Acheson furnace for producing graphite anode materials and furnace charging technology of furnace

A negative electrode material, Acheson furnace technology, applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of inconvenient control of the operation process, low quality of recarburizers, and limited cooling methods, etc. Achieve the effect of shortening the furnace time, high degree of graphitization and significant energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

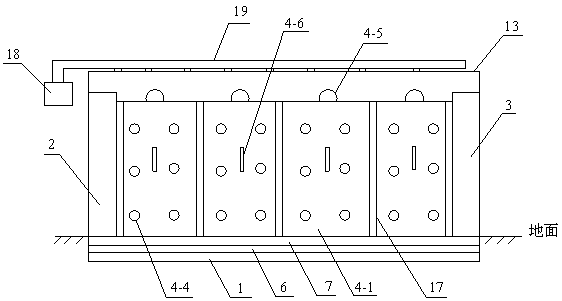

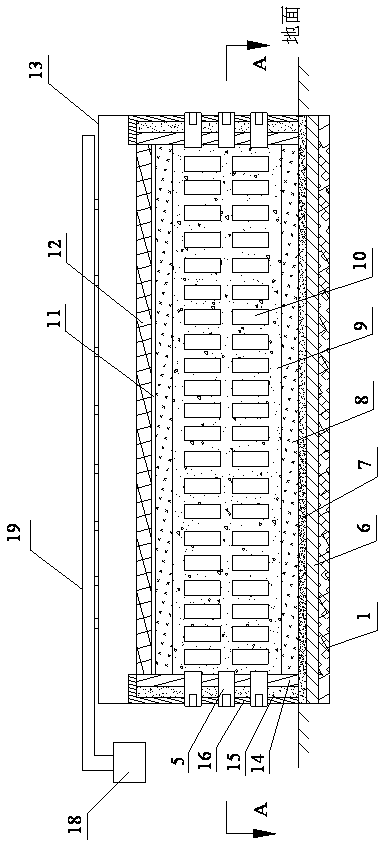

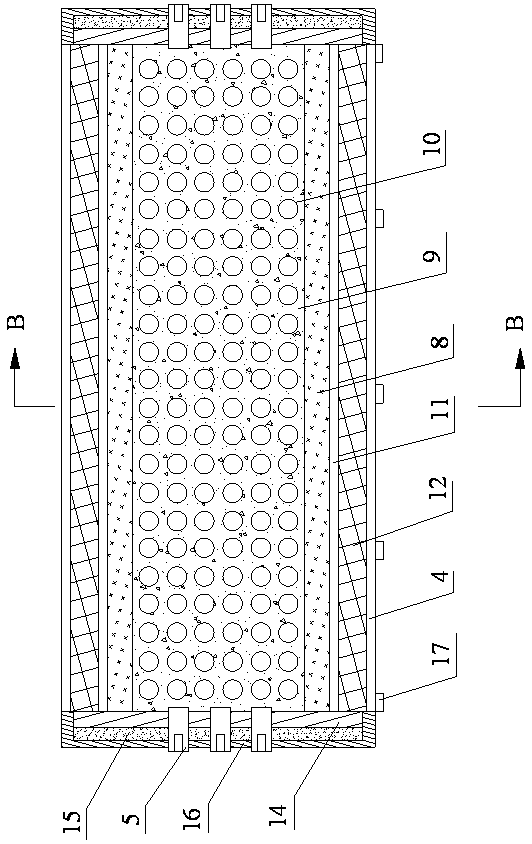

[0065] This embodiment provides a kind of Acheson furnace for producing graphite-based negative electrode materials, including a furnace body surrounded by a furnace base 1, a furnace head wall 2, a furnace tail wall 3 and a furnace wall plate 4, and the furnace body is formed by a furnace The central axes of the head wall 2 and the furnace tail wall 3 are symmetrical, the furnace head wall 2 and the furnace tail wall 3 are respectively provided with conductive electrodes 5, and the upper part of the furnace base 1 is sequentially provided with a quartz sand layer 6 and a charcoal layer. The black layer 7 and the upper part of the carbon black layer 7 are provided with a furnace core, and the furnace core includes several layers of crucibles, a calcined coke layer 9 arranged on the outer surface of the crucible, and a petroleum coke layer 8 arranged on the outer surface of the calcined coke layer 9. A molding board 11 is arranged on the top and sides of the core, an insulating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com