Torch combustion system with automatically adjustable sound speed

A torch combustion system and torch combustion technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of manual adjustment, inability to automatically adjust the size of the gas outlet, consumption of a large amount of steam, etc., to reduce radiation, flame rigidity and The effect of improving combustion, reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

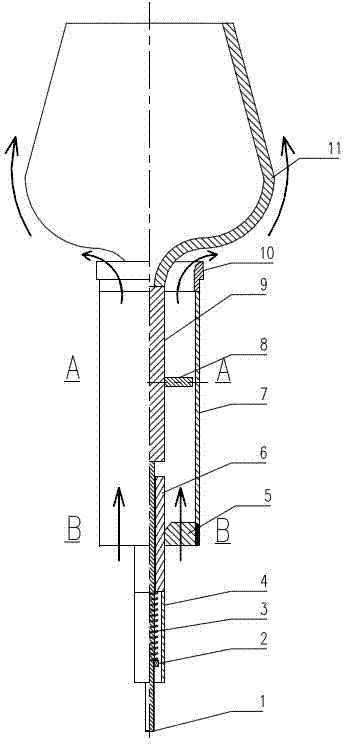

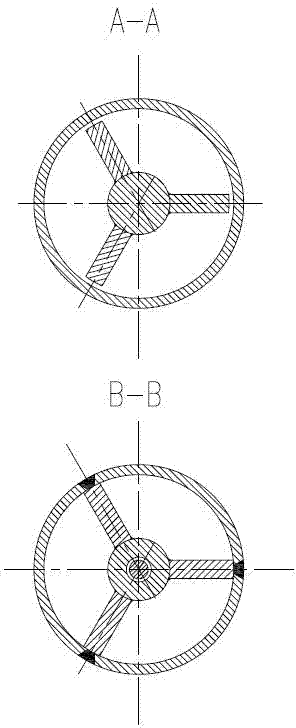

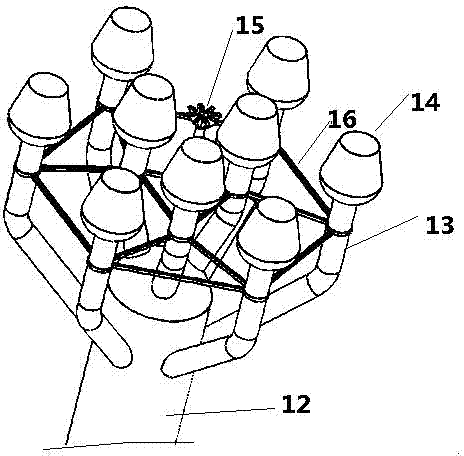

[0024] Such as Figure 1-4 shown.

[0025] A torch combustion system with automatic adjustable speed of sound, which includes a torch burner 14, a torch main pipe 12, a torch branch pipe 13, a plum blossom-shaped flame stabilizer 15, and a vibration damping bracket 16. The torch burner 14 is installed on the torch branch pipe 13, and the torch branch pipe 13 and the air inlet of quincunx-shaped flame stabilizer 15 are all linked to each other with torch main pipe 12, and each torch branch pipe 13 is connected into an integral structure by damping support 16, as image 3 As shown, the layout of each torch branch pipe 13 on the torch main pipe 12 is in addition to color and image 3 In addition to the form, you can also use Figure 4 The two common forms shown in . And the structure of each flare burner 14 is as figure 1 As shown, it includes a wind deflector 11, an external sleeve 7 and a support rod 9, the wind deflector 11 can adopt a conta body structure composed of mult...

Embodiment 2

[0030] Such as Figure 5-7 shown.

[0031] Figure 5 It is an optional embodiment of the present invention for ground flares. It includes ground flare main pipe 17, ground flare branch pipe 18 and flare burner 14. During the working process, the outlet area of the flare gas is adjusted by the interaction between the flare gas pressure and the spring to achieve the optimal combustion effect under 100% design conditions, which can replace the ground flare subsystem and achieve the purpose of automatic adjustment. Figure 6 , 7 With Figure 5 The layout of the equivalent flare main pipe 17 and the ground flare branch pipe 18 is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com