Glass plate and manufacturing method thereof and device employed in manufacturing method

A manufacturing method and glass plate technology, which is applied in the fields of microceramic glass plates and opaque glass plates, can solve problems such as unfavorable energy saving and heat preservation, general noise reduction performance, glass damage, etc., and achieve excellent heat preservation and heat insulation performance, and remarkable environmental protection and energy saving effects , Yield improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

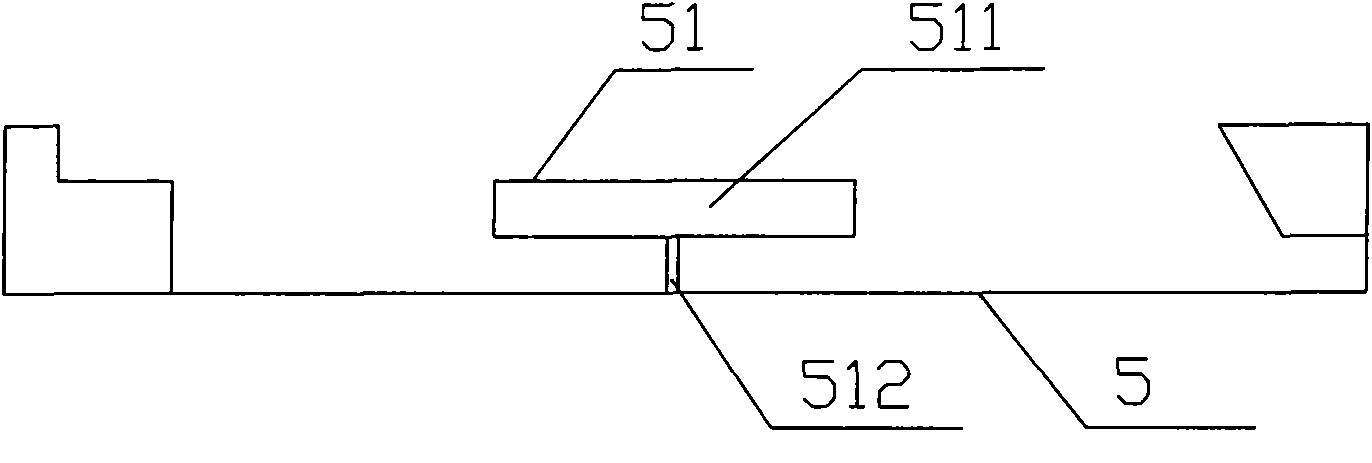

[0042] Such as Figure 11 As shown, the glass plate of the present invention is an opal glass or a glass-ceramic plate, including a glass plate 8, and a cavity is provided in the glass plate body 81, and the cavity is a rectangular cross-sectional through hole 82 penetrating along one direction of the glass. . Such as Figure 12 , 14 As shown in and 18, the hole wall of the rectangular through hole 82 provided on the glass body 81 forms a groove 83 on the glass plate-side plate surface, thus forming a hanging groove 84 for fixing or hanging the glass, so as to meet the requirements of the glass. Board mounting needs to be fixed. The size of the hanging slot can be set according to the requirements of use. Such as Figure 13 , 16 As shown in and 17, two hanging grooves 84 are set on the body 81 of the glass plate 8 with through holes, which are parallel to the direction of the through holes, forming a glass plate with both through holes 82 and hanging grooves 84. The rel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com