Water fuel oxyhydrogen combustion-supporting boiler

A water fuel, hydrogen and oxygen technology, applied in steam boilers, combustion methods, combustion equipment, etc., can solve the problems of large harmful gas emissions, low combustion thermal efficiency, ecological environment pollution, etc., achieve rapid response, improve burnout rate, The effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

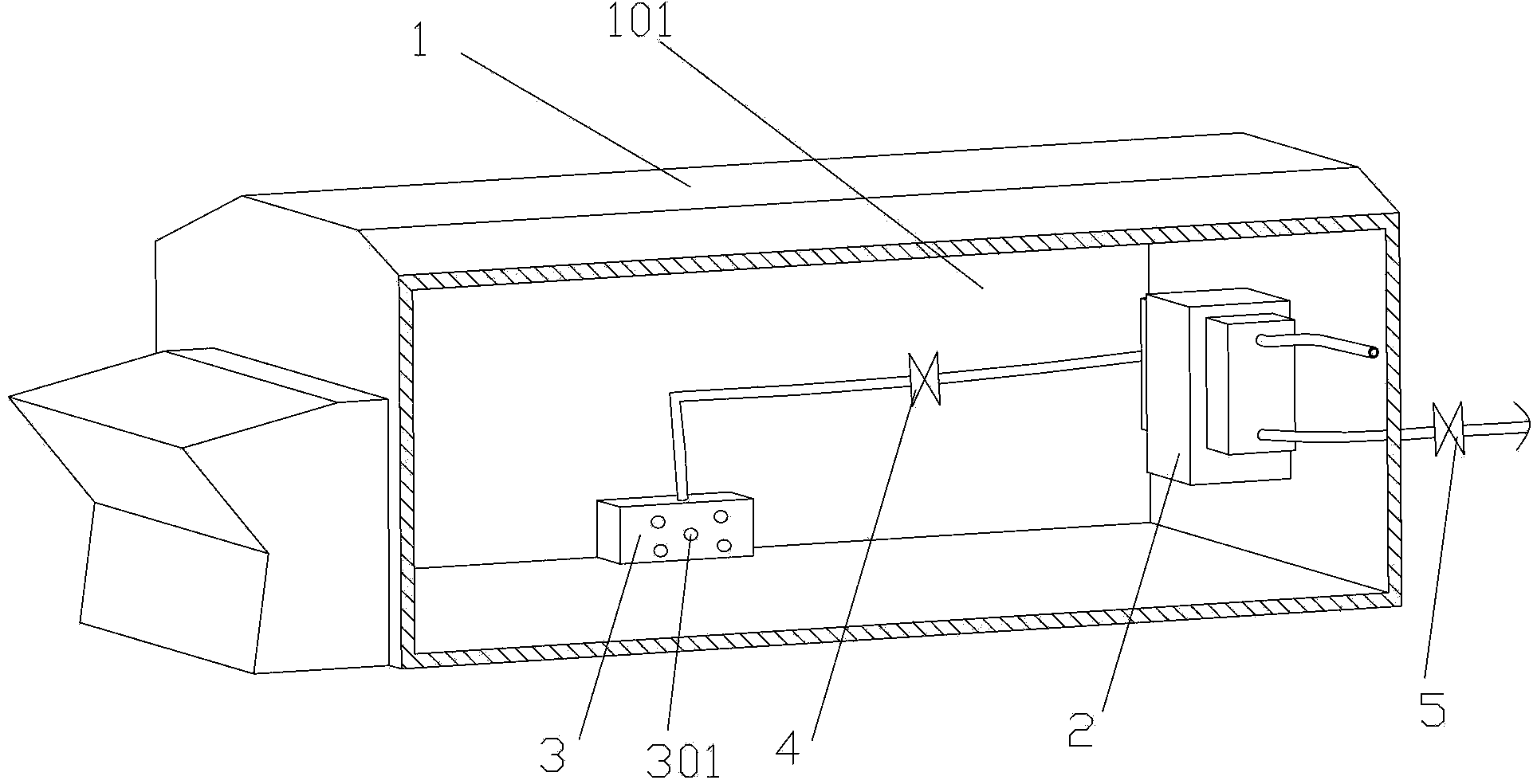

[0024] figure 1 It schematically shows a water-fueled hydrogen-oxygen combustion boiler according to the first embodiment of the present invention.

[0025] Such as figure 1 As shown, the water-fuel hydrogen-oxygen combustion-supporting boiler includes a furnace body 1 and a hydrogen and oxygen gas generating device 2 . In addition, an air injector 3, a regulating valve 4 and a water control valve 5 are also included.

[0026] The furnace body 1 has a furnace 101 . The hydrogen and oxygen gas generating device 2 is fixed in the furnace 101 and can supply hydrogen and oxygen gas to the furnace 101 . The gas injector 3 is built in the furnace 101 , communicates with the hydrogen and oxygen gas generating device 2 , and is used for injecting hydrogen and oxygen gas to the furnace 101 . The regulating valve 4 is located on the pipeline connecting the injector 3 and the hydrogen and oxygen gas generating device 2 . The water control valve 5 is located on the pipeline connectin...

Embodiment 2

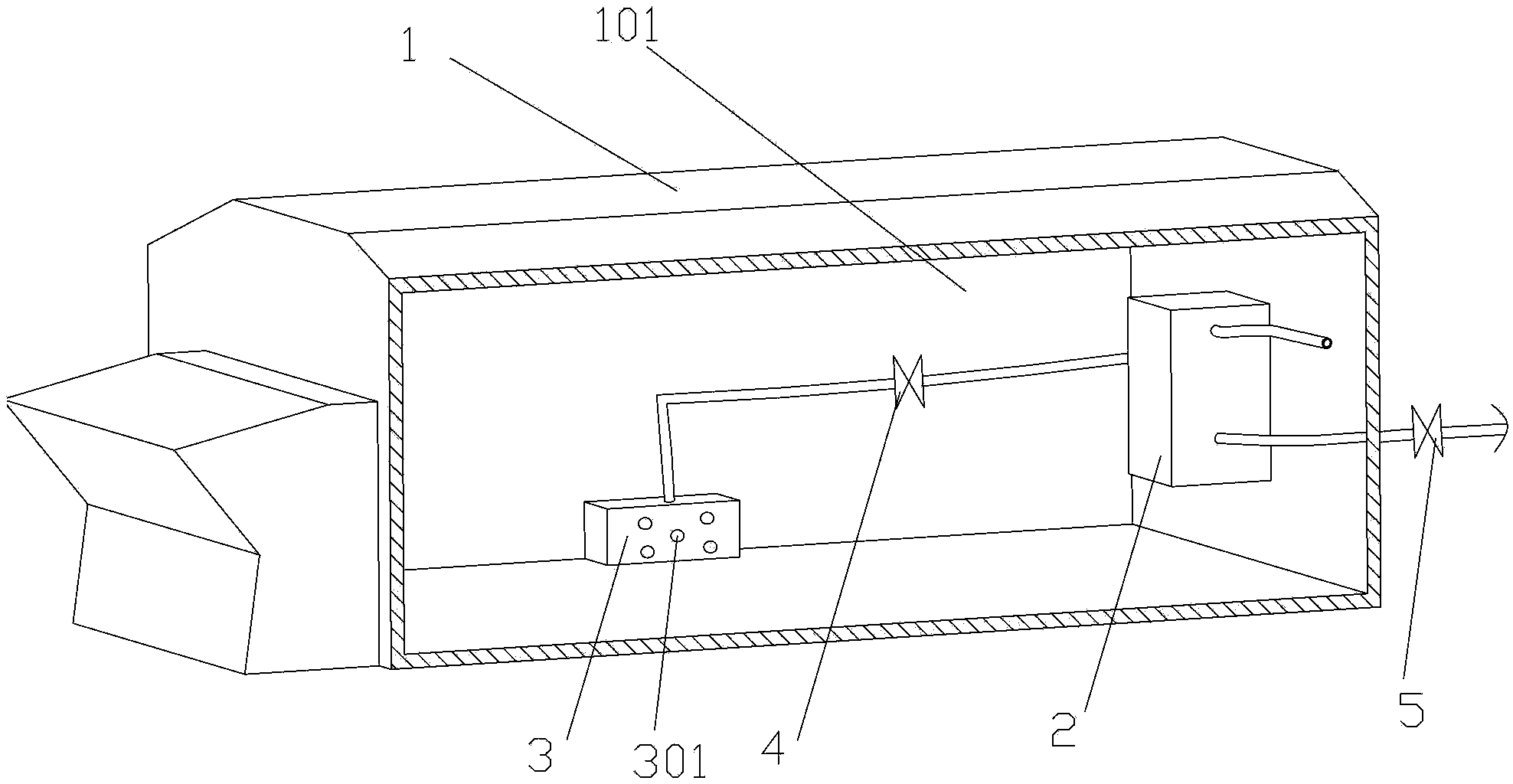

[0042] image 3 It schematically shows a water-fueled hydrogen-oxygen combustion boiler according to the second embodiment of the present invention.

[0043] Such as figure 1 , 2 As shown, the difference between this embodiment and the first embodiment is that the hydrogen and oxygen gas generating device 2 does not include the gas distribution chamber 8; the gas injector 3 communicates with the first gas outlet 602; the regulating valve 4 is located between the gas injector 3 and the second gas outlet. An air outlet 602 is connected to the pipeline.

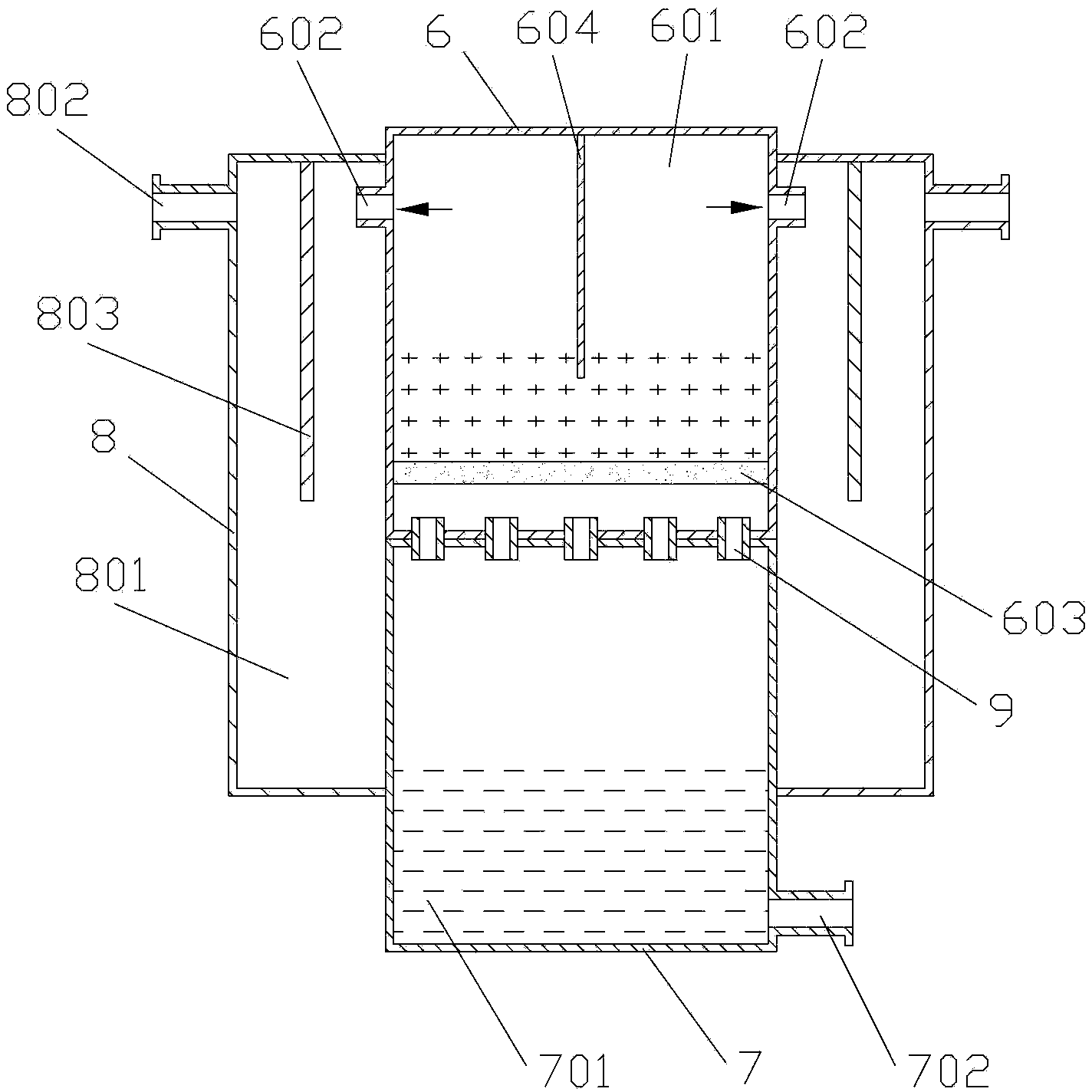

[0044] When the water-fuel hydrogen-oxygen combustion-supporting boiler of the present invention is used, the reaction table 603 is placed with a reaction catalyst, and the water storage space 701 stores water and communicates with an external water source to maintain continuous water inflow. When the boiler is burning, the water in the water storage space 701 is in an evaporating state, and the water vapor enters the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com