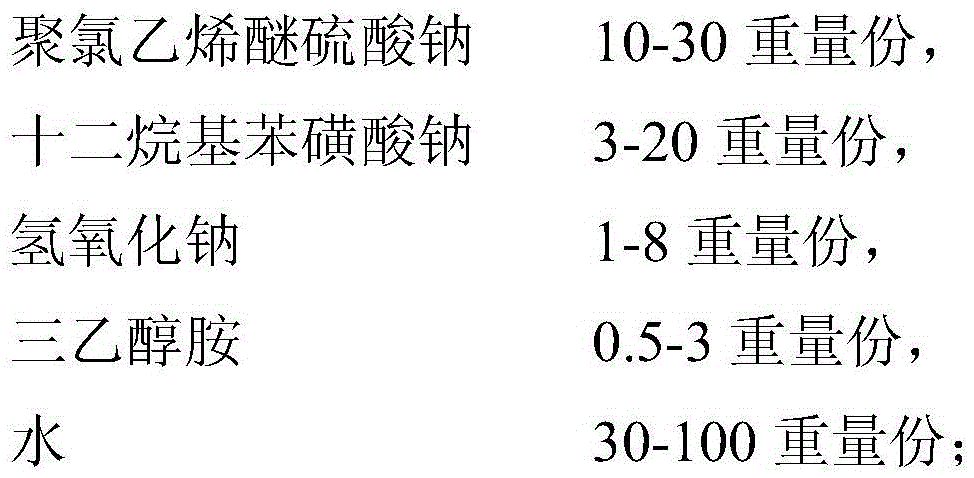

Environment-friendly coal saving agent

ActiveCN105542900AGood environmental protection and energy saving effectImprove performanceSolid fuelsLiquid productCerium nitrate

The embodiment discloses an environment-friendly coal saving agent including a component A and a component B; the component A comprises polyvinyl chloride ether sodium sulfate, sodium dodecyl benzene sulfonate, sodium hydroxide and triethanolamine, and the component B comprises sodium chloride, potassium chloride, potassium chlorate, calcium chloride, sodium nitrate, manganese sulfate, ferrous sulfate and cerium nitrate. The environment-friendly coal saving agent provided by the invention makes the component A having good roles of supporting combustion, cleaning ash, removing coke and fixing sulfur and the component B having excellent permeability and catalysis properties dissolved into one whole, has a synergistic effect, and effectively optimizes and improves the properties of the additives; and secondly, the environment-friendly coal saving agent is a liquid product, is mixed with fire coal more evenly, allows the effective components to be permeated into the fire coal in short time, and has better environmental-protection and energy-saving effects. Therefore, the environmental-protection coal saving agent promotes full combustion of the fire coal, and has good environmental-protection and energy- saving effects.

Owner:北京幄福环保科技有限公司

Polyvinyl chloride loop route production method

ActiveCN103408393AReduce usageSolve the problem of mercury pollution and environmental protectionPreparation by hydrogen halide split-offPreparation by halogen halide additionFixed bedClosed loop

Owner:BEIJING UNIV OF CHEM TECH

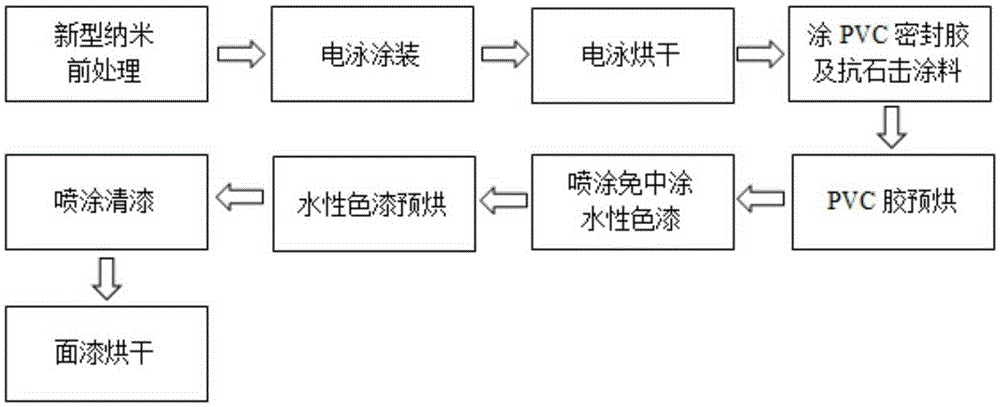

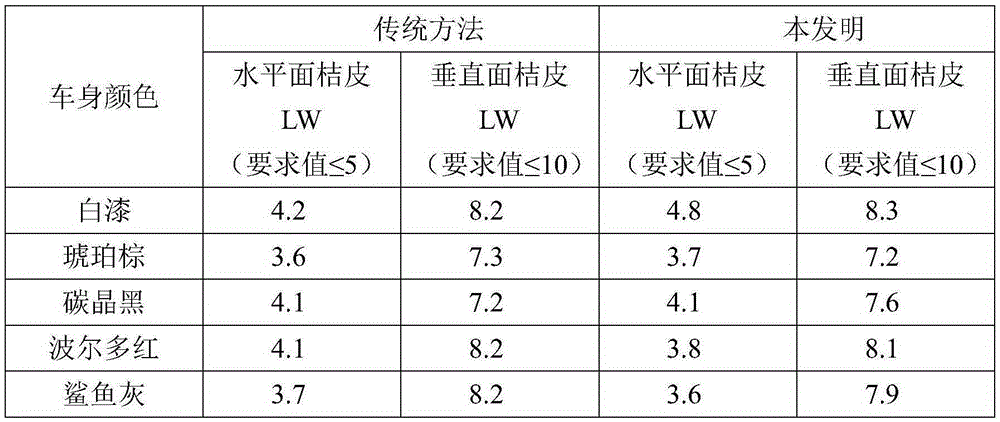

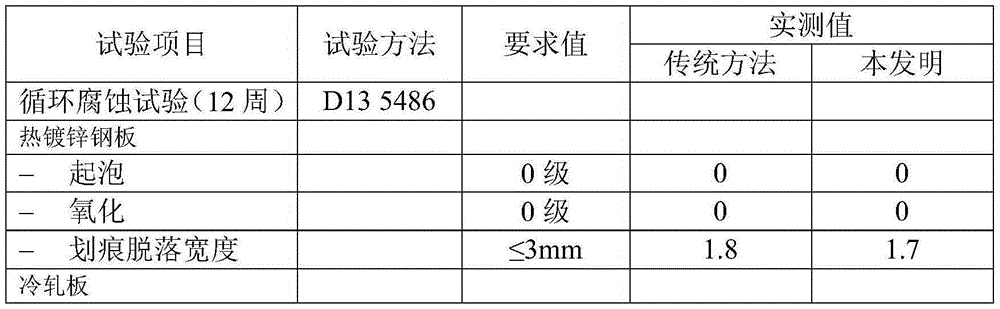

Car body coating method of novel nanometer pretreatment combining floating-coating-free water paint

ActiveCN105381942AAccelerated corrosionImprove adhesionPretreated surfacesMetallic material coating processesProduction lineSocial benefits

The invention discloses a car body coating method of novel nanometer pretreatment combining floating-coating-free water paint. The method includes the following steps of novel nanometer pretreatment, electrophoretic coating, electrophoretic drying, PVC sealant and stone-chip-resistant paint coating, PVC sealant pre-drying, floating-coating-free water colored paint spraying, water colored paint pre-drying, varnish spraying and finish paint drying. Compared with a traditional coating method of phosphorization pretreatment combining solvent type floating-coating finish paint, the car body coating method has the beneficial effects that the area of a factory and a production line are saved, a building period is shortened, environmental protection benefits are great, and the social benefits of low pollutant emission, energy conservation and consumption reduction are remarkable.

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE

Chili pepper cleaning system

PendingCN109700051AEasy to cleanEasy to processClimate change adaptationFood treatmentWater filterEngineering

The invention discloses a chili pepper cleaning system. The chili pepper cleaning system comprises a cleaning device, a water filter, a drying device, a secondary dust removing device and a control system, wherein the water filter is arranged below the cleaning device; and the drying device is arranged between the water filter and the secondary dust removing device. When the chili pepper cleaningsystem is used for cleaning chili peppers, electric control cylinders are arranged to enable a floating-preventing pressing plate to decline so as to achieve the effect of separation on dried chili peppers, the dried chili peppers are soaked in cleaning liquid, cleaning is convenient, and the cleaning efficiency is improved; and most of moisture of the cleaned chili peppers is connected into a water collecting box through mesh holes of a mesh conveyor belt, water in the water collecting box can achieve the effect of recycling by using a waste water recycling system, and the condition that waste of water is effectively avoided. The dried chili peppers enter the drying device to be dried, so that the surfaces of the cleaned chili peppers are free from accumulated water; and after the dried chili peppers are dried, the dried chili peppers enter from the top end of the secondary dust removing device, and in the process of falling down, floating dust remaining on the surfaces of the dried chili peppers can be removed, later stage making and processing of the chili peppers are facilitated, and the practicality is high.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

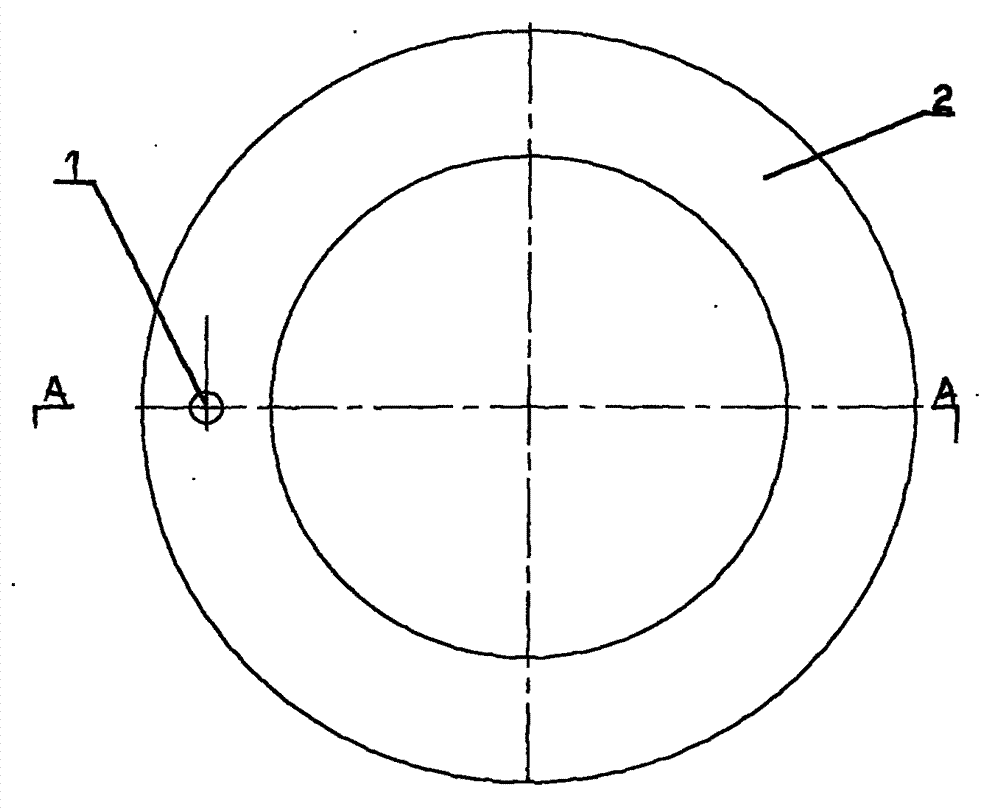

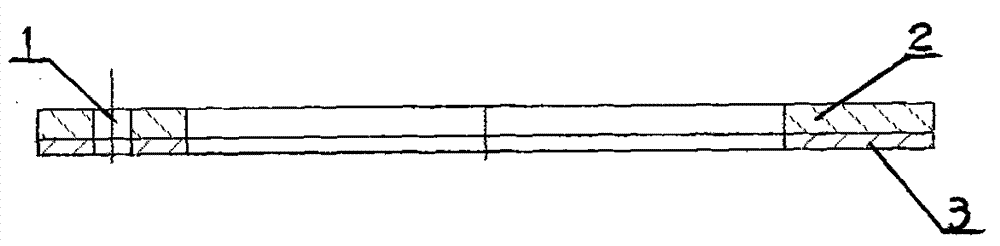

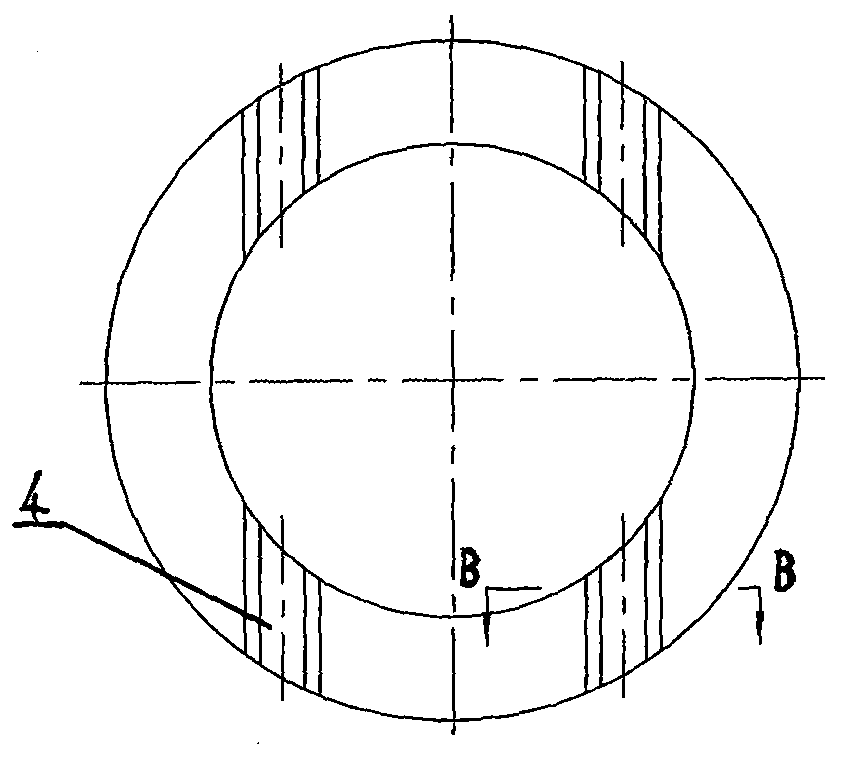

Near-net shape forming manufacturing method for thrust collars of sliding bearings of automobiles

The invention relates to a near-net shape forming manufacturing method for thrust collars of sliding bearings of automobiles. The near-net shape forming manufacturing method includes: utilizing a seamless steel tube as a steel lining back of a thrust collar of a sliding bearing, disposing backing materials of the steel lining back in a lower die of an axial swing grinding machine to be processed rotationally; during process, moving the lower die upwards for feeding, rotating an upper die of the axial swing grinding machine into an inner hole of a cut seamless steel tube by an eccentric swing angle ranging from 1.5 degrees to 5 degrees, pressing ends of the tube to deform locally by the upper die until the peripheral end of the integral steel tube deforms by continuously rotating, grinding the peripheral end to be a planar ring, and manufacturing the planar ring into the steel lining back of the thrust collar of the sliding bearing; sanding, removing dust and cleaning; paving a thin layer of copper alloy powder and sintering; grinding in a swing manner secondarily, and alloying and sintering secondarily to form the thrust collar. By the near-net shape forming manufacturing method for the thrust collars of the sliding bearings of the automobiles, the thrust collars of the sliding bearings of the automobiles can be manufactured in a lossless and near net shape forming manner, and utilization rate of metal materials can be improved. Besides, the near-net shape forming manufacturing method is lossless, few in processing procedures, low in manufacturing cost and fine in product quality and can realize near net shape forming.

Owner:胡长安

Comprehensive utilization method of arsenious waste hydrochloric acid

InactiveCN108250243ASimple processReduce manufacturing costGroup 5/15 element organic compoundsDesalinationEconomic benefits

The invention relates to a comprehensive utilization method of arsenious waste hydrochloric acid. The method comprises the following steps of slowly adding the arsenious waste hydrochloric acid into an alkaline benzyl arsonic acid sodium mother solution to perform acid-base neutralization reaction to precipitate benzyl arsonic acid; enabling the precipitated benzyl arsonic acid to be subjected todehydration to obtain a benzyl arsonic acid product; preparing a sub-arsonic acid sodium solution by reusing a dehydrated arsenious waste solution through crystal desalination. The alkaline benzyl arsonic acid sodium mother solution is prepared through the following steps of enabling arsenic trioxide to react with an excessive sodium hydroxide solution to obtain sodium arsenite and then reacting with benzyl chloride to obtain the benzyl arsonic acid sodium mother solution. The invention creatively provides comprehensive utilization of the arsenious waste hydrochloric acid to produce the benzylarsonic acid, the arsenious waste hydrochloric acid is effectively treated, turning waste into wealth is achieved, comprehensive recycle is realized, not only can the environmental protection problembe solved, but also the economic benefit can be improved.

Owner:红河砷业有限责任公司

Anti-corrosion anti-flaming nonferrous metal material and preparation method thereof

The invention discloses an anti-corrosion anti-flaming nonferrous metal material and a preparation method thereof. The anti-corrosion anti-flaming nonferrous metal material is characterized in that the nonferrous metal material comprises, by weight, 20-30 parts of silver-lead master alloy, 12-14 parts of gypsum powder, 6-8 parts of glass fiber, 3-5 parts of quartz, 8-10 parts of borax, 15-20 parts of triethanolamine, 3-5 parts of trisodium phosphate, 3-5 parts of sodium benzoate, 6-8 parts of calcium phytate, 2-4 parts of titanium dioxide, 2-4 parts of copper oxide, 2-4 parts of cobaltous oxide, 0.5-0.7 part of a corrosion inhibitor and 0.6-0.8 part of fire retardant. The silver-lead master alloy enables the nonferrous metal material to have good corrosion resistance; an anti-oxidant solution makes the oxidation resistance of the nonferrous metal material be improved, so that the prepared nonferrous metal material is stable and reliable in fire resistance and free of smoky fire and smoke, has good decorative performance and is convenient to machine and obvious in effects of environmental protection and energy saving; in addition, the corrosion inhibition effect of the corrosion inhibitor on nonferrous metal is better than that of a BTA corrosion inhibitor, and oxidation losses are low; the composite material is made to have certain strength and heat transfer performance by adding the filling materials.

Owner:YANGZHONG HUYANG SHIPPING CO LTD

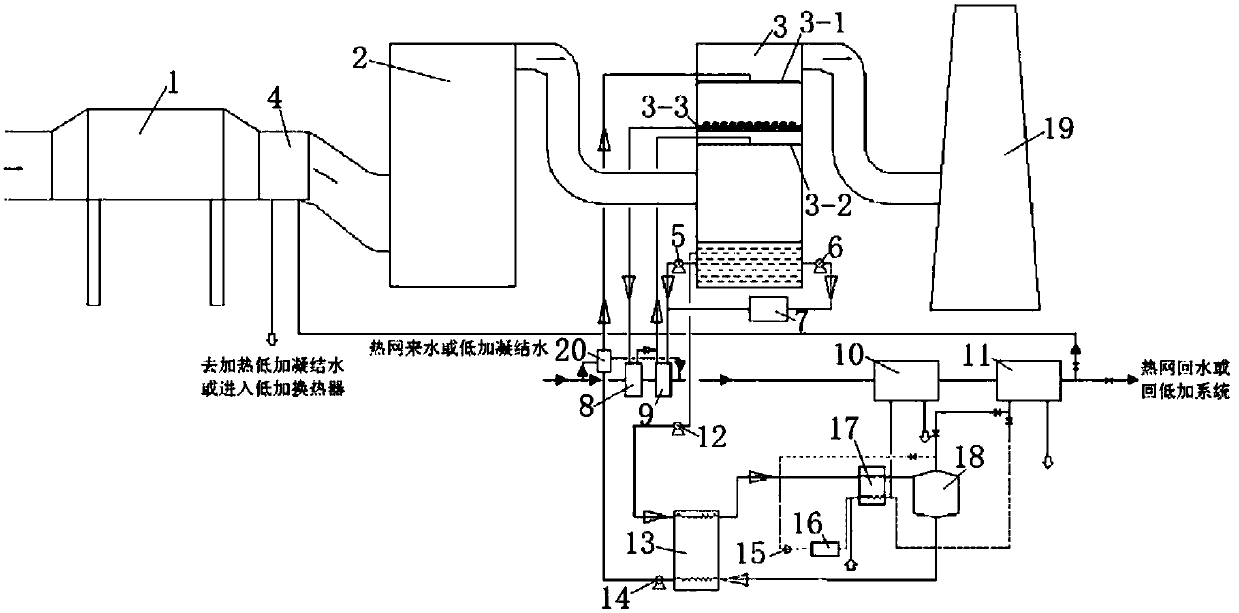

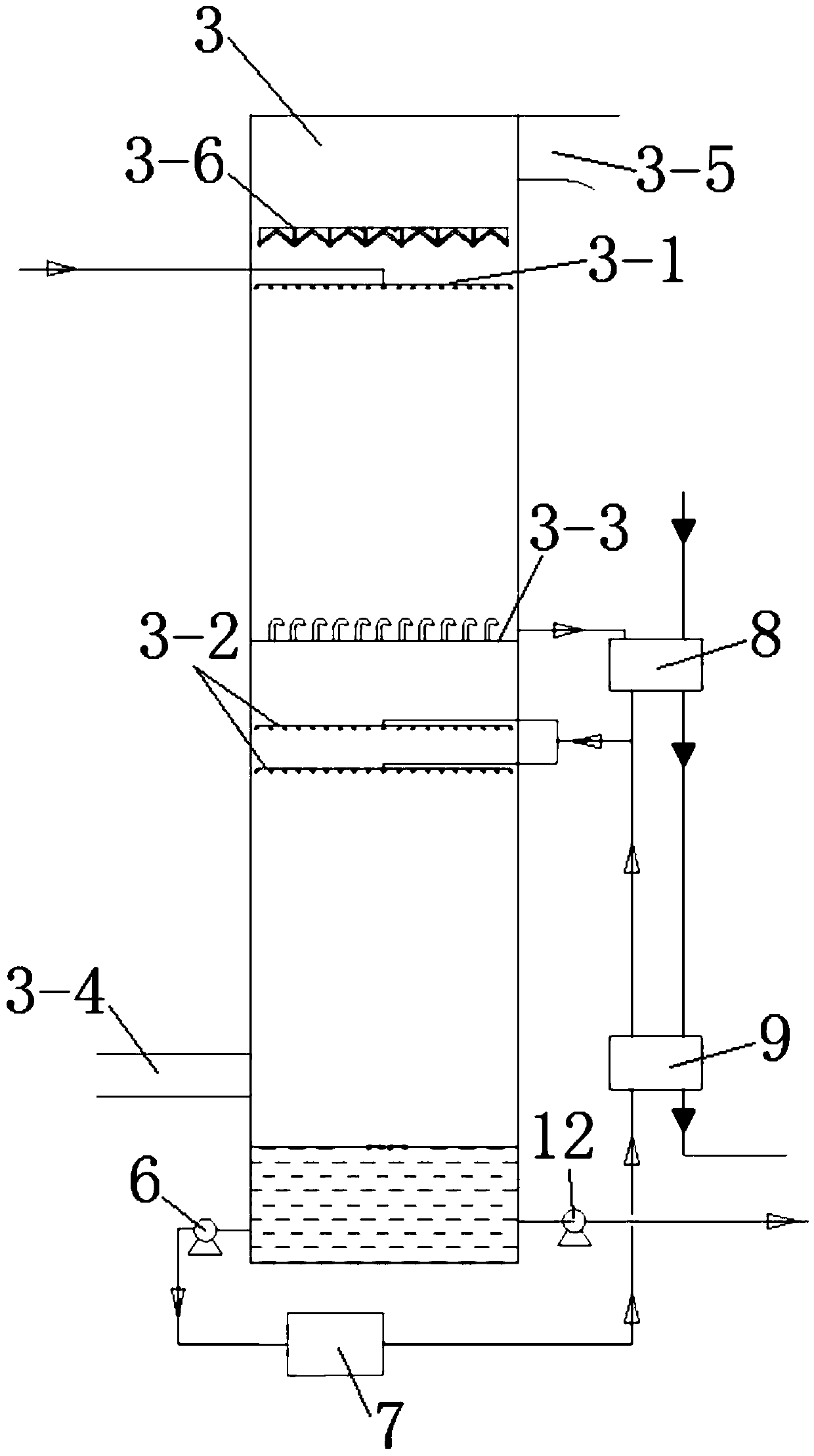

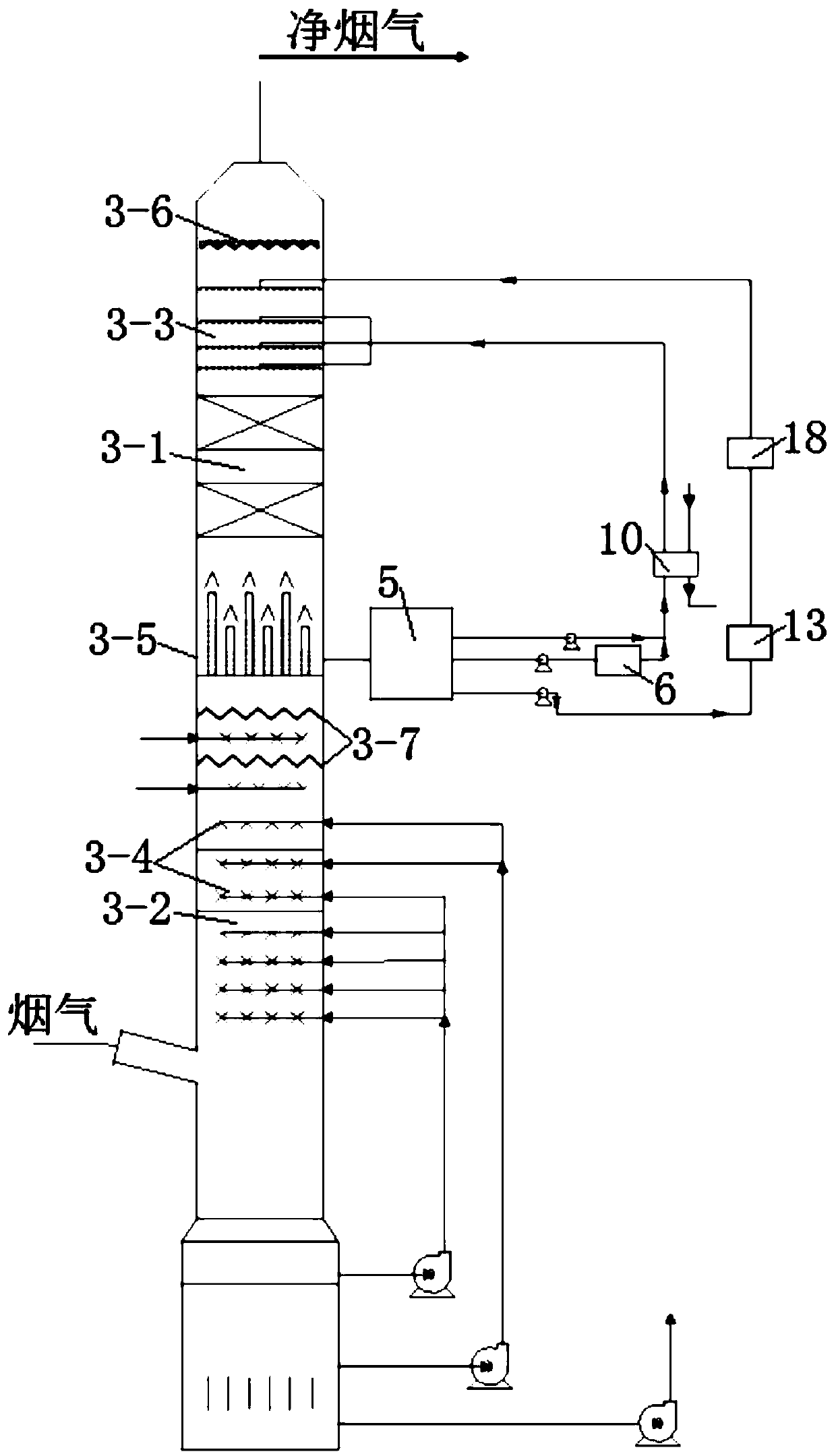

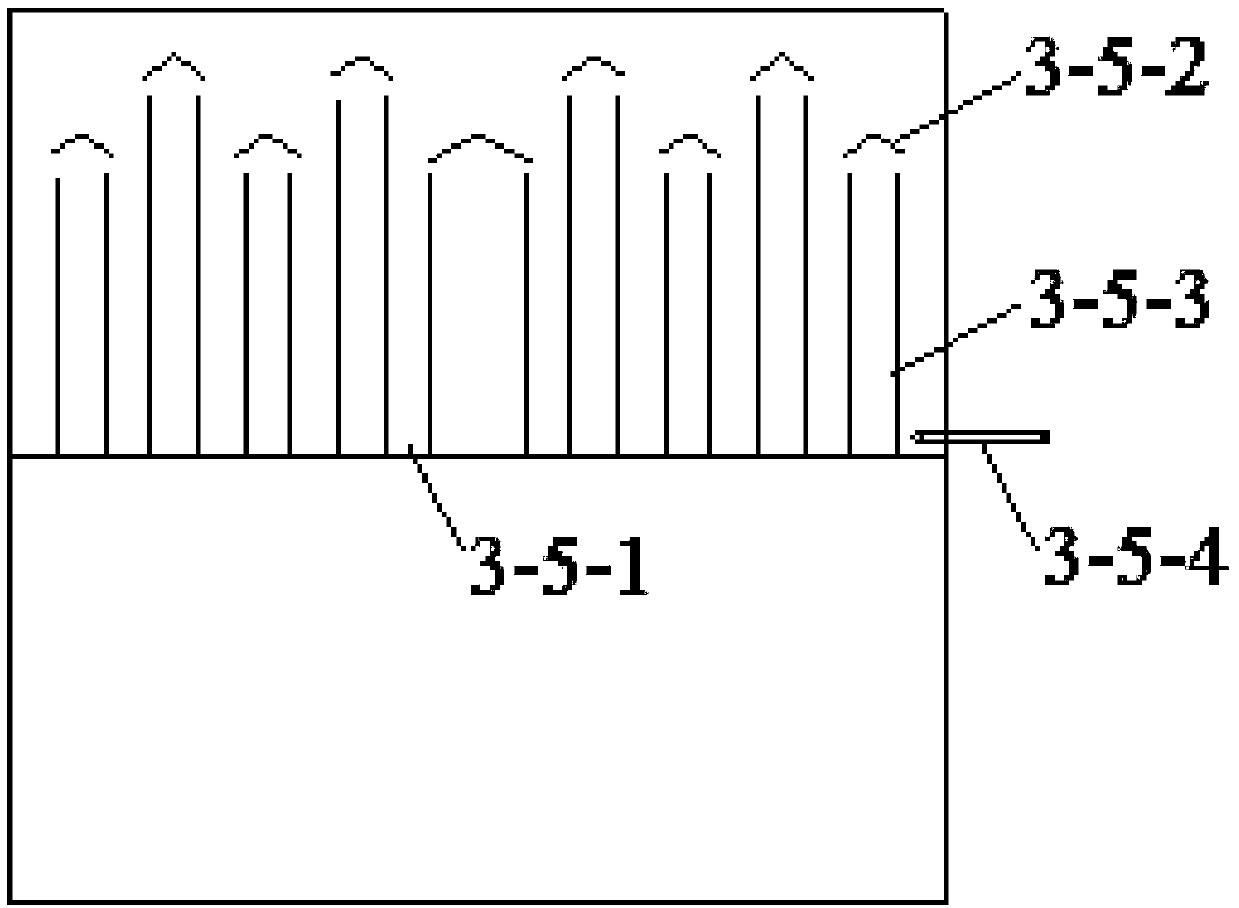

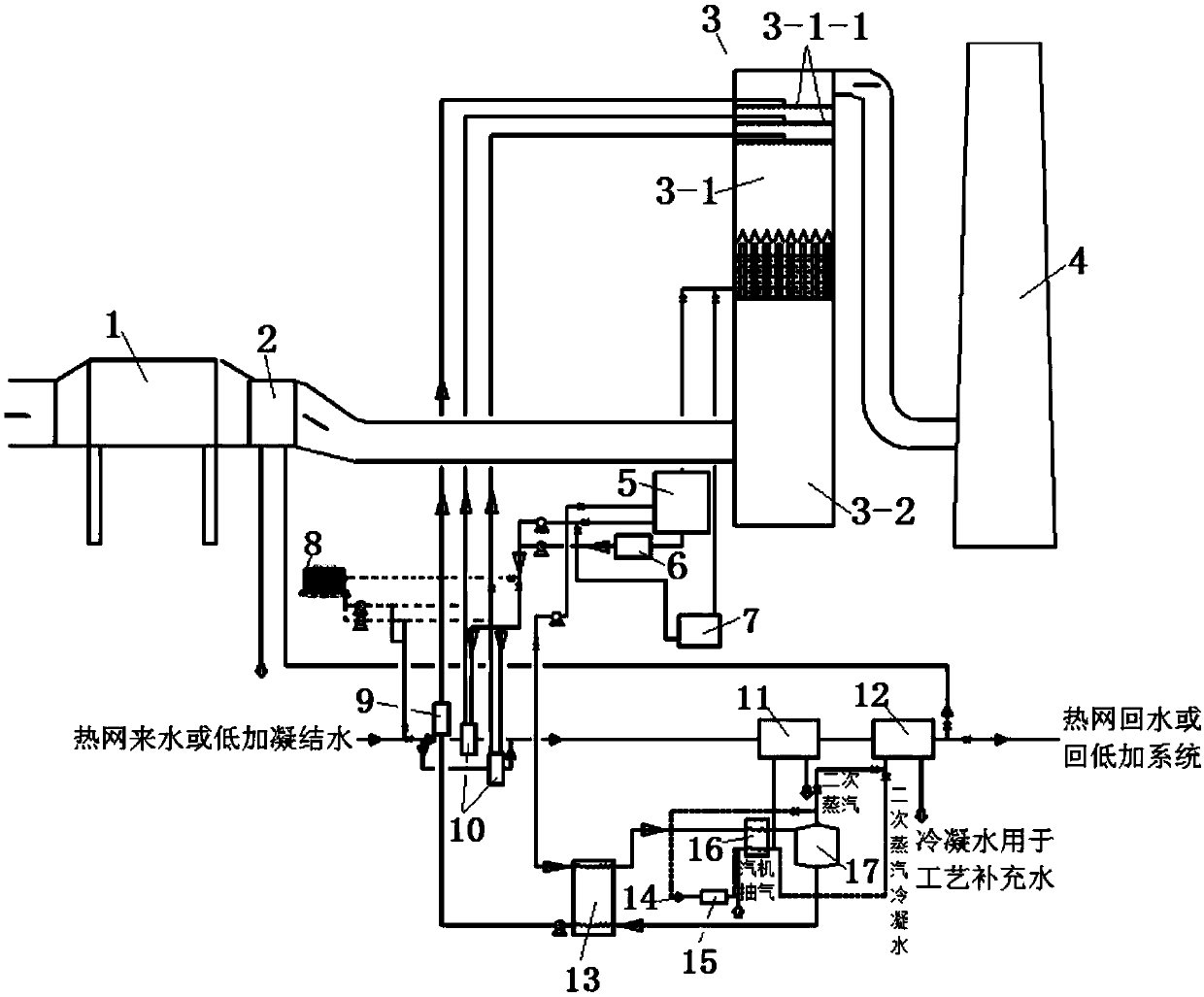

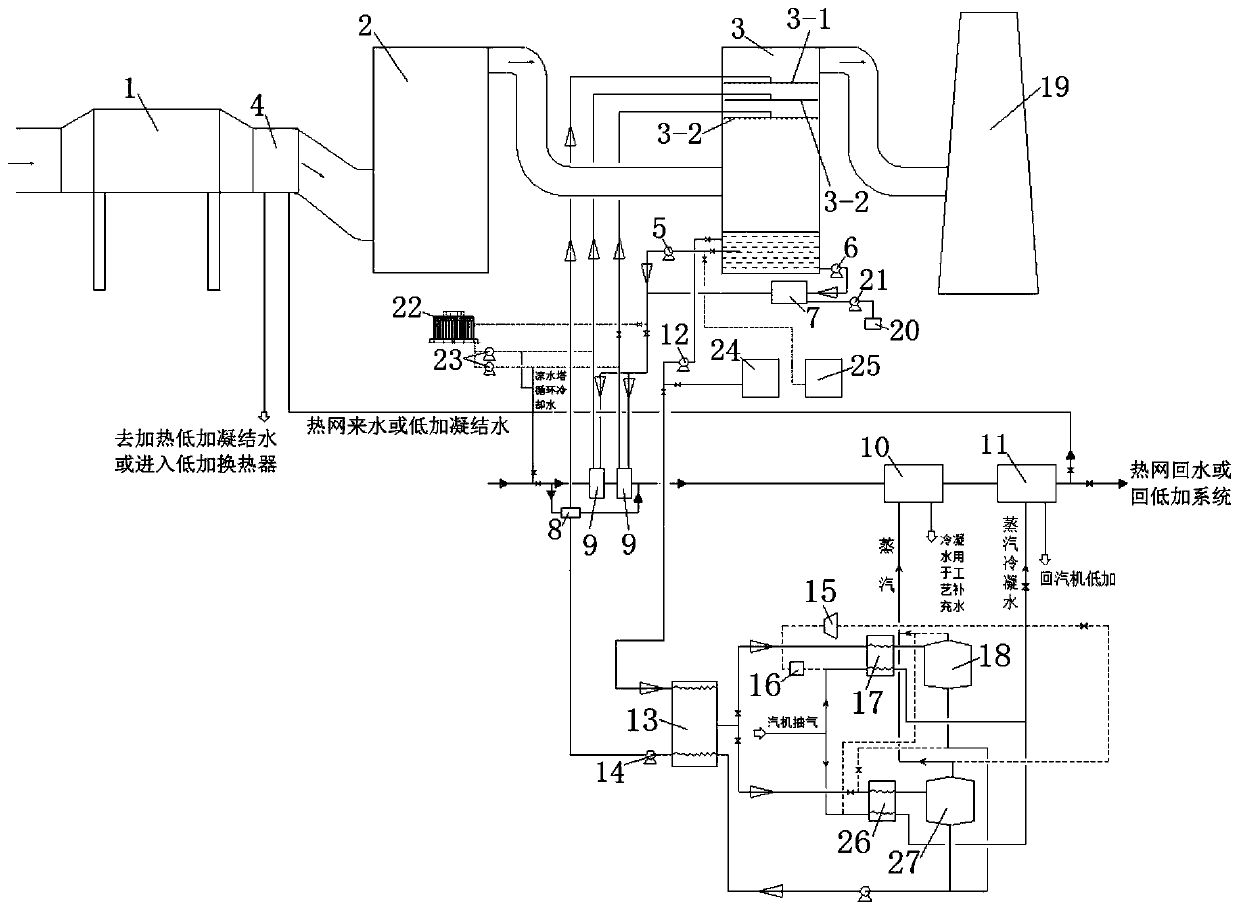

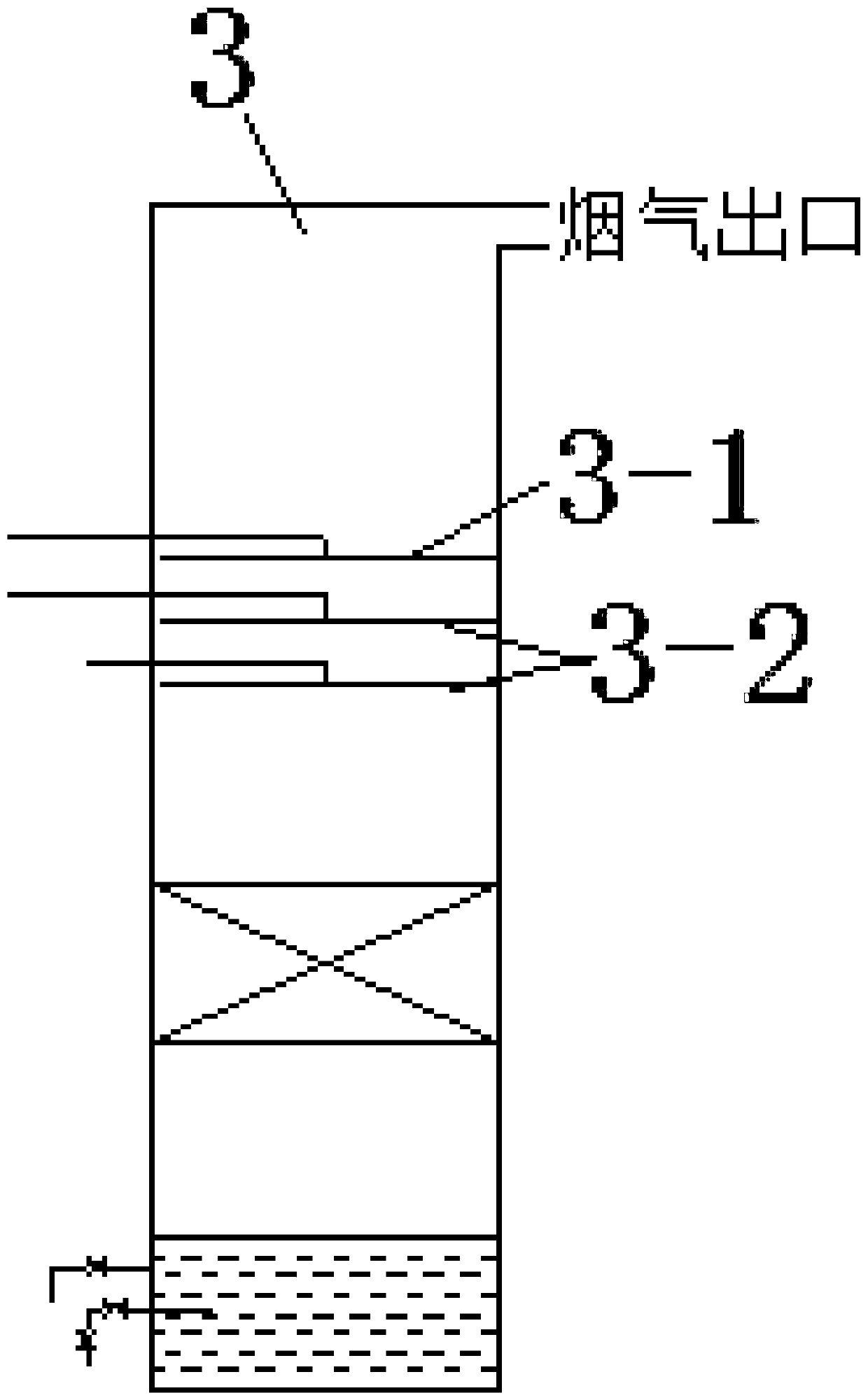

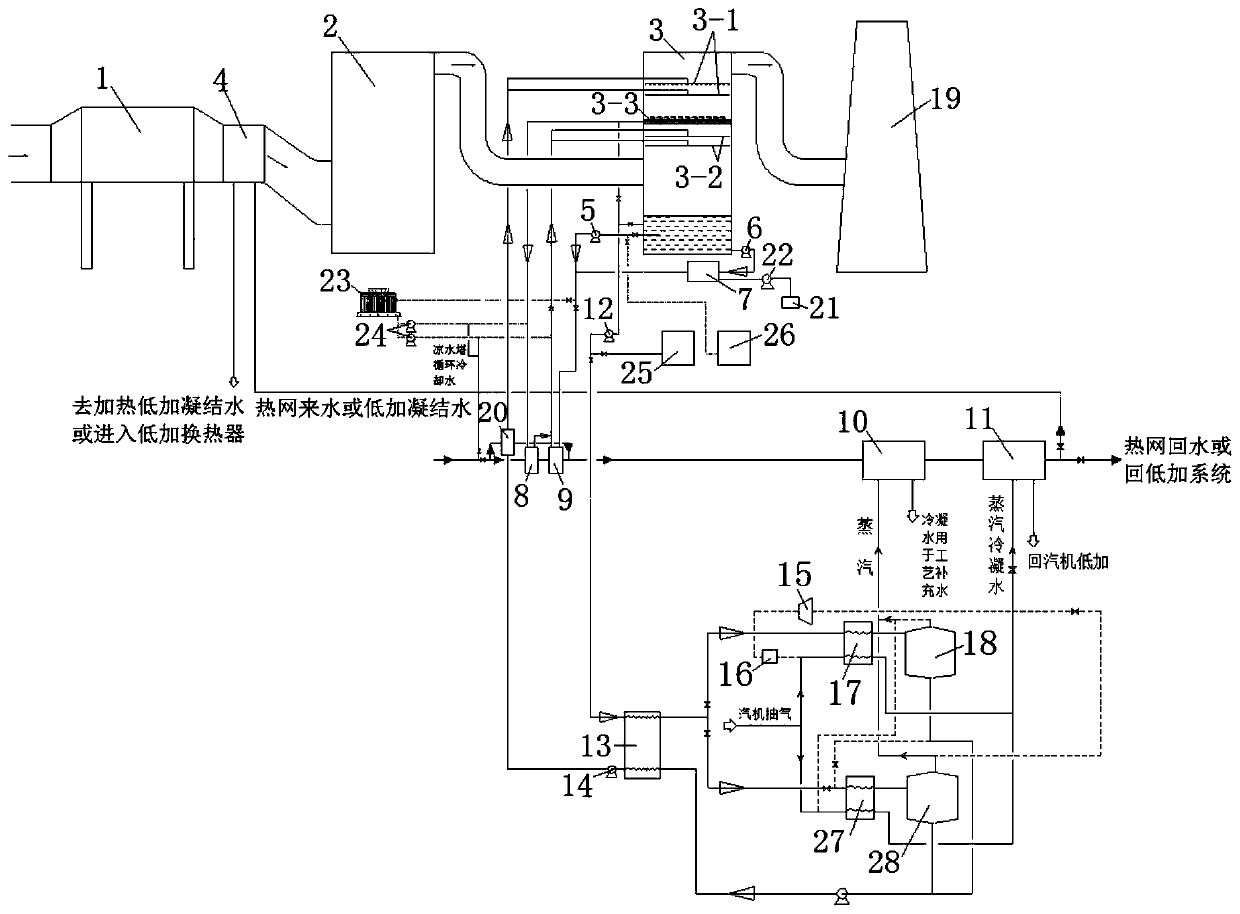

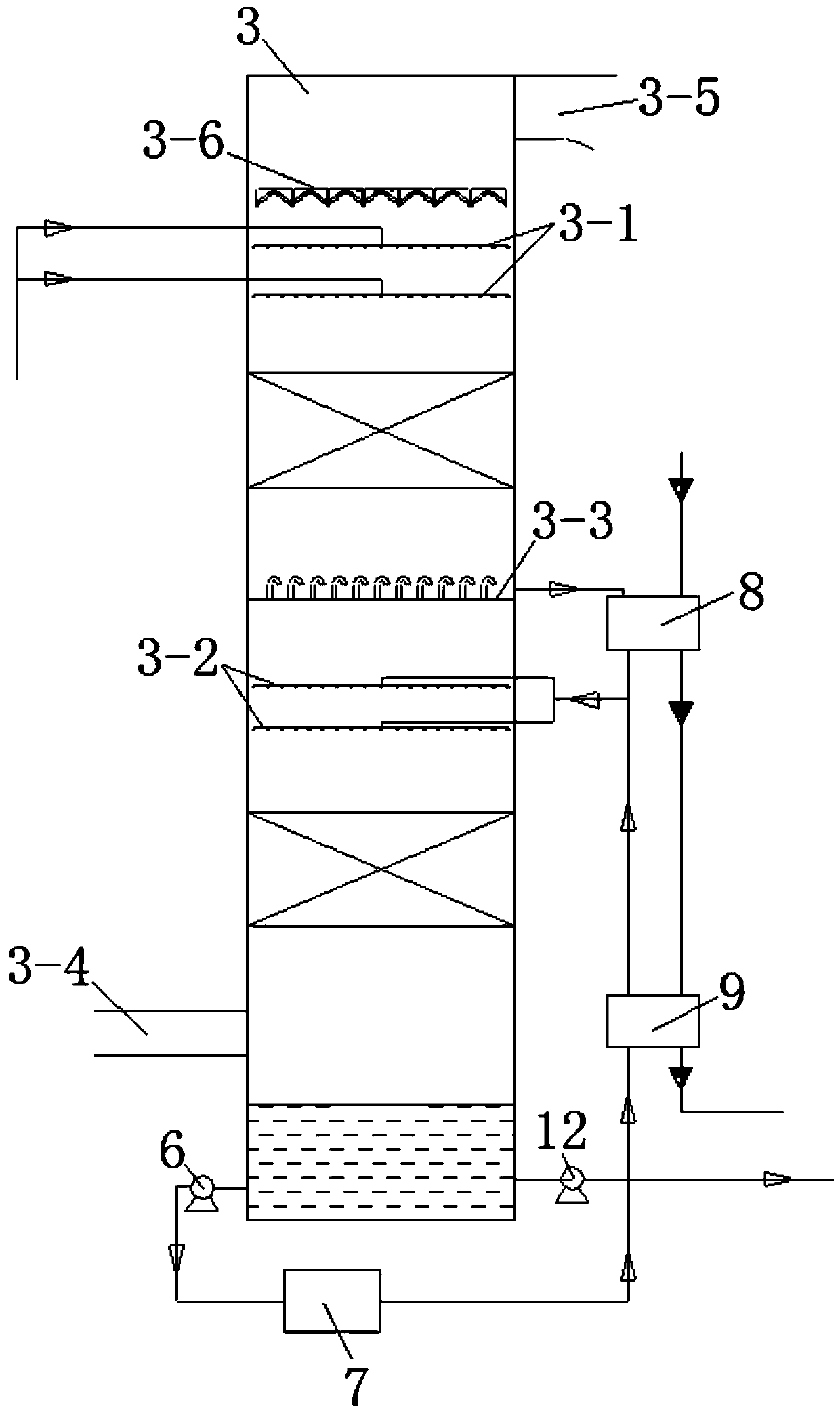

Energy-saving and water-saving flue gas treatment system

PendingCN109569200AAvoid the needSolve the problem of only investing but not earningGas treatmentDispersed particle separationWater savingWater vapor

The invention discloses an energy-saving and water-saving flue gas treatment system. The energy-saving and water-saving flue gas treatment system has the advantages that a liquid storage unit is arranged in an absorption device of the energy-saving and water-saving flue gas treatment system, an inner cavity is divided into a first glue gas treatment zone and a second flue gas treatment zone by theliquid storage unit, flue gas can flow into the absorption device from the bottom of the absorption device and can be in countercurrent contact with concentrated solution sprayed from the top of theabsorption device, moisture in the flue gas can be absorbed by concentrated solution in the second flue gas treatment zone, the concentrated solution in the second flue gas treatment zone can be diluted, latent heat released in moisture phase change procedures can be separated out, and the glue gas and the concentrated solution can be heated until the temperatures of the flue gas and the concentrated solution reach 55-65 DEG C; heated concentrated solution can be led out via the liquid storage unit and can be fed into a first heat exchanger, heat exchange can be carried out on the heated concentrated solution and heat exchange media (such as heat network water), the heat exchange media can be heated by the temperatures of 3-10 DEG C, the concentrated solution can be cooled until the temperature of the concentrated solution is approximately consistent with the temperature of a solution inlet in the top of the second flue gas treatment zone, then the concentrated solution can be fed intothe first flue gas treatment zone, and moisture in the flue gas can continue to be absorbed; cascade heat exchange is adopted for the first time, accordingly, the heat exchange quality can be effectively enhanced, and sensible heat in the original flue gas and latent heat in water vapor of clean flue gas can be deeply recycled and can be utilized.

Owner:CHINA HUADIAN ENG +1

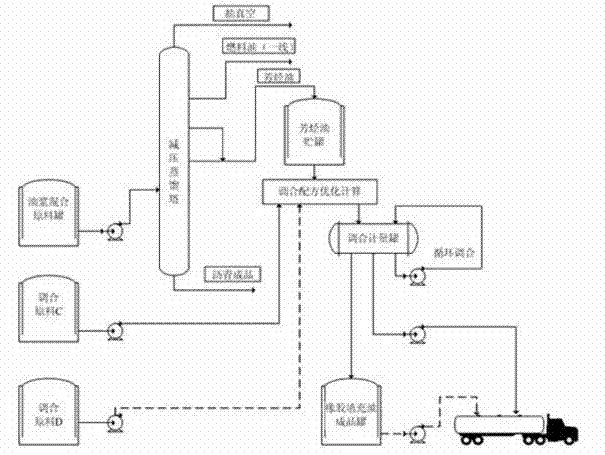

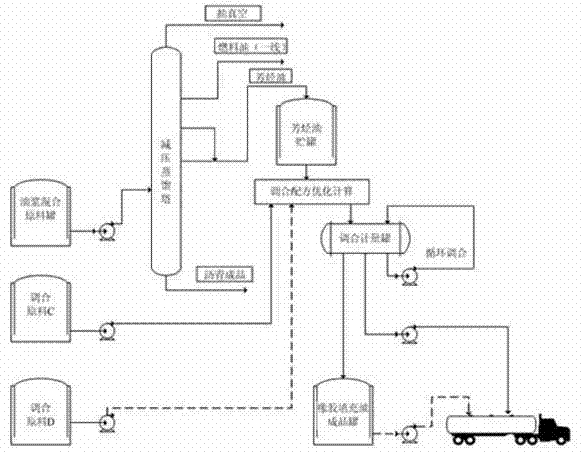

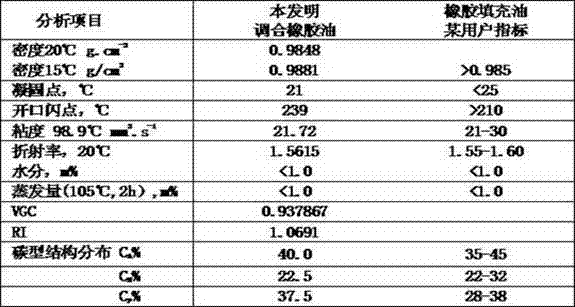

Blending production method of aromatic hydrocarbon rubber extender oil

The invention discloses a blending production method of aromatic hydrocarbon rubber extender oil; aromatic hydrocarbon oil is selected as a main raw material; based on performance parameters of the selected aromatic hydrocarbon oil and performance indexes of a rubber extender oil finished product, one or more than one of extract oil, vacuum cut distillate oil and recovered lubricating oil heavy fraction are selected as auxiliary raw materials; an optimized blending formula is obtained by calculation and small experiment; all the raw materials are mixed in a blending metering tank according to the formula so as to perform physical circulating blending and thus to perform large-scale production. The process flow is simple; the production operation is easy to control; the labor intensity is low; the product quality is stable; the production throughput is high; the production scale is easy to amplify; resources for high-quality aromatic hydrocarbon rubber extender oil production are effectively increased, and the production cost of the product is reduced. Specifically, by means of continuous reduced-pressure distillation and physical blending, no waste gas or sulfur-containing harmful gas is discharged; no waste water is discharged; no poisonous or harmful solvent is used in the production process; and the production method has outstanding environmental protection and energy saving effect.

Owner:SUZHOU INDAL PARK DAHUA GASOLINEEUM

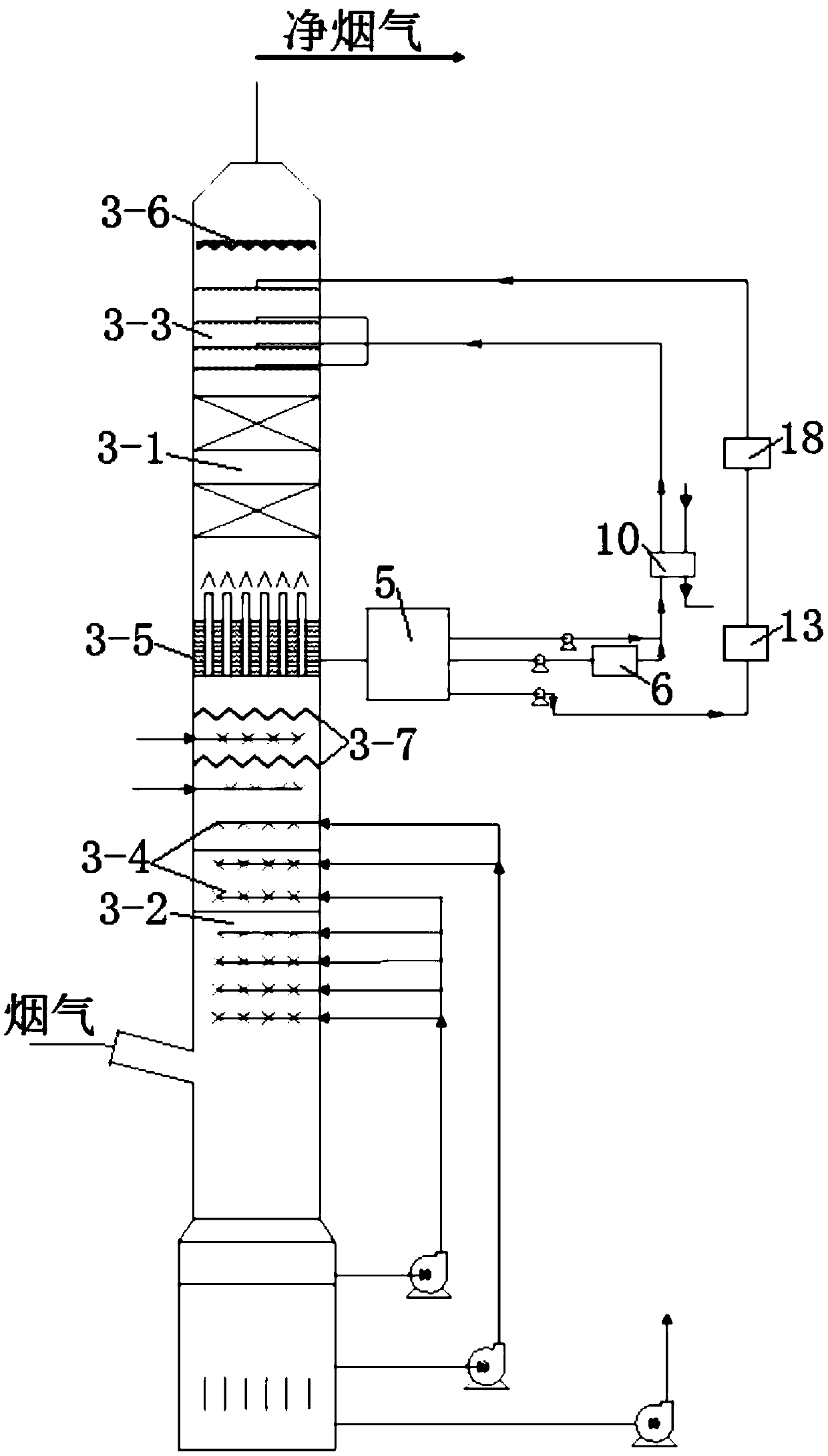

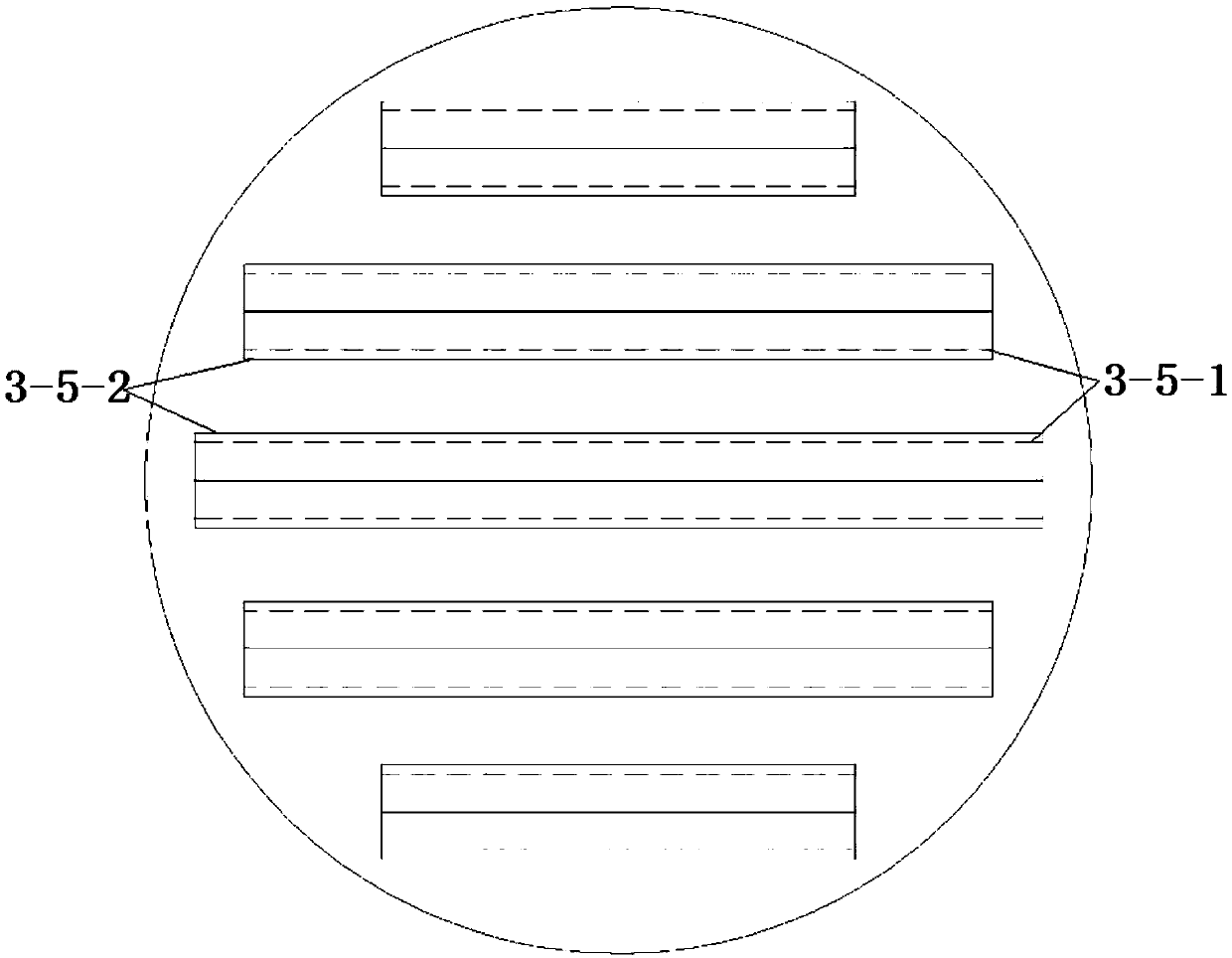

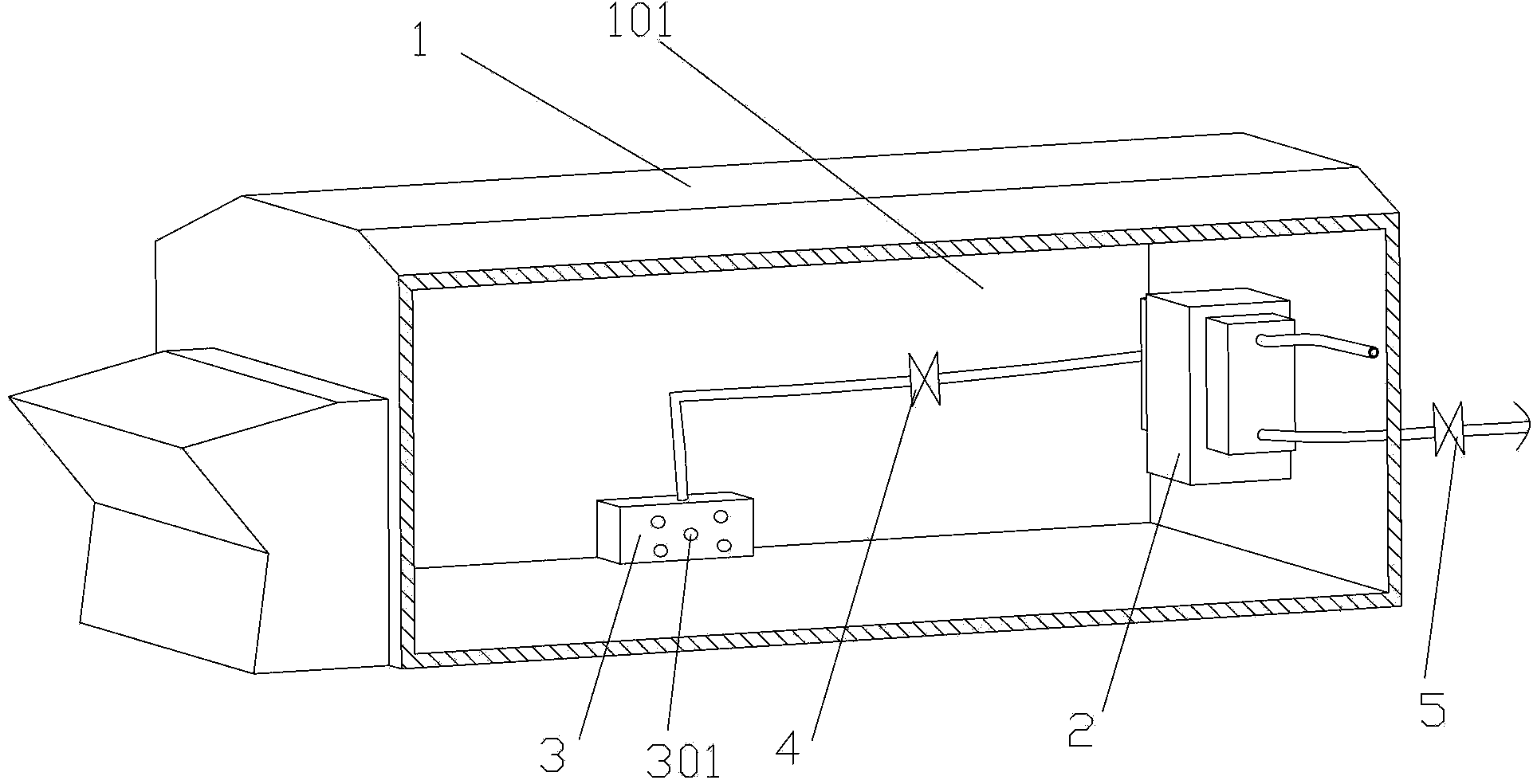

Desulfurization and white smoke elimination device

PendingCN111482058AAvoid the needSolve the problem of only investing but not earningGas treatmentDispersed particle separationWater vaporFlue gas

The invention discloses a desulfurization and white smoke elimination device. According to the device, a desulfurization section and an absorption section are sequentially arranged in a shell of a flue gas purification device from bottom to top, a liquid storage unit with a specific structure is arranged between the desulfurization section and the absorption section, a first spraying layer is arranged between the absorption section and the top end of the shell, and a second spraying layer is arranged between the flue gas inlet of the desulfurization section and the liquid storage unit. Flue gas enters the absorption section from the desulfurization section, and is in countercurrent contact with a concentrated solution or clear water sprayed at the top of the absorption section. In the heating season, the concentrated solution absorbs water in the flue gas and becomes thin, latent heat is released in a precipitated moisture phase change process to heat flue gas and saline solution, theheated solution is collected by the liquid storage unit, heat exchange is conducted through a first heat exchanger on the first circulation loop, the balance state in the absorption section is flexibly controlled through the amount of taken-away heat, sensible heat of raw flue gas and latent heat of purified flue gas water vapor are deeply recycled, the situation that in the prior art, a large number of cold sources are needed for flue gas cooling and condensation is avoided, and water resources are greatly saved.

Owner:CHINA HUADIAN ENG +1

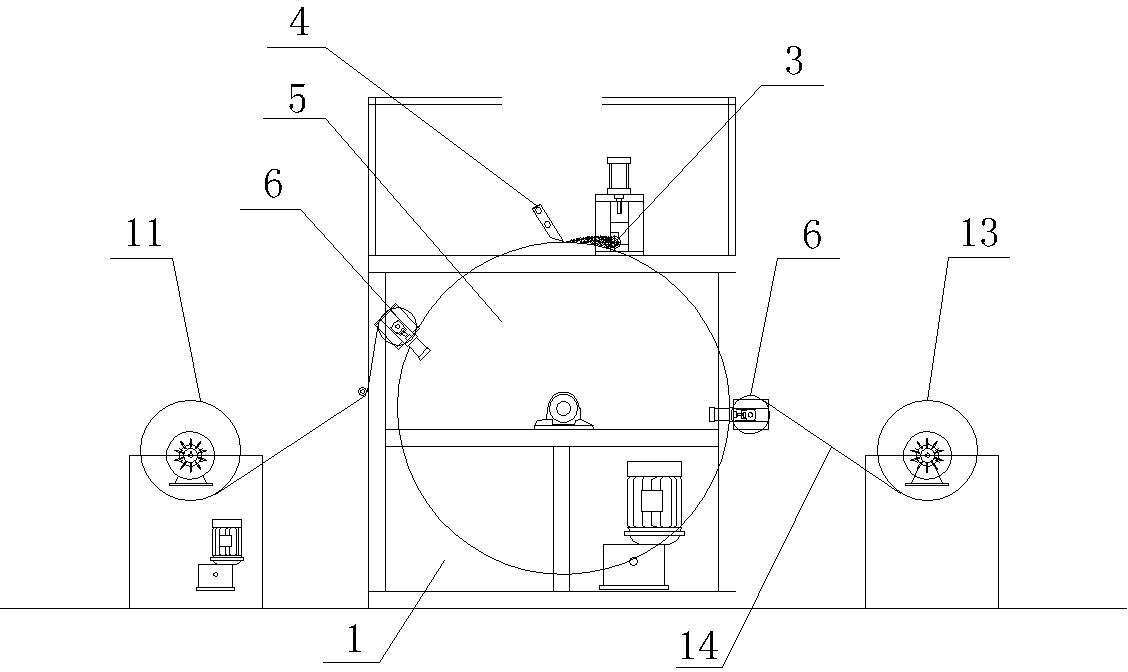

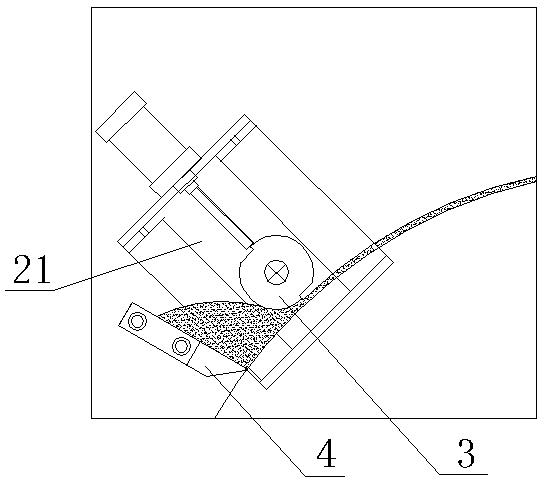

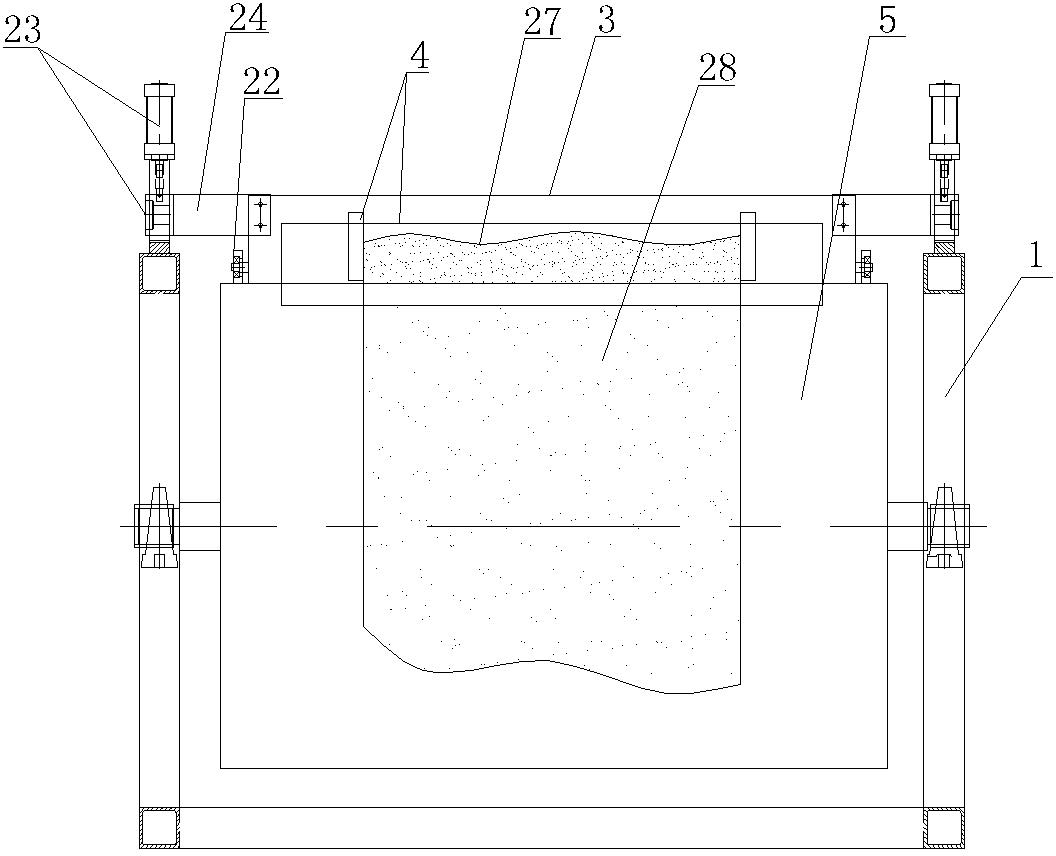

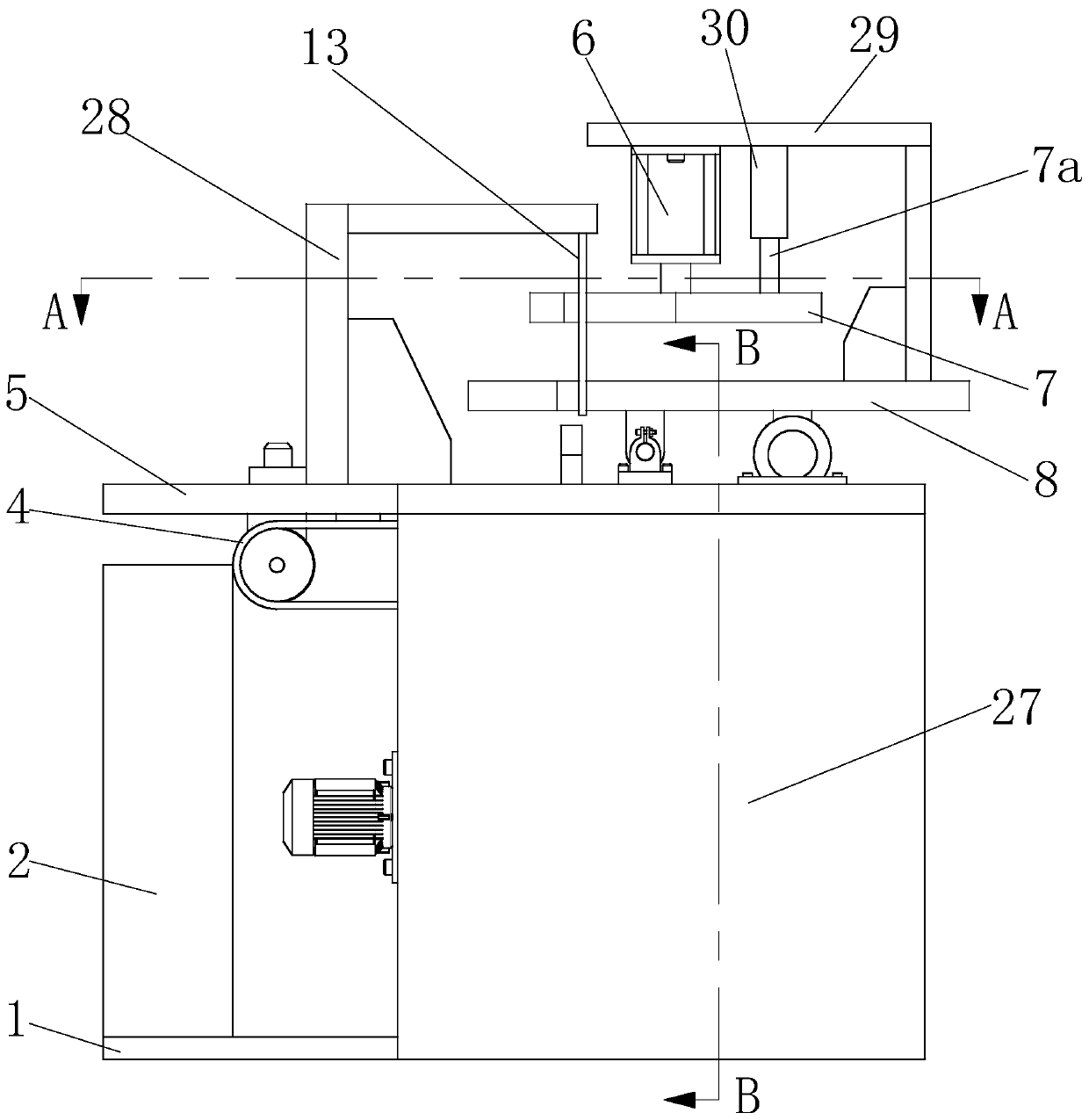

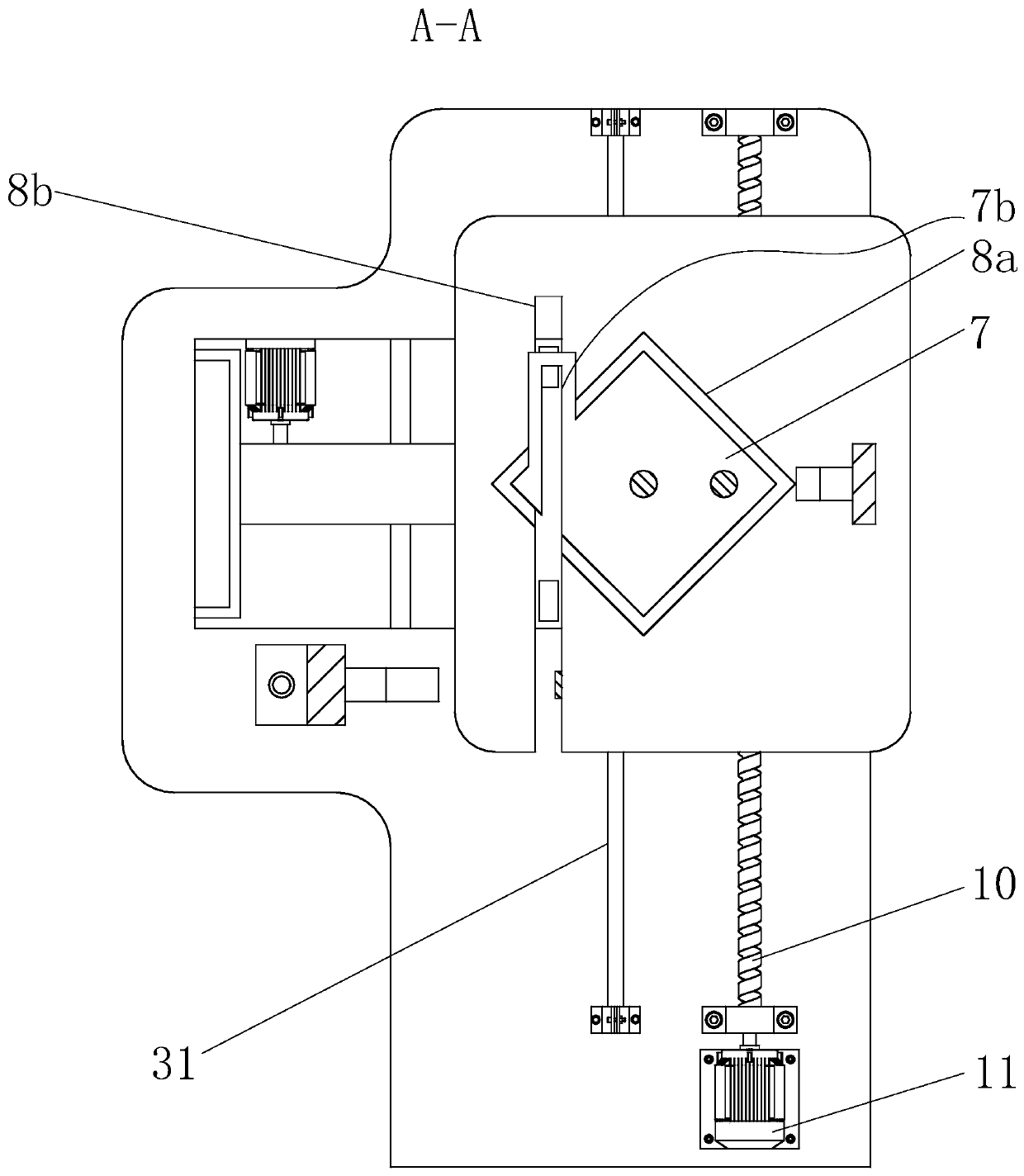

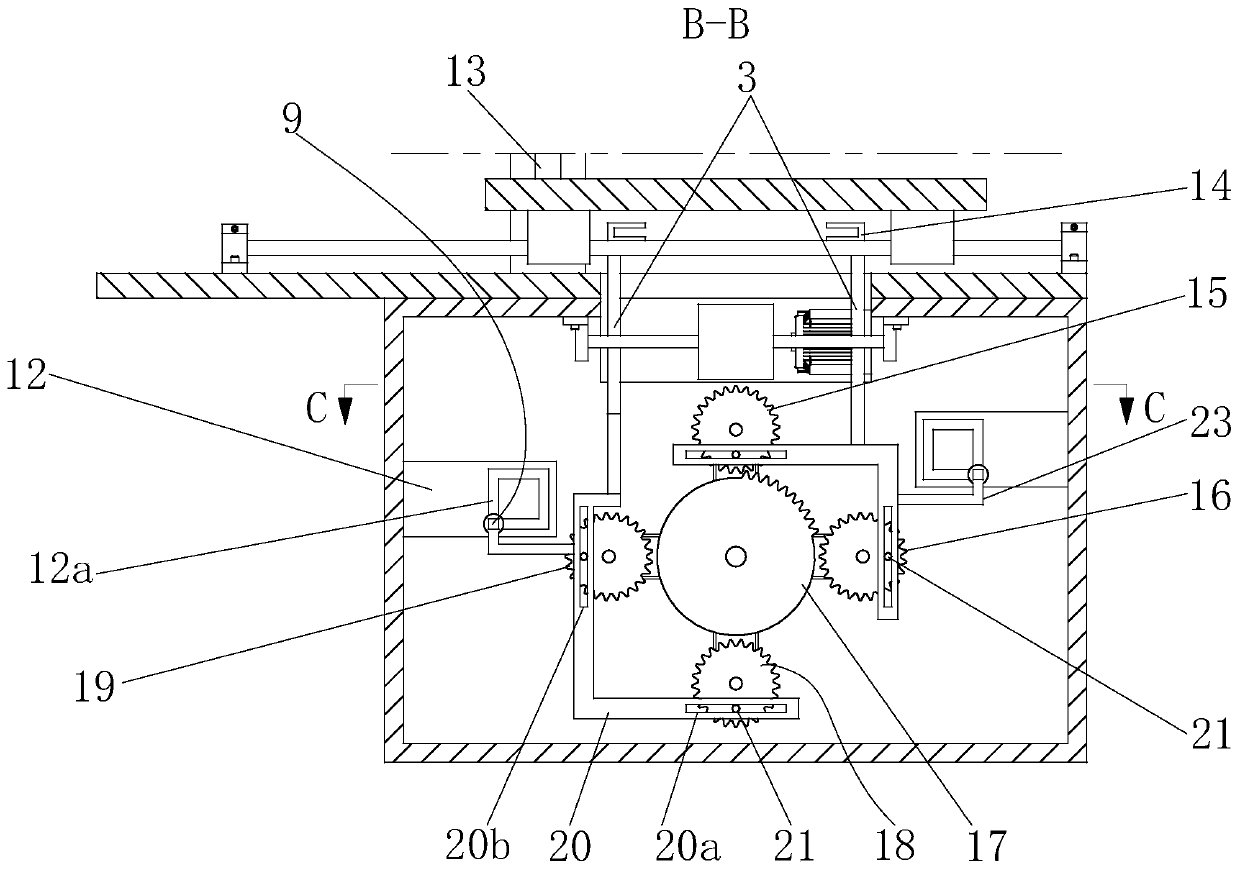

Safety type corner cutting device for medicinal paper

ActiveCN109927081AEasy to useGood environmental protection and energy saving effectMetal working apparatusTransmission equipmentMedical treatment

The invention relates to a safety type corner cutting device for medicinal paper. The safety type corner cutting device comprises a bottom connecting plate, a collecting box is arranged on the bottomconnecting plate, the right side of the bottom connecting plate is fixedly connected with a cabinet box, and the upper end of the cabinet box is fixedly connected with a bearing plate, a hanging bracket is arranged on the left part of the upper end of the bearing plate, and a cutting knife is fixedly arranged on the hanging bracket, the right part of the upper end of the bearing plate is providedwith lead screw transmission equipment, the lead screw transmission equipment is connected with a loading plate, and a clamping assembly is arranged on the loading plate, a conveyor belt is arranged between the upper portion of the cabinet box and the collecting box, and a set assembly is installed on the lower portion of the cabinet box. The cutting device is convenient to use, not only the cutting process of the corners of stacked medicinal paper can be completed in a high-automation manner, but also two clamping blocks can be controlled to sequentially ascend together, clamp the paper towards each other, descend together and return in opposite direction after the paper is cut, the corner parts of the cut medicinal paper can be automatically recovered, the good environment-friendly and energy-saving effects are achieved, and relatively labor-saving is achieved.

Owner:SHIYUAN TECH WUHU NEW MATERIALS CO LTD

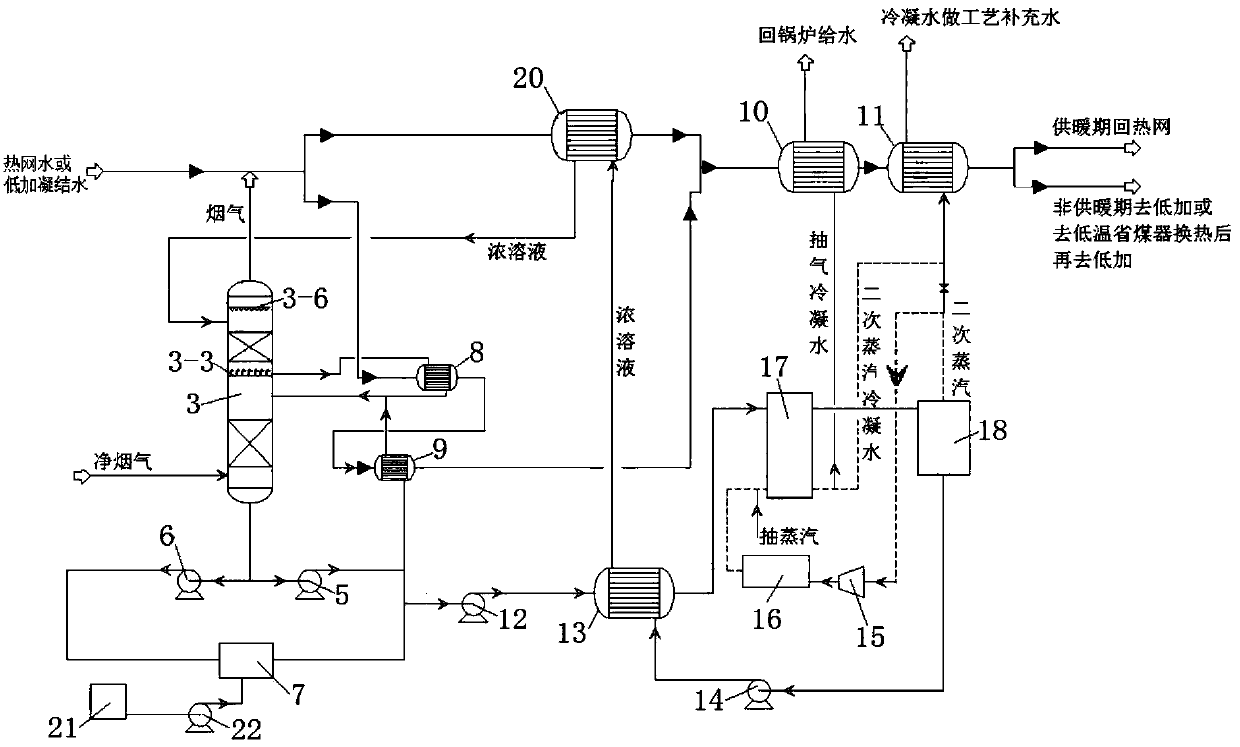

Single-tower double-circulation energy-saving white smoke elimination device

PendingCN111482056AAvoid the needSolve the problem of only investing but not earningGas treatmentDispersed particle separationWater vaporFlue gas

The invention discloses a single-tower double-circulation energy-saving white smoke elimination device. According to the device, a desulfurization section and an absorption section are sequentially arranged in a shell of a flue gas purification device from bottom to top, a liquid storage unit is arranged between the desulfurization section and the absorption section, a first spraying layer is arranged between the absorption section and the top end of the shell, and a second spraying layer is arranged between the flue gas inlet of the desulfurization section and the liquid storage unit. Flue gas enters the absorption section from the desulfurization section, and is in countercurrent contact with a concentrated solution or clear water sprayed at the top of the absorption section. In the heating season, the concentrated solution absorbs water in the flue gas and becomes thin, latent heat is released in a precipitated moisture phase change process to heat the flue gas and saline solution,the heated solution is collected by the liquid storage unit, heat exchange is conducted through a first heat exchanger on a first circulation loop, the balance state in the absorption section is flexibly controlled through the amount of taken-away heat, sensible heat of raw flue gas and latent heat of purified flue gas water vapor are deeply recycled, the situation that in the prior art, a large number of cold sources are needed for flue gas cooling and condensation is avoided, and water resources are greatly saved.

Owner:CHINA HUADIAN ENG +1

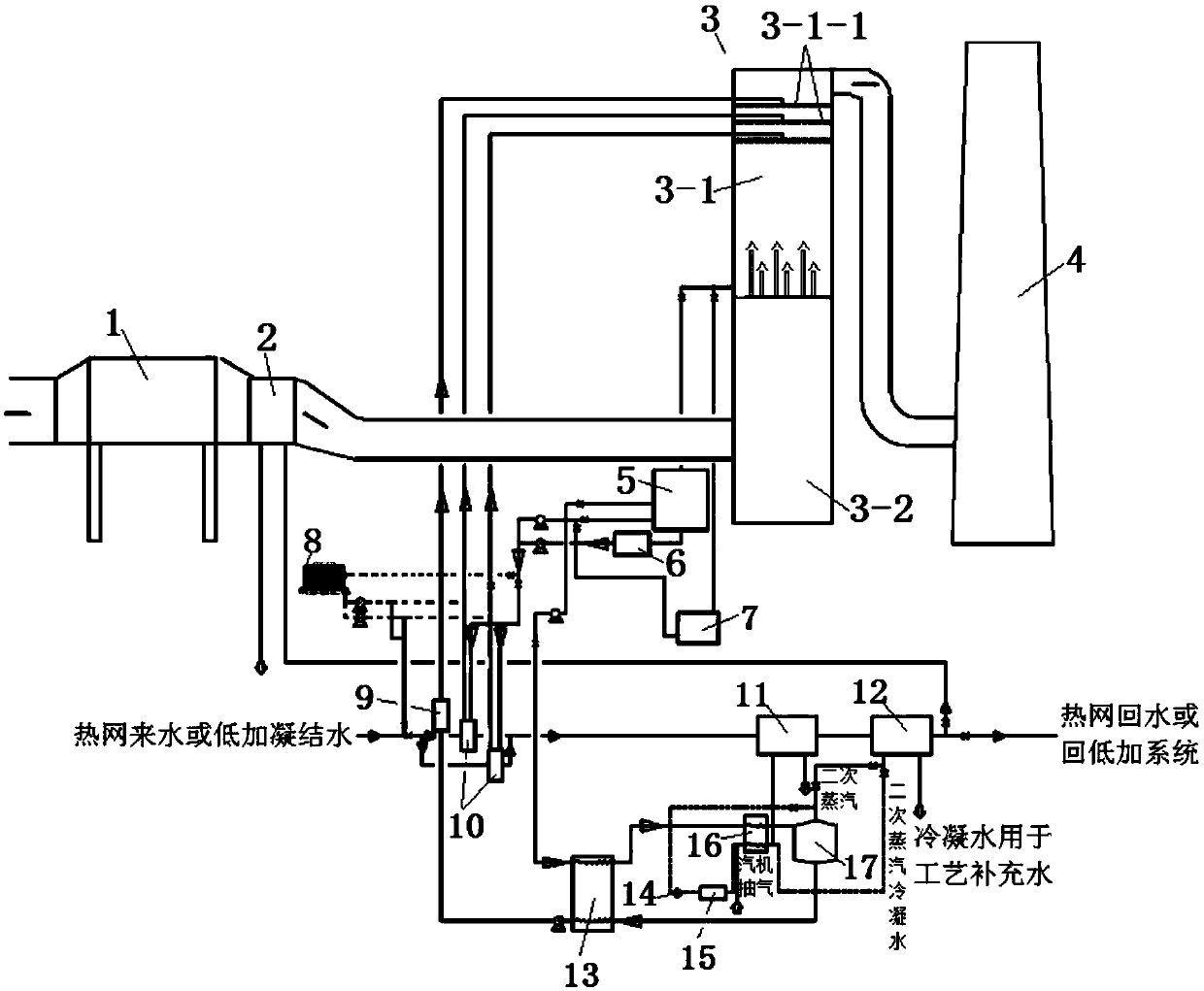

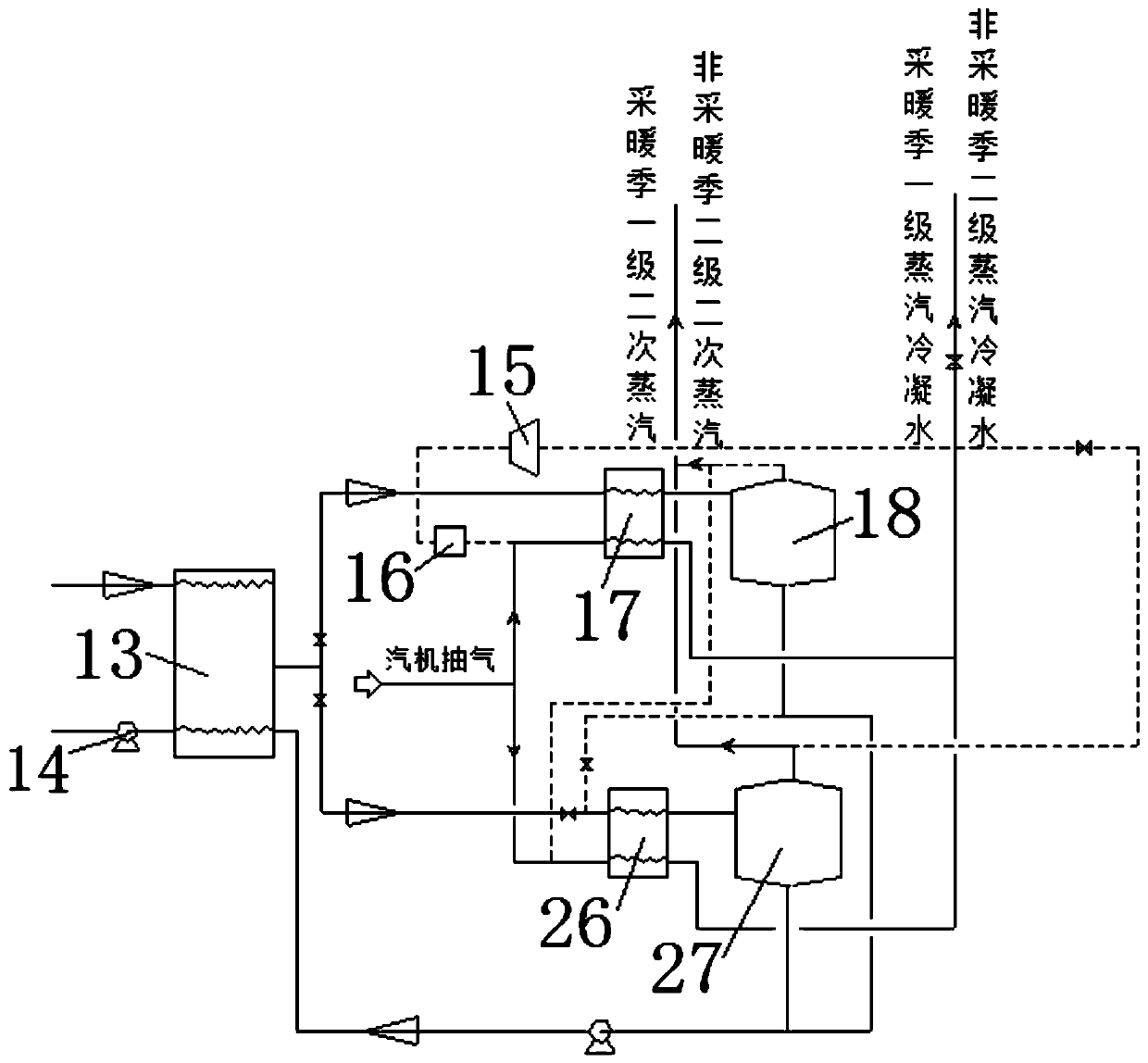

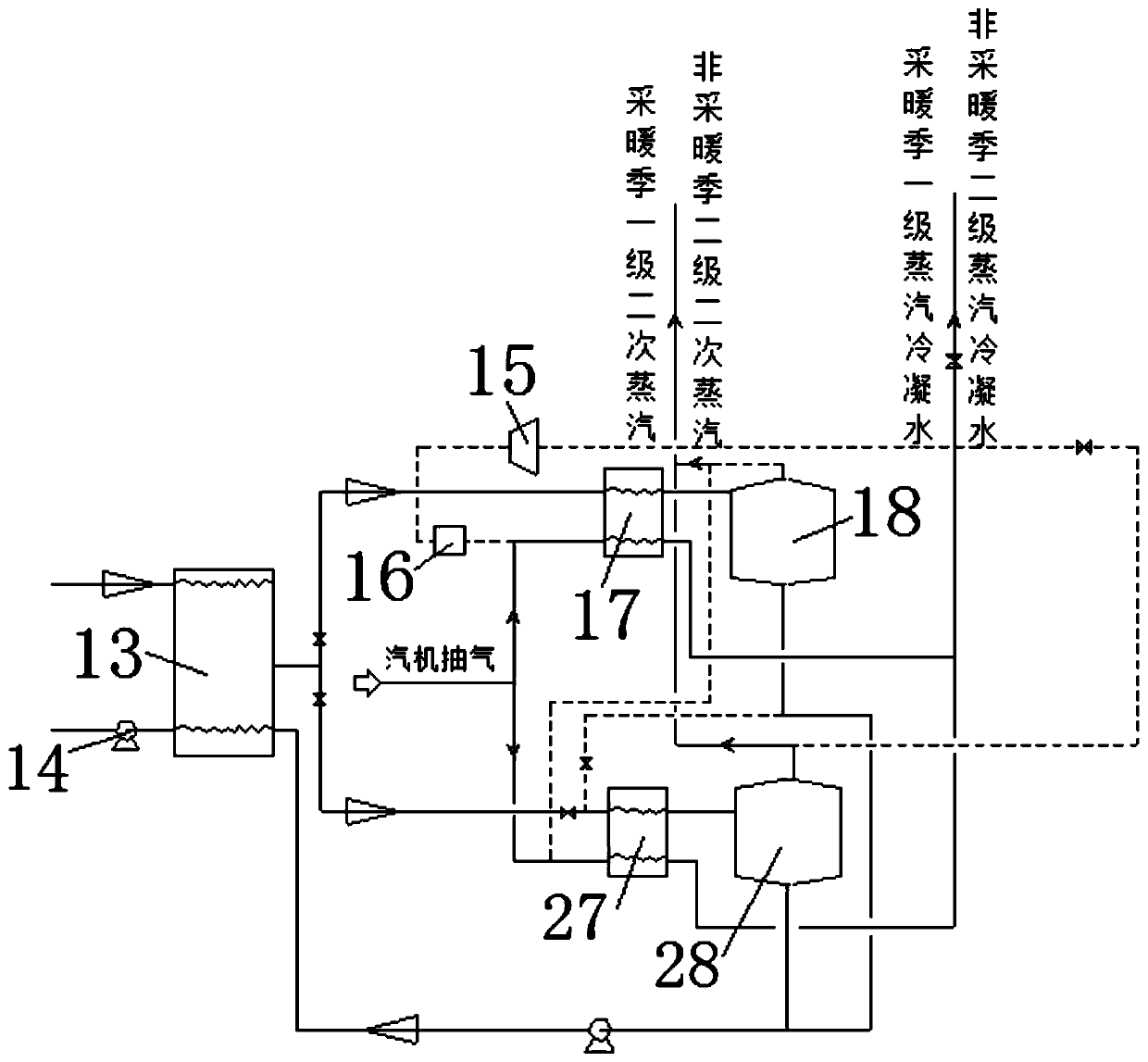

Dual regeneration energy saving device

PendingCN109838804AFlexible control of balance stateAvoid the needSteam generationIndirect heat exchangersWater vaporFlue gas

The invention discloses a dual regeneration energy saving device. The dual regeneration energy saving device is provided with a first circulation loop, at least a stage of second circulation loop, a refrigerating device and at least a stage of second heat exchanger, and flue gas enters from the bottom of an absorption device to be in countercurrent contact with a concentrated solution or clean water sprayed from the top of the absorption device. During a heating season, the concentrated solution absorbs the water in the flue gas to become thinner, the latent heat released in the phase change process of water is dissolved out, the flue gas and a salt solution are heated, the heated solution is subjected to heat exchange through a second heat exchanger or a refrigeration device on the secondcirculation loop, and the equilibrium state in the absorption device can be flexibly controlled by using the amount of the heat taken away; in a non-heating season, the clean water can be used for spraying to cool the flue gas except using the concentrated solution, the saturated net flue gas can be cooled and analyzed, the water lifting effect is achieved, and the heated water can be recycled after being subjected to heat exchange by the second heat exchanger or the refrigeration device; and finally, the sensible heat of the original flue gas and the latent heat of the net flue gas water vapor are deeply recovered and utilized by the above means.

Owner:CHINA HUADIAN ENG +1

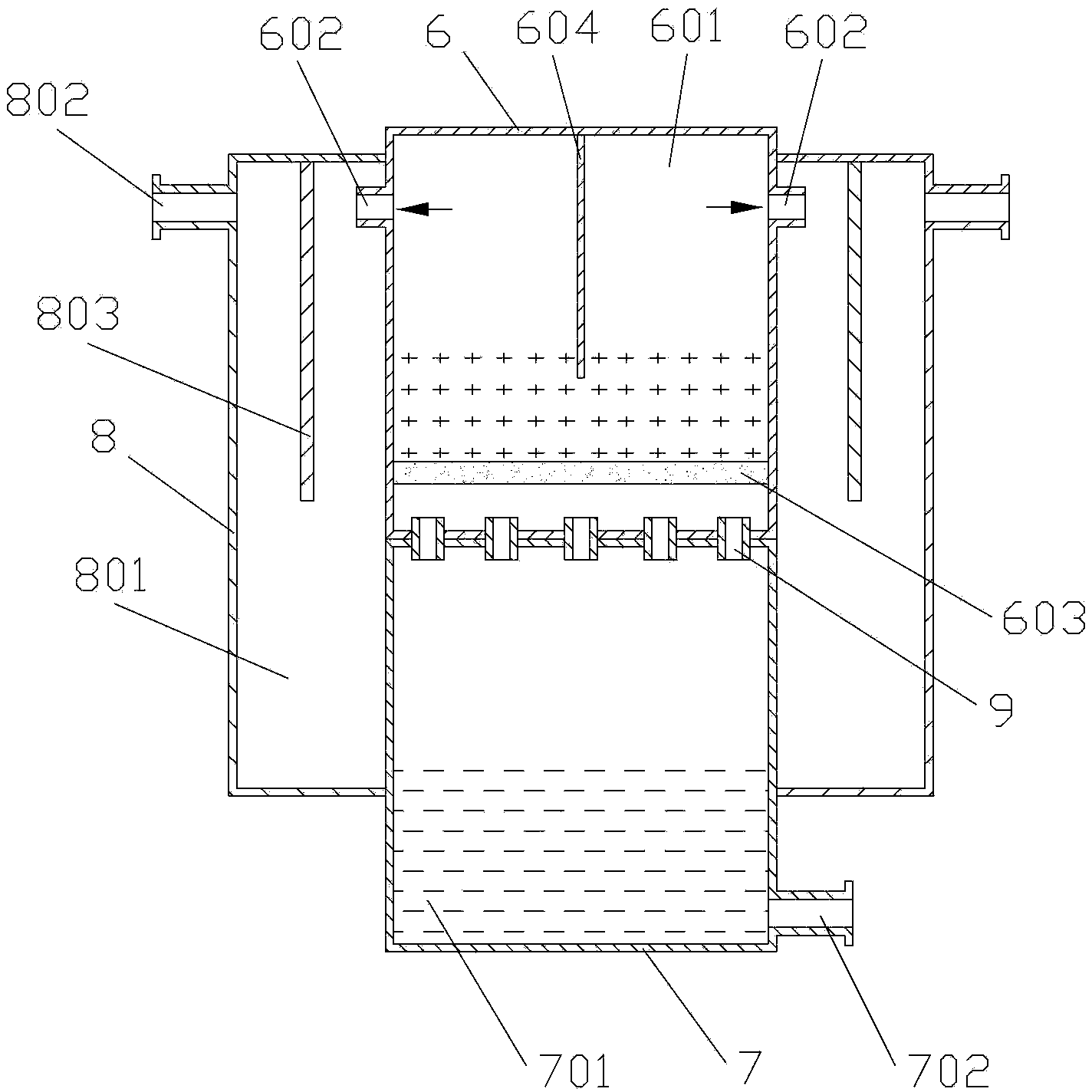

Water fuel oxyhydrogen combustion-supporting boiler

InactiveCN104296157AImprove burnout rateEmission reductionWater heatersSteam boilersWater storageCombustion

The invention discloses a water fuel oxyhydrogen combustion-supporting boiler. The water fuel oxyhydrogen combustion-supporting boiler comprises a boiler body with a hearth, and further comprises a hydrogen and oxygen generating device which is fixed into the hearth and supplies hydrogen and oxygen to the hearth. The hydrogen and oxygen generating device comprises a hydrogen and oxygen generating chamber and a water storage chamber, the hydrogen and oxygen generating chamber is hollow, and a reaction space is formed inside the hydrogen and oxygen generating chamber. The hydrogen and oxygen generating chamber is provided with a first gas outlet communicated with the reaction space. A reaction table for containing a reaction catalyzer is arranged inside the reaction space. The water storage chamber is connected to the lower end of the hydrogen and oxygen generating chamber and provided with a water storage space communicated with the reaction space. The water storage chamber is provided with a water inlet communicated with the water storage space. The water fuel oxyhydrogen combustion-supporting boiler has the advantages that the fuel burn-off rate can be effectively improved, the burning heat efficiency is improved, harmful gas emission is reduced, the environment-friendly and energy-saving effects are remarkable, and the structure is compact.

Owner:杨雪燕 +2

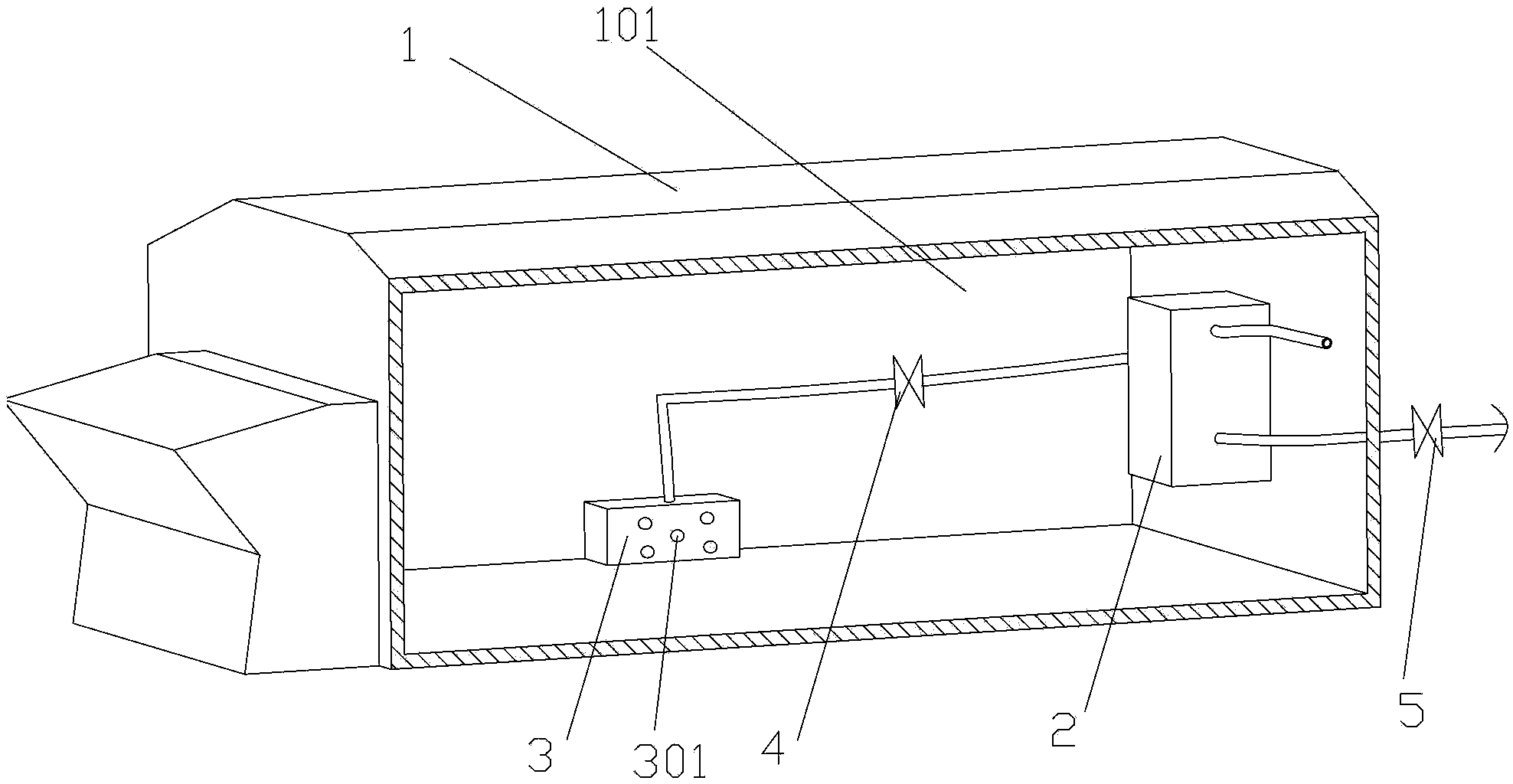

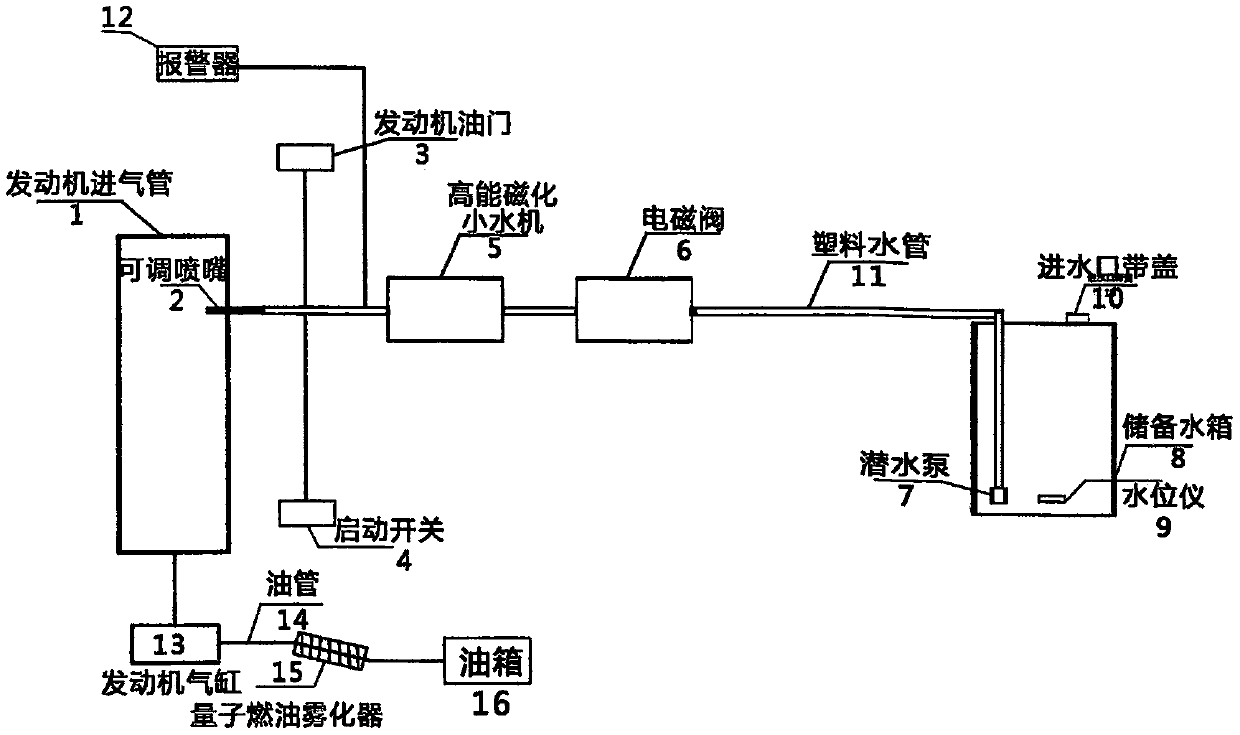

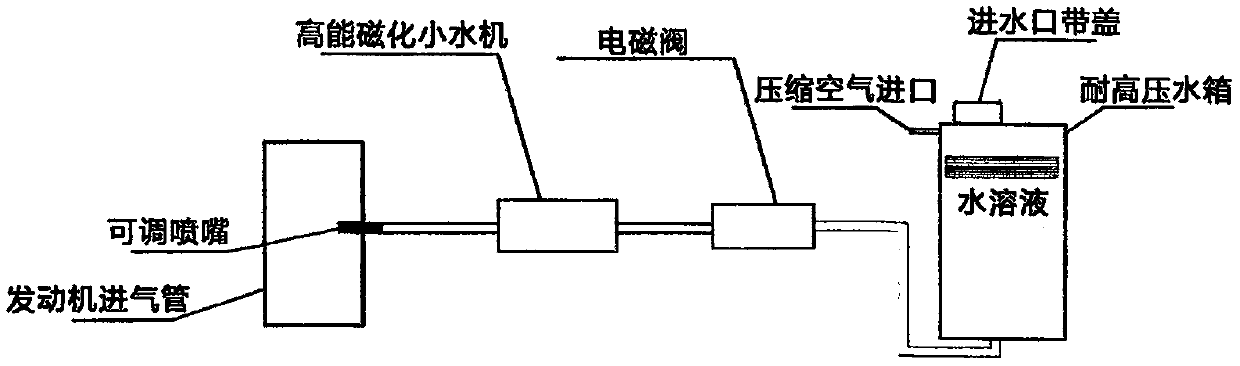

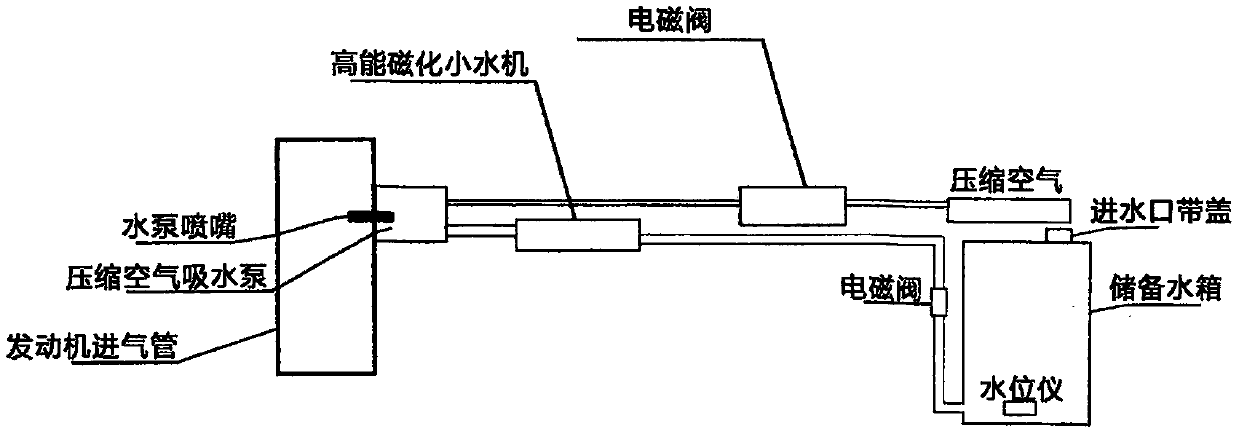

Environment-friendly and energy-conservation matching device using fuel engine device

InactiveCN110043394AImprove mixed combustion effectImprove the effect of environmental protection and energy savingNon-fuel substance addition to fuelMachines/enginesChemical reactionAlcohol

The invention discloses a matching device using a fuel engine device for achieving environment friendliness and energy conservation. Drinking water in a reserve water tank is sprayed into a gas inletpipe of an engine in a mist form through a water pump via an adjustable nozzle, engine, gas and water are sufficiently mixed and combusted in an air cylinder, and environment friendliness and energy conservation are achieved through a physical reaction and a chemical reaction. In order to ensure that the matching device runs safely and smoothly, an accelerator of the engine is linked with the water pump through a starting switch. The reserve water tank has an alarming function when the water level is low, and has the automatic power off and alarming functions when not water exists. A special magnetized small water machine and an electromagnetic valve are sequentially installed between the nozzle and the water pump, and an environment-friendly additive added in the water tank has the watersoftening function. The lubricating function, the corrosion resisting function, the wear resisting function and the soft sealing function of the air cylinder are achieved, the service life of the engine can be prolonged, and improving of the environment-friendly and energy-conservation effects of the engine can be assisted. A proper amount of methyl alcohol is added into the water tank in winter so that it can be ensured that the system cannot be frozen forever. A quantum fuel atomizer is installed in a transplanting manner, and the environment-friendly and energy-conservation comprehensive effect can be improved. The matching device is simple in structure, low in cost, easy and convenient to install and operate and easy to popularize.

Owner:李建华 +2

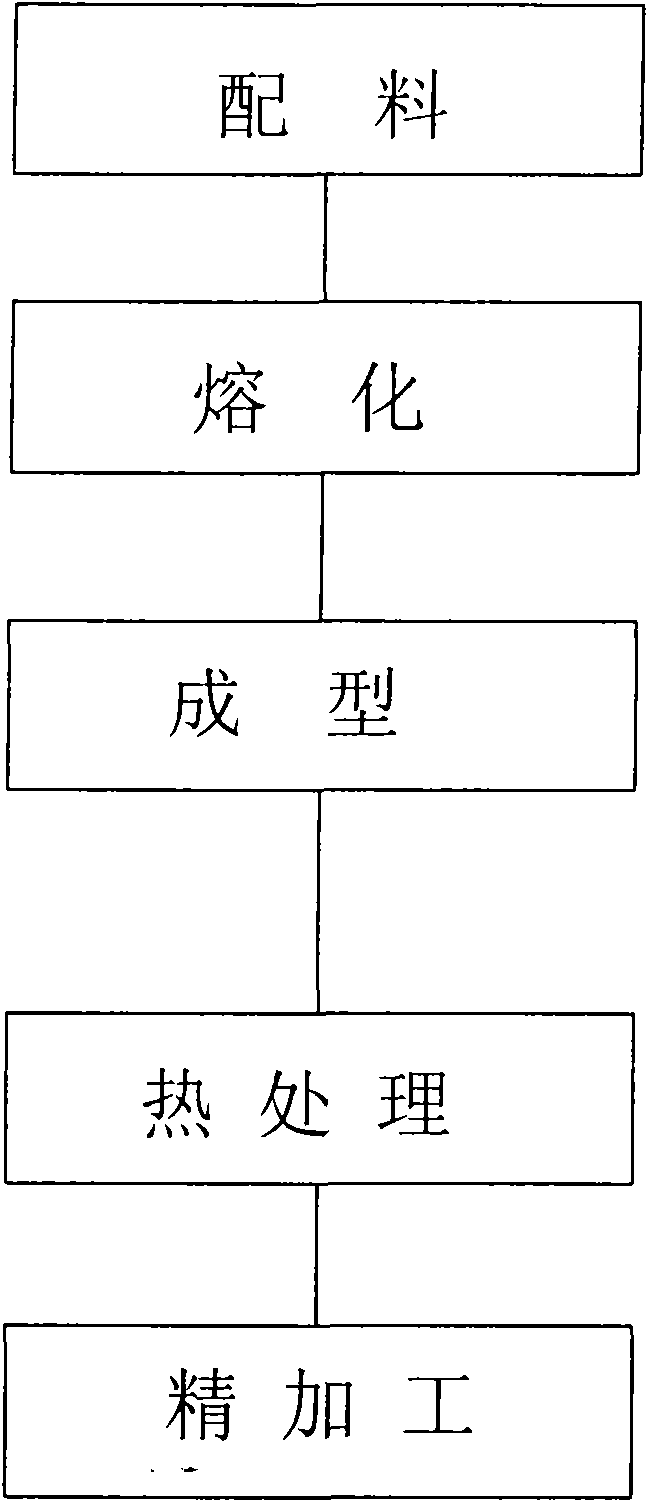

Glass plate and manufacturing method thereof and device employed in manufacturing method

ActiveCN101786788AImprove thermal insulationImprove noise reductionGlass rolling apparatusGlass productionThermal insulationEngineering

The invention discloses a novel glass plate, a manufacturing method thereof and a device employed in the manufacturing method. Where the novel glass plate comprises a glass plate body which is provided with a cavity; a hanging groove is arranged at one side face of the glass plate body in response to installation needs; the method comprises the following steps: 1. burdening, 2. melting, 3. moulding, 4. thermal treatment, 5. carrying out cutting finish machining according to actual needs to obtain an opacifying glass plate or a microcrystal glass plate with a cavity or with both the cavity and the hanging groove; the device employed in the manufacturing method is additionally provided with a moulding device on the basis of the previous device; the opacifying glass plate or the microcrystal glass plate feature excellent thermal insulation effect, obvious noise reduction function, noticeable environmental protection and energy conservation effect; in addition, compared with solid core plates of the same specification, the glass plates obtained in the invention consumes obviously reduced raw materials, reduces power consumption for glass plate thermal treatment, features convenient installation and construction and improves production efficiency and productivity effect.

Owner:北京盛康宁科技开发有限公司

Near-net shape forming manufacturing method for thrust collars of sliding bearings of automobiles

The invention relates to a near-net shape forming manufacturing method for thrust collars of sliding bearings of automobiles. The near-net shape forming manufacturing method includes: utilizing a seamless steel tube as a steel lining back of a thrust collar of a sliding bearing, disposing backing materials of the steel lining back in a lower die of an axial swing grinding machine to be processed rotationally; during process, moving the lower die upwards for feeding, rotating an upper die of the axial swing grinding machine into an inner hole of a cut seamless steel tube by an eccentric swing angle ranging from 1.5 degrees to 5 degrees, pressing ends of the tube to deform locally by the upper die until the peripheral end of the integral steel tube deforms by continuously rotating, grinding the peripheral end to be a planar ring, and manufacturing the planar ring into the steel lining back of the thrust collar of the sliding bearing; sanding, removing dust and cleaning; paving a thin layer of copper alloy powder and sintering; grinding in a swing manner secondarily, and alloying and sintering secondarily to form the thrust collar. By the near-net shape forming manufacturing method for the thrust collars of the sliding bearings of the automobiles, the thrust collars of the sliding bearings of the automobiles can be manufactured in a lossless and near net shape forming manner, and utilization rate of metal materials can be improved. Besides, the near-net shape forming manufacturing method is lossless, few in processing procedures, low in manufacturing cost and fine in product quality and can realize near net shape forming.

Owner:胡长安

Method for preparing autoclaved aerated building block with high tensile strength and low shrinking by using waste spinning flax materials

InactiveCN102241046AHigh strengthHigh compressive strengthSolid waste managementCeramic shaping apparatusProgrammable logic controllerCoal

The invention discloses a method for preparing an autoclaved aerated block with high tensile strength and low shrinking by using waste spinning flax materials. The method comprises the following steps: (1) preparing raw materials for standby, wherein the prepared raw materials comprises coal ash, furnace dregs, ardealite, waste ramie, concrete, lime, aluminum powder paste, additives and the like; (2) utilizing a PLC (programmable logic controller) system to add the prepared materials into a mixing blender for pouring, wherein the ratio of coal ash to furnace dregs to ardealite to concrete to lime is 59.67:10.53:3:5.5:21.3, the aluminum powder is 0.06%-0.07% of the total weight of dry materials and the waste ramie is 0.025%-0.04% of the total weight of dry materials; and stirring the raw materials, pouring the mixture into a mould, standing in a procuring chamber, cutting and forming by using a PLC turning cutter set, processing in an autoclaved kettle which takes pressure saturated steam as a medium to produce an environment-friendly autoclaved aerated block with high tensile strength and low shrinking.

Owner:TONGLING FENGZE BUILDING MATERIALS TECH

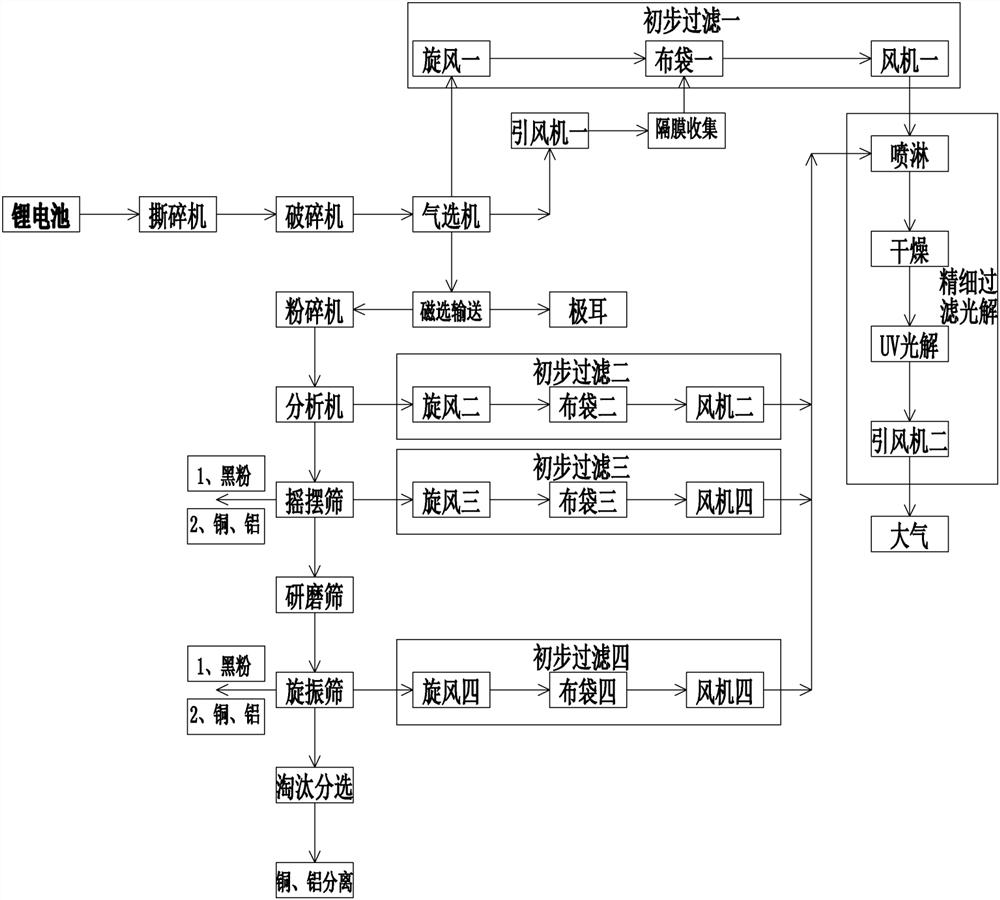

Lithium battery recovery process

InactiveCN112290111AEasy to operateFast material distribution efficiencyWaste accumulators reclaimingBattery recyclingProcess engineeringBattery recycling

The invention provides a lithium battery recovery process. The lithium battery recovery process comprises the following steps: S1, feeding: arranging a lithium battery; S2, tearing and crushing, namely crushing the cleaned lithium battery; S3, preliminary sorting: separating a diaphragm from the lithium battery crushed aggregates; S4, magnetic separation conveying: separating the tabs from the lithium battery crushed aggregates; S5, multi-stage crushing, grinding, refining and sorting: carrying out multi-stage crushing, grinding, refining and sorting on the lithium battery crushed aggregates to obtain recyclable materials; and S6, jigging sorting, namely conducting jigging sorting on the ground and sorted lithium battery crushed aggregates, and separating the remaining recyclable materials. The invention discloses an environment-friendly lithium battery recovery process which is convenient to operate and high in recycling efficiency.

Owner:SUZHOU XIRAN IND EQUIP

Dual-regenerative flue gas treatment system

PendingCN109821340AAvoid the needSolve the problem of only investing but not earningDispersed particle separationWater vaporFlue gas

The invention discloses a dual-regenerative flue gas treatment system. The dual-regenerative flue gas treatment system has the advantages that a liquid storage unit arranged in an absorption device divides an inner cavity into a first flue gas treatment area and a second flue gas treatment area, flue gases flow from the bottom of the absorption device to be in countercurrent contact with concentrated solutions sprayed at the top of the absorption device, the concentrated solutions of the second flue gas treatment area absorb water in the flue gases to become dilute, and the latent heat released during water phase change is precipitated out to heat the flue gases and the concentrated solutions to 55-65 DEG C; the heated concentrated solutions are guided by the liquid storage unit to enter afirst heat exchanger to exchange heat with heat exchange media, and then enter the first flue gas treatment area to continue absorbing the water in the flue gases after being cooled to the temperature approximately equal to a top solution inlet of the second flue gas treatment area; the graded heat exchange is used for the first time, and the sensible heat of the original flue gases and the latent heat of purified flue gas water vapor are deeply recycled and utilized; the connection mode of a regeneration system is flexibly selected according to the characteristics of the heating season and the non-heating seasons, and accordingly, the energy consumption is lowered.

Owner:CHINA HUADIAN ENG +1

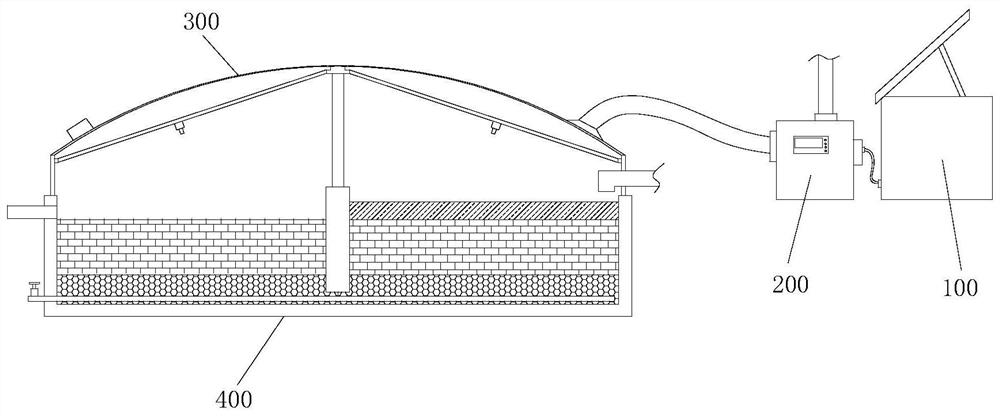

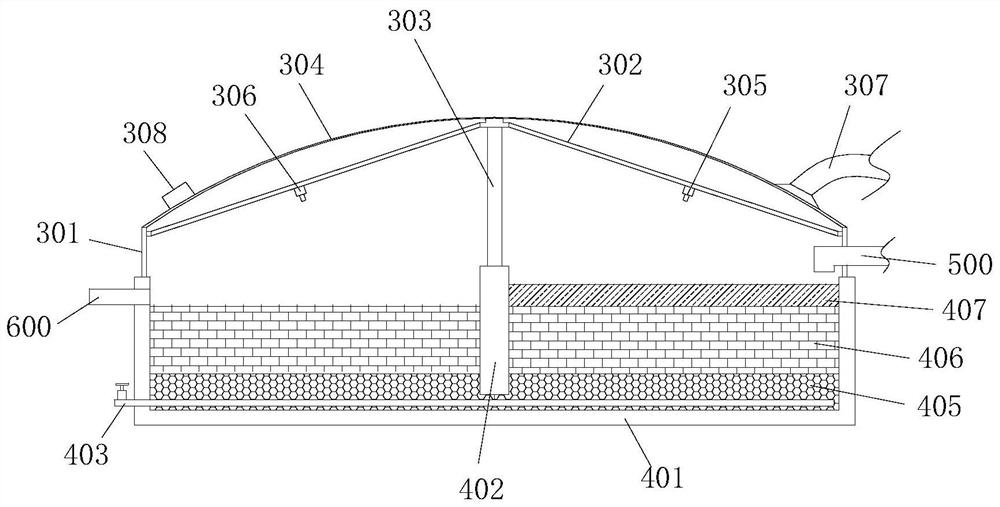

Method for treating organic matters in constructed wetland

InactiveCN113200608AImprove the efficiency of decomposing organic matterGood environmental protection and energy saving effectWater contaminantsBiological water/sewage treatmentConstructed wetlandHeat conservation

The invention discloses a method for treating organic matters in a constructed wetland. An electric energy storage module, a refrigeration module, a low-temperature simulation module and a wetland experiment area are adopted. The wetland experiment area comprises a wetland partition pool. The electric energy storage module comprises an energy storage box and a solar panel. The refrigeration module comprises a refrigeration box, an air-cooled water chiller, a frequency converter and an air cooler. The low-temperature simulation module comprises a supporting coaming, a heat-insulating light-transmitting cover and a cold air pipe. According to the invention, the constructed wetland partition pool is used for the experiment of treatment of organic matters in a wetland, under the condition that a qualified wetland environment is formed, the upper end of the wetland partition pool is sealed and covered by adopting the supporting coaming and the heat-insulating light-transmitting cover, then the air-cooled water chiller is used for refrigeration, and the cold air is fed into the wetland partition pool by the air cooler through the cold air pipe. According to the method, the organic matter decomposition efficiency of the low-temperature microbial flora is well improved, meanwhile, a solar energy storage mode is adopted in an electric power energy supply part, and good environment-friendly and energy-saving effects are achieved.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com