High-heat preserving high-sound insulation high-strength seamless ultra-hollow wall board and technique thereof

A technology of hollow wall panels and high thermal insulation, which is applied in the fields of high-strength super-hollow wall panels, high thermal insulation, and high sound insulation. It can solve the problems of poor bonding force, reduced strength, fire prevention and poor strength, etc., and achieves strong seismic load capacity and long working hours. and construction period reduction, environmental protection and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

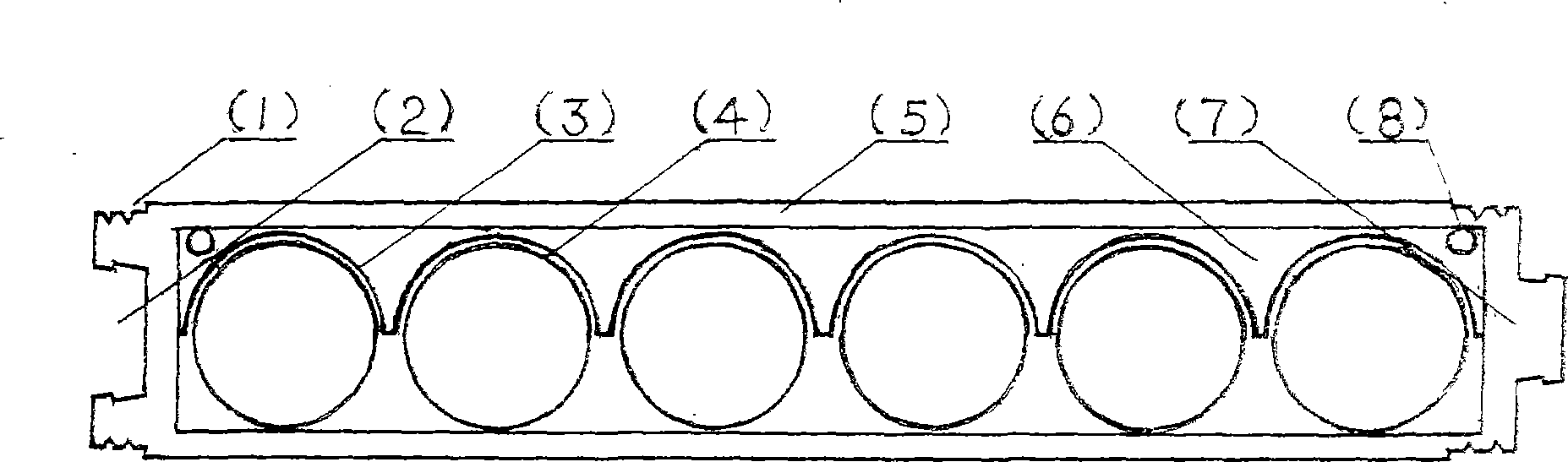

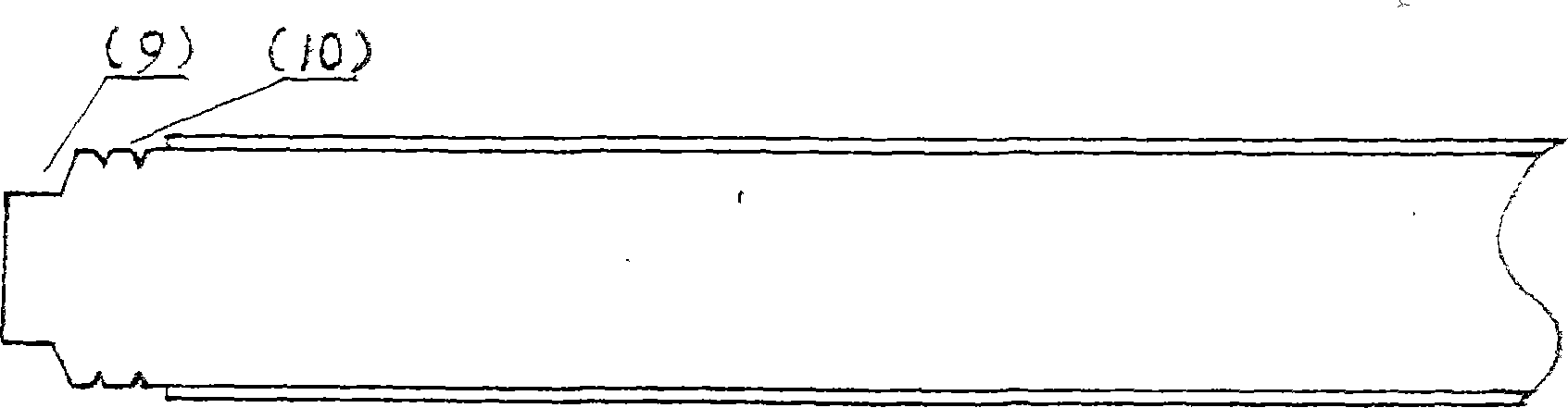

[0048] Such as figure 1 Including the internal structure of the panel body and the external structure of the panel body, the internal structure of the panel body consists of a wallboard surface layer 5, a wallboard inner layer 6 and an ultra-hollow high-density air cylinder or vacuum air cylinder 4, and the outer layer of the air cylinder is provided with a plastic fixing card 3; The external structure of the board body is composed of protruding shuttles 7 and grooves 2 with interlocking barbs, lock seams 1 and 10 with shallow grooves and transverse grooves, vertical threading holes 8, nail bolt installation lines and cloth texture. There are fixed gaps 9 at both ends of the wallboard, and the high-density air cylinder or vacuum air cylinder 4 can be cylindrical, square or rectangular.

[0049] 1. The internal structure of the board:

[0050] The inner surface of the wallboard surface layer 5 is closely adhered to the inner layer 6 of the wallboard, and at least five super-ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com