Blending production method of aromatic hydrocarbon rubber extender oil

A technology of rubber filler oil and production method, which is applied in the fields of hydrocarbon distillation and petroleum industry, and can solve the problems of complex circulation processes such as import, storage, subpackaging, transportation, transfer, etc., large demand gap for aromatic rubber filler oil products, and insufficient Adapt to large-scale production and other issues, achieve the effect of highlighting environmental protection and energy saving, easy to enlarge the production scale, and easy to control the production operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

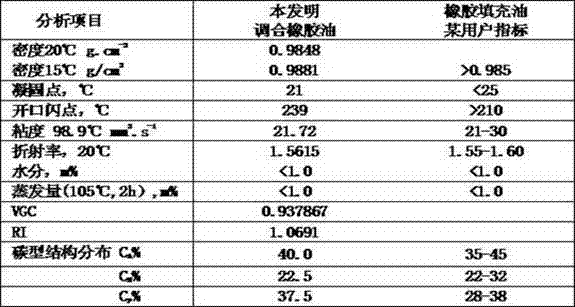

[0017] In order to make full use of the petrochemical by-product mixed oil slurry resources in the domestic market and produce high-quality rubber filler oil products, technical research was carried out by a special organization, and the properties of different raw materials for rubber filler oil production were analyzed. After raw material selection, processing technology tests, and analysis The creators of the present invention have successfully developed a blending production method of aromatic rubber extender oil through the establishment and improvement of the method, optimization of the blending formula, test sample manufacturer’s test, determination of the product production plan, procurement of raw materials, and trial production. And put into large-scale production.

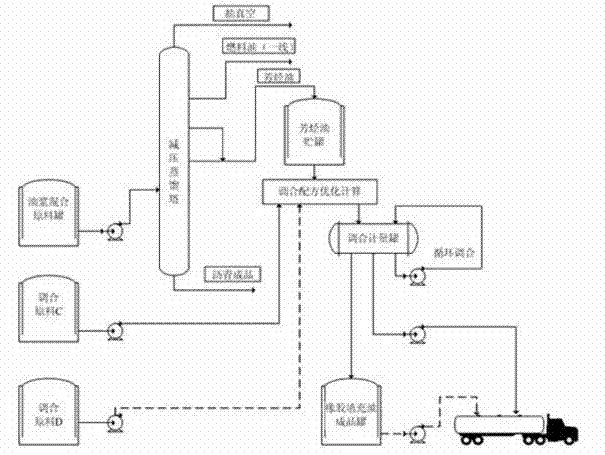

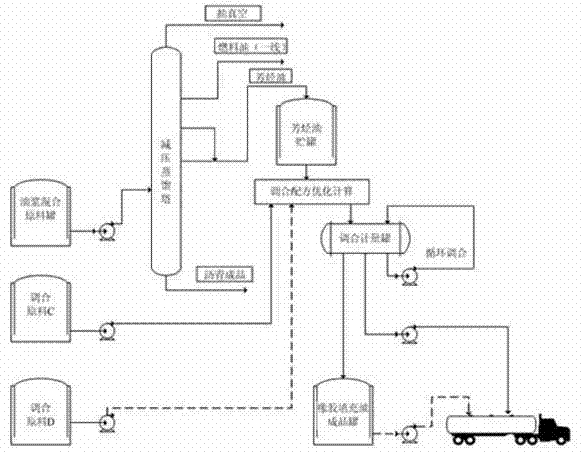

[0018] Such as figure 1 Shown is a schematic flow chart of the present invention blending and producing aromatic rubber extender oil. It can be seen from the diagram that the overall flow of the blendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com