Graphitization technology of Acheson furnace for producing anode materials

An Acheson furnace, a technology for producing negative electrodes, applied in the field of negative electrode material preparation, can solve problems such as inconvenient control of the operation process, limited cooling methods, prolonging the production time, etc., and achieve the effects of shortening the production time, significant energy saving effects, and increasing benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

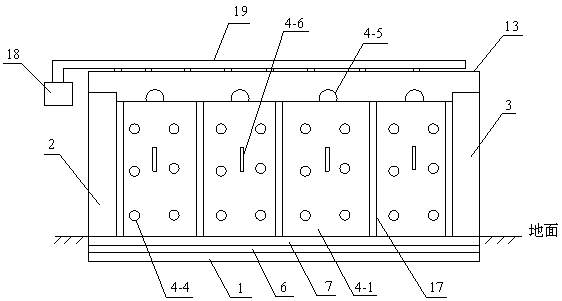

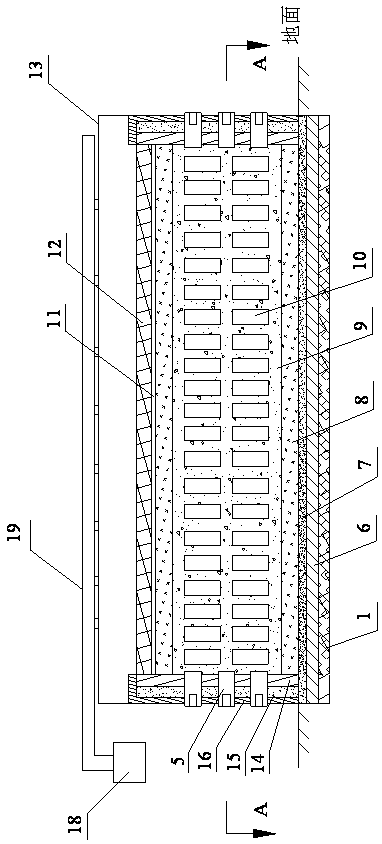

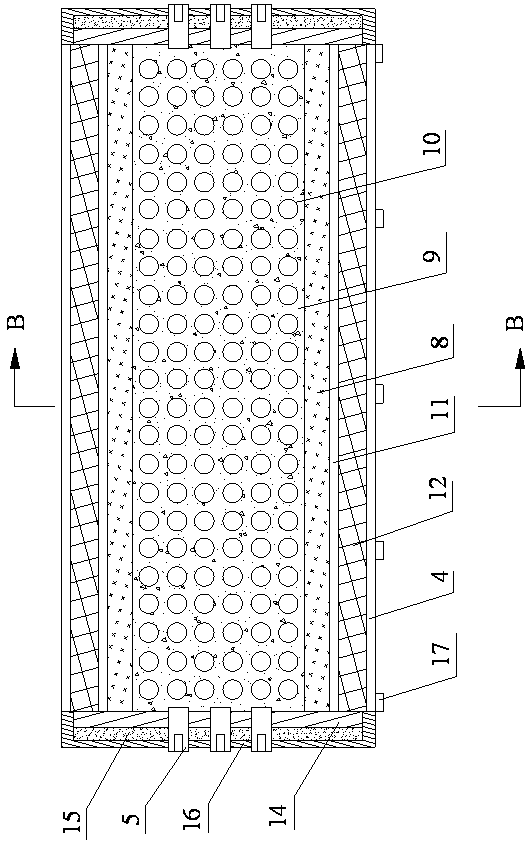

[0060] A kind of graphitization process of producing negative electrode material Acheson furnace provided by this embodiment comprises the following steps:

[0061] Step S1: Lay quartz sand, metallurgical coke grains and carbon black on the furnace base in sequence, tamp them down, hoist and fix the furnace wall panels, hoist forming plates and steel plates in sequence on the inside of the furnace wall panels, and pre-install the furnace wall panels and forming panels. Reserve the space for filling the insulation material, and reserve the space for filling petroleum coke between the forming plate and the steel plate, and fix the forming plate and the steel plate respectively;

[0062] Step S2: laying petroleum coke on the upper part of the carbon black, compacting it, laying calcined coke on the upper part of the petroleum coke, loading the negative electrode material raw materials into the crucible, placing the first layer of crucible on the upper part of the calcined coke, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com